Z-Offset changes suddenly during first layer

-

Yes, the three Z motors are on the Duex. I have been running this specific Z setup since about a year (with just a single fixed hotend rather than toolchanging) with no issues, so I would rule out any "design" issues.

However, I will check all the connectors again, that could certainly be an issue. -

My Moai print completed overnight and there are various distinct issues:

- It appears that after a really clean first layer (I watched that live) the Z is not dropping enough in the next layers, the first mm or so it really squishes the filament into the previous layer. After 5 or so layers, it works fine, probably because it finally adjusted to the "wrong" Z.

- The squish only happens on T0. T1 is not affected. That's in line with another dual color print from a few days ago where the same issue showed.

- In addition, any other layer than the first shows a weird Y axis offset. First layer is ok, everything after that not so much.

To me it appears that for some reason, the tool offsets are not used correctly...

I'm calibrating my tool offsets in X, Y and Z with the E3D vernier scale print.

-

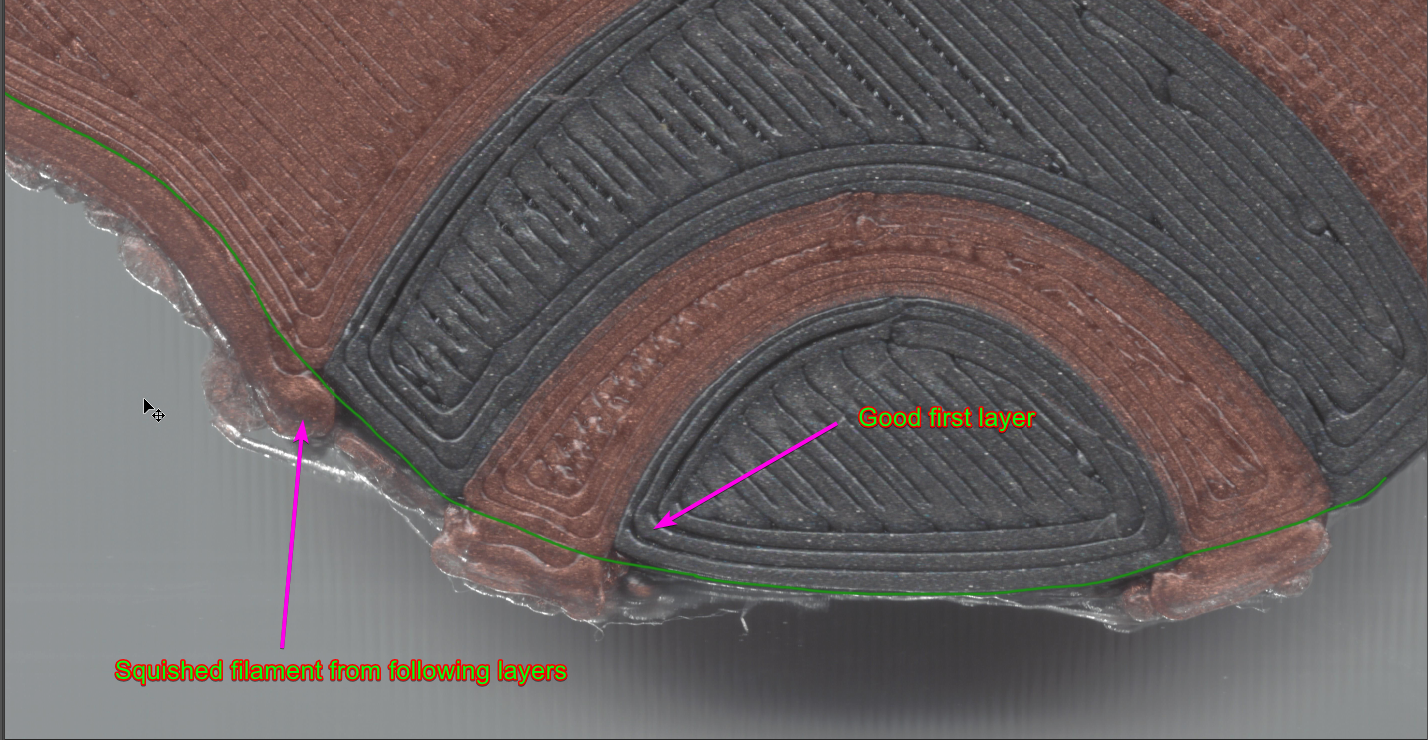

Here's a scan of the underside of the Moai.

What you can see here is the following:- The thin green line indicates the normal outer perimeters (3 lines à 0.3mm for copper, 3 lines à 0.4mm for dark grey) I watched these lines lay down during the first layer and they were as good as I can hope for

- Everything past the green line is filament that squished down from the following layers, it wasn't there when the first layer finished.

- There is no meaningful offset in X or Y between the two filaments in the first layer, while later in the print there is

Squished first layers

Offset in Y (see the gap next to the ear)

Filament being squished out the front

-

@Diamondback

Does the gap reflect your y-offset, but in the wrong direction?

I've just started with dual tool stuff and was surprised to read that eg. for copy mode the offsets have reversed signs.

Meaning, the X-axis left from center gets a positive offset (although it's on the lower side), the U axis is on the right off the center and has a neg. offset.

Not sure about Z offset, but if you've set your offsets wrong, it would explain a lot. (but not the Random factor) -

What surprises me is that the E3D offset calibration print works perfectly fine in terms of X/Y calibration. (In case you don't know that, it's basically a vernier scale that you print and then you can easily see what offsets there are currently)

Looks like this:

And of course that the X/Y offsets work fine for the first layer...

-

@Diamondback why not use TAMV? much easier for nozzle X/Y calibration https://github.com/HaythamB/TAMV

-

@jay_s_uk Yea that's supposed to be the next step, but I really think something is fundamentally wrong with my setup and the vernier print should work just fine for getting things to print in a useful manner.

I mean, even single extruder prints don't work due to the Z issue... -

Have you checked that the 8 screws that hold the bed assembly to the linear rail slider are tight? I was getting wildly varying height maps, and the reason turned out to be loose screws.

EDIT: I see from an earlier post that you gave 3 Z motors, so it is not an E3D TC and the above probably doesn't apply.

-

@dc42 Yep, custom motion system, will check all the Z mountings anyway, good idea

-

I've just printed a portion of the Moai with switched extruders, so what was previously printed by T0 is now T1 and vice versa.

Observations:

- T0 Z-Offset worked for about 3/4 of its layer, then it blocked the nozzle, I let it continue because T0 was the accents so no huge harm

- T1 Z-Offset is spot on, first layer consistently looks as good as it used to look before the toolchanging hardware

- T1 following layers are all perfectly aligned in X, Y and Z, this makes me think that my motion system itself is fine (ie no huge Z backlash issues or head positional issues)

- T0 following layers show the known problem, not aligned properly, squishing in all directions...

This leads me to the following possible causes:

- T0 tool is somehow broken or damaged and behaves differently than what is expected

- T0 offsets are being messed with in software somehow

-

Oh wow, I think i finally figured out what's going on. At least something that is going on.

My hotend holder is deforming under the pressure from the extruder... This tilts the whole hotend, moving the nozzle in Y and Z.

I just noticed this very extremely when going from first to second layer, the first layer is fairly slow (30m/s) and the second is twice as fast.

The higher speed deformed the holder a lot more, giving an explanation for the perfect first layer and then the sudden issue with layer 2.I'm not sure yet why it would cause issues during the first layer as it still sometimes does, but right now I'm printing beefier holders and then see if that helps.

T1 was also less affected since it's using a 0.4mm nozzle vs the 0.3mm on T0...Fingers crossed that this is purely a hardware issue on my side and no obscure firmware thing

-

Yea, I think this was indeed the problem. After installing much stronger parts for the hotend holder, the nozzle does not dive anymore. (Btw these weren't stupidly small parts or bad filament, they were printed in carbon fiber reinforced nylon, which is much stiffer than anything else I have around, so that really wasn't on my radar...)