@phaedrux

config.g

; Configuration file for Duet 3 (firmware version 3.2RC3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.1.10 on Mon Dec 07 2020 21:49:17 GMT+0000 (Greenwich Mean Time)

; General preferences

G21 ; Work in millimetres

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"Duet 3" ; set printer name

M669 K1 ; select CoreXY mode

G4 S1 ;wait for expansion boards to start

;

; Drives (20.XX) denotes the Can-Bus address that the toolboard LC1 is operating on

;

M671 X-4.5:190:478.5 Y-3.52:435:-3.52 P0.2 S5 ; Define positions of Z leadscrews or bed levelling screws Ratrig Stock

M569 P0.3 S1 ; Duet 3 physical drive 0.0 goes backwards (X)

M569 P0.4 S1 ; Duet 3 physical drive 0.1 goes backwards (Y)

M569 P0.0 S0 ; Duet 3 physical drive 0.0 goes Forwards (Front Left Motor)

M569 P0.1 S0 ; Duet 3 physical drive 0.1 goes Forwards (Middle Back Motor)

M569 P0.2 S0 ; Duet 3 physical drive 0.2 goes Forwards (Front Right Motor)

M569 P20.0 S0

M584 X0.4 Y0.3 Z0.0:0.1:0.2 E20.0 ; 3 * Z motors connected, E20.0 = tool board , Need to keep Z in this order to match lead screw postions.

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X160.00 Y160.00 Z1600.00 E409 ; set steps per mm for Hamera

M566 X400.00 Y400.00 Z6.00 E120.00 P1 ; set maximum instantaneous speed changes (mm/min) ratrig stock

M203 X10800.00 Y10800.00 Z1000.00 E3600.00 ; set maximum speeds (mm/min) ratrig stock

M201 X5000.00 Y5000.00 Z100.00 E3600.00 ; set accelerations (mm/s^2) ratrig stock

M906 X1400 Y1400 Z1400 E1000 I30 ; set motor currents (mA) and motor idle factor in per cent

;M593 F34.2 <---- look into. ; cancel ringing at 34.2Hz

M84 S30 ; Set idle timeout

; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X400 Y380 Z400 S0 ; set axis maxima

; Endstops

M574 X1 S3 ; configure sensorless endstop for high end on X

M574 Y1 S3 ; configure sensorless endstop for high end on Y

M574 Z1 S2 ; Set endstops controlled by probe

; Z-Probe

M950 S0 C"20.io0.out" ; create servo pin 0 for BLTouch

M558 P9 C"^20.io0.in" H5 F100 R0.2 T6000 A5 B1 ; set Z probe type to bltouch and the dive height + speeds

G31 P25 X32.5 Y-42 Z5.492 ; set Z probe trigger value, offset and trigger height

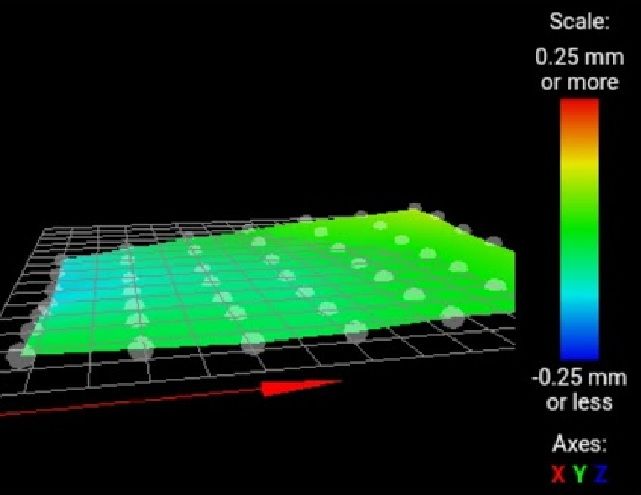

M557 X35:400 Y30:320 P7 ; define 5x5 mesh grid

; Bed Heaters

M308 S0 P"temp0" Y"thermistor" T100000 B3950K ; configure sensor 0 as thermistor on pin temp0

M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0

M307 H0 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

; Hotend Heaters

M308 S1 P"20.temp0" Y"thermistor" T100000 B4725 C7.06e-8 ; Toolboard configure sensor 0 as a E3D thermistor on pin temp0

M950 H1 C"20.out0" T1 ; Toolboard create nozzle heater output on out1 and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S301 ; set temperature limit for heater 1 to 301C

; Fans

M950 F0 C"20.out1" ;Toolboard create fan 0 (Hotend cooling) on pin out1 and set its frequency

M106 P0 S0 H1 T10 Q500 L255 ; set fan 0 value. Thermostatic control is turned off

M950 F1 C"20.out2" Q500 L255 ; Toolboard (Partcooling) Fan1 on pin out2 and set its frequency

M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on

; Fan for cooling duet

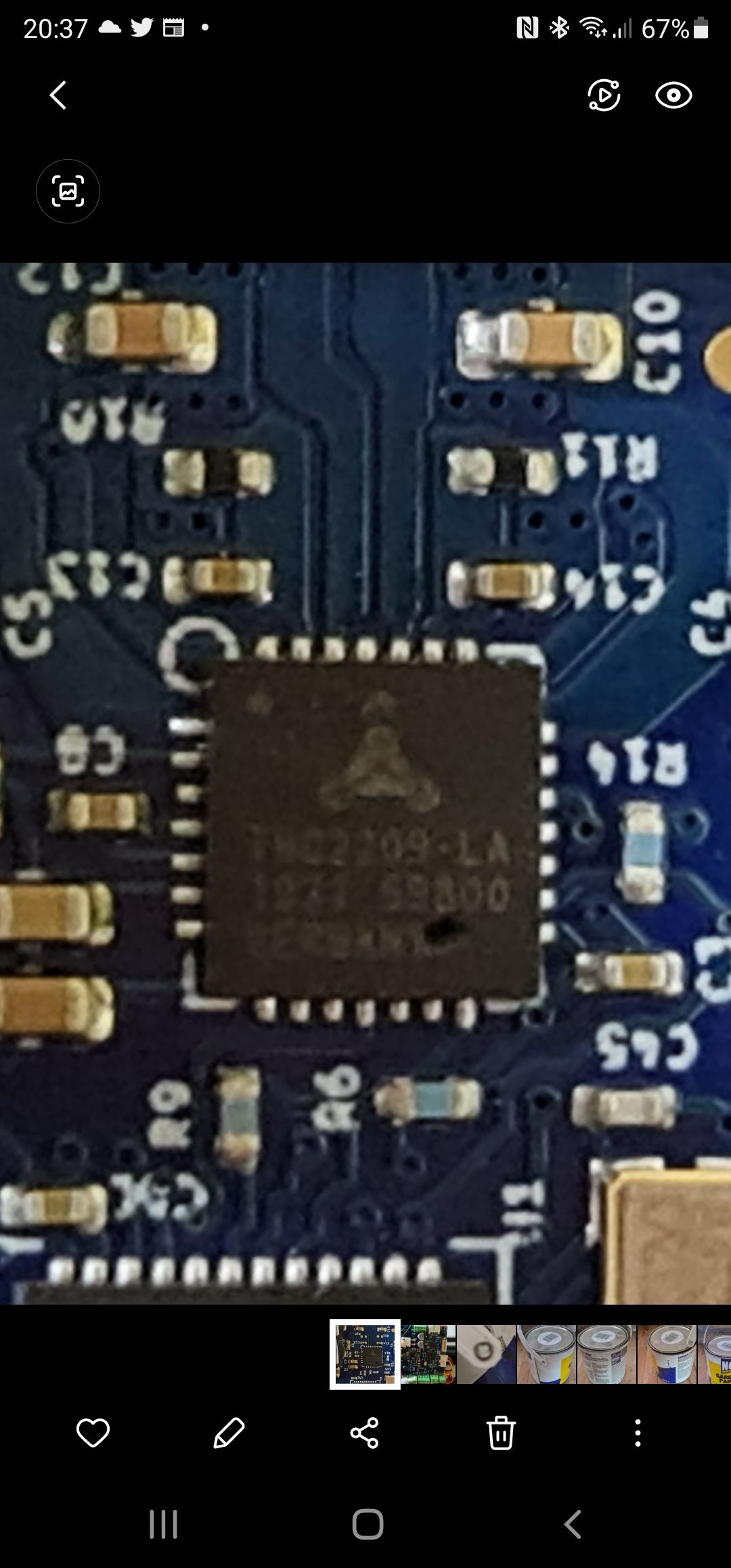

M308 S2 Y"drivers" A"DRIVERS" ; configure sensor 2 as temperature warning and overheat flags on the TMC2660 on Duet

M308 S3 Y"mcu-temp" A"MCU" ; configure sensor 3 as thermistor on pin e1temp for left stepper

M950 F2 C"out7" Q100 ; create fan 2 on pin fan2 and set its frequency

M106 P2 H2:3 L0.15 X1 B0.3 T40:70 ; set fan 2 value

; Tools

M563 P0 D0 H1 F0 S"HOTEND" ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets from bed center.

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C

;Custom settings are not defined

; Linear Advance

M572 D0 S0.03

; Retract

M207 P0 S1.8 F2400 Z0.3 ; default Hemera retract settings

; Miscellaneous

M575 P1 S1 B57600 ; enable support for PanelDue

M501 ; load saved parameters from non-volatile memory

M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss

T0 ; select first tool

bed.g

; this script compensates for what the Z offset is

; so if G31 P500 X-30 Y-15 Z1.7 then first probe will be at

; X30 Y20 (when G30 P0 X0 Y5)

M561 ; clear any bed transform

G28

G30 P0 X35 Y5 Z-99999 ; probe near front left leadscrew

G30 P1 X200 Y335 Z-99999 ; probe near Rear leadscrew

G30 P2 X400 Y5 Z-99999 S3 ; probe near Right leadscrew and calibrate 3 motors

G30 P0 X35 Y5 Z-99999 ; probe near ;front left leadscrew

G30 P1 X200 Y335 Z-99999 ; probe near ;Rear leadscrew

G30 P2 X400 Y5 Z-99999 S3 ; probe near ;Right leadscrew and calibrate 3 motors

G29 ; probe the bed and enable compensation

G1 X200 Y200