If you are talking about the SuperVolcano 80W heaters, I have run two of them without a problem, although I generally I only heat one of them at a time.

Posts made by Zhang Jianyu

-

RE: Duet wifi with 2x 80w heatersposted in General Discussion

-

RE: Question about configure polar printer.posted in Firmware installation

In the M92 command, the Y parameter is the steps per degree of rotation of the turntable.

When you give a G1 H1 or G1 H2 command (or G1 S1/G1 S2 for older firmware versions), the Y coordinate in that command must be specified in degrees.

-

RE: Belt Printer supportposted in Firmware wishlist

Would it be possible to do this by defining a matrix with M669?

-

RE: SD extension via CONN_SD design questionsposted in Third-party add-ons

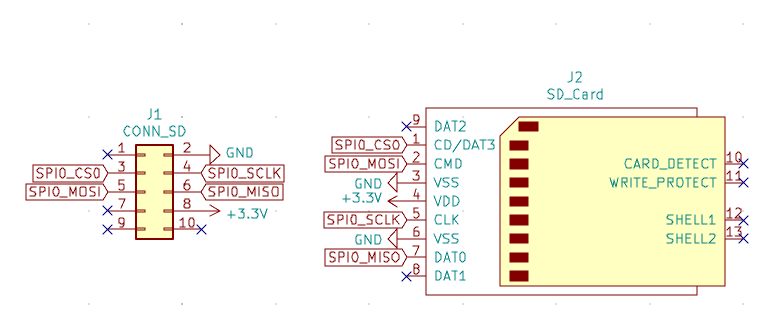

Also, here is the schematic i have made (pardon the sideways power ports):

-

SD extension via CONN_SD design questionsposted in Third-party add-ons

Hello all,

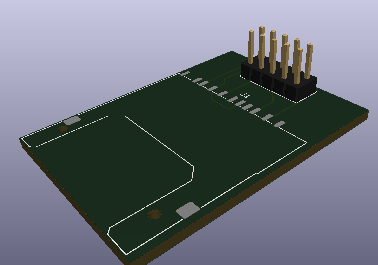

I want to make a SD card extension to plug into CONN_SD on Duet 2 wifi/eth, basically just extending the SPI signals 150-200mm to an SD socket.

I don't have much electronics design experience, so I have a couple basic questions if anybody knows:

-

Would any passive components be recommended at the SD socket when extending in this way?

-

Related to the Duet, would running a PanelDue via the 4-wire cable, and a separate SD extension (rather than using PanelDue SD slot) cause any trouble?

Here is a picture of what I have in mind: Imagine a cable connecting this to CONN_SD. (no SD card holder model is in KiCad so it only shows the pads and connector).

Any guidance is appreciated. Thanks!

-

-

RE: New heater tuning algorithmposted in Beta Firmware

The new auto-tune is working well for me on Duet 2 board. Thanks for your work on this

-

RE: 7.5 Amp fuse blown?posted in Duet Hardware and wiring

It's possible, as USB would be supplying 5V power separately. Or U3 (5V buck converter) is damaged.

You can check the fuse quite easily if you have a multimeter, simply by checking resistance or continuity across it (remove it from the holder first). If it's blown you will not get a reading. If it's good you will get 0 ohms or close to it.

-

RE: Tuning thermistorposted in Tuning and tweaking

SRS calc is this:

C =((1/T1-1/T2)-(Math.log(R1)- Math.log(R2))*(1/T1-1/T3)/(Math.log(R1)-Math.log(R3)))/((Math.pow(Math.log(R1),3)-Math.pow(Math.log(R2),3)) - (Math.log(R1)-Math.log(R2))*(Math.pow(Math.log(R1),3)-Math.pow(Math.log(R3),3))/(Math.log(R1)-Math.log(R3))); B =((1/T1-1/T2)-C*(Math.pow(Math.log(R1),3)-Math.pow(Math.log(R2),3)))/(Math.log(R1)-Math.log(R2)); A = 1/T1-C*(Math.log(R1))*(Math.log(R1))*(Math.log(R1))-B*Math.log(R1); -

RE: Tuning thermistorposted in Tuning and tweaking

For the reciprocal I am using dot '.' as a decimal separator. Since you use comma decimal separator ',' you'll need to put that in instead.

So the corrected one for you will be

1/2,3399e-4Regarding the slight difference in output, it's likely just due to the precision of the calculations on the computer.

The bit about the 1/B and β being equal is not of real practical use but I find it interesting

-

RE: Tuning thermistorposted in Tuning and tweaking

It takes some time to get a handle how everything fits together.

IIRC, a Steinhart-Hart C coefficient of 0 will result in a B coefficient that is the exact reciprocal of the β value. So the choice of using the same parameter names is probably just to simplify the implementation internally.

-

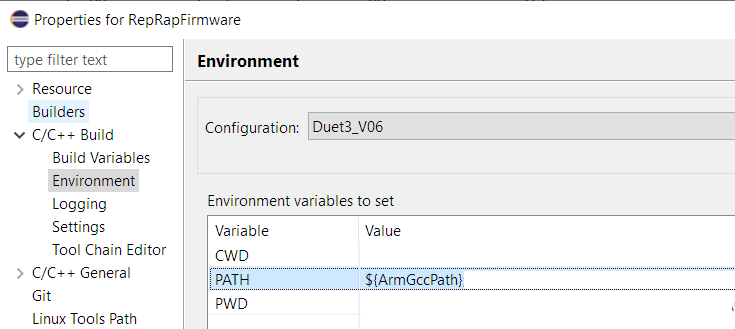

RE: Improving Build Instructionsposted in Firmware developers

Mine has the following path as well which contains the make.exe

C:\Program Files\GNU ARM Eclipse\Build Tools\2.6-201507152002\bin

I think the list is semi-colon delimited (the screenshot I posted had a bit scrubbed for privacy). In the end you want something looking like this:

PATH: ${ArmGccPath};C:\Program Files\GNU Arm Eclipse\......\bin

-

RE: Tuning thermistorposted in Tuning and tweaking

@LB What you are missing is that there are two distinct operating modes that both use a 'B' parameter.

If you are using simple Beta value calculation, the B parameter will represent the β value, in your case, 3970.

If you are using the steinhart-hart model (recommended because it is a better fit), the B parameter represents the reciprocal of the Steinhart-Hart B coefficient. In your example, 1/2.33994e-4 which is ~4273. The way you can tell this model is being used, is if you have a non-zero C parameter.

Unfortunately the way the information is displayed on the config tool does not make this distinction clear.

-

RE: Cnc and 3d printer on the same machine ?posted in General Discussion

Duet 3 can reconfigure on the fly, so you should be able to define a button or macro to run which would reconfigure the machine for different operating modes.

You should be able to control without a raspberry pi, either over USB which provides a basic serial interface to send g-code, or over Ethernet which would provide the duet web control interface.

-

RE: Improving Build Instructionsposted in Firmware developers

Right click the project, click Properties,

Go to C++ Build -> Environment.

There should be PATH variable visible here as well, double check that everything is the same as the system path. You should see the 'C:\program files\arm....' and 'C:\program files\GNU...' here as well.

-

RE: PID parameters and small MCU/thermistor temperature oscillationsposted in Duet Hardware and wiring

@akstrfn said in PID parameters and small MCU/thermistor temperature oscillations:

I've also noticed a potential buildup between duet ground and mains earth when using PSU (but not when using USB) by shorting the bed ground output to earth which makes the bed LED next to MOSFET light up.

This is normal because the bed power is switched on the negative side. By shorting negative to earth, you are bypassing the mosfet switch and leaving the bed in a permanent on state.

-

RE: emergency stopposted in Duet Hardware and wiring

Is it possible the emergency stop command is resetting the buzzer output signal as well?

To test this, you could try to insert a delay before the emergency stop to see if the buzzer works (for a short time) and then stops, something like:

M42 P5 S1 ; activate buzzer G4 S5 ; wait 5 seconds M400 ; wait for buffered commands to execute (maybe does nothing?) M112 ; e-stop -

RE: emergency stopposted in Duet Hardware and wiring

Trigger 1 is already reserved for a print pause trigger, so you could try renaming your file to trigger2.g and reconfiguring the trigger to use T2.

If you are calling other macro files with

M98command, I think it will only look in the /sys/ folder. To get around this, you could move all your macros to /sys/, or use the full path like so in your script:M98 P"0:/macros/mymacro.g" -

RE: Heater fault and PS_ON signal.posted in Duet Hardware and wiring

You would need to configure a

M143heater protection instance to trigger a power shutdown. Something like this:M143 H1 P1 S300 A3 ; Set heater 1 monitor 1 to trigger printer shutdown if temp exceeds 300Csee https://duet3d.dozuki.com/Wiki/Gcode#Section_M143_in_RRF_3_01RC2_and_later

-

RE: Power control for duet 3posted in Duet Hardware and wiring

Crydom and Schneider Electric are both reliable brands. I would add that amazon has a big counterfeit product problem as well.

-

RE: duet 2 wifi is really loudposted in Tuning and tweaking

The Duet 2 WiFi does not support stealthchop because it uses TMC2660 drivers which don't provide said feature. That being said, there are tuning methods to reduce the sound level: https://duet3d.dozuki.com/Wiki/Reducing_Stand-Still_Noise

Not sure if these apply when running (rather than at standstill) but it might be worth a shot.