Question about significance of height map.

-

@Phaedrux said in Question about significance of height map.:

@fcwilt said in Question about significance of height map.:

The normal multi-point height map will be done once I have the bed as level as I can get it.

I'd probably do a detailed one now just to get a higher resolution picture of how the bed is fading off at the back left. Is it a sharp dip? Is it fairly steady? Might tell you if it's a bed defect or if it's more likely the rail. After that the only way to be sure is some slight adjustment and recheck.

Dinner got in the way of doing more work on the problem.

The bed is a brand new, just arrived piece of 6mm cast aluminum plate, flat within .015, according to the vendor.

So I'm hoping that some adjustment of the rail(s) can yield an improvement because I don't know where to get a flatter piece of metal.

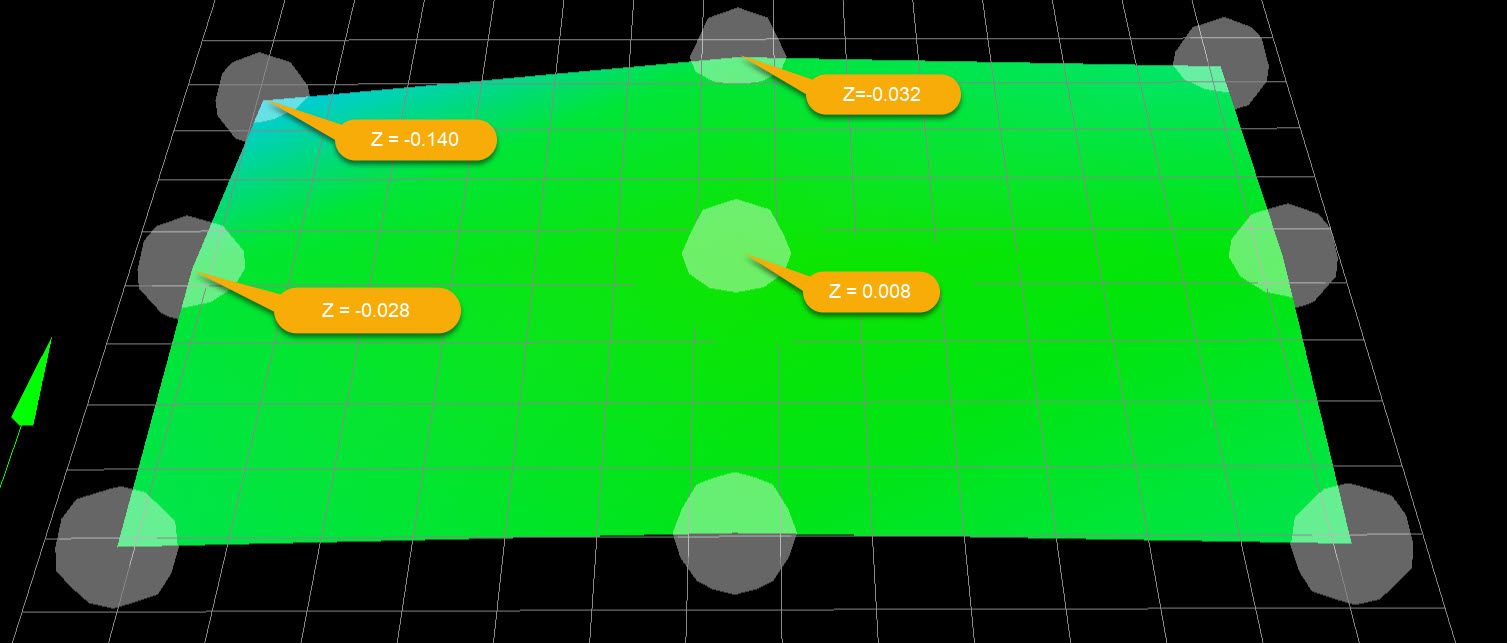

Attached is a 9 point height map to show the center point which is probed to set the Z=0 datum.

Frederick

-

@fcwilt Considering the height map shows front left, front right & rear right pretty much level I wouldn't imagine this to be a result of the rear left adjustment. Winding the rear left to compensate would drop the front right. You mentioned the 3 adjustment points are near perfect, everything outside of those areas can't be adjusted without adversely effecting somewhere else. So if you are showing a dip in the rear left corner without a countering rise in the front right I would say there is a dip. One thing I have noticed is the height map seems a little exaggerated. This might be a minor dip in reality.

My bad, I should have been clearer when I said checked it manually. I mean with a paper test or dial indicator if you have one.

-

@fcwilt Is this last map done at printing temp?

-

@fcwilt said in Question about significance of height map.:

The bed is a brand new, just arrived piece of 6mm cast aluminum plate, flat within .015, according to the vendor.

So I'm hoping that some adjustment of the rail(s) can yield an improvement because I don't know where to get a flatter piece of metal.Imagine my disappointment when my plate arrived with a slight dip in the corner. The detailed heightmap shows it clearly. Rather than try and bend it I just live with mesh compensation.

-

@Hytek said in Question about significance of height map.:

@fcwilt Considering the height map shows front left, front right & rear right pretty much level I wouldn't imagine this to be a result of the rear left adjustment.

The adjustment screws are in the left-front, center-rear and right-front. So I could raise the left-rear but naturally that will drop the right-front.

Which is why I wondered if the left Y rail could be responsible for this condition.

Thanks.

Frederick

-

@Phaedrux said in Question about significance of height map.:

Imagine my disappointment when my plate arrived with a slight dip in the corner. The detailed heightmap shows it clearly. Rather than try and bend it I just live with mesh compensation.

Really? That's disappointing.

Is there a source of truly flat plate? Or is it the kind of thing that gets damaged in shipment?

I have not be able to find a machinist in my rural area with the equipment to grind a plate flat.

Thanks.

Frederick

-

@Hytek said in Question about significance of height map.:

@fcwilt Is this last map done at printing temp?

No. I'm simply trying to get this newly installed bed as level as possible.

Once that is done I will start in on creating the multi-point height maps at printing temps.

Thanks.

Frederick

-

@fcwilt said in Question about significance of height map.:

Is there a source of truly flat plate? Or is it the kind of thing that gets damaged in shipment?

In my case I could have paid extra for a flatness report and guarantee. In retrospect I should have done that. I think for the smaller sizes of plate the flatness is harder to guarantee.

Shipping damage is totally possible too. I only found out about it after I had bonded it to the heater and PEI sheet, so I didn't bother trying to straighten it myself.

-

If you have a nearby machine shop maybe they'll let you play with their surface plate to verify flatness (but if its anything like here they'll charge an arm and a leg just to talk to you).

budget solution might be get some Prussian blue and rub it on the back of the thickest mirror you can find, then rub the mirror on the alu plate. next try rubbing the plate on the mirror and see which is likely giving you less deflection of the mirror that is supposedly flat?

non-budget solution, buy a 50kg granite surface plate and watch the mail man trying to deliver it to your mailbox..

yet another option is to get three supposedly flat plates and lap them on each other, eventually cancelling out all unevenness ending up with three truly flat plates?

-

@bearer said in Question about significance of height map.:

non-budget solution, buy a 50kg granite surface plate and watch the mail man trying to deliver it to your mailbox..

Thank you for those ideas.

I think the granite surface plate is my favorite.

Frederick

-

@fcwilt said in Question about significance of height map.:

I think the granite surface plate is my favorite.

i had a blast with mine, tl;dr after 2 weeks of sitting at the local depot it was returned to the UK via Oslo, then flown back to Oslo, put on a flatbed truck with a crane and driven 500km and delivered to my door after 3 weeks for a 2-3 days express delivery because health and safety here say people can't lift more than 25kg without using a crane.

(expression of mailman when he asked "what is it" and I replied "a granite "rock". a very flat rock mind you" = worth the wait)

top tip, get one with some sort of leveling system, as drilling holes to attach adjustable feet is a "¤#"#¤&%" pain.

-

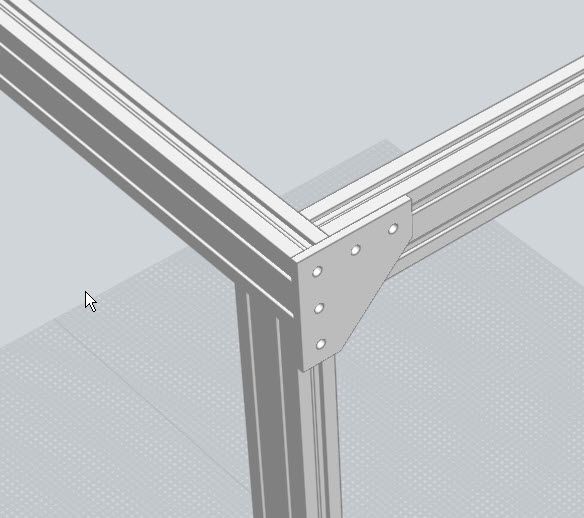

@fcwilt it could well be the rails. From your CAD, it seems they are bolted straight to the extrusion? Do they bolt to T-Nuts or have you drilled them?

I've found it hard to get the two y-extrusions perfectly parallel. On top of that, they usually aren't very flat, and if you have drilled them, they will have likely deformed slightly. This can then bend the rail itself a little (though your rails look pretty hench so maybe not?) -

I'm not so sure you've got a real problem with that plate. I think you just need to use more test points when you run the manual bed leveling assistant. The assistant will then average the error over the entire surface and give you the best leveling adjustment. I use 9 points on the bed surface with the assistant and it works great.

Do you have any idea how hard it is to bend a 6 mm thick piece of aluminum? You can forget about damage in shipping, unless they drove a truck over it, which you'd see by the tire tracks on the box.

-

@bearer said in Question about significance of height map.:

(expression of mailman when he asked "what is it" and I replied "a granite "rock". a very flat rock mind you" = worth the wait)

-

@engikeneer said in Question about significance of height map.:

@fcwilt it could well be the rails. From your CAD, it seems they are bolted straight to the extrusion? Do they bolt to T-Nuts or have you drilled them?

The rails are bolted to the extrusion at every other hole using this type of fastener:

I've found it hard to get the two y-extrusions perfectly parallel. On top of that, they usually aren't very flat

The extrusions are 40x20. They are bolted to the rest of the frame using those corner plates.

Shifting the rear end up slightly would be possible but it would be mostly trial and error.

I was not able to think of any way to insure the two Y rails are parallel using the tools I have on hand.

Now if I had access to that granite plate...

Thanks.

Frederick

-

Hi,

Thanks. I am going to run the assistant again using more points.

And good to know the plate is likely as flat as it was when it left the vendor.

Frederick

-

can you rotate the plate 90,

190180 or 270 degrees?(or even clamp a piece of mirror to it, non reflective side up, if the sensor in use would trigger off it?)

-

Hi,

Well it turns out it was an issue with the left Y rail not being parallel to the right Y rail.

I had to way to compare them directly but I was able to mount a dial indicator measuring the height of the very end of the left rail relative to the top of the rear horizontal extrusion.

Adjusting the rail height was still trial and error (adjust, level, create height map, analyze, repeat) but at least I was able to adjust the rail in known amounts.

It turned out that a 0.001 inch adjustment made a significant difference.

The total adjustment I made is unknown because the idea of using the dial indicator came AFTER I had made the first adjustment where I tried to match the alignment of the tops of the left and right extrusions to the horizontal extrusion.

My bad.

In any case the "droop" in the left rear corner is gone. The bed is not perfect but the four corners are within 0.02 mm which is the best I have ever achieved.

And I am going to settle for that for fear of screwing something up by striving for "perfection".

Thanks to all for the help.

Frederick

-

@Phaedrux

Where did you order your plate from?I've often considered getting a metal bed plate with magnets built in to replace.the glass.bed + buildtak magnet sticker for my 310mm circle plate but I haven't found anywhere willing to make it and certify flatness.

-

@Baenwort said in Question about significance of height map.:

@Phaedrux

Where did you order your plate from?This is what I purchased:

https://www.midweststeelsupply.com/store/castaluminumplateatp5

Frederick