How reliable is the IR bed sensor Vs BLTouch?

-

I use 3dLac on my glass because I can lay down the first layer at the same speed I print at (generally 60 - 90mm/sec) and because when the glass cools, parts just fall off (but sometimes need a tap). But that plays havoc with DC's IR probe so I'd imagine that hair spray would have a similar effect.

-

@deckingman is there indication that 3DLac is anything other than branded hairspray?

Edit: Genuine enquiry, not trying to be provocative.

-

@doctrucker said in How reliable is the IR bed sensor Vs BLTouch?:

@deckingman is there indication that 3DLac is anything other than branded hairspray?

Edit: Genuine enquiry, not trying to be provocative.

Only the sales blurb Quote " The Original and Unique spray adhesive created to use with 3D printers". That and the fact that it's fragrance free. But it could be hair spray without fragrance - who knows?

TBH, I've never done a back to back comparison because my wife doesn't use hair spray (and I don't have enough hair to warrant it either

) .

) .If hair spray works for you and you can get it cheaper than 3D Lac, then stick with it (pun intended

).

). -

Due to the stupid restrictions of not being able to send aerosols via Air (I live on the island of cyprus so everything is normally flown in) I can't buy 3dlac...

So I use printafix (basically hairspray in a pump bottle) and it doesn't appear to mess with the IR Sensor.

-

Odds are its polyvinylpyrrolidone (PVP) which is the main ingredient in most hairsprays, but its probably also lacking some of the hair specific stuff like fragrance.

I'd love to do a test, but also suffer from shipping restrictions, and while I'm a huge fan of empirical data I don't think getting married for science is something I'm likely to do, but lets find out...:D

-

@calvinx said in How reliable is the IR bed sensor Vs BLTouch?:

Due to the stupid restrictions of not being able to send aerosols via Air (I live on the island of cyprus so everything is normally flown in) I can't buy 3dlac...

So I use printafix (basically hairspray in a pump bottle) and it doesn't appear to mess with the IR Sensor.

Fair enough. For info, you can get 3D lac in 100mm pump action sprays but it's s**t expensive. A 400mm pressurised spray is about £10 if you shop around but a 100mm pump action is about £7.00, so nearly 3 times the price per unit volume.

Edit - Strewth! I just checked the price for "PrintaFix here in the UK and it's £12 to £15 for 100mm and £55 for 500ml. So it might be worth seeing if you can get 3DLac in 100ml pump action shipped to Cyprus. On the other hand, it does play havoc with the IR sensor so maybe not.

-

On the Ultimaker 2+ at my old work, I used a sugar solution for bed adhesion: https://hackaday.com/2019/01/05/sugar-as-a-bed-adhesive-for-3d-printing/

It's a bit of a hassle to put on (need to do 3 layers, let it dry out in between, but doesn't take long if bed is heated), but sticks PLA and ABS beautifully (didn't try PETG), and can do a number of prints before having to be redone. Cheap too! You can mix up a larger amount and put it in a spray bottle too. Don't know how it would work with IR probe though, assume similar to hairspray. If I ever get my Cartesian printer back up and running with IR probe, I'll try it out.Ian

-

I suggest not using the IR probe if you use any sort of coating on the glass. It works fine on uncoated glass (except mirror) if there is a uniform matt surface underneath - preferably matt black. And most brands of PLA print well on uncoated glass, if you prepare the glass correctly before you fir it to the bed plate.

-

that's strange, we are running IR sensors on crealities coated glass sheets with no problems.

-

I bought one of the IR sensors, but have not yet installed it. I'm currently using piezo sensors for a Z probe, but am having some consistency problems with it occasionally. My hope is that a contactless sensor will be better.

My build platform is aluminum with a sheet of glass, usually hairsprayed. I have been considering the BBQ paint for the aluminum surface, but I'm starting to wonder if the glass is necessary if I'm not bashing the nozzle into the aluminum all the time. I was thinking of trying a piece of sheet steel instead.

-

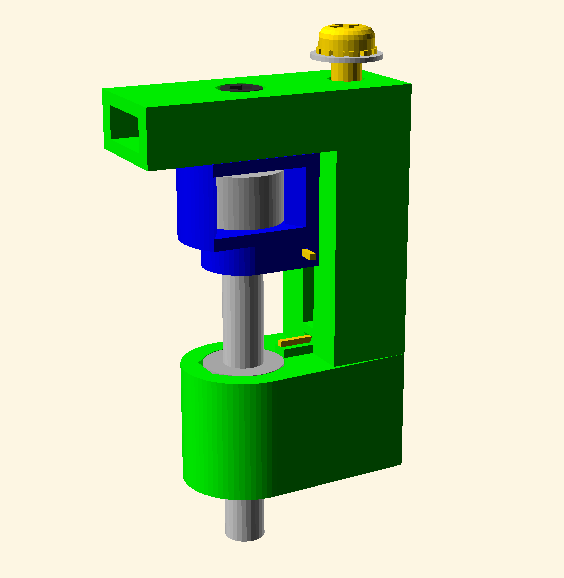

This is what I use on one of my machines.

It is a 4mm rod that runs in an LM4UU bearing and is held above the nozzle by a magnet. When I remove a print I manually deploy it by pulling it down away from the magnet. It then closes two gold contacts together and hangs below the nozzle.

When I start the next build my host software checks the contacts are closed and prompts me if I have forgotten to deploy it. It then probes the bed using successive approximation to find the z microstep where the contacts just open.

When it has finished probing it lowers Z axis until the probe is attracted to the magnet, which lifts it clear of the nozzle.

Is it too simple?

-

@deckingman said in How reliable is the IR bed sensor Vs BLTouch?:

... I don't have enough hair to warrant it either

There are all kind of hair sprays. https://youtu.be/2GeF7A05zQ8?t=16

-

@calvinx said in How reliable is the IR bed sensor Vs BLTouch?:

that's strange, we are running IR sensors on crealities coated glass sheets with no problems.

thats because they are coated with a black surface that is opaque and not reflective or transparent.