Tool board Failure during Print

-

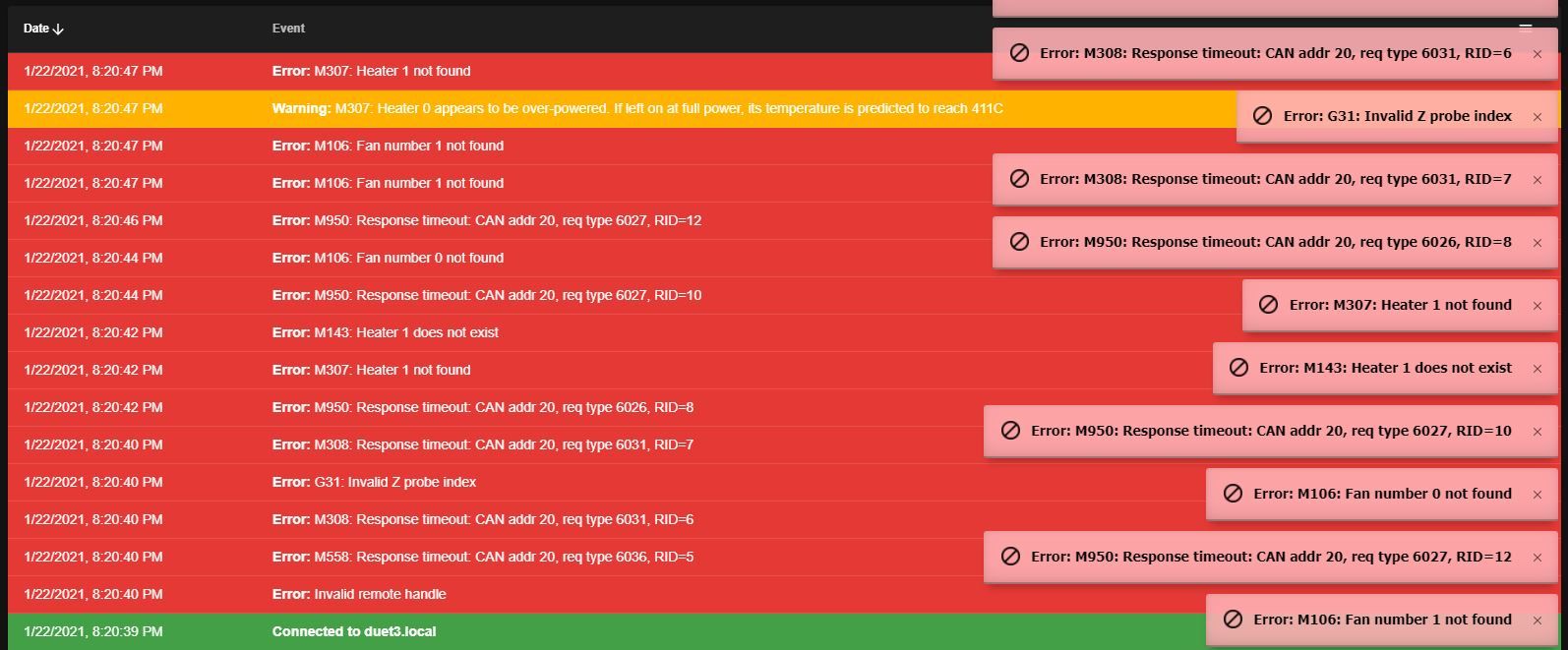

During my Last Print approx 2h in the print failed after a reset i have lost all comms to the toolboard,

I have disconnected everything except power and comms,

looking for ideas to whats gone wrong.

-

@Turricann said in Tool board Failure during Print:

During my Last Print approx 2h in the print failed after a reset i have lost all comms to the toolboard,

I have disconnected everything except power and comms,

looking for ideas to whats gone wrong.

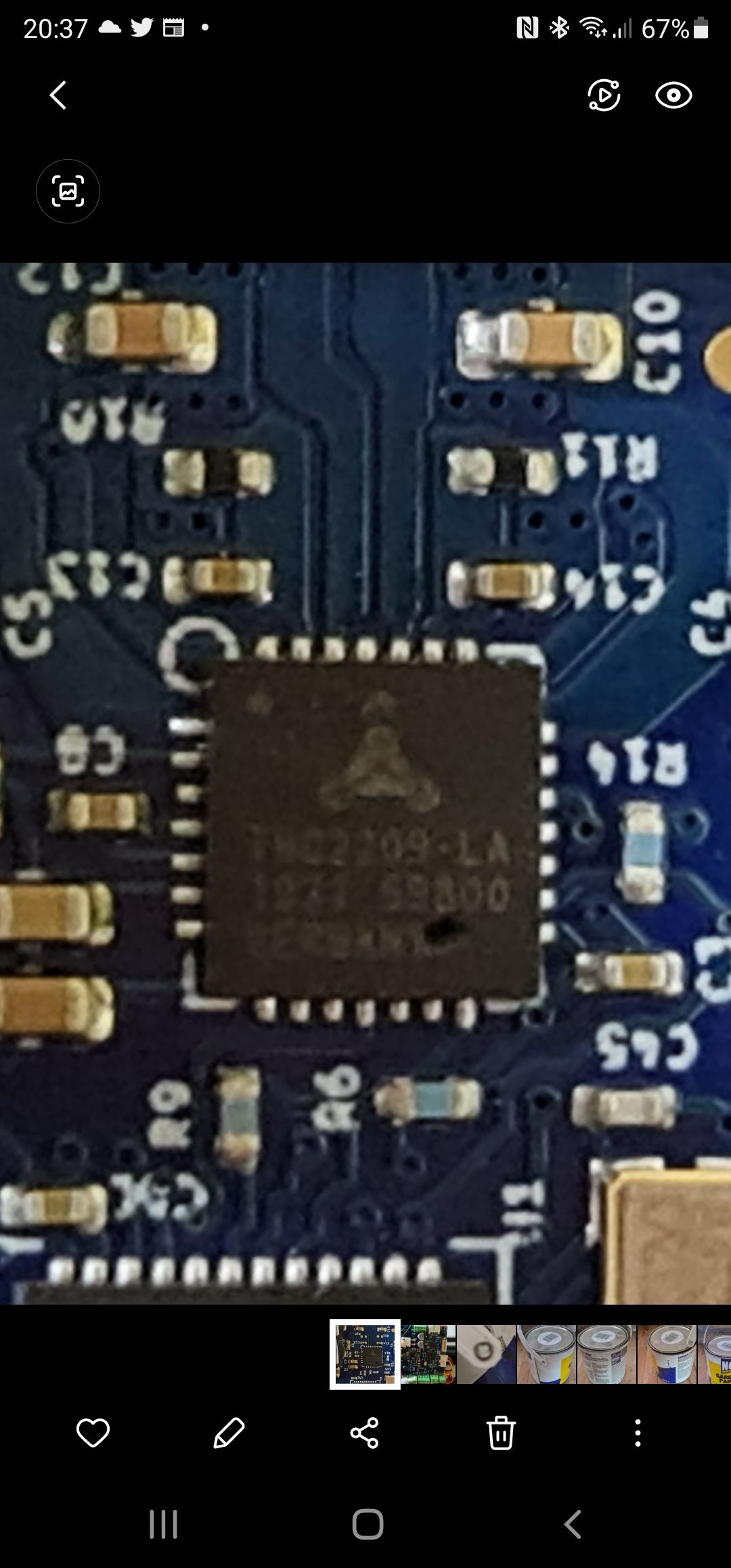

Well found the Issue the driver on the tool board has a hole in it.

-

Ouch. That's a big crater. Any idea what might have gone wrong? Shorts? Anything else damaged?

Otherwise...

Can you provide some more details?

What's your hardware? SBC mode?

Firmware version?

config.g? -

No Connected everything except motor to duet and it works fine. checked motor wiring with meter and all seems ok . Blue led and red led lit solid on tool board but no comms and does nothing if you try to reset the tool board oh and hotend cooling fan come on as expected.

The board had been working perfectly been used for the last two weeks printing upgrades for my printer.

Current Firmware RRF3.2

System setup Pi3 to Duet 3 6hc connected to tool board,

Config.g

; General preferences

G21 ; Work in millimetres

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"Duet 3" ; set printer nameM669 K1 ; select CoreXY mode

M569 P0.0 S0 ; Duet 3 physical drive 0.0 goes backwards (X)

M569 P0.1 S1 ; Duet 3 physical drive 0.1 goes backwards (Y)

;M584 P0.2 S0 ; Empty Header for Extruder Motor.

M569 P0.3 S0 ; Duet 3 physical drive 0.3 goes backwards (Z1 Right Middle Motor)

M569 P0.4 S0 ; Duet 3 physical drive 0.4 goes backwards (Z2 Front left Motor)

M569 P0.5 S0 ; Duet 3 physical drive 0.5 goes backwards (Z3 Back Left Motor)

M569 P20.0 S0

M584 X0.0 Y0.1 Z0.3:0.4:0.5 ; 3 * Z motors connected to 0.3 (Right Middle), 0.4 (Front left), 0.5 (Back Left Motor) Need to keep in this order to match lead screw postions.

M584 E20.0 ; set drive mapping -- tool board

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X160.00 Y160.00 Z1600.00 E839.86 ; set steps per mm M92 Z400 for 1.8º degree steppers and M92 X160 Y160 for 0.9º (calculated extruder 839.86)M671 X205:-205:-205 Y0:-205:205 S20 ; Bed Pivot points Where kinnermatic mounts are located the Actual leadscrews Positions @ Right middle (X245 Y30),Front left (X-245 Y-173), left Rear (X-245 Y-225) (Sxx = tollerance ie 20mm)

M566 X600.00 Y600.00 Z360.00 E600.00 P1 ; set maximum instantaneous speed changes (mm/min)

M203 X6000.00 Y6000.00 Z600.00 E1200.00 ; set maximum speeds (mm/min)

M201 X3000.00 Y3000.00 Z120.00 E120.00 ; set accelerations (mm/s^2)

M906 X900 Y900 Z900 E800 I30 ; set motor currents (mA) and motor idle factor in per cent

;M593 F34.2 <---- look into. ; cancel ringing at 34.2Hz

M84 S30 ; Set idle timeout; Axis Limits

M208 X-195 Y-195 Z0 S1 ; set axis minima

M208 X200 Y200 Z450 S0 ; set axis maxima; Endstops

M574 X1 S3 ; configure sensorless endstop for high end on X

M574 Y1 S3 ; configure sensorless endstop for high end on Y; Z-Probe

M574 Z1 S2 ; Set endstops controlled by probe

M558 P8 C"^20.io0.in" I1 H10 F500 T6000 ; Toolboard P8 Z probe mode for ToolBoard, Prusa PindaV2 sensor config.(F= Bed speed to probe.) (H= distance bed moves during probing) ( S= tollerance) (p= probe type)

M308 S2 P"20.temp1" A"Pinda V2" Y"thermistor" A20 T100000 B3950 ; Toolboard, Prusa PindaV2 temperature config.

G31 P500 X-30 Y15 Z0.235 ; set Z probe trigger value, offset and trigger height

M557 X-180:180 Y-170:170 S42 ; define mesh grid; Bed Heaters

M308 S0 P"temp0" Y"thermistor" T100000 B3950K ; configure sensor 0 as thermistor on pin temp0

M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0

M307 H0 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C; Hotend Heaters

M308 S1 P"20.temp0" Y"PT1000" ; Toolboard configure sensor 0 as a PY1000 thermistor on pin temp0

M950 H1 C"20.out0" T1 ; Toolboard create nozzle heater output on out1 and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S301 ; set temperature limit for heater 1 to 301C; Fans

M950 F0 C"20.out1" ;Toolboard create fan 0 on pin out1 and set its frequency

M106 P0 S0 H-1 Q500 ; set fan 0 value. Thermostatic control is turned off

M950 F1 C"20.out2" Q500 ; Toolboard Partcooling Fan1 on pin out2 and set its frequency

M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on

M950 F2 C"out7" Q500 ; Toolboard Partcooling Fan1 on pin out2 and set its frequency

M106 P1 S1 H1 T25 ; set fan 1 value. Thermostatic control is turned on; Tools

M563 P0 S"HOTEND" D0 H1 F0 ; define tool 0

G10 P0 X-9 Y-13 Z0 ; set tool 0 axis offsets from bed center.

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C;Custom settings are not defined

; Retract

;M207 P0 S1.8 F2400 Z0.3; Miscellaneous

M575 P1 S1 B57600 ; enable support for PanelDue

M501 ; load saved parameters from non-volatile memory

M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss

T0 ; select first tool -

So this was a brand new tool board that had been working otherwise fine?

-

5 weeks old, yep printed quite a few things used about 1/2 a roll of PETG and was just finishing a E3D Hemera mount when it failed.

-

This is the first time I've heard of a TMC2209 failing in a Duet3D product. I authorise a warranty replacement of this tool board. Please contact your supplier.

-

@dc42 Thanks I have contacted ooznest who was the supplier.