Poor print quality with RRF3 - especially 3.2.2.

-

@jens55 Different filaments have different properties. I'm told that Nylon is a bugger for absorbing water (never used it myself) but PLA is reasonably forgiving. On the other had, it seems to go brittle if left on the machine too long but often, pulling out a couple of metres or so will sort it out. There is a school of thought that say UV light plays a part in that.

What you doing is probably fine. If you didn't buy a batch at a time and store it at home, it'd likely sit in Amazon's warehouse until you or someone else bought it. Just be on the lookout for print defects when you first fit a new reel, or again, if you know the filament has been opened and sitting around for a while.

Personally I prefer to buy it more sort of "as and when" I need it. There is less chance of getting a number of bad reels because they all come from the same (bad) batch. I stick with the same supplier - they've served me well over the years and I know they'd likely do a refund or send another reel if I came across a bad one.

-

@deckingman, you can have an Ender 3 on the side, as a reference for filament quality.

-

@zapta said in Poor print quality with RRF3 - especially 3.2.2.:

@deckingman, you can have an Ender 3 on the side, as a reference for filament quality.

Not sure why people are so fixated about this print to print variability being due to filament. Not impossible but the idea that nnn metres could produce a bad print and the next nnn metres of the same reel could produce an acceptable print, is among the least plausible I'd have thought.

-

@deckingman

Your filament storage method is out off question for me, but I still stick to somethings wrong with cold start.

Might be, the firmware(s) of the boards involved click together easier after a reboot. I have created the habit, to issue an emergency stop from DWC, after I've played around with mesh bed leveling or Z-probe adjustment.

Just to give MCU and memory a clean wipeout. -

@o_lampe Looking through these forums, there are numerous instances where cycling power often seems to fix things. It makes one wonder......Perhaps an electrical component somewhere which performs differently when it's warm/cold?

One could speculate forever. All I can do is keep plugging away and doing what dc42 asks. Maybe something will show up with the diagnostics that 3.3 beta will provide and which I plan to do later.

And when someone says "well what do you expect? you are using beta firmware!", as has happened before, I'll likely commit murder....

-

@deckingman well what do you expect? you are using ... oh, never mind.

Ian (feeling a little scared)

-

@droftarts I know who you are (but I don't know where you live so you are safe .......for now).

-

@deckingman yes, you do, you sent me a roll of 3mm clear filament! Oh no! He’s got my address! Going into hiding...

Ian

-

@deckingman said in Poor print quality with RRF3 - especially 3.2.2.:

you are using beta firmware

Let's hope it's just a firmware issue and not a hardware thing. There are so many threads about CAN-stuff going wild...it might be interference or crosstalking. AFAIK, it's their first attempt to implement CAN. And according to German Automobile Clubs, electric failure is the most frequent reason for parking your car unvolontary. (Cars are full of CAN-devices)

-

@dc42 David,

I've installed 3.3.beta1 on all boards. I cleared the console, ran M122 on all boards after the instal, then downloaded the console output as a text file. Then I homed the printer, and repeated the "clear console - run M122s -download text" sequence again. Then started a print and repeated that M122 sequence again mid print. And finally, one more time at the end. I've created a folder on Google drive and put each of those 4 console.txt files in a separate folder. So it should be self explanatory - here is a link https://drive.google.com/drive/folders/1m1BnwUsU035TQT_76kcl3Yiz4BPApXg8?usp=sharing

I don't see any of the non zero oos on the expansion boards but I do see some send timeouts on the main board for the mid print and post print reports (102 mid-print and 373 post print).

The print itself if still cooling down on the build plate so I haven't looked closely at it but it doesn't look good. Not as bad as some that I've seen, but not as good as "acceptable" ones either.

HTH

-

@droftarts Fortunately for you, I didn't keep a record or your address - so you can come out from under the duvet now.

-

@deckingman, thanks for those M122 logs. If the print quality is between the bad ones and the acceptable ones, that is confusing! Can you confirm that you have been running with the same pressure advance setting (perhaps none) throughout all the recent prints?

As you said, you are getting a nonzero number of send timeouts. In theory this should mean that some messages (probably movement messages) have been lost; but in that case the expansion boards should have reported some 'oos' (out-of-sequence) errors. So I am still trying to work out the reason for this apparent conflict. The other user I was working with had a similar effect: a small number of 'oos' errors (and corresponding defects in the print) but several hundred times as many send timeouts.

My suspicion is that the CAN peripheral is delaying the reporting of successful transmissions by longer than the timeout period. However, I would like to eliminate the send timeouts as a possible reason for the issue you are seeing. So please upgrade once more, this time to the firmware binaries at https://www.dropbox.com/sh/q5uqqkjbmhgvlhq/AACYqG0ynLME9ogoLd1zLB2Xa?dl=0. These are later versions of 3.3beta1 and fully compatible with them. So no need to do anything different this time. I expect these binaries to get rid of the send timeouts, and also to get rid of the spurious 'bm' errors reporting on the 3HC after homing.

-

@dc42 Ref the print quality - let's go with bad rather than acceptable. But the way things have been, it's possible that the next print might be worse (or better).

I can confirm that everything is exactly the same - including PA (and it's still the same reel of filament. I tell a lie - the part cooling fans are no longer connected since one of the most acceptable prints was done without any part cooling.

I've downloaded the binaries - it might be a day or two before I get chance to instal them and run another print.

As I'm running a beta, is there anything else you'd like me to check?

-

@deckingman did you swap extruders?

Ian

-

@droftarts said in Poor print quality with RRF3 - especially 3.2.2.:

@deckingman did you swap extruders?

Ian

Er no. I thought it best to only change one thing - in this case the firmware. But thanks for reminding me. I'll do another print "as is" with David's latest binaries, then I'll change to another extrude and repeat.

-

@deckingman said in Poor print quality with RRF3 - especially 3.2.2.:

I tell a lie - the part cooling fans are no longer connected since one of the most acceptable prints was done without any part cooling.

What filament are you printing with? If it's PLA then please reconnect the print cooling fans, because in my experience print cooling makes a huge difference with PLA, and some of the issues with the prints you posted before looked to me like the effects of insufficient cooling. If you are using PETG then print cooling seems to me to be far less important.

-

@dc42 That's not born out by previous prints https://drive.google.com/drive/folders/1XmFXYBGnj3rXJRLg1muSNBd18AbP2ZDl?usp=sharing. The reason why I disconnected the fans was because people were talking about intermittent fan issues. So I disconnected them completely to see just how bad it would be, and was surprised when I ended up with one of the best prints of the batch. Therefore I deduced that running without fans would eliminate one potential variable (knowing that decent prints could be produced with that configuration).

I use the auto cooling feature of Slic3R in any case so the fans don't do much if the layer time is less than circa 15 seconds or if it's doing bridges. And the fans are arranged so that no direct air flows over the nozzle. It's something that I have played around with a lot over the years.

Maybe it's because I print temp towers without fans and so end with using lower temperatures than a lot of people. Again, something that I've played around with a lot over the years.

-

@dc42 David,

Tried the binaries from your dropbox. The main board reports being 3.3beta1+1 but the expansion boards come back as being 3.3beta1 (2021-02-14 16:32:08) which I think is the same as last time. Is that what you would expect?

Anyway, as before, after installing all the updates which went as expected with all 4 boards updating and then being prompted to do a reset, I cycled the power (just to be sure) then ran an initial M122 and all 4 boards and downloaded the console text. Then I heated the bed and ran a home all and repeated the M122 reports. Then I started a print which was going well - extremely well - in fact one of the best I've seen for a long time. Part way through, I did another set of M122s.

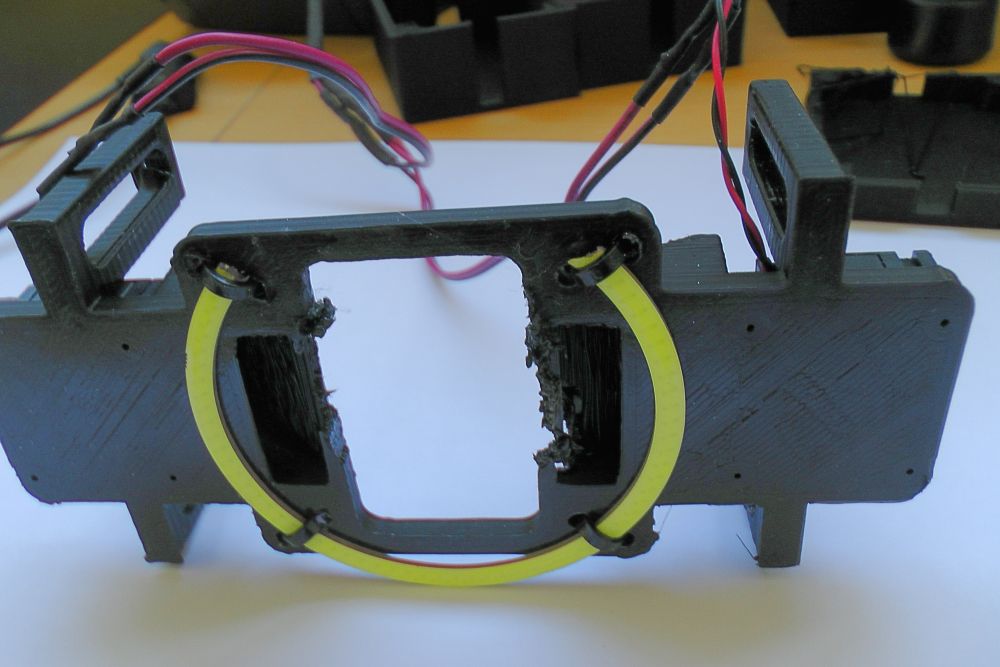

A short time after that, the printer went into self destruct mode. It looks like a massive shift in the X direction and the carriage was doing it's best to head butt the side of the printer frame into pulp. But the UV axis didn't suffer the same shift which has caused the cabling and Bowden tubes to tear the hot end off it's Kinematic mount.

I had the forethought to pause the print rather than bang the emergency stop button. So at that point, I ran another sequence of M122s on all the boards. I could not however download the console output using DWC - it just didn't do anything. So I managed to copy the text and paste it into notepad++ and save that file.

I then turned the printer off and re-aligned the gantries, but with the hot end dangling on whatever wires haven't been torn out. I didn't see any obvious shorts but it might well have blown a fuse .Then I tried jogging the gantries around and everything seems normal. To be clear, all motors and belts are functioning as normal, so the sudden massive X shift doesn't appear to have been caused by a mechanical failure.

I don't see much from a cursory glance at the M122 reports, but then I don't really know what I'm looking at.

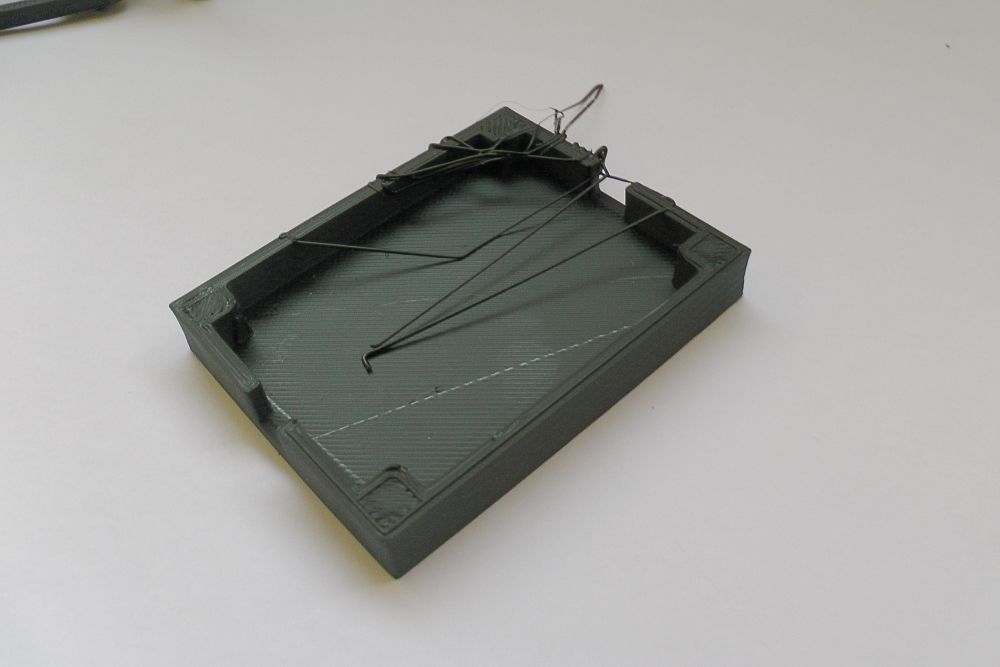

I've uploaded all the files to another folder on my google drive, As before, the console outputs for the initial, post homing and mid print M122s are in separate folders. The console output after I hit pause are in a file called "Console dump after pause" (there are two M122s for board 3 - that was just me sending M122 B3 twice by mistake). I've also posted a picture of the carriage showing the hot end torn out of it's mount and the pile of spaghetti that it tried to produce while it was head butting the printer frame into submission (it lost the fight). But if you look below that, you'll see that start of a print which was looking really quite nice.

BTW, the XY and Z motors are connected to board 3, UVA and B are connected to the main board and the 6 extruders are connected to boards 1 and 2.

Here is a link to google drive folder. https://drive.google.com/drive/folders/1oLJvwhLCwxKpKRt6UN-UCsyjkjdVFOL_?usp=sharing

It'll be some time before I get all the damage repaired and I'm in a position to test anything else.......

-

Further to my last, I've completed a damage assessment. It seems that the belts, motors, idlers etc all seem OK. The gantries can all be jogged around using my joystick. The hot end heats so looks like the heater cartridge, thermistor, and wiring survived.

But the X end stop is permanently triggered so there is an open circuit wire there somewhere. When the hot end got torn off it's mount, it destroyed the part cooling fan plate because it was plastic and got melted. But I had disconnected the fans in any case, so I can live with that for now. Also, the "cob" light I had around the nozzle is broken, but again, I can live without that.

Up until the catastrophic failure, the print was actually looking quite good (ignore the spaghetti caused by the sudden massive X shift).

It looks like I can straighten out the hot end mount without having to make any new parts - it's just a bit twisted. And I can live without fans/lights for now. I need to sort out the open circuit X end stop but that shouldn't take long.

The only thing that changed before this all happened was the firmware. Same print file, same settings. Even the same reel of filament. So obviously, I won't try any more prints with this particular firmware.

-

Sorry to hear about that head crash and damage. Hopefully the data collected proves useful.