Delta running a duet maestro wants to sound like a train?

-

Really perplexed here. After a disturbing amount of upgrades to a stock AnyCubic Predator and thinking my hotend was rubbing against previous layers of filament producing weird sounds I decided to run it with no filament.

It turns out it was not the hotend scraping against filament but the printer itself having issues at that speed. What doesn't make sense is that the speed does not seem all that high for the upgrades that have been done.

-E3D smart effector

-Haydn magball arms 450mm (stock arms were 440mm)

-0.9 E3D stepper motors rated at 1.4AI decided to take a video slowly increasing speed here https://photos.app.goo.gl/KbKvoyWWHPPTZX4p7

@Upto 20 seconds 100% x 1800 = 1800 mm/min, Sounds fine

@20 seconds 150% x 1800 = 2700, One click sound

@40 seconds 170% x 1800 = 3060, increased clicking

@120 seconds 200% x1800=3600, even worse

This was with the following jerk, accel and speed

M201 X1100.00 Y1100.00 Z1100.00 E1100.00 ;

M203 X9000.00 Y9000.00 Z9000.00 E4800.00 ;

M566 X600 Y600 Z600 E1200.00 ;I have tried a drastically lower acceleration, jerk and speed combination

M201 X500 Y500 Z500 E60 ;

M203 X9000.00 Y9000.00 Z9000.00 E4800.00 ;

M566 X300 Y300 Z300 E60

and 1100mA

Full config here: https://pastebin.com/Hbw07rSDI have tried at different currents

800mA

1300mA

1000mA

1100mAI've tightened belts equally by measuring the deflection from the extrusion using a constant mass at the same point on the belt for each tower. I have tried with extremely loose belts to extremely tight in the past but that was prior to have a good way of getting all the belts equally tensioned. Maybe it is a matter of having the belts too far on the tight side or too far on the loose side.

This is my first delta I admit so I could be doing something very simple wrong but after going through all the usual suspects that I would have for a cartesian printer I am at a complete loss.

-

I'm not absolutely sure what that is... but it is EXACTLY in sync with X,Y position. The very first click occurs just as the tip crosses the white line extending left (and slightly up in the perspective of the video) on the base. Once it is at full speed and there are many clicks, some of them sounding different than others, each unique click repeats as the effector crosses the exact same X,Y point around the circumference of the circle.

So, yeah, it is speed related, but it is not purely speed. There is something positional, perhaps "per tower", perhaps not, that the speed is exposing.

So... you said loose or tight it does this. So probably not a binding bearing or shaft. Hmmm...

Debugging data gathering: Does a smaller/larger circle, run at the speed where it only clicks once, click at the same "line" as it goes around the circle? Or not? In other words, is it X,Y dependent on the repetitive cycle, or tower/belt/motor/idler dependent (i.e. it still repeats, but at a different X,Y)???

Keep posting vids. Perhaps move the mic on your phone near each tower at a given speed, to see if we can isolate the clicks.

-

Yep, the current cylinder is 50mm will run one at 100mm and 25mm when I get home. Also thinking of running it at 256 microsteps without interpolation and possibly reflashing firmware. Thanks for the thoughts.

-

@dc42 @T3P3Tony @deckingman just wanted to drop this on your radar really eager to start printing with my Duet have had this printer since March (pretty embarrassing) this seems like the last hurdle to figure out!

-

Could you do diagonal moves so only 1 stepper moves (by a large amount)?

Last time I heared a sound like this, there was a bad bearing in a car and the spring jumped on steering....

I think it's probably not a motor or idler bearing because the frequency would be higher (multiple full rotations).

Do you use linear rails by any chance? I cannot make it out on the video...

To eliminate a few things ... what happens if you detach the head and and extruder so run the same program again with just the pulleys running?

-

Good call I will try that out. Wheels are used on the towers no linear rails here. Will test that out when I get home and post it up!

-

You could also try individual tower moves (G1 S2 moves) to see whether the noise is related to just one tower.

-

@dc42 Would you recommend running that with the end effector and everything in place?

G1 S2 X-100

G1 S2 Y-100

G1 S2 Z-100No F parameter used for the following correct? Probably makes sense to home and use the full height of the axis instead of 100?

-

After some additional sad tests I think I may have found the culprit...stealthchop mode. If I switch to mode 2 (spreadcycle) I can boost all the way to 5000mm/min without any weird sounds. Not quite sure why that is but hey now I can sleep not feeling completely defeated!

https://photos.app.goo.gl/yFVgQ6X5qB8rPhpx7Just for a complete picture I removed the Haydn rods and allowed the end effector to dangle with a 50mm print going. This video shows an increase from 1800 to 3600 and how the sound gets worse. https://photos.app.goo.gl/pCZNfyn7aQSvHeXK8

-

Ran in spreadcycle last night and had a print complete. Unfortunately still had layer shifts. Rerunning it now without filament to see if I hear sounds.

-

do all carriages move up and down without the slightest bit of resistance?

what are the motors you are using for a,b,c?

the switchover from stealthchop2 to spreadcycle at higher speeds produces noticeable noise and has a high potential for layer shifts.

-

@singhm29 said in Delta running a duet maestro wants to sound like a train?:

@dc42 Would you recommend running that with the end effector and everything in place?

G1 S2 X-100

G1 S2 Y-100

G1 S2 Z-100No F parameter used for the following correct?

You can use an F parameter to set the speed, otherwise it will use the default.

Probably makes sense to home and use the full height of the axis instead of 100?

No, if you move individual carriages the full height of the axis, you might damage your printer. On my delta you can't have one carriage at the top and another at the bottom without the rods detaching and the effector likely to crash into a tower.

-

@singhm29 said in Delta running a duet maestro wants to sound like a train?:

Ran in spreadcycle last night and had a print complete. Unfortunately still had layer shifts. Rerunning it now without filament to see if I hear sounds.

Which firmware version are you running?

-

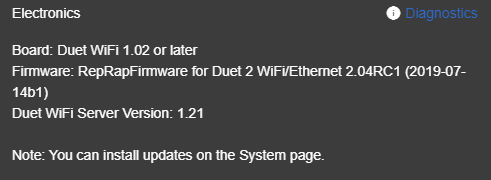

READ: FIRMWARE_NAME: RepRapFirmware for Duet 2 Maestro FIRMWARE_VERSION: 2.02RC5(RTOS) ELECTRONICS: Duet Maestro 1.0 FIRMWARE_DATE: 2018-11-28b1

-

I also reluctantly pulled a Duet Ethernet from another printer to see how that would do. No problems with movement as shown in that video so can rule out this being a hardware issue.

-

@singhm29 said in Delta running a duet maestro wants to sound like a train?:

FIRMWARE_VERSION: 2.02RC5

Probably a good idea to update to 2.04RC1

https://github.com/dc42/RepRapFirmware/releases

https://github.com/dc42/RepRapFirmware/blob/dev/WHATS_NEW.md -

@phaedrux said in Delta running a duet maestro wants to sound like a train?:

@singhm29 said in Delta running a duet maestro wants to sound like a train?:

FIRMWARE_VERSION: 2.02RC5

Probably a good idea to update to 2.04RC1

https://github.com/dc42/RepRapFirmware/releases

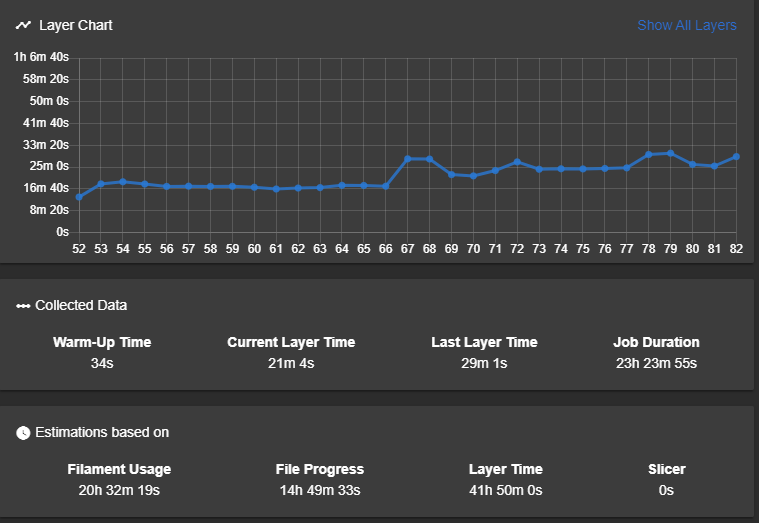

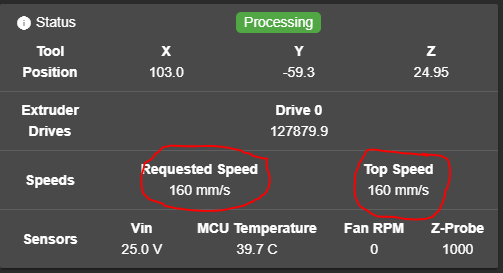

https://github.com/dc42/RepRapFirmware/blob/dev/WHATS_NEW.mdYeah, I'd recommend that as well. Currently running on my large-ish delta:

Which is 23.5 hours into a job, somewhere between 15 to 20 to go... and printing flawlessly and quietly.

I have not tried to push or tune up speeds yet... and this is an experimental print in that it was sliced in Slic3r Prusa Edition.

Anyway, the point being that I highly recommend 2.04RC1 on a Delta.