An "hardware" advice for linear rails

-

@deckingman said in An "hardware" advice for linear rails:

@thedragonlord said in An "hardware" advice for linear rails:

Guys thanks to everybody for the very precious advices! At the end I want to be more cautios as I can so I've decided to add another linear rail in the back of the 2020 extrusion. I'll loose about 2,5cm of Y space but for me is not a problem.

Thanks again!

If the extra rail is just to increase stiffness, you could use a piece of flat steel or some such, which would save you some money. BTW, I never claimed that your rail would deflect by any amount because you didn't specify a length. I merely used a 1 metre length to keep the maths simple and illustrate the importance of doing the maths. I hope you saw through the pedantic criticism of my effort to help you.

I did! I really appreciated your help!

-

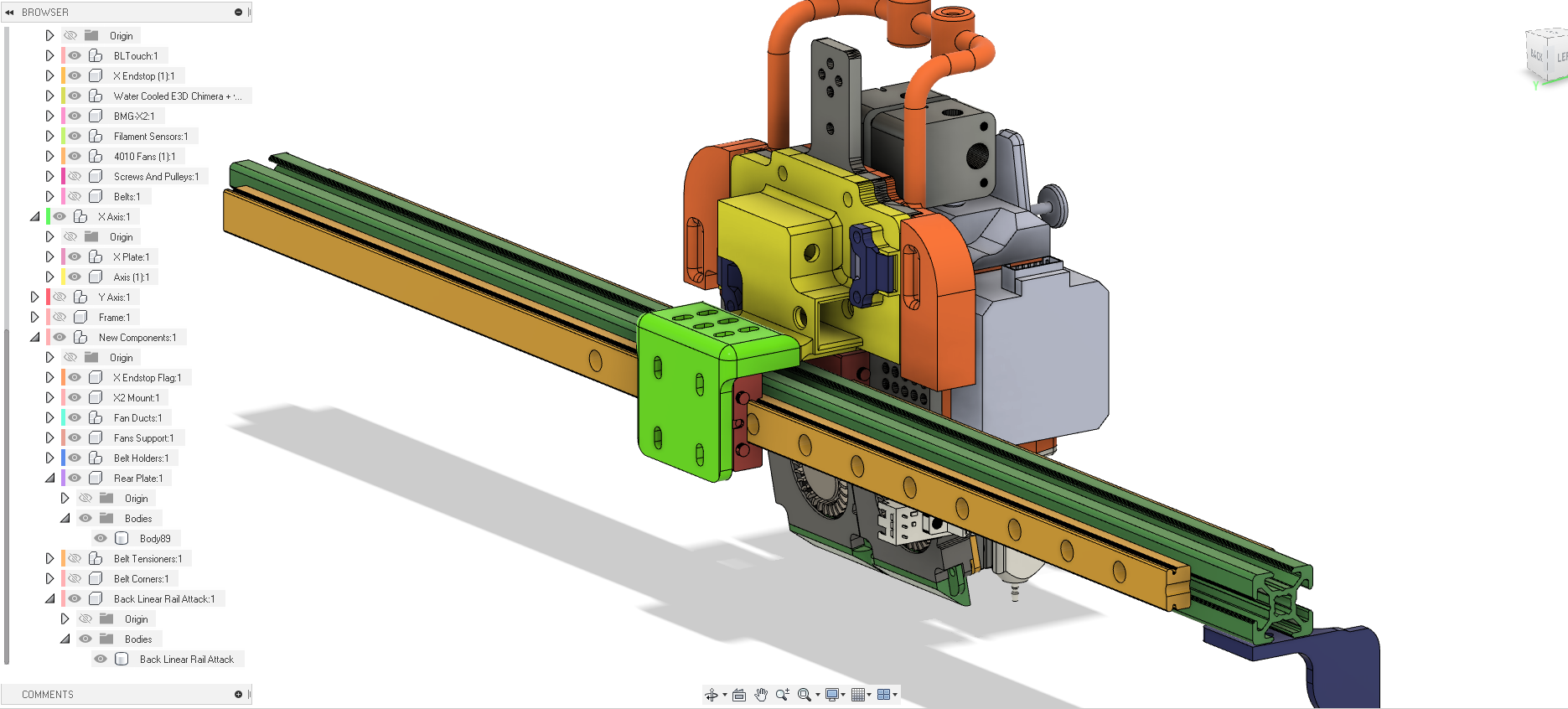

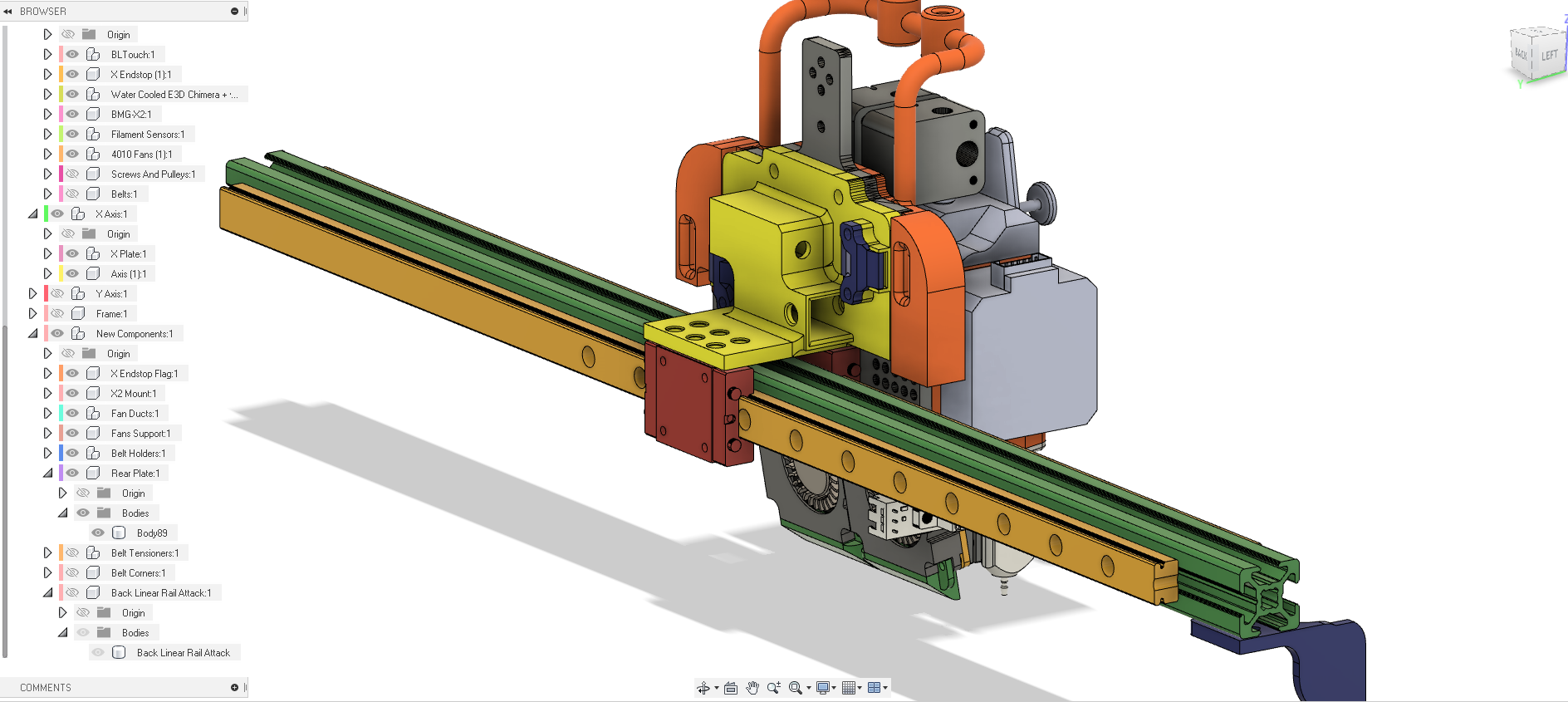

Here's the mod!

How about it?

Thanks!

-

@thedragonlord

The yellow tongue could be much thicker for my liking or have vertical struts (like an U-shape) -

@o_lampe said in An "hardware" advice for linear rails:

@thedragonlord

The yellow tongue could be much thicker for my liking or have vertical struts (like an U-shape)mmmmhh....I think you're right! I thing I'm going to take of tthe middle row of screws and add an u shape vertical "fin" in their palce...the thickness is already at 5,2mm....thanks!

-

@o_lampe said in An "hardware" advice for linear rails:

@thedragonlord

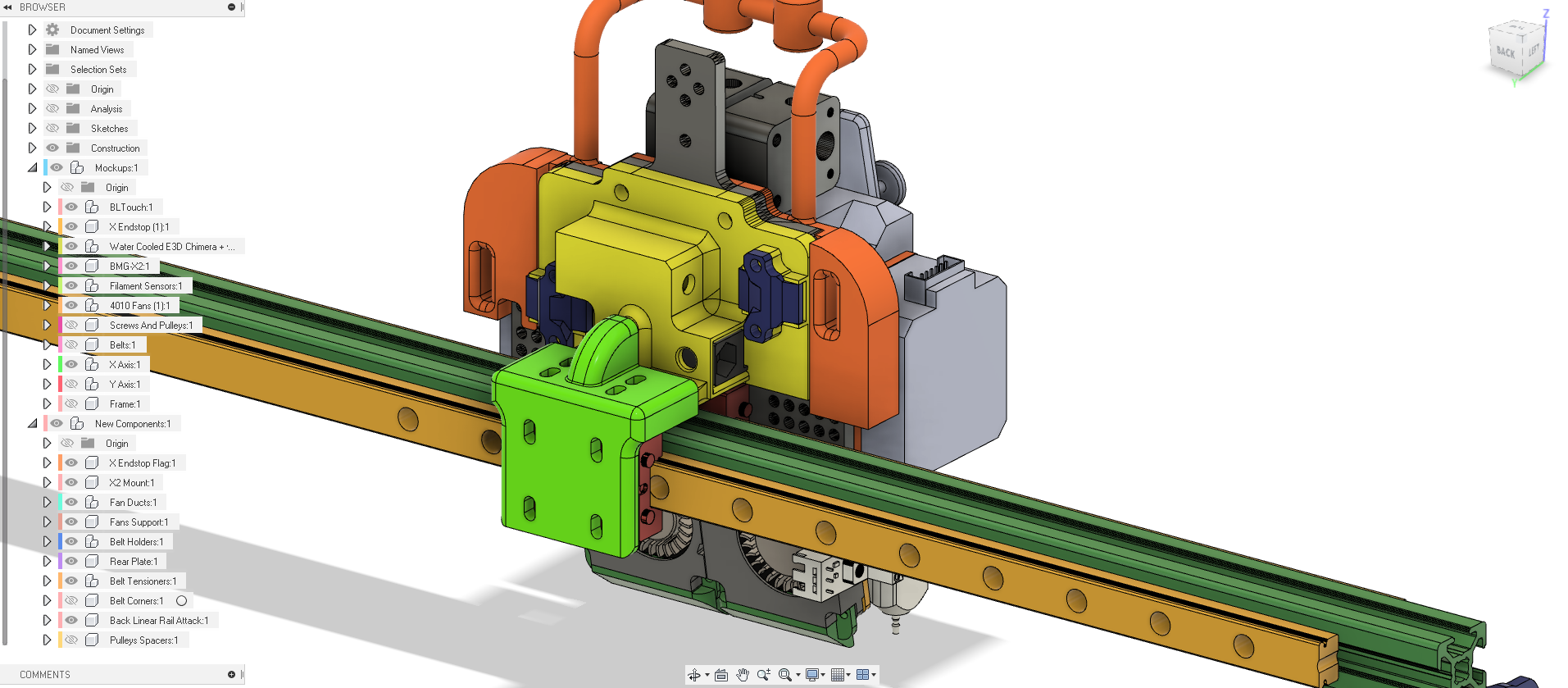

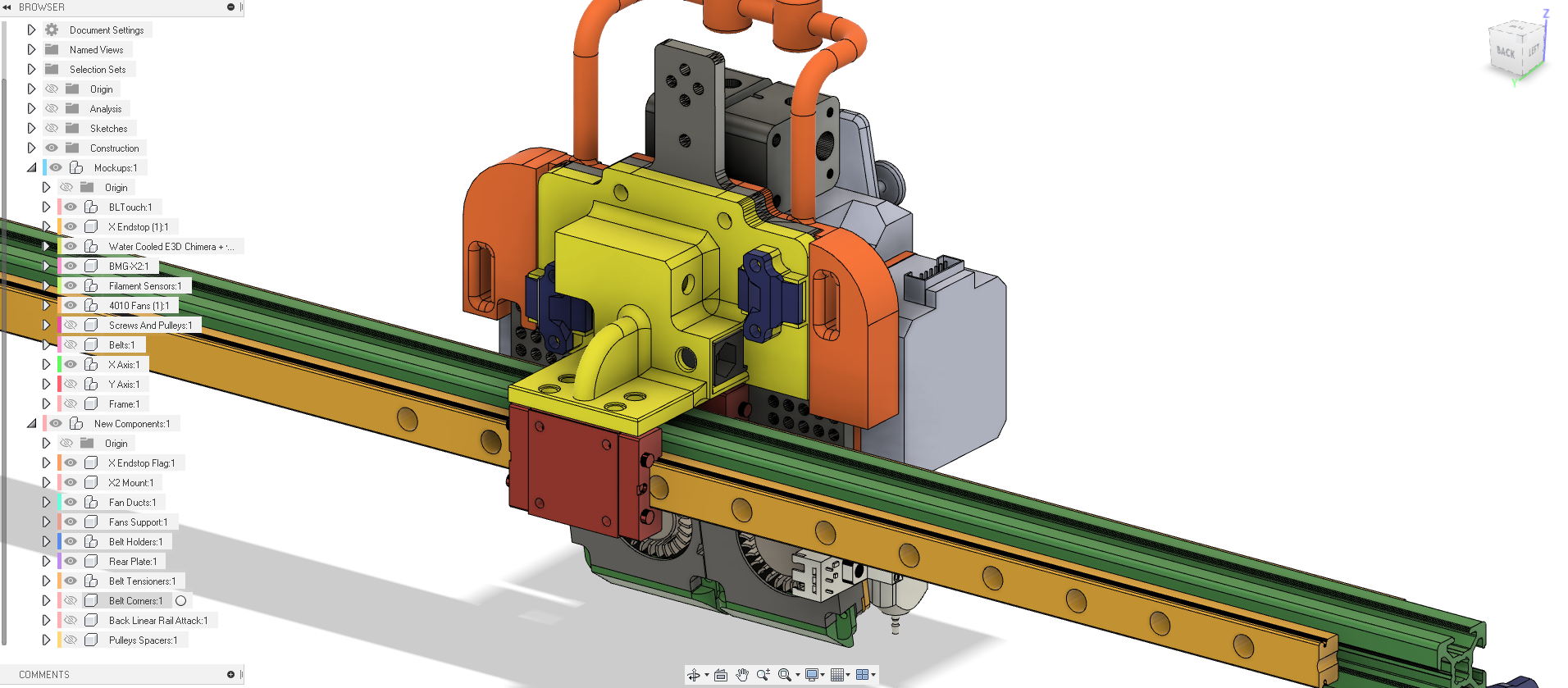

The yellow tongue could be much thicker for my liking or have vertical struts (like an U-shape)better like this?:

-

@thedragonlord, now that you have two rails, you may want stepping back and rethinking the position of the parts and the load distribution. For example, moving the two motors (heave) on top of the rails. Just a thought.

-

@zapta said in An "hardware" advice for linear rails:

@thedragonlord, now that you have two rails, you may want stepping back and rethinking the position of the parts and the load distribution. For example, moving the two motors (heave) on top of the rails. Just a thought.

It's impossible, the X2 is a single piece

-

@thedragonlord said in An "hardware" advice for linear rails:

It's impossible, the X2 is a single piece

You can also rethink the x2 choice.

-

@zapta said in An "hardware" advice for linear rails:

@thedragonlord said in An "hardware" advice for linear rails:

It's impossible, the X2 is a single piece

You can also rethink the x2 choice.

no, I've already bought it

-

@thedragonlord said in An "hardware" advice for linear rails:

@zapta said in An "hardware" advice for linear rails:

@thedragonlord said in An "hardware" advice for linear rails:

It's impossible, the X2 is a single piece

You can also rethink the x2 choice.

no, I've already bought it

-

@phaedrux said in An "hardware" advice for linear rails:

Does that apply if he is happy with the X2 and wants to use it?

Frederick

-

@phaedrux said in An "hardware" advice for linear rails:

@thedragonlord said in An "hardware" advice for linear rails:

@zapta said in An "hardware" advice for linear rails:

@thedragonlord said in An "hardware" advice for linear rails:

It's impossible, the X2 is a single piece

You can also rethink the x2 choice.

no, I've already bought it

I'm not English so maybe I don't understand your humor....I was just asking for advices....

-

@fcwilt said in An "hardware" advice for linear rails:

Does that apply if he is happy with the X2 and wants to use it?

My understanding in mechanical engineering is almost none but looking at the final design, that small piece of support at the back looks to me as an afterthought. From my experience, when new data is presented (e.g. a single guide can't support well the dual head), it's useful to revisit the entire design to see what other aspects are affected by that change, a wholistic approach if you may.

I am not suggesting that @TheDragonLord is doing anything wrong, especially if this is a hobby project, or that I could do anything better (I can't), just suggesting to step back and revisit the entire design in light of that change. it's easier to make changes now while it's still on paper.

My 2c.

-

Can I ask what the second rail is achieving?

If they are decent carriages and rails, it doesn't stiffen the system any more than a non-connected section of steel would do - i.e. bolt the rail on and leave the carriage off it will be just as effective for stiffness.

You have removed some moment from the first carriage (now the cantilever moment due to offset of the head from the rail is carried in push-pull between two rails, previously it was a fixed-end moment) but the single carriage alone was only at about 10% of its moment capacity (or would be if it was actually HiWin) by my reckoning:

Hiwin data is in https://www.hiwin.com/pdf/linear_guideways.pdf and particularly page 89 of the file, which has loading data:

MGN12H has a load rating 5.88 kN - about 600 kg - so the direct load is not significant fraction of the capacity.

More relevantly, M.R is 38.22 N.m. You are imposing 0.7 x 9.81 x 0.025 = 0.171 N.m (I'm guessing a 25mm offset from CoG to rail effective position). So you're at under 1% of the supposed static moment capacity in that direction.

This doesn't take into account inertial loading when you accelerate the head along the rail. However, suppose you allow 1g acceleration horizontally, the M.P value will also be 0.17 Nm (if the propelling belt aligns with the rail), or still under 1% of capacity.

It doesn't include drag from filament, cables etc. but I'm assuming they will be no more than similar to the weight forces.

Nor does it include factors of safety. Hiwin suggest FoS up to 5 (see page 6) even with impact. So applying that you're at about 5% of capacity in each of the two principal moments. Even if their effects sum directly, you're at about 10% of capacity.

So yes, converting that moment to a push-pull on two (if you can make them share load and not fight each other) will reduce the utilisation, from about 10% to about 5% (I think the first carriage will still be carrying the X-acceleration moment). Getting two rails to cooperate seems quite a lot of work to move from ten-times-stronger-than-it-needs-to-be to twenty-times-stronger.

It would probably help if the rails are so poor your carrages have slop under moment loading, but then buying one good rail might be a better option than two poor ones.

-

@fcwilt said in An "hardware" advice for linear rails:

Does that apply if he is happy with the X2 and wants to use it?

Not at all. Just that sometimes rethinking a design means really rethinking it.

-

@thedragonlord said in An "hardware" advice for linear rails:

@phaedrux said in An "hardware" advice for linear rails:

@thedragonlord said in An "hardware" advice for linear rails:

@zapta said in An "hardware" advice for linear rails:

@thedragonlord said in An "hardware" advice for linear rails:

It's impossible, the X2 is a single piece

You can also rethink the x2 choice.

no, I've already bought it

I'm not English so maybe I don't understand your humor....I was just asking for advices....

No humor. Just saying to consider all options.

-

@achrn said in An "hardware" advice for linear rails:

Can I ask what the second rail is achieving?

If they are decent carriages and rails, it doesn't stiffen the system any more than a non-connected section of steel would do - i.e. bolt the rail on and leave the carriage off it will be just as effective for stiffness.

You have removed some moment from the first carriage (now the cantilever moment due to offset of the head from the rail is carried in push-pull between two rails, previously it was a fixed-end moment) but the single carriage alone was only at about 10% of its moment capacity (or would be if it was actually HiWin) by my reckoning:

Hiwin data is in https://www.hiwin.com/pdf/linear_guideways.pdf and particularly page 89 of the file, which has loading data:

MGN12H has a load rating 5.88 kN - about 600 kg - so the direct load is not significant fraction of the capacity.

More relevantly, M.R is 38.22 N.m. You are imposing 0.7 x 9.81 x 0.025 = 0.171 N.m (I'm guessing a 25mm offset from CoG to rail effective position). So you're at under 1% of the supposed static moment capacity in that direction.

This doesn't take into account inertial loading when you accelerate the head along the rail. However, suppose you allow 1g acceleration horizontally, the M.P value will also be 0.17 Nm (if the propelling belt aligns with the rail), or still under 1% of capacity.

It doesn't include drag from filament, cables etc. but I'm assuming they will be no more than similar to the weight forces.

Nor does it include factors of safety. Hiwin suggest FoS up to 5 (see page 6) even with impact. So applying that you're at about 5% of capacity in each of the two principal moments. Even if their effects sum directly, you're at about 10% of capacity.

So yes, converting that moment to a push-pull on two (if you can make them share load and not fight each other) will reduce the utilisation, from about 10% to about 5% (I think the first carriage will still be carrying the X-acceleration moment). Getting two rails to cooperate seems quite a lot of work to move from ten-times-stronger-than-it-needs-to-be to twenty-times-stronger.

It would probably help if the rails are so poor your carrages have slop under moment loading, but then buying one good rail might be a better option than two poor ones.

Thanks for your scientific approach! I perfectly understood what you said. My rails aren't comparable to HiWin, they are cheap chinese ones bought on Amazon but I've already had them in my own. The cost of a single HiWin is higher than X2 cost so for now I've preferred to buy the X2, try to make it work with the rails I own...in future I'll see...I've thought mounting the opposite rail mainly not for the stiffness but to reduce as much as I can the oscillation during the direction change and along the travels in Y. Of course, as is absolutely obviuos, I'm not an engeneer and maybe I'm saying (and doing) a lot of bul@@@@its...on the other hand I always like to learn new thing, to assemble, reassemble and try add new features in my printer not only to make it print better but because I like manual working and learning....so thanks to everybody for the precious help, I really appreciated all the advices you gave me based on scientific facts...when the 10mm belts and pulleys will arrive I'll assemble the whole and I'll let you know the result....

-

@thedragonlord said in An "hardware" advice for linear rails:

I've thought mounting the opposite rail mainly not for the stiffness but to reduce as much as I can the oscillation during the direction change and along the travels in Y.

(Assuming Y motion means movement perpendicular to the 2020, ie where the whole gantry moves, not the head moving along the gantry:)

I didn't include the moment arising from that when considering the effects on the carriage because it looked to me like your head CoG is near to the level of the 2020. That is, the vertical offset between the centre of mass (and therefore the point where the inertia forces will act, effectively) and the axis of the 2020 looks quite small. As such, there is little moment on the carriage arising due to those accelerations.

The interia forces will cause the 2020 to flex, however, and I agree that the rail will stiffen against that. It will also balance (and cancel) any bimetallic curvature (which was mentioned in the thread), if you are changing the temperatures around the gantry enough for that to be significant.

-

@achrn said in An "hardware" advice for linear rails:

@thedragonlord said in An "hardware" advice for linear rails:

I've thought mounting the opposite rail mainly not for the stiffness but to reduce as much as I can the oscillation during the direction change and along the travels in Y.

(Assuming Y motion means movement perpendicular to the 2020, ie where the whole gantry moves, not the head moving along the gantry:)

I didn't include the moment arising from that when considering the effects on the carriage because it looked to me like your head CoG is near to the level of the 2020. That is, the vertical offset between the centre of mass (and therefore the point where the inertia forces will act, effectively) and the axis of the 2020 looks quite small. As such, there is little moment on the carriage arising due to those accelerations.

The interia forces will cause the 2020 to flex, however, and I agree that the rail will stiffen against that. It will also balance (and cancel) any bimetallic curvature (which was mentioned in the thread), if you are changing the temperatures around the gantry enough for that to be significant.

so in your opinion the second rail is almost unuseful in my configuration if I understood well, right?

-

@thedragonlord said in An "hardware" advice for linear rails:

so in your opinion the second rail is almost unuseful in my configuration if I understood well, right?

I don't think it's an easy yes / no.

I don't think it's necesary.

It will have some minor benefits, but I don't think they are large (if your rails are reasonable ones).

If you can make the gantry run smoothly (i.e. no binding or stiffening of the carriages) it won't do any harm.Personally, I'd use a larger section (2040 or a hollow box) as the gantry rather than double up the rails. For a 500mm span gantry I would probably go larger than 2020, but I haven't built a printer with a traveling gantry so I'm going by theory not practical experience.