New heated enclosure printer

-

@coseng We are using the BLTouch in actively heated chambers above 65c without much issue. Below is from our config. Note A20. It is set that high to combat bad readings, but I don't believe we've ever seen it need to probe more than 5-6 times before an accurate reading is captured.

M558 K0 P9 C"20.io0.in" H3.5 F90 T12000 A20 R0.1 S0.01 -

@oozebot Thanks for the settings. I will try to keep it a bit away from the printhead with a remote sense rod and see how the solenoid reacts to the additional mass.

-

@dc42 >>The 6HC does not provide step and direction outputs for external drivers. The EXP1XD does.

Do you think 4 of them daisy chained would have the bandwidth for the xyuv motors? Is there an upper limit on step rate as you plug in more of them? Not that I want to hack this stuff much but is it not possible to pull the step/dir signals directly from the 6HC board?

-

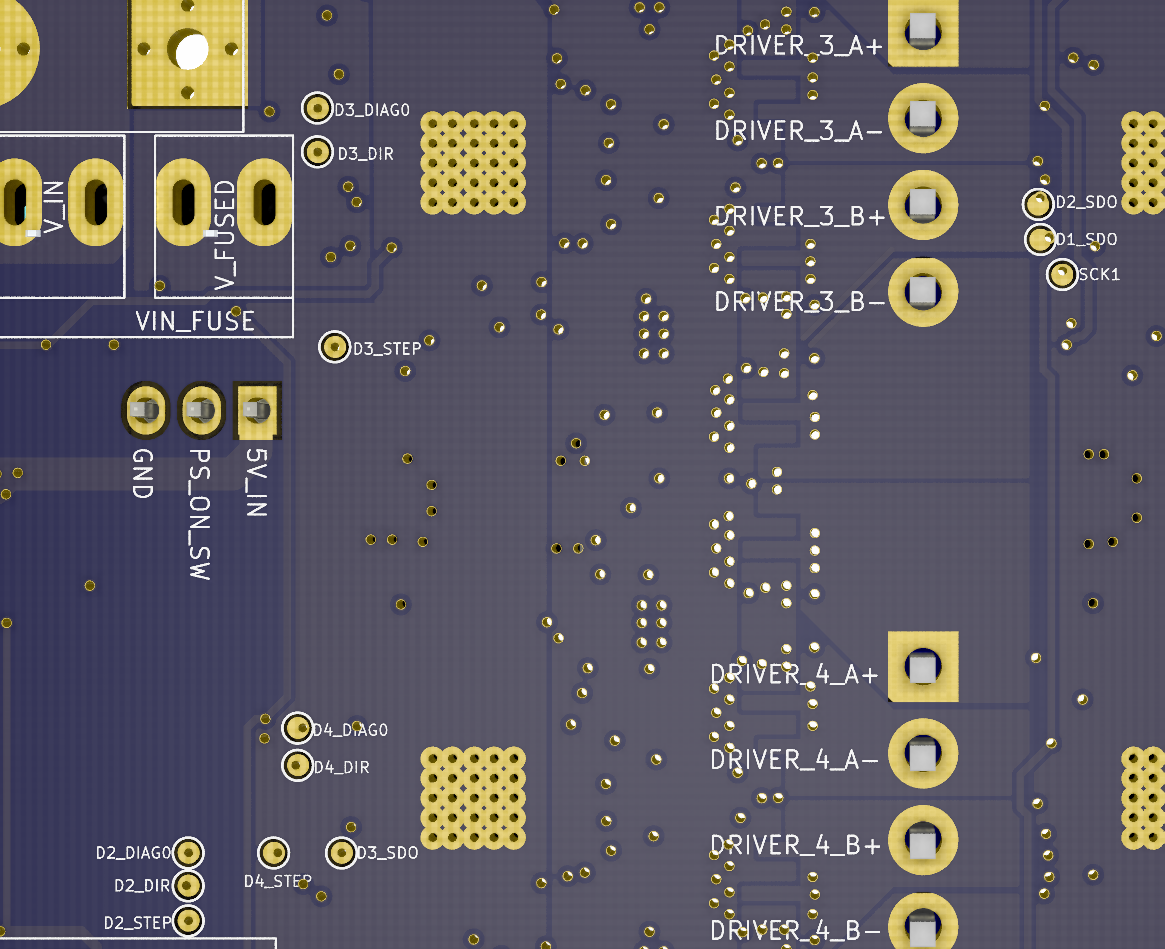

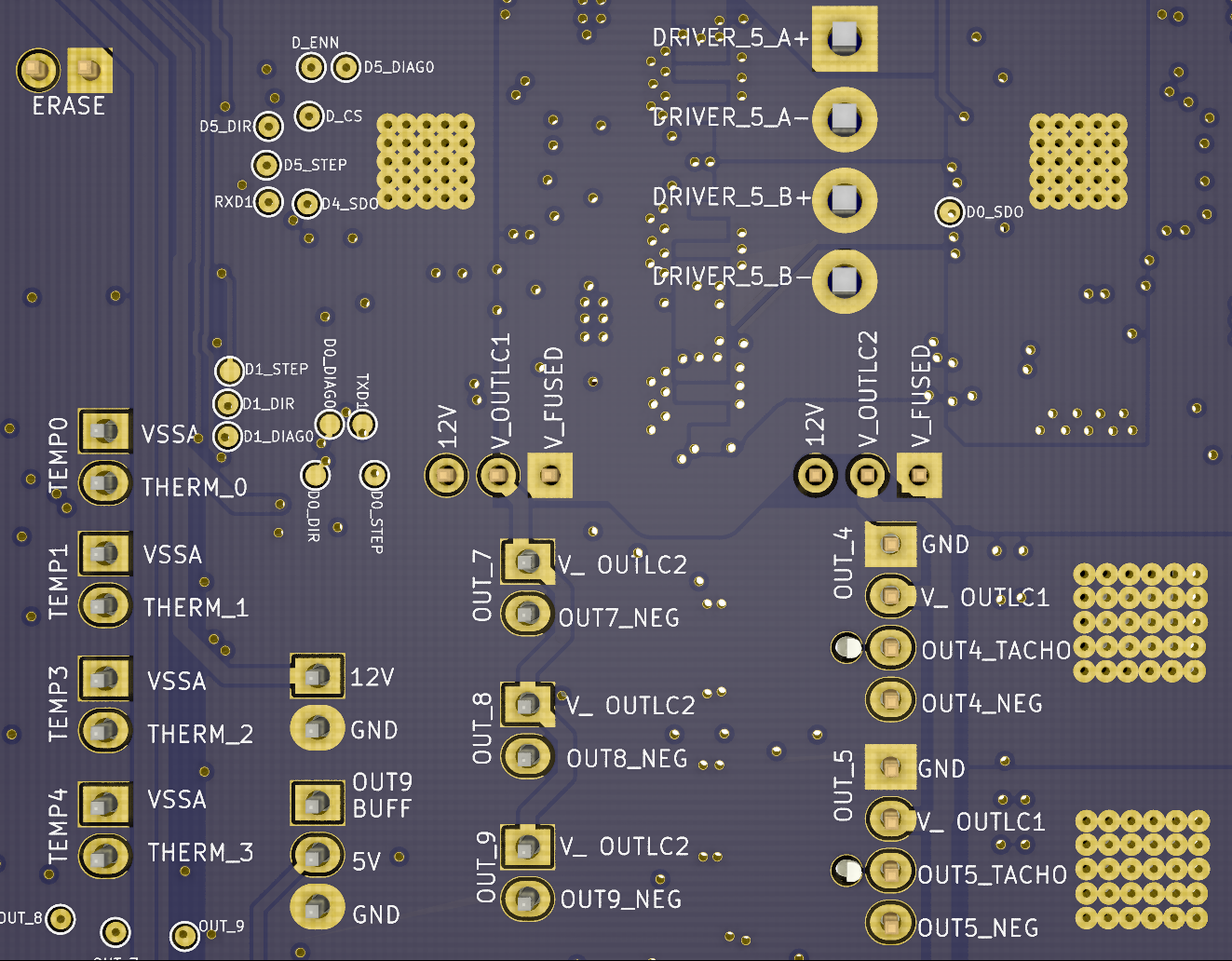

@coseng it's possible to connect to the step and direction signals of the internal drivers, but it's a hack and somewhat tricky. Those signals are available as small circular test pads on the underside of the board. You would need to use fine wires to connect to them. The signal levels are 3.3V at low current, so for most external drivers you would need to use a buffer to shift them to 5V at higher current. Possibilities for this include a Duet 2 Expansion Breakout Board, or a 7406 or 74LS06 chip.

We are working on a Duet 3 main board supporting external drivers, but it isn't ready yet.

There should be enough CAN bandwidth to drive four EXP1XD boards from a MB6HC.

-

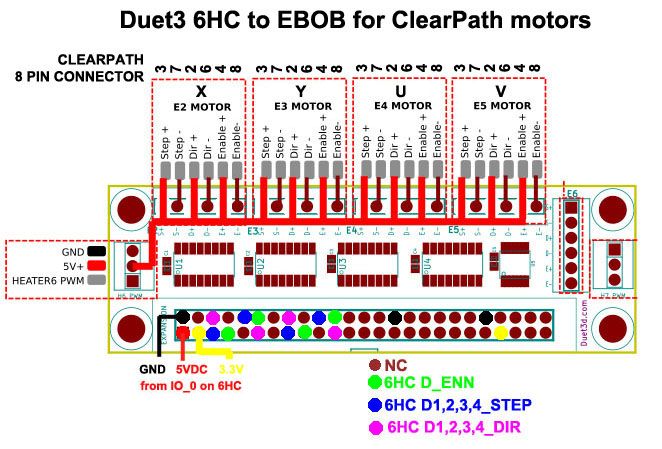

@dc42 >>Possibilities for this include a Duet 2 Expansion Breakout Board

That seems like a nice clean solution for the XYUV motors. Doing a motor count, there are 7 total: 2 extruders, 1 Z axis, and XYUV. I saw in one of your other posts that Y and V are slaved together so can I use one of the breakout board's outputs for both the Y and V controller inputs? That would end up with X, Y(V), and U being output as step/dir pulses through the breakout board and Z and the two extruder steppers being driven directly from the 6HC.

-

Just got a bunch of linear rails in from ebay that will take care of all the motion axes.

Once I figure out the motor drive configuration I'll start on the CAD model. It will be as basic as possible to let me get fabricating parts ASAP. -

@dc42 I am comfortable with doing a solder modification to the 6HC to access the step/dir outputs and routing it to a Duet 2 EBB, though the 1XP approach seems neater but has more communications and setup overhead. Which solution do you think would give the best results?

-

@dc42 I hate to bug you, but could you let me know the pads to solder to for the expansion board hack? That is my preferred method for using ecternal drivers if there are no drawbacks besides needing to solder carefully. I want to get all the parts ordered but want to be sure they are the right ones.

-

Note that you will get warnings about issues with the onboard drivers. Also soldering onto the test pads will void your warranty.

-

@t3p3tony Thanks! I understand about voiding the warranty. Are the driver warnings anything to be concerned with in terms of damage to the board or printing issues? I don't want to open a can of worms but being a little old school and given an equal choice, prefer a hardware solution to a software one.

-

@coseng The warnings will be the stepper drivers complaining the is an open circuit between the motor connector pins. This should not cause any damage but be aware those pins will be "live" when the stepper driver is enabled so shorts across them will probably damage the board.

I need to check with @dc42 if M569 R-1 can be used to disable the internal driver without disabling the step and direction signals.

-

@t3p3tony OK. I'll put empty connector housings on the stepper outputs to be sure nothing will contact them. 'M569 R-1' working would be nice but is not necessary. I'll place an order with Filastruder for all the parts. Thanks for the help.

-

@coseng if you leave the motor currents set at zero in RRF then you won't get any warnings about motors being disconnected.

-

@dc42 OK, thanks. That seems to about cover it. I have all the hardware on order and will start to draw up the mechanicals and post some progress as it goes. I'm sure there will be more questions along the way!

-

@t3p3tony Can you give me a hand confirming which pins on the Duet2 expansion board 50 pin connector get connected to the enable, step, and direction pads on the Duet 6HC? From the Duet2 pinout, I think it is DX_STEP on 6HC to EX_STEP on EBB, DX_DIR on 6HC to EX_DIR on EBB, DX_DIAGO on 6HC to EX_EN on EBB, but what about the EX_STOP pin on the EBB?

Thanks,

Chris -

6HC DxSTEP - > EBOB EySTEP

6HC DxDIR - > EBOB EyDIR

6HC DRIVER_ENN -> EBOB EzENThere is only one Enable line on the 6HC as the individual onboard drivers are controlled over SPI so your external drivers will be enabled en masse.

Diag0 is an output from the onboard driver to the main processor so do not connect to that,

the EBOB does not break out the endstop pins from the 50 way connector.

Sources:

-

@t3p3tony OK, I will split the single 6HC enable signal to the 4 external stepper drivers. I am OK with using the onboard endstop connectors unless I am not understanding you. the motors with integrated drivers do not have endstop functionality.

One more question. For the EBOB wiki: The Duet Expansion Breakout Board uses a differential output signal of -3.6V to +3.6V.........for those few drivers that really do need 5V........

Do I need to do this? The inputs on the motor driver are 5-24VDC.

'5V differential outputs are not directly compatible with ClearPath inputs because differential drivers' guaranteed output voltage swing is typically not guaranteed to meet the ClearPath input minimum input voltage requirements. While differential drivers may work initially, they may fail over time as the environment changes, i.e. the motor heats up, components age, and so forth. This can result in erratic operation that is difficult to debug.'

https://www.teknic.com/files/downloads/clearpath_user_manual.pdf P.43-47.

-

@coseng regarding the 5V signal level question, yes as the notes say if the driver needs 5V then connect +5V to the 5V supply on the EBOB and connect the STEP(-), DIR(-) etc signals to the corresponding terminals on the clearpath as shown on page 47 of the datasheet.

-

@t3p3tony OK, so I think this is what you mean:

-

@coseng, just to make yo aware: using the DRIVERS_ENN line to feed to the EBOB Enable inputs, the drivers will get enabled as soon as VIN power is stable and the on-board drivers have been initialised. They will be disabled only when VIN power to the 6HC is removed.

You will need to select the polarity of the Enable outputs to be correct for your servos. DRIVERS_ENN will go low to enable the drivers. If you are using single ended 5V drive, then connect ENA+ of your servo to +5V, and ENA- to either Enable+ or Enable- on the EBOB, whichever gives the correct polarity.