Best posts made by Pertti

-

RE: BL-Touch to Alfawise U10posted in Duet Hardware and wiring

@phaedrux

Thank You all! First testprints going on! So far so good. I removed the z endstop and replaced it with z-probe. -

RE: Why not brushless motors in direct drive extruders?posted in General Discussion

Ha-haa, here it is,found in Hollow shaft extruder thread:

https://www.youtube.com/watch?v=f0SuaIMxAs0 -

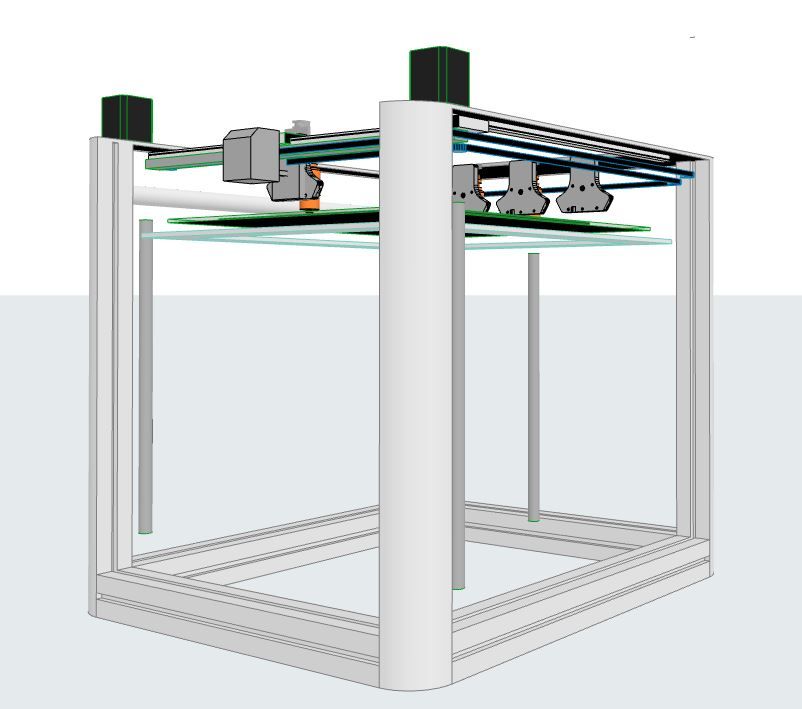

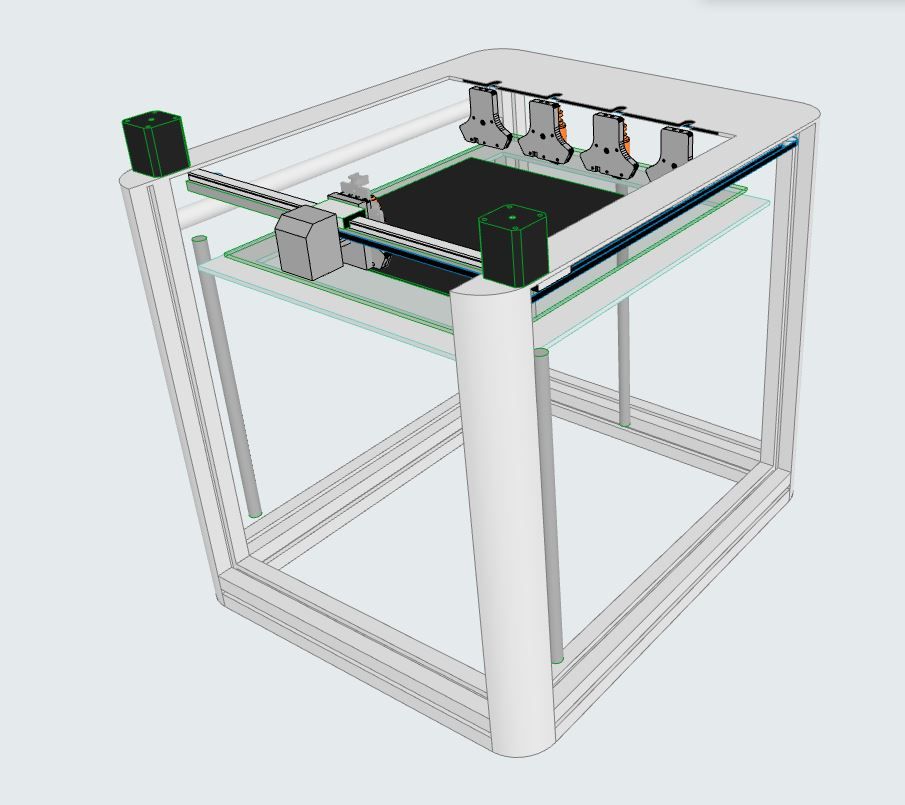

E3d Toolchanger to a Leapfrog frameposted in My Duet controlled machine

Hello!

My old Leaprog Creatr is going to have a facelift now. The good thing of the frame is that it is strong and rigid. I ordered some E3d parts and now I´m starting the modification with two tools. If I succeed then I add 2 tools more.

The final purpose is to print landscape models.

-

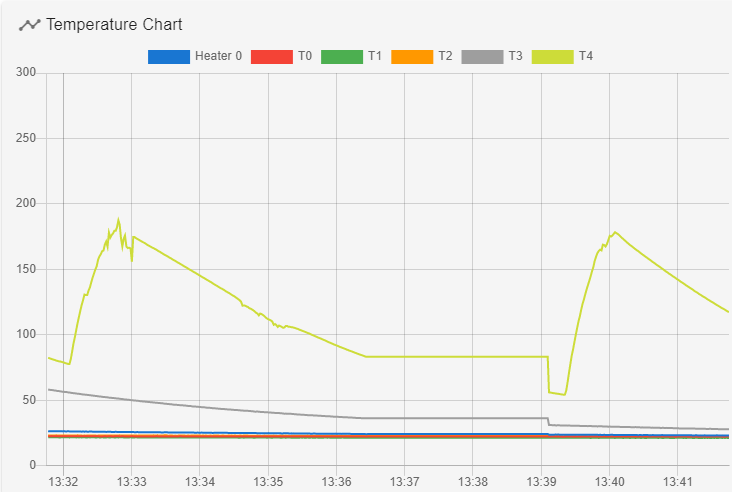

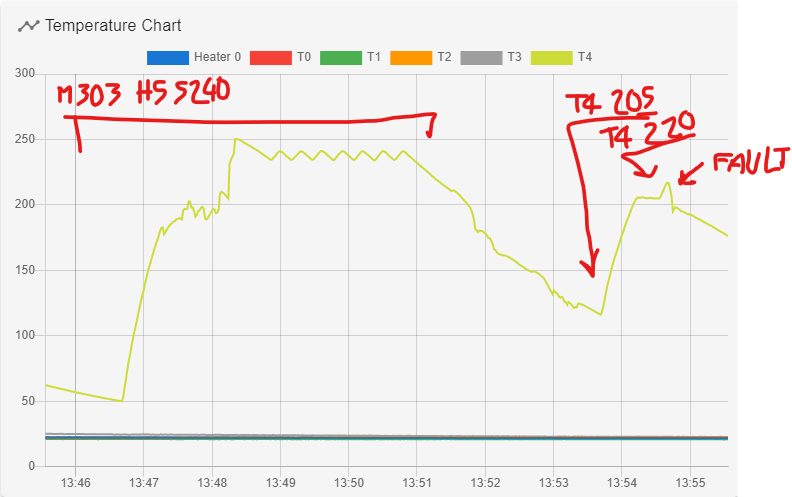

Revo Six Heater 5 fault and temperature readingsposted in Duet Hardware and wiring

My Revo Six has some difficulties in reaching temperatures over 200 degreeds.

Error: Heater 5 fault: temperature rising too slowly: expected 1.70°C/sec measured 0.55°C/sec

I run M303 H5 S240

result:

M307 H5 R1.801 K0.337:0.000 D1.40 E1.35 S1.00 B0 V24.0

The test looks like this:

The temperature readings seem to fly through rouhg air...

Do I need a new E3D Revo heatercore perhaps?Board: Duet 2 WiFi (2WiFi)******************

Firmware: RepRapFirmware for Duet 2 WiFi/Ethernet 3.4.1 (2022-06-01) -

RE: X turned down, replacig with E?posted in Using Duet Controllers

Here´s the answers, pasting them here resulted spam.

-

RE: X turned down, replacig with E?posted in Using Duet Controllers

0:/sys/config.g ;0:/sys/config.g ; Leaprog 200804 ; TITAN AERO ; Configuration file for Duet WiFi (firmware version 2.03) ; executed by the firmware on start-up ; Tässä versiossa y=z akselissa ; generated by RepRapFirmware Configuration Tool v2.1.5 on Sat Jan 11 2020 15:38:33 GMT+0200 (Itä-Euroopan normaaliaika) ; General preferences ;M303 H2 S240 ;Auto tuning Heater2 G90 ; send absolute coordinates... M143 M83 ; ...but relative extruder moves M550 P"Leapfrog-Duet" ; set printer name ; Network M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives dualextruder M569 P0 S0 ; physical drive 0 goes forwards X M569 P1 S0 ; physical drive 1 goes backwards Y muutetto S0 210509 M569 P2 S1 ; physical drive 2 goes backwards Z M569 P3 S1 ; physical drive 3 goes backwards E0 M569 P4 S0 ; physical drive 4 goes forwards E1 ;M584 X4 Y1 Z2 E3 ; X is now port 4 drive mapping vaihdettu E-> X M584 X0 Y1 Z2 E3:4 ; set drive mapping ;M584 X0 Z1 Y2 E3:4 ; set drive mapping vaihdettu z-y M350 X16 Y16 Z16 E16:16 I1 ; configure microstepping with interpolation M92 X400.00 Y66.67 Z654.02 E144.00:144.00 ;dualextruder set steps per mm M92 X66.67 Y66.67 Z654.02 E137.00:137.00 ;M92 X66.67 Y66.67 Z654.02 E837.00:93.00 ;titan aero; set steps per mm M566 X900.00 Y900.00 Z12.00 E120.00:120.00 ; set maximum instantaneous speed changes (mm/min) M203 X6000.00 Y6000.00 Z180.00 E1200.00:1200.00 ; set maximum speeds (mm/min) M201 X500.00 Y500.00 Z20.00 E250.00:250.00 ; set accelerations (mm/s^2) ;M906 X800 Y1600 Z1600 E800:800 I30 ; set motor currents (mA) and motor idle factor in per cent M906 X800 Y800 Z1600 E800:800 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X0 Y0 Z0 S1 M208 X270 Y300 Z200 S0 ; set axis maxima ; Endstops M574 Z0 S1 ; set active low and disabled endstops M574 Z0 S0 M574 X1 Y1 S1 ; set active high endstops ; Z-Probe M558 P0 H5 F120 T6000 ; disable Z probe but set dive height, probe speed and travel speed M557 X15:200 Y15:195 S20 ; define mesh grid ; Heaters ;M305 P0 T100000 B4138 R4700 ; set thermistor + ADC parameters for heater 0 ;M143 H0 S120 ; set temperature limit for heater 0 to 120C ;M305 P1 T100 B3950 R4700 ; set thermistor + ADC parameters for heater 1 ;M143 H1 S280 ; set temperature limit for heater 1 to 280C ;M305 P2 T100 B3950 R4700 ; set thermistor + ADC parameters for heater 2 ;M143 H2 S280 M305 P0 T100000 B4138 R4700 ; set thermistor + ADC parameters for heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M305 P1 T100000 B3950 R4700 ; set thermistor + ADC parameters for heater 1 ,T was 100000 ;M305 P1 B4725 C7.060000e-8 ; titan aero M143 H1 S290 ; set temperature limit for heater 1 to 280C M305 P2 T100000 B3950 R4700 ; set thermistor + ADC parameters for heater 2 ,T was 100000 M143 H2 S290 ; set temperature limit for heater 2 to 280C M307 H1 A455.9 C183.2 D17.7 S1.00 V24.1 B0 M307 H2 A499.7 C172.7 D10.4 S1.00 V24.1 B0 M570 H1 P4 T25 s1 M570 H2 P10 T25 M570 S120 ; Fans ;M106 P0 S0.5 I0 F500 H1 T45 ;M106 P1 T45 H1 ;M106 P0 S0 I0 F500 H-1 ; set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off ;M106 P1 S1 I0 F500 H-1 ; set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned off ;M106 P2 S1 I0 F500 H-1 ; set fan 2 value, PWM signal inversion and frequency. Thermostatic control is turned off M106 P1 T45 B0.1 H1 ; enable thermostatic mode for fan 1 M106 P0 T45 B0.1 H1 ; enable thermostatic mode for fan 2 ; Tools M563 P0 D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P1 R160 S0 ; set initial tool 0 active and standby temperatures to 0C M563 P1 D1 H2 F0 ; define tool 1 G10 P1 X24.3 Y1.0 Z0 ; set tool 1 axis offsets oli G10 P1 X22.4 Y6.4 Z0 G10 P2 R160 S0 ; set initial tool 1 active and standby temperatures to 0C ;M563 P0 D0 H1 ; tool 0 uses extruder 0, heater 1 (and fan 0) ; Custom settings are not defined