Pertti

@Pertti

Architect, glider pilot, dronebuilder

Best posts made by Pertti

-

RE: BL-Touch to Alfawise U10posted in Duet Hardware and wiring

@phaedrux

Thank You all! First testprints going on! So far so good. I removed the z endstop and replaced it with z-probe. -

RE: Why not brushless motors in direct drive extruders?posted in General Discussion

Ha-haa, here it is,found in Hollow shaft extruder thread:

https://www.youtube.com/watch?v=f0SuaIMxAs0 -

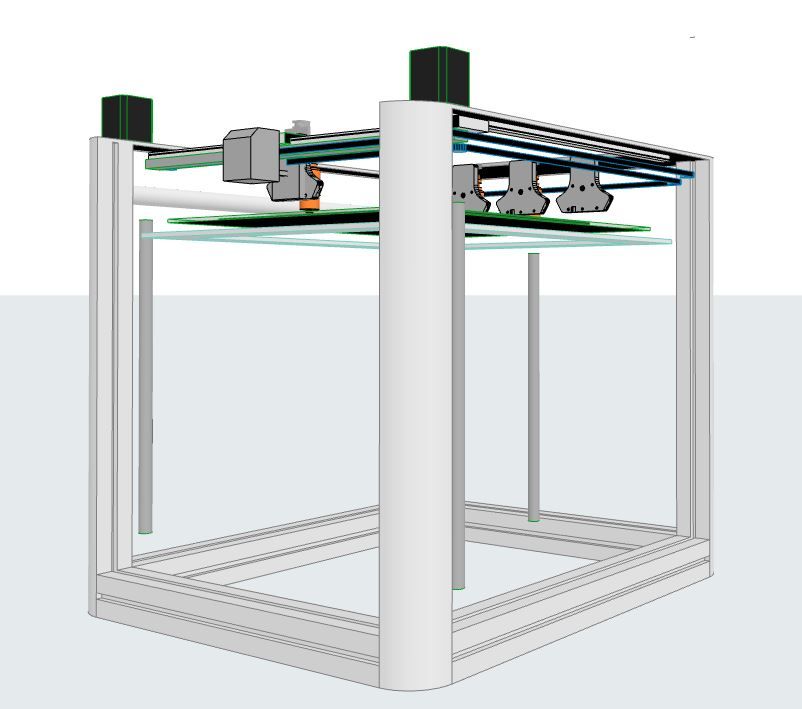

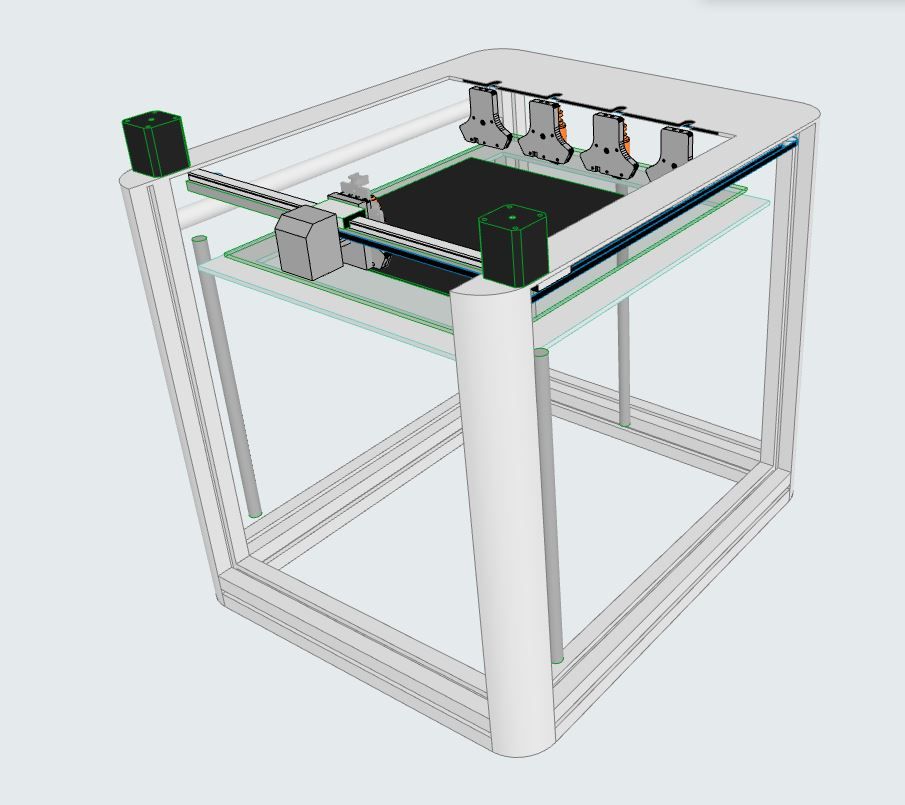

E3d Toolchanger to a Leapfrog frameposted in My Duet controlled machine

Hello!

My old Leaprog Creatr is going to have a facelift now. The good thing of the frame is that it is strong and rigid. I ordered some E3d parts and now I´m starting the modification with two tools. If I succeed then I add 2 tools more.

The final purpose is to print landscape models.

-

Revo Six Heater 5 fault and temperature readingsposted in Duet Hardware and wiring

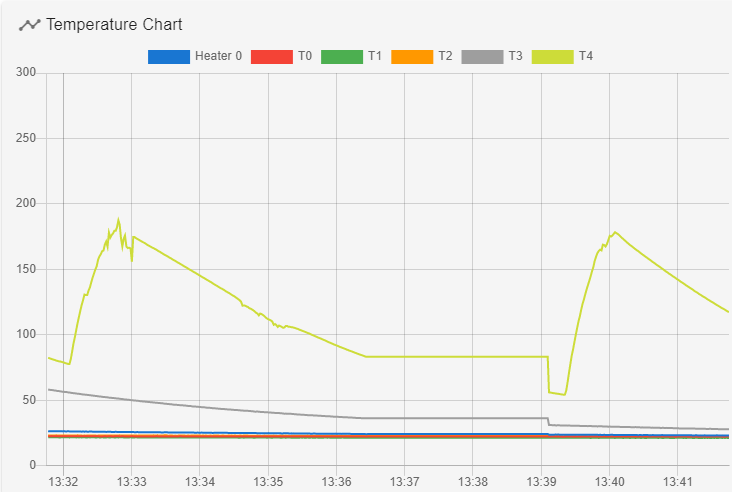

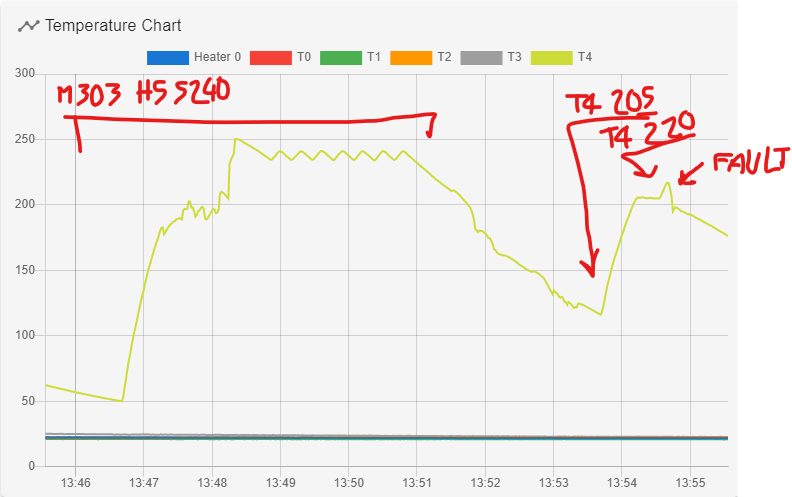

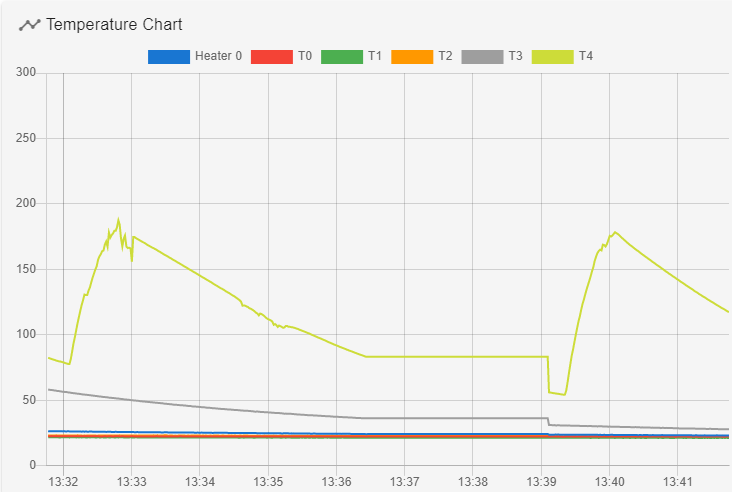

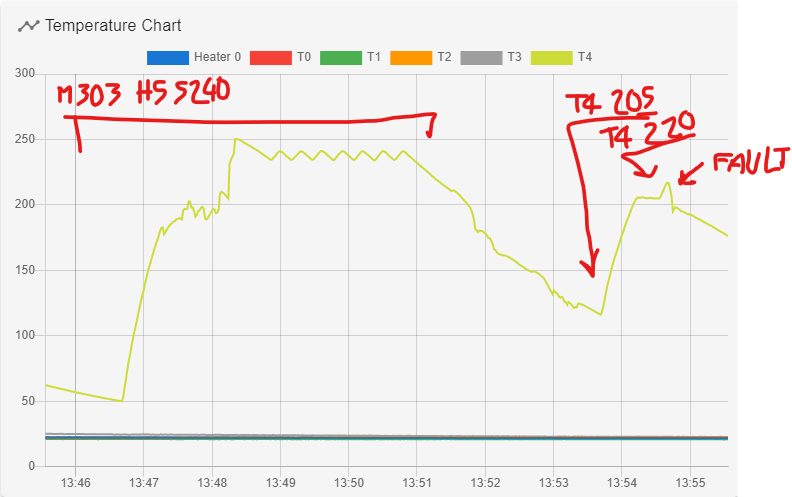

My Revo Six has some difficulties in reaching temperatures over 200 degreeds.

Error: Heater 5 fault: temperature rising too slowly: expected 1.70°C/sec measured 0.55°C/sec

I run M303 H5 S240

result:

M307 H5 R1.801 K0.337:0.000 D1.40 E1.35 S1.00 B0 V24.0

The test looks like this:

The temperature readings seem to fly through rouhg air...

Do I need a new E3D Revo heatercore perhaps?Board: Duet 2 WiFi (2WiFi)******************

Firmware: RepRapFirmware for Duet 2 WiFi/Ethernet 3.4.1 (2022-06-01) -

RE: X turned down, replacig with E?posted in Using Duet Controllers

Here´s the answers, pasting them here resulted spam.

-

RE: X turned down, replacig with E?posted in Using Duet Controllers

0:/sys/config.g ;0:/sys/config.g ; Leaprog 200804 ; TITAN AERO ; Configuration file for Duet WiFi (firmware version 2.03) ; executed by the firmware on start-up ; Tässä versiossa y=z akselissa ; generated by RepRapFirmware Configuration Tool v2.1.5 on Sat Jan 11 2020 15:38:33 GMT+0200 (Itä-Euroopan normaaliaika) ; General preferences ;M303 H2 S240 ;Auto tuning Heater2 G90 ; send absolute coordinates... M143 M83 ; ...but relative extruder moves M550 P"Leapfrog-Duet" ; set printer name ; Network M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives dualextruder M569 P0 S0 ; physical drive 0 goes forwards X M569 P1 S0 ; physical drive 1 goes backwards Y muutetto S0 210509 M569 P2 S1 ; physical drive 2 goes backwards Z M569 P3 S1 ; physical drive 3 goes backwards E0 M569 P4 S0 ; physical drive 4 goes forwards E1 ;M584 X4 Y1 Z2 E3 ; X is now port 4 drive mapping vaihdettu E-> X M584 X0 Y1 Z2 E3:4 ; set drive mapping ;M584 X0 Z1 Y2 E3:4 ; set drive mapping vaihdettu z-y M350 X16 Y16 Z16 E16:16 I1 ; configure microstepping with interpolation M92 X400.00 Y66.67 Z654.02 E144.00:144.00 ;dualextruder set steps per mm M92 X66.67 Y66.67 Z654.02 E137.00:137.00 ;M92 X66.67 Y66.67 Z654.02 E837.00:93.00 ;titan aero; set steps per mm M566 X900.00 Y900.00 Z12.00 E120.00:120.00 ; set maximum instantaneous speed changes (mm/min) M203 X6000.00 Y6000.00 Z180.00 E1200.00:1200.00 ; set maximum speeds (mm/min) M201 X500.00 Y500.00 Z20.00 E250.00:250.00 ; set accelerations (mm/s^2) ;M906 X800 Y1600 Z1600 E800:800 I30 ; set motor currents (mA) and motor idle factor in per cent M906 X800 Y800 Z1600 E800:800 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X0 Y0 Z0 S1 M208 X270 Y300 Z200 S0 ; set axis maxima ; Endstops M574 Z0 S1 ; set active low and disabled endstops M574 Z0 S0 M574 X1 Y1 S1 ; set active high endstops ; Z-Probe M558 P0 H5 F120 T6000 ; disable Z probe but set dive height, probe speed and travel speed M557 X15:200 Y15:195 S20 ; define mesh grid ; Heaters ;M305 P0 T100000 B4138 R4700 ; set thermistor + ADC parameters for heater 0 ;M143 H0 S120 ; set temperature limit for heater 0 to 120C ;M305 P1 T100 B3950 R4700 ; set thermistor + ADC parameters for heater 1 ;M143 H1 S280 ; set temperature limit for heater 1 to 280C ;M305 P2 T100 B3950 R4700 ; set thermistor + ADC parameters for heater 2 ;M143 H2 S280 M305 P0 T100000 B4138 R4700 ; set thermistor + ADC parameters for heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M305 P1 T100000 B3950 R4700 ; set thermistor + ADC parameters for heater 1 ,T was 100000 ;M305 P1 B4725 C7.060000e-8 ; titan aero M143 H1 S290 ; set temperature limit for heater 1 to 280C M305 P2 T100000 B3950 R4700 ; set thermistor + ADC parameters for heater 2 ,T was 100000 M143 H2 S290 ; set temperature limit for heater 2 to 280C M307 H1 A455.9 C183.2 D17.7 S1.00 V24.1 B0 M307 H2 A499.7 C172.7 D10.4 S1.00 V24.1 B0 M570 H1 P4 T25 s1 M570 H2 P10 T25 M570 S120 ; Fans ;M106 P0 S0.5 I0 F500 H1 T45 ;M106 P1 T45 H1 ;M106 P0 S0 I0 F500 H-1 ; set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off ;M106 P1 S1 I0 F500 H-1 ; set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned off ;M106 P2 S1 I0 F500 H-1 ; set fan 2 value, PWM signal inversion and frequency. Thermostatic control is turned off M106 P1 T45 B0.1 H1 ; enable thermostatic mode for fan 1 M106 P0 T45 B0.1 H1 ; enable thermostatic mode for fan 2 ; Tools M563 P0 D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P1 R160 S0 ; set initial tool 0 active and standby temperatures to 0C M563 P1 D1 H2 F0 ; define tool 1 G10 P1 X24.3 Y1.0 Z0 ; set tool 1 axis offsets oli G10 P1 X22.4 Y6.4 Z0 G10 P2 R160 S0 ; set initial tool 1 active and standby temperatures to 0C ;M563 P0 D0 H1 ; tool 0 uses extruder 0, heater 1 (and fan 0) ; Custom settings are not defined

Latest posts made by Pertti

-

duet2wifi servo control by cellphoneposted in General Discussion

Hi !

I have an extra duet2 wifi which has lost some extruder drivers. My goal is to use it for experiments.Now I managed to connect a servo as advised in the manual wiht external 5v power.

;configuration:

M950 S0 C"exp.heater3" ; assign GPIO port 0 to heater3 on expansion connector, servo mode

;move servo with

M280 P0 S80 ; set 80deg servo position on GPIO port 0

;turn off servo with

M42 P0 S0I made two macros that move the servo.

The problem is that I can not see the macro buttons in my cellphone. I have to go down to the files \ macros to move the servo.

Is it possible to use the fan control slider and how? -

RE: E3D Rapidcahange Revo jamposted in General Discussion

@elmoret Done.

Meanwhile I made a quick repair by recycling used heatblock and thermistor. I also sealed the tube parts with silver soldier

-

E3D Rapidcahange Revo jamposted in General Discussion

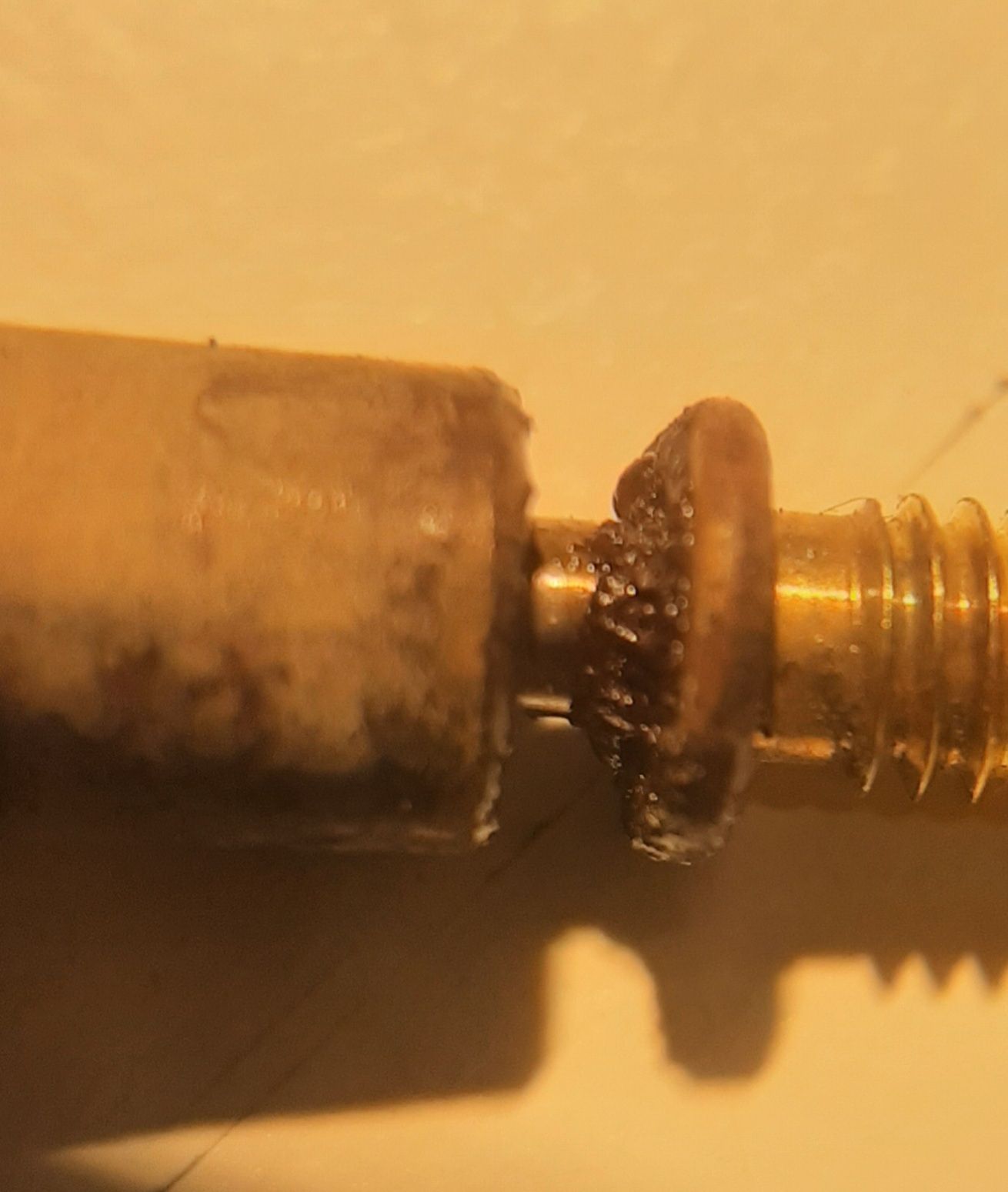

Hi! Sorry to say, but I found it hard to pull out this nozzle of the heatblock. By warming it up by torch it was possible to remove it. Usually You can pull it out with no effort but now I discovered some dark material (propably filament) around the neck of the nozzle. Propably it acts as an insulation, because printing was impossible due blockage.

Perhaps the nozzle leaked from the joint. Left in the picture is a not used nozzle.

-

RE: Why not brushless motors in direct drive extruders?posted in General Discussion

@o_lampe I like this group because of this habit of sharing and commenting innovations.

-

RE: Why not brushless motors in direct drive extruders?posted in General Discussion

Ha-haa, here it is,found in Hollow shaft extruder thread:

https://www.youtube.com/watch?v=f0SuaIMxAs0 -

3d printed nozzles?posted in General Discussion

Just wondering if there are metal 3d printted nozzles. The method would allow interesting shapes in order to produce fast filament flow.

-

RE: Revo Six Heater 5 fault and temperature readingsposted in Duet Hardware and wiring

@Phaedrux Ok, looks like a thermistor issue.

-

Revo Six Heater 5 fault and temperature readingsposted in Duet Hardware and wiring

My Revo Six has some difficulties in reaching temperatures over 200 degreeds.

Error: Heater 5 fault: temperature rising too slowly: expected 1.70°C/sec measured 0.55°C/sec

I run M303 H5 S240

result:

M307 H5 R1.801 K0.337:0.000 D1.40 E1.35 S1.00 B0 V24.0

The test looks like this:

The temperature readings seem to fly through rouhg air...

Do I need a new E3D Revo heatercore perhaps?Board: Duet 2 WiFi (2WiFi)******************

Firmware: RepRapFirmware for Duet 2 WiFi/Ethernet 3.4.1 (2022-06-01)