@alankilian

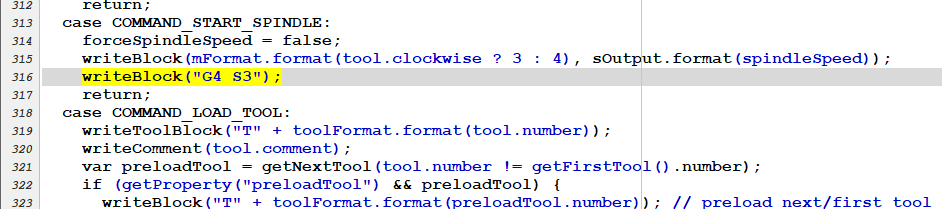

I followed your suggestion and a lookup table to pick the initial potentiometer position and then fine tune the spindle RPM with a loop.

This worked well enough for some initial tests. But for me, it was no satisfying permanent solution.

After taking some voltage measurements, I figured that the motor controller simply needs a 0-5V Control Signal.

So I used a PWM to analog converter to provide the control signal and to galvanically separate the inverter from the Duet Board.

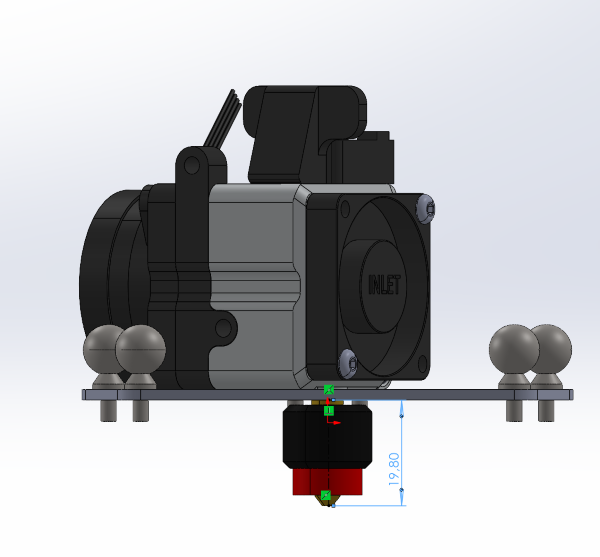

I am using a multifix toolpost to quickly change between tools. In order to avoid manually calibrating a new tool, I wrote a macro that can automatically set the offsets for a given tool using a touch probe. Since the multifix toolpost is very repeatable, the offsets do not need to be recalibrated after a toolchange.

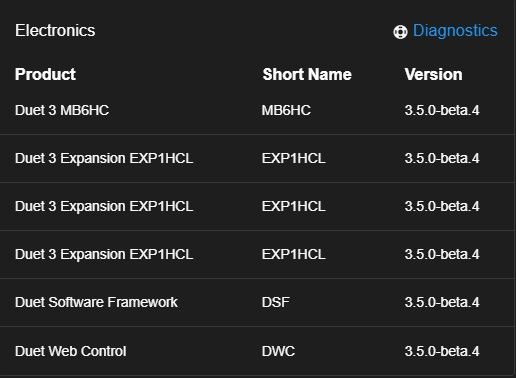

I am very happy how this project turned out. The Duet3HC is a formidable controller for small CNC-Maschines.

Video: Paulimot CNC-converion test.mp4

Cheers

Max