@Phaedrux

Not a problem

M122

M122

=== Diagnostics ===

RepRapFirmware for Duet 3 MB6HC version 3.2 running on Duet 3 MB6HC v0.6 or 1.0 (standalone mode)

Board ID: 08DJM-956L2-G43S4-6JKDD-3SJ6T-TB6GH

Used output buffers: 1 of 40 (36 max)

=== RTOS ===

Static ram: 149788

Dynamic ram: 93192 of which 132 recycled

Never used RAM 115720, free system stack 122 words

Tasks: NETWORK(ready,171) ETHERNET(blocked,109) HEAT(blocked,271) CanReceiv(blocked,927) CanSender(blocked,350) CanClock(blocked,349) TMC(blocked,19) MAIN(running,671) IDLE(ready,19)

Owned mutexes:

=== Platform ===

Last reset 84:30:27 ago, cause: software

Last software reset at 2021-03-19 23:20, reason: User, GCodes spinning, available RAM 115720, slot 0

Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x00400000 BFAR 0x00000000 SP 0x00000000 Task MAIN Freestk 0 n/a

Error status: 0x00

Aux0 errors 0,0,0

Aux1 errors 0,0,0

MCU temperature: min 39.6, current 40.5, max 44.5

Supply voltage: min 22.9, current 23.9, max 24.6, under voltage events: 0, over voltage events: 0, power good: yes

12V rail voltage: min 12.1, current 12.2, max 12.3, under voltage events: 0

Driver 0: position 30073, standstill, reads 53715, writes 130 timeouts 0, SG min/max 0/915

Driver 1: position 35556, standstill, reads 53715, writes 130 timeouts 0, SG min/max 0/125

Driver 2: position 365607, standstill, reads 53705, writes 140 timeouts 0, SG min/max 0/1023

Driver 3: position 0, standstill, reads 53796, writes 50 timeouts 0, SG min/max 0/198

Driver 4: position 0, standstill, reads 53706, writes 140 timeouts 0, SG min/max 0/1023

Driver 5: position 0, standstill, reads 53835, writes 11 timeouts 0, SG min/max 0/0

Date/time: 2021-03-23 11:50:47

Slowest loop: 69.48ms; fastest: 0.03ms

=== Storage ===

Free file entries: 10

SD card 0 detected, interface speed: 25.0MBytes/sec

SD card longest read time 3.3ms, write time 22.6ms, max retries 0

=== Move ===

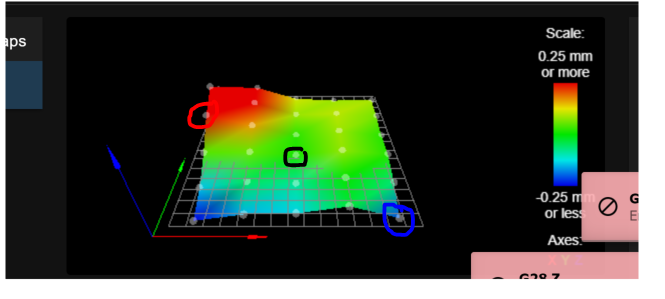

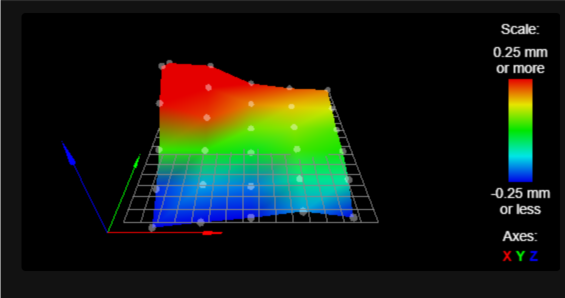

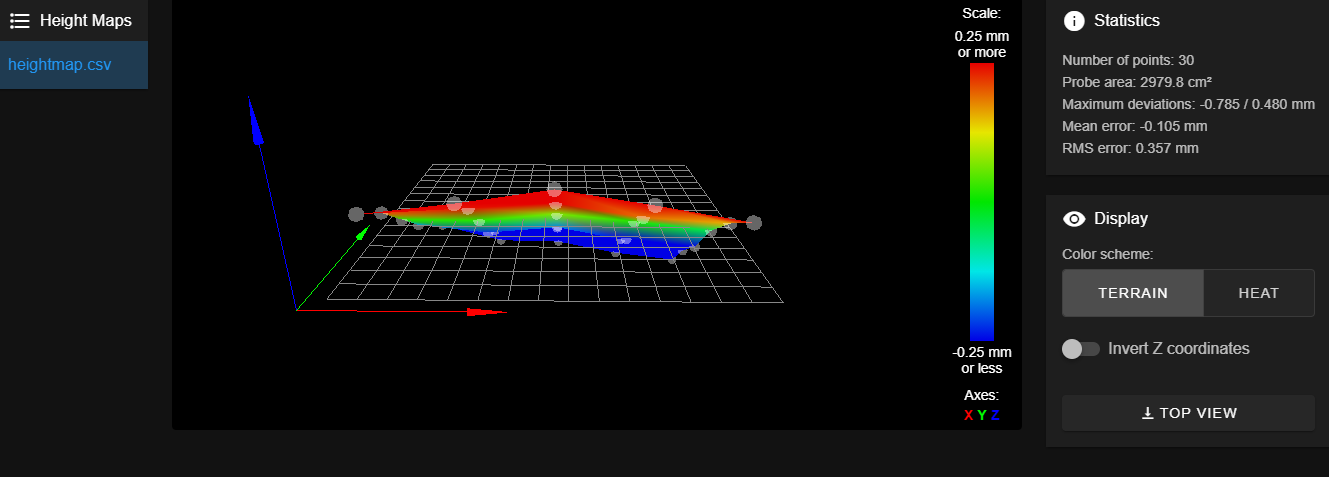

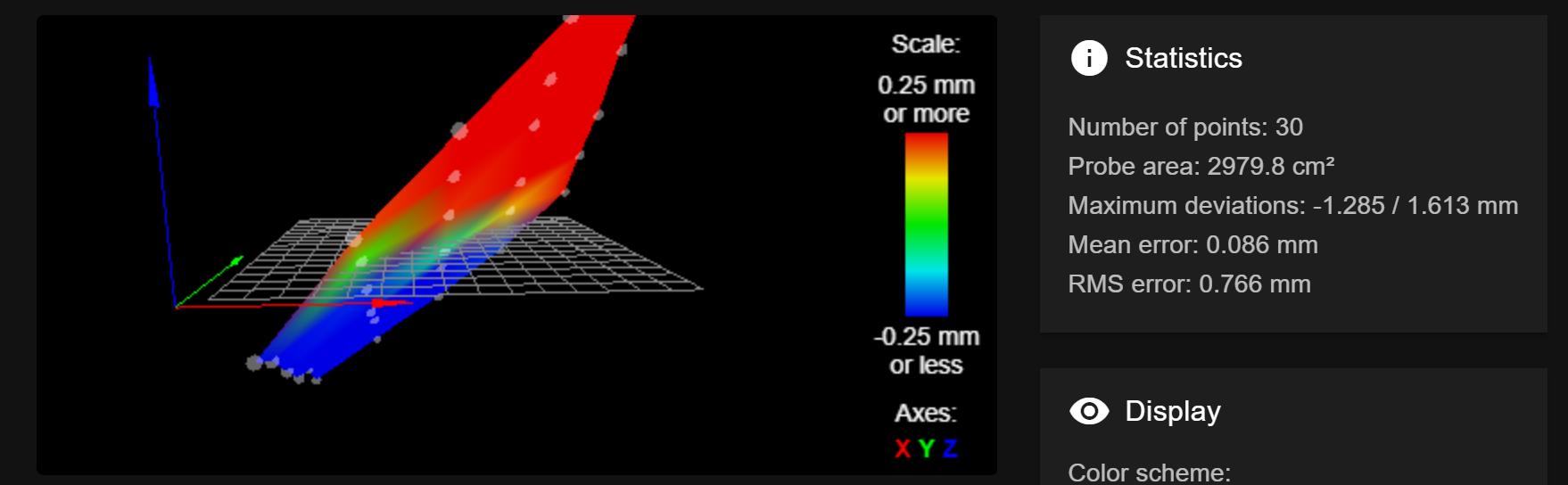

DMs created 125, maxWait 416792ms, bed compensation in use: mesh, comp offset 0.000

=== MainDDARing ===

Scheduled moves 3200, completed moves 3200, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 33], CDDA state -1

=== AuxDDARing ===

Scheduled moves 0, completed moves 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1

=== Heat ===

Bed heaters = 0 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1, chamberHeaters = -1 -1 -1 -1

Heater 0 is on, I-accum = 0.0

Heater 1 is on, I-accum = 0.6

=== GCodes ===

Segments left: 0

Movement lock held by null

HTTP is idle in state(s) 0

Telnet is idle in state(s) 0

File is idle in state(s) 0

USB is idle in state(s) 0

Aux is idle in state(s) 0

Trigger is idle in state(s) 0

Queue is idle in state(s) 0

LCD is idle in state(s) 0

SBC is idle in state(s) 0

Daemon is idle in state(s) 0

Aux2 is idle in state(s) 0

Autopause is idle in state(s) 0

Code queue is empty.

=== Network ===

Slowest loop: 67.65ms; fastest: 0.02ms

Responder states: HTTP(0) HTTP(0) HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0), 0 sessions Telnet(0), 0 sessions

HTTP sessions: 1 of 8

- Ethernet -

State: active

Error counts: 0 0 1 0 0

Socket states: 5 2 2 2 2 0 0 0

=== CAN ===

Messages queued 1217061, send timeouts 2738195, received 0, lost 0, longest wait 0ms for reply type 0, free buffers 48

M98 P"config.g"

M98 P"config.g"

HTTP is enabled on port 80

FTP is disabled

TELNET is disabled```

Config

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.2.0 on Wed Jan 06 2021 20:53:06 GMT-0500 (Eastern Standard Time)

; General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"Gigabot" ; set printer name

; Network

M552 P0.0.0.0 S1 ; enable network and acquire dynamic address via DHCP

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet

; Drives

M569 P0.0 S1 ; physical drive 0.0 goes forwards

M569 P0.1 S0 ; physical drive 0.1 goes backwards

M569 P0.2 S1 ; physical drive 0.2 goes forwards

M569 P0.3 S1 ; physical drive 0.3 goes forwards

M569 P0.4 S1 ; physical drive 0.4 goes forwards

M584 X0.0 Y0.1 Z0.2:0.4 E0.3 ; set drive mapping

M671 X-109:707 Y300:300 S2.5 ; leadscrews at left (connected to Z) and right (connected to E1) of X CHANGE AFTER FIGURE OUT POSITION OF BL ON MOUNT/limits

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X59.26 Y59.26 Z2015.50 E393.46 ; set steps per mm

;M566 X900.00 Y900.00 Z60.00 E120 ; set maximum instantaneous speed changes (mm/min) WAS 120

;M203 X6000.00 Y6000.00 Z180.00 E7000.00 ; set maximum speeds (mm/min)

;M201 X500.00 Y500.00 Z20.00 E3500 ; set accelerations (mm/s^2)

M566 X600.00 Y600.00 Z12.00 E120.00 ; Set maximum instantaneous speed changes (mm/min)

M203 X18000.00 Y18000.00 Z180.00 E15000.00 ; Set maximum speeds (mm/min) this allows 585 mm3 max flow rate

M201 X3000.00 Y3000.00 Z20.00 E10000.00 ; Set accelerations (mm/s^2)

M906 X950 Y1900 Z950:950 E950 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout

; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X607 Y603 Z578.5 S0 ; set axis maxima

M208 X0:607 Y0:603 ; max movement allowed

; Endstops

M574 X1 S1 P"!io0.in" ; configure active-high endstop for low end on X via pin !io0.in

M574 Y2 S1 P"!io1.in" ; configure active-high endstop for high end on Y via pin !io1.in

; Z-Probe

M950 S0 C"io7.out" ; create servo pin 0 for BLTouch

M558 P9 C"^io7.in" H5 F120 T6000 ; set Z probe type to bltouch and the dive height + speeds ORIGINAL

;M558 P9 C"^io7.in" H3 F60 T6000 A3 R0.75 S-1 ; will probe each spot 3x then average it out

G31 P25 X-5 Y48 Z2.5 ; G31 P25 X-5 Y48 Z2.09 PRIOR TO MARCH 19set Z probe trigger value, offset and trigger height

;M557 X5:600 Y47:603 S40 ; define mesh grid

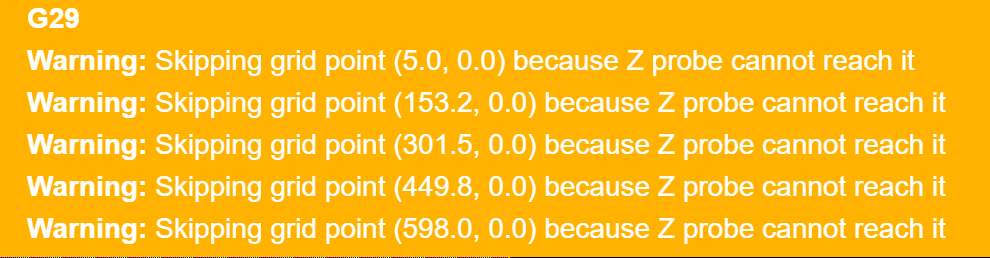

M557 X5:598 Y0:603 P5:7

; Heaters

;Bed heater config

M308 S0 P"temp0" Y"thermistor" T100000 B4138 A"Heated bed"; configure sensor 0 as thermistor on pin temp0

M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0

M307 H0 R0.418 C453.0 D4.22 S1.00 V23.9

M307 H0 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

;Hotend heater config

;M308 S1 P"temp1" Y"pt1000" A"PT1000" ; configure sensor 1 as thermocouple via CS pin spi.cs1 PT1000 code

;M950 H1 C"out1" T1 ; create nozzle heater output on out1 and map it to sensor 1 PT1000 code

M308 S1 P"spi.cs0" Y"rtd-max31865" A"PT100" ; configure sensor 1 as thermocouple via CS pin spi.cs1 CODE FOR PT100

M950 H1 C"out1" T1 ; create nozzle heater output on out1 and map it to sensor 1 CODE FOR PT100

;M307 H1 R1.424 C485.5 D8.34 S1.00 ; PID SETTINGS FOR HOTEND previous one

M307 H1 R1.558 C264.3 D6.50 S1.00

;M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S450 ; set temperature limit for heater 1 to 450C

; Fans

M950 F0 C"out7" Q500 ; create fan 0 on pin out4 and set its frequency

M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off

M950 F1 C"out8" Q500 ; create fan 1 on pin out5 and set its frequency

M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on

; Tools

M563 P0 D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C

; Custom settings are not defined

; Miscellaneous

T0 ; select first tool

M555 P2

homeall.g

; homeall.g

; called to home all axes

;

; generated by RepRapFirmware Configuration Tool v3.2.0 on Wed Jan 06 2021 20:53:07 GMT-0500 (Eastern Standard Time)

G91 ; relative positioning

G1 H2 Z5 F6000 ; lift Z relative to current position

G1 H1 X-598 Y617 F4000 ; move quickly to X and Y axis endstops and stop there (first pass)

G1 H2 X5 Y-5 F6000 ; go back a few mm

G1 H1 X-598 Y617 F360 ; move slowly to X and Y axis endstops once more (second pass)

G90 ; absolute positioning

G91 ; relative positioning

G1 H2 Z5 F6000 ; lift Z relative to current position

G90 ; absolute positioning

G1 X300 Y300 F6000 ; go to first probe point

G30 ; home Z by probing the bed

G91 ; relative positioning

G1 H1 Y617 F4000 ; move quickly to Y axis endstop and stop there (first pass)

G1 H2 Y-5 F6000 ; go back a few mm

G1 H1 Y617 F360 ; move slowly to Y axis endstop once more (second pass)

G90 ; absolute positioning

homey.g

; homey.g

; called to home the Y axis

;

; generated by RepRapFirmware Configuration Tool v3.2.0 on Wed Jan 06 2021 20:53:07 GMT-0500 (Eastern Standard Time)

G91 ; relative positioning

G1 H2 Z5 F6000 ; lift Z relative to current position

G1 H1 Y617 F4000 ; move quickly to Y axis endstop and stop there (first pass)

G1 H2 Y-5 F6000 ; go back a few mm

G1 H1 Y617 F360 ; move slowly to Y axis endstop once more (second pass)

G1 H2 Z-5 F6000 ; lower Z again

G90 ; absolute positioning

homez.g

; homez.g

; called to home the Z axis

;

; generated by RepRapFirmware Configuration Tool v3.2.0 on Wed Jan 06 2021 20:53:07 GMT-0500 (Eastern Standard Time)

G91 ; relative positioning

G1 H2 Z5 F6000 ; lift Z relative to current position

G90 ; absolute positioning

G1 X300 Y300 F4000 ; go to first probe point

G30 ; home Z by probing the bed

; Uncomment the following lines to lift Z after probing

;G91 ; relative positioning

;G1 Z5 F100 ; lift Z relative to current position

;G90 ; absolute positioning

beg.g

; bed.g

; called to perform automatic bed compensation via G32

;

; generated by RepRapFirmware Configuration Tool v3.2.0 on Wed Jan 06 2021 20:53:06 GMT-0500 (Eastern Standard Time)

;M561 ; clear any bed transform

;G29 ; probe the bed and enable compensation

G28 ; home

G30 P0 X0 Y300 Z-99999 ; probe near a leadscrew, half way along Y axis

G30 P1 X600 Y300 Z-99999 S2 ; probe near a leadscrew and calibrate 2 motors

Prusaslicer start gcode

M572 D0 S0.025 ;hemeera pressure avance attempt

G90 ; use absolute coordinates

M83 ; extruder relative mode

M104 S170 ; set extruder temp for bed leveling

M140 S[first_layer_bed_temperature] ; set bed temp

;M109 R170 ; wait for bed leveling temp

M190 S[first_layer_bed_temperature] ; wait for bed temp

;G28 ; home all without mesh bed level

G32

G29 ; mesh bed leveling

G29 S1

M104 S[first_layer_temperature] ; set extruder temp

G92 E0.0

G1 Y0 X0 F4000

G1 Z3 F720

M109 S[first_layer_temperature] ; wait for extruder temp

; intro line

G1 X0 F1000

G1 Z0.2 F720

G1 X60 E38.0 F900

G1 X130 E30.0 F700

G92 E0.0

Let me know if anything else would be helpful.