Maybe a bit broader, but having the file editor as some sort of non-modal popup that can be moved/minizmized/changed in size would be quite helpful in a bunch of situations. Bonus points if we can open multiple files at once.

Best posts made by Diamondback

-

RE: Feature Request - Position Overlay while editing filesposted in Duet Web Control wishlist

-

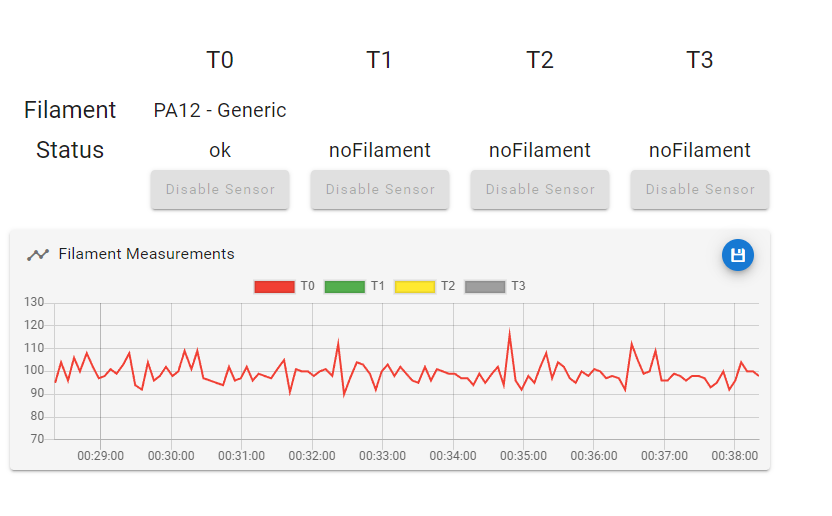

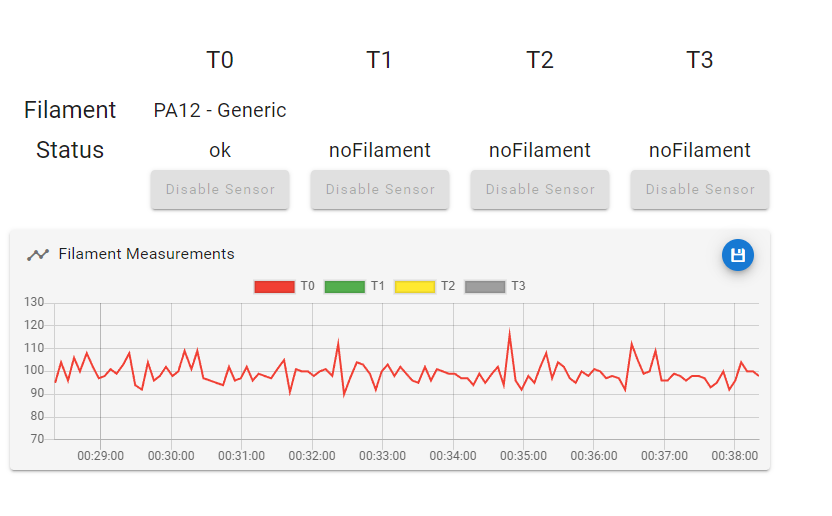

RE: Filament Monitor Data Access from OMposted in Filament Monitor

@dc42 Thanks for adding this in 3.5 rc2

Very useful

Very useful

(The sensor here is almost 1m away from the extruder, so in case the signal looks too noisy, that's why)

-

RE: Forum Cover over the Holiday Season 2022posted in General Discussion

Thanks for all your work and dedication, can't wait to see what 2023 brings along.

-

Toolhead board for Toolchangersposted in Hardware wishlist

I'd like to get some discussion going on a toolhead specific board for toolchangers.

Here's my current setup on the toolhead:- 1x Stepper (the coupler)

- 3x Endstops/switches (X-Axis, Z-Probe, "Tool-Present" switch)

- 1x Accelerometer with USB cable used for data transmission

- 1x Dotstar 8x8 grid

Overall that's a fairly chunky amount of cables being routed to my toolhead, so I would really like to see some sort of solution that involves just running power and CAN over there.

The 1LC toolboard covers almost all of it, but I don't think it can do the dotstars and it's also quite bulky in size and with a bunch of stuff I don't need (heater output, fan outputs)

So having a slimmed down version of that would be amazing.

Alternatively, a board that can do all of the above and at the same time connect to the actual tool via pogo pins (ie another stepper driver, some more IO etc, that way you'd have one board that covers both the head logic as well as the tool stuff.

Of course, this might need some further software refinement for dynamically connecting to/disconnecting from the stepper/heater/fans etcAre there maybe already other CAN connected and Duet compatible boards that would give me such an option?

-

RE: Temp gradient using neopixel and Duet 3 mini 5+posted in Tuning and tweaking

The if/elif conditional is exclusive, that means as soon as one condition evaluates to "true", it stops looking at the rest.

For example, as soon as your status is processing or busy, the leds will ALWAYS be white, everything after that won't even be checked.The same applies to the temp checks, you are checking if the temperature is above 170°C and after that, you check for the temperature being > 230°C, but 230°C is also > 170°C, so it will never actually end up executing this code.

It appears (from the way you wrote this), you'd want to use a bunch of non exclusive conditionals or switch around the order to make more sense.

; LED control if {state.status} == "paused" M150 R255 B255 P255 S20 ; purple M300 S4000 P50 G4 P300 M300 S4000 P50 ; double beep if {state.status} == "processing" || {state.status} == "busy" M150 R255 U255 B255 P255 S20 ; white if {heat.heaters[1].current} <= 70 M150 R255 U255 B0 P255 S20 F1 ; yellow if {heat.heaters[1].current} > 170 M150 R255 U80 B0 P255 S20 F1 ; orange if {heat.heaters[1].current} >= 230 M150 R255 U0 B0 P255 S20 F1 ; red if {state.status} == "idle" M150 R0 U255 B0 P255 S20 ; greenFor the purple, you'll have to come up with some other condition depending on when exactly you actually want that to show up.

-

RE: Filament Material Changes without Load - Unload ???posted in Firmware wishlist

@sputnikoc3d said in Filament Material Changes without Load - Unload ???:

@fcwilt said in Filament Material Changes without Load - Unload ???:

@sputnikoc3d said in Filament Material Changes without Load - Unload ???:

my goal isnt to improve my load and unload routines ... which I can do at a later time.

I just change the filament "by hand" and then select the newly loaded filament from the DWC.

Frederick

Wait ... wuuuutt ?

Why do I have to load and unload ... obviously Im doing something wrong. I want the ability to do just what youre doing - lol wth ..

Frederick probably just means that he has no code in the load/unload macros, that way, DWC doesn't do anything when "loading" or "unloading filaments, other than showing a different string in the interface.

-

RE: Probing outside allowed areaposted in General Discussion

Just in case someone finds this in the future. I went the recommended route and manually extend the allowed area in bed.g like this:

bed.g

[...] M208 Y{global.minY}:{global.maxYMesh} ; extend allowed space for probing near the edge of the bed G29 S0 G1 X400 Y{global.maxY} F20000 ; Park M208 Y{global.minY}:{global.maxY} ;reset safe moving space to normalIn config.g I create the referenced globals from above:

[...] ; Axis Limits global minY = -149 global maxY = 72 M208 X-146:159 Y{global.minY}:{global.maxY} C0:250 Z0:290 ; set axis minima & maxima [...] global minYMesh = global.minY global maxYMesh = 115 M557 X-146:150 Y{global.minYMesh}:{global.maxYMesh} P10 ; define mesh grid [...]This works fine and is maintenance free in terms of having to maintain hardcoded coordinates in multiple places.

-

RE: Failed stock SD Card on 6HC 1.02posted in General Discussion

@T3P3Tony That is very kind of you, but I really don't think the overall time, effort and expenses are warranted here for a tiny SD card. I'd rather have the Duet Team put that saved money towards the team fund

Really just wanted to let you know about it in case a pattern appears.

-

Filament Monitor Data Access from OMposted in Filament Monitor

Hey,

would it be possible to expose some more data of the Magnetic Filament Monitors in the obejct model?

I'm specifically thinking about this the new custom graph feature of the BtnCmd plugin to create a graph of the filament throughput measurements.Not only does this look nice, it might also be helpful in debugging some things.

Latest posts made by Diamondback

-

RE: Filament Monitor Data Access from OMposted in Filament Monitor

@dc42 Thanks for adding this in 3.5 rc2

Very useful

Very useful

(The sensor here is almost 1m away from the extruder, so in case the signal looks too noisy, that's why)

-

RE: Magnet Filament Monitor V4 - Calibration Issueposted in Filament Monitor

@dc42 Good news

With 3.5rc2, all my sensors appear to work for now

With 3.5rc2, all my sensors appear to work for now  They collect data that seems right, they change status when inserting filament etc.

They collect data that seems right, they change status when inserting filament etc.

I haven't tested yet what happens if they actually detect an issue, but so far so good. Will keep you posted if anything weird comes up. Many thanks

-

RE: [3.5 rc1+] Error while changing filamentposted in Beta Firmware

@chrishamm Anything else I can help with?

-

RE: [3.5 rc1+] Error while changing filamentposted in Beta Firmware

@chrishamm

Actual filament files: (I've picked one specific filament, there are many more like this)

load.gM98 P"/macros/FilamentConfig/PETG/load"unload.g

M98 P"/macros/FilamentConfig/PETG/unload"config.g

M98 P"/macros/FilamentConfig/PETG/config"Filament specific redirection layer: (Each filament type has its own set of macros with the same code but different parameters)

/macros/FilamentConfig/PETG/load:

M98 P"/macros/FilamentConfig/Generic/load" T230 S210 R150 F{global.pebbleFeedSpeedDefault}/macros/FilamentConfig/PETG/unload:

M98 P"/macros/FilamentConfig/Generic/unload" T240/macros/FilamentConfig/PETG/config:

M98 P"/macros/FilamentConfig/Generic/config" N"PETG - Generic"Generic macros:

/macros/FilamentConfig/Generic/load:set global.toolheadDisplayState = "filamentLoad" var extrusionTemp = var.T var extrusionMinTemp = var.S var retractionMinTemp = var.R set global.pebbleFeedSpeed = var.F ;apply commanded pebble feed speed M98 P"/macros/Misc/Lights/On" M291 P"Heating for purge" R"Filament" S0 T5 M98 P"/macros/Toolchanging/HomeIfNotHomed" var previousTemp = tools[state.currentTool].active[0] M568 P{state.currentTool} S{var.extrusionTemp} R0 M116 P{state.currentTool} M302 S{var.extrusionMinTemp} R{var.retractionMinTemp} ;Cold extrusion settings if move.axes[1].userPosition > 0 ;make sure we do not try to move to the purge location without being far away from the dock G90 G1 Y0 F25000 G1 X-70 F25000 G1 Y-220 F25000 M400 M98 P"/macros/Misc/Beep" M291 P"Ready to feed new filament?" R"Filament Loading" S2 var keepFeeding = true while var.keepFeeding == true G1 E300 F3000 M400 M291 S4 P"Filament loaded correctly?" R"Filament Loading" K{"Yes", "No, feed again"} if input == 0 set var.keepFeeding = false M98 P"/macros/Tool/Purge" M568 P{state.currentTool} S{var.previousTemp} R0 M116 P{state.currentTool} M98 P"/macros/Misc/Beep" set global.toolheadDisplayState = "idle" set global.deactivateToolAfterFilamentChange = true/macros/FilamentConfig/Generic/unload:

set global.toolheadDisplayState = "filamentUnload" var releaseTemp = var.T M98 P"/macros/Misc/Lights/On" var previousTemp = tools[state.currentTool].active[0] M568 P{state.currentTool} S{var.releaseTemp} R0 M116 P{state.currentTool} M98 P"/macros/Misc/Beep" G91 G1 E-10 F3000 G4 S2 G1 E-30 F10000 M291 P"Ready to pull out filament?" R"Filament" S2 G1 E-500 F5000 G90 M400 M568 P{state.currentTool} S{var.previousTemp} R0 M116 P{state.currentTool} M98 P"/macros/Misc/Beep" set global.toolheadDisplayState = "idle" set global.deactivateToolAfterFilamentChange = true/macros/FilamentConfig/Generic/config:

if state.currentTool < 0 M99 var pressureAdvance = 0 var retractionDistance = 0.5 var retractionSpeed = 2000 var zHopDistance = 0 var minExtrudeTemp = 180 var pebbleFeedSpeed = global.pebbleFeedSpeedDefault var name = param.N var nozzleSize = global.toolNozzleSizes[state.currentTool] M98 P"/macros/FilamentConfig/Generic/GetFilamentSettingsWithNameAndSize" N{var.name} S{var.nozzleSize} if global.lastMacroResult == null var errMsg = "Can't find filament settings for filament '" ^ var.name ^ "' and " ^ var.nozzleSize ^ "mm nozzle , falling back to defaults!" echo {var.errMsg} M291 P{var.errMsg} R"Filament Config" S2 else set var.pressureAdvance = global.lastMacroResult[0] set var.retractionDistance = global.lastMacroResult[1] set var.retractionSpeed = global.lastMacroResult[2] set var.zHopDistance = global.lastMacroResult[3] set var.minExtrudeTemp = global.lastMacroResult[4] set var.pebbleFeedSpeed = global.lastMacroResult[5] var minRetractTemp = var.minExtrudeTemp - 30 echo "Using filament settings: " ^ var.name ^ " with " ^ var.nozzleSize ^ "mm nozzle, Retraction: " ^ var.retractionDistance ^ "mm@" ^ var.retractionSpeed ^ "mm/min, Z-Hop: " ^ var.zHopDistance echo "PA: " ^ var.pressureAdvance ^ ", minimum extrusion temperature: " ^ var.minExtrudeTemp ^ ", pebble feed speed: " ^ var.pebbleFeedSpeed M207 S{var.retractionDistance} F{var.retractionSpeed} Z{var.zHopDistance} ;retraction settings M572 D{tools[state.currentTool].extruders[0]} S{var.pressureAdvance} ;pressure advance settings M302 S{var.minExtrudeTemp} R{var.minRetractTemp} ;cold extrusion settings set global.pebbleFeedSpeed = var.pebbleFeedSpeed ;set pebble feed speedIn order of appearance...

/macros/Misc/Lights/On:M42 P1 S230/macros/Toolchanging/HomeIfNotHomed:

if !move.axes[0].homed || !move.axes[1].homed || !move.axes[2].homed || !move.axes[3].homed echo "Not all axis homed, starting full homing process" G28/macros/Misc/Beep

M300 S500 P400/macros/Tool/Purge:

M98 P"/macros/Toolchanging/Wiper/PrimeBrush" R15 G90 M564 S1/macros/Toolchanging/Wiper/PrimeBrush:

var primeRepeats = 4 if exists(var.R) set var.primeRepeats = var.R M98 P"/macros/Toolchanging/Wiper/PrimeBrushPebbleDisk" R{var.primeRepeats}/macros/Toolchanging/Wiper/PrimeBrushPebbleDisk:

if state.currentTool < 0 echo "Can't Prime & Brush, no tool selected!" M99 var brushStartPositionX = -80 var brushStartPositionY = -220 var brushEndPositionX = -130 var brushEndPositionY = -220 var pebblePositionX = -151.0 var pebblePositionY = -220.0 var diskStep = 50 var wiperHeightPurgeInitial = 20.6 var wiperHeightPurgeBulk = var.wiperHeightPurgeInitial - 1.5 var wiperHeightRotate = var.wiperHeightPurgeBulk - 2 var wiperHeightIdle = var.wiperHeightPurgeInitial - 5 var wiperHeightBrush = var.wiperHeightPurgeInitial + 0.5 var wiperPurgeAmountPrime = 2 var wiperPurgeAmountInitial = 2 var wiperPurgeAmountBulk = 3 var wiperHeightFeedrate = 3000 if state.currentTool < 0 echo "Can't Prime & Brush, no tool selected!" M99 if heat.heaters[tools[state.currentTool].heaters[0]].current > heat.coldExtrudeTemperature M106 S255 M564 S0 G90 G1 W{var.wiperHeightIdle} F{var.wiperHeightFeedrate} G1 X{var.brushStartPositionX} Y{var.brushStartPositionY} F25000 G1 W{var.wiperHeightBrush} F{var.wiperHeightFeedrate} G1 X{var.brushEndPositionX} Y{var.brushEndPositionY} F25000 G1 W{var.wiperHeightPurgeBulk} F{var.wiperHeightFeedrate} G1 X{var.pebblePositionX} Y{var.pebblePositionY} F25000 var primeRepeats = 10 if exists(var.R) set var.primeRepeats = var.R while iterations < var.primeRepeats G92 D0 M83 M106 S255 G90 G1 W{var.wiperHeightPurgeInitial} F5000 ;G11 if iterations == 0 G1 E{var.wiperPurgeAmountPrime} F{global.pebbleFeedSpeed} else G0 E1 F3000 G1 E{var.wiperPurgeAmountInitial} F{global.pebbleFeedSpeed} M106 S255 ;G1 W{var.wiperHeightPurgeBulk} F5000 G1 W{var.wiperHeightPurgeBulk} E{var.wiperPurgeAmountBulk} F{global.pebbleFeedSpeed/7} G4 P400 G0 E-1 F3000 ;G10 G90 G92 D0 G1 W{var.wiperHeightRotate} D{var.diskStep} F10000 G91 ;G1 D{var.diskStep} F20000 G90 G90 M106 S0 G1 W{var.wiperHeightPurgeBulk} F{var.wiperHeightFeedrate} G1 X{var.brushEndPositionX} Y{var.brushEndPositionY} F25000 G1 W{var.wiperHeightBrush} F{var.wiperHeightFeedrate} G1 X{var.brushStartPositionX} Y{var.brushStartPositionY} F25000 M564 S1 else echo "Skipping Prime & Brush due to unheated tool"/macros/FilamentConfig/Generic/GetFilamentSettingsWithNameAndSize:

set global.lastMacroResult = null if !exists(param.N) || !exists(param.S) M99 var name = param.N var size = param.S while iterations < #global.filamentSettings if global.filamentSettings[iterations][0] == var.name var nozzleSizeId = -1 while iterations < #global.nozzleSizeMap if global.nozzleSizeMap[iterations] == var.size set var.nozzleSizeId = iterations if var.nozzleSizeId >= 0 var settings = global.filamentSettings[iterations][1][var.nozzleSizeId] set global.lastMacroResult = var.settings M99 else echo "Can't find nozzle size id for nozzle size: " ^ var.size M99 echo "Can't find filament settings for filament: " ^ var.name -

[3.5 rc1+] Error while changing filamentposted in Beta Firmware

Hey,

I'm getting a weird error while using the DWC "change filament" functionality:Error: M701: Unload the current filament before you attempt to load another one Error: Push(): stack overflow on HTTPI guess the first line is a follow-up to the stack overflow error?

Any clue what might be happening here? I think this started with the 3.5rc1.M122:

=== Diagnostics === RepRapFirmware for Duet 3 MB6HC version 3.5.0-rc.1+ (2023-11-01 10:30:38) running on Duet 3 MB6HC v1.02 or later (standalone mode) Board ID: 08DJM-9P63L-DJ3T0-6J1F4-3S06S-9A1V9 Used output buffers: 3 of 40 (33 max) === RTOS === Static ram: 154836 Dynamic ram: 132700 of which 20 recycled Never used RAM 29620, free system stack 136 words Tasks: NETWORK(1,ready,36.2%,147) ETHERNET(5,nWait,0.3%,117) ACCEL(6,nWait,0.0%,348) HEAT(3,nWait,0.0%,325) Move(4,nWait,0.0%,216) CanReceiv(6,nWait,0.0%,795) CanSender(5,nWait,0.0%,334) CanClock(7,delaying,0.0%,350) TMC(4,nWait,8.3%,59) MAIN(1,running,55.1%,103) IDLE(0,ready,0.0%,30), total 100.0% Owned mutexes: === Platform === Last reset 00:24:14 ago, cause: software Last software reset at 2023-11-12 12:49, reason: User, Gcodes spinning, available RAM 29468, slot 2 Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x00400000 BFAR 0x00000000 SP 0x00000000 Task MAIN Freestk 0 n/a Error status: 0x00 MCU temperature: min 40.9, current 42.1, max 42.2 Supply voltage: min 23.5, current 23.8, max 23.9, under voltage events: 0, over voltage events: 0, power good: yes 12V rail voltage: min 12.2, current 12.3, max 12.5, under voltage events: 0 Heap OK, handles allocated/used 495/405, heap memory allocated/used/recyclable 24576/24388/1184, gc cycles 337 Events: 0 queued, 0 completed Driver 0: standstill, SG min 0, mspos 456, reads 35702, writes 19 timeouts 0 Driver 1: standstill, SG min 0, mspos 360, reads 35703, writes 19 timeouts 0 Driver 2: standstill, SG min 0, mspos 424, reads 35703, writes 19 timeouts 0 Driver 3: standstill, SG min 0, mspos 904, reads 35703, writes 19 timeouts 0 Driver 4: standstill, SG min 0, mspos 520, reads 35699, writes 23 timeouts 0 Driver 5: standstill, SG min 0, mspos 408, reads 35703, writes 19 timeouts 0 Date/time: 2023-11-12 13:13:54 Slowest loop: 13.69ms; fastest: 0.05ms === Storage === Free file entries: 19 SD card 0 detected, interface speed: 25.0MBytes/sec SD card longest read time 3.1ms, write time 2.3ms, max retries 0 === Move === DMs created 125, segments created 6, maxWait 1308373ms, bed compensation in use: none, height map offset 0.000, ebfmin 0.00, ebfmax 0.00 no step interrupt scheduled Moves shaped first try 0, on retry 0, too short 0, wrong shape 0, maybepossible 0 === DDARing 0 === Scheduled moves 28, completed 28, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 1], CDDA state -1 === DDARing 1 === Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === Heat === Bed heaters 0 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1, chamber heaters -1 -1 -1 -1, ordering errs 0 Heater 0 is on, I-accum = 0.0 Heater 1 is on, I-accum = 0.2 === GCodes === Movement locks held by null, null HTTP is idle in state(s) 0 Telnet is idle in state(s) 0 File is idle in state(s) 0 USB is idle in state(s) 0 Aux is idle in state(s) 0 Trigger is idle in state(s) 0 Queue is idle in state(s) 0 LCD is idle in state(s) 0 SBC is idle in state(s) 0 Daemon is doing "G4 P500" in state(s) 0 0, running macro Aux2 is idle in state(s) 0 Autopause is idle in state(s) 0 File2 is idle in state(s) 0 Queue2 is idle in state(s) 0 Q0 segments left 0, axes/extruders owned 0x8000000f Code queue 0 is empty Q1 segments left 0, axes/extruders owned 0x0000000 Code queue 1 is empty === Filament sensors === check 0 clear 0 Extruder 0: no data received, errs: frame 0 parity 0 ovrun 0 pol 0 ovdue 0 Extruder 1: no data received, errs: frame 0 parity 0 ovrun 0 pol 0 ovdue 0 Extruder 2: no data received, errs: frame 0 parity 0 ovrun 0 pol 0 ovdue 0 Extruder 3: no data received, errs: frame 0 parity 0 ovrun 0 pol 0 ovdue 0 === CAN === Messages queued 13155, received 29867, lost 0, errs 0, boc 0 Longest wait 1ms for reply type 6042, peak Tx sync delay 10, free buffers 50 (min 49), ts 7274/7273/0 Tx timeouts 0,0,0,0,0,0 === Network === Slowest loop: 40.94ms; fastest: 0.03ms Responder states: MQTT(0) HTTP(0) HTTP(0) HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0) Telnet(0) HTTP sessions: 1 of 8 = Ethernet = Interface state: active Error counts: 0 0 0 1 0 0 Socket states: 5 2 2 2 2 0 0 0 === WiFi === Interface state: disabled Module is disabled Failed messages: pending 0, notrdy 0, noresp 0 Socket states: 0 0 0 0 0 0 0 0 === Multicast handler === Responder is inactive, messages received 0, responses 0 -

RE: does not completely finish the last layer of the print 3.5.0-b4posted in Beta Firmware

@dc42 Some more prints done, nothing new to report, all working fine.

-

RE: does not completely finish the last layer of the print 3.5.0-b4posted in Beta Firmware

@dc42 So far no issues with not finishing the print with this build.

-

RE: [3.5 RC1] Toolchanges messing up Z height?posted in Beta Firmware

No, i'm not using G92 during my print at all. It's being used for the homing process of the coupler axis once, but that's about it.

-

RE: does not completely finish the last layer of the print 3.5.0-b4posted in Beta Firmware

@dc42 More info on this from my side. What I have been seeing appears to be the combination of two issues.

- Not finishing of the extrusion bit of the print file

- Some weird crashing/stalling movement issues after pausing and unpausing the print

The first issue seems to be new with RC1, but the second issue also just happened to me on beta 4. I will try to actually replicate what it's doing, maybe without a tool or without a nozzle or something. It's kinda scary, but I don't fully understand what exactly is happening. The printer makes very loud nosies as if it's stalling/crashing into something, but ultimately it somehow ends up moving in the right places. I haven't been able to actually see what it's doing, I only heard it a couple of times and saw the end result. I will try to film it or something and then make a new thread about that.

-

RE: does not completely finish the last layer of the print 3.5.0-b4posted in Beta Firmware

@dc42 Can you elaborate what sort of condition lead to the SD print not finishing properly? Can you tell what it would do "instead"?

Would it just ignore all the rest of the file? Or just parts of it? What I can imagine given the behavior I saw is that RRF ignored the last few lines of actual extrusion but then executed all the management stuff afterwards (tool deselection, toolhead parking etc)

In that case the headcrash would happen due to the nozzle still being in the middle of the print and Z not being lifted...

Is that something that seems plausible?I really want to understand this issue and help debug it but I'm not really fond of destroying another Revo nozzle...