Here you go:

LARGE SOFIA LAMPSHADE.gcode

Posts made by MaxGyver

-

RE: [3.6.0-rc.2] Code 3 move errorposted in Beta Firmware

The issue is also present in 3.6.0-rc.1

Error: Code 3 move error: new: start=651528999 overlap=5623 time now=651492690, existing: s=651491803 t=42819 d=20.46 u=8.0975e-4 a=-1.5504e-8 f=18 -

RE: [3.6.0-rc.2] Code 3 move errorposted in Beta Firmware

Yes, I had the same Code 3 move error. I did not copy the error code tough.

-

RE: [3.6.0-rc.2] Code 3 move errorposted in Beta Firmware

I just upgraded the printer to a RPI5 with a clean install...still the same error

@jay_s_uk said in [3.6.0-rc.2] Code 3 move error:

@MaxGyver can you also, just for completeness, provide the M122 output from your connected toolboard etc?

Sure, here are the diagnostics of all boards including the mainboard:

M122 B0 === Diagnostics === RepRapFirmware for Duet 3 MB6HC version 3.6.0-rc.2 (2025-03-31 12:17:13) running on Duet 3 MB6HC v1.01 (SBC mode) Board ID: 0JD2M-999AL-D25S4-7J1D2-3SJ6K-T51V3 Used output buffers: 1 of 40 (18 max) === RTOS === Static ram: 137420 Dynamic ram: 98632 of which 0 recycled Never used RAM 106540, free system stack 132 words Tasks: LASER(5,nWait 7,0.0%,167) SBC(2,nWait 7,0.9%,825) HEAT(3,nWait 6,0.0%,367) TMC(4,nWait 6,3.1%,375) CanReceiv(6,nWait 1,0.1%,782) CanSender(5,nWait 7,0.0%,329) CanClock(7,delaying,0.0%,350) MAIN(1,running,95.6%,500) IDLE(0,ready,0.4%,29) USBD(3,blocked,0.0%,149), total 100.0% Owned mutexes: HTTP(MAIN) === Platform === Last reset 00:18:15 ago, cause: software Last software reset at 2025-04-01 16:42, reason: User, Gcodes spinning, available RAM 96348, slot 2 Software reset code 0x6003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x00400000 BFAR 0x00000000 SP 0x00000000 Task SBC Freestk 0 n/a === Storage === Free file entries: 20 SD card 0 not detected, interface speed: 37.5MBytes/sec SD card longest read time 0.0ms, write time 0.0ms, max retries 0 === Move === Segments created 61, maxWait 260198ms, bed comp in use: mesh, height map offset 0.000, hiccups added 0/0 (0.00/12.06ms), max steps late 0, ebfmin 0.00, ebfmax 0.00 Pos req/act/dcf: 74103.00/69052/0.53 48913.00/48970/-0.49 902.00/900/0.64 No step interrupt scheduled Driver 0: standstill, SG min n/a, mspos 8, reads 28346, writes 11 timeouts 0 Driver 1: standstill, SG min n/a, mspos 8, reads 28346, writes 11 timeouts 0 Driver 2: standstill, SG min n/a, mspos 8, reads 28346, writes 11 timeouts 0 Driver 3: standstill, SG min n/a, mspos 8, reads 28346, writes 11 timeouts 0 Driver 4: standstill, SG min n/a, mspos 8, reads 28346, writes 11 timeouts 0 Driver 5: standstill, SG min n/a, mspos 8, reads 28346, writes 11 timeouts 0 Phase step loop runtime (us): min=0, max=30, frequency (Hz): min=1102, max=9868 === DDARing 0 === Scheduled moves 181, completed 176, LaErrors 0, Underruns [0, 0, 0] Segments left 1, axes/extruders owned 0x80000007, drives owned 0x80000007 Code queue is empty === DDARing 1 === Scheduled moves 0, completed 0, LaErrors 0, Underruns [0, 0, 0] Segments left 0, axes/extruders owned 0x00000000, drives owned 0x00000000 Code queue is empty === Heat === Bed heaters -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1, chamber heaters 2 -1 -1 -1 -1 -1 -1 -1, ordering errs 0 === GCodes === Movement locks held by null, null HTTP* is doing "M122 B0" in state(s) 0 Telnet is idle in state(s) 0 File* is idle in state(s) 3 USB is idle in state(s) 0 Aux is idle in state(s) 0 Trigger* is idle in state(s) 0 Queue is idle in state(s) 0 LCD is idle in state(s) 0 SBC is idle in state(s) 0 Daemon is idle in state(s) 0 Aux2 is idle in state(s) 0 Autopause is idle in state(s) 0 File2 is idle in state(s) 0 Queue2 is idle in state(s) 0 === Filament sensors === Driver 31: no filament === CAN === Messages queued 5971, received 71111, lost 0, ignored 0, errs 0, boc 0 Longest wait 9ms for reply type 6024, peak Tx sync delay 372, free buffers 50 (min 46), ts 5193/5192/0 Tx timeouts 0,0,0,0,0,0 === SBC interface === Transfer state: 5, failed transfers: 0, checksum errors: 0 RX/TX seq numbers: 42674/42674 SPI underruns 0, overruns 0 State: 5, disconnects: 0, timeouts: 0 total, 0 by SBC, IAP RAM available 0x27a7c Buffer RX/TX: 776/2296-0, open files: 0 === Duet Control Server === Duet Control Server version 3.6.0-rc.2 (2025-03-31 10:53:52, 64-bit) HTTP+Executed: > Executing M122 File 0:/gcodes/LARGE SOFIA LAMPSHADE.gcode is selected, processing File: Buffered code: G1 X559.936 Y489.031 E95.74515 Buffered code: G1 X562.242 Y489.426 E97.48178 Buffered code: G1 X564.283 Y490.57 E99.21853 Buffered code: G1 X565.909 Y492.472 E101.07594 Buffered code: G1 X626.069 Y596.422 E190.22657 Buffered code: G1 X626.881 Y598.616 E191.96309 Buffered code: G1 X626.911 Y600.956 E193.70017 Buffered code: G1 X626.077 Y603.314 E195.55672 Buffered code: G1 X566.134 Y707.39 E284.70781 Buffered code: G1 X564.639 Y709.19 E286.44466 Buffered code: G1 X562.628 Y710.386 E288.18143 Buffered code: G1 X560.168 Y710.843 E290.03869 Buffered code: G1 X440.064 Y710.969 E379.18981 Buffered code: G1 X437.758 Y710.574 E380.92644 Buffered code: G1 X435.717 Y709.43 E382.66319 Buffered code: G1 X434.091 Y707.528 E384.5206 Buffered code: G1 X373.931 Y603.578 E473.67123 Buffered code: G1 X373.119 Y601.384 E475.40775 Buffered code: G1 X373.089 Y599.044 E477.14483 Buffered code: G1 X373.923 Y596.686 E479.00138 Buffered code: G1 X433.866 Y492.61 E568.15247 Buffered code: G1 X435.074 Y491.156 E569.55563 Buffered code: G1 E566.55563 F6000 Buffered code: G92 E0 Buffered code: G1 Z2 F18000 Buffered code: G92 E0 Buffered code: G1 X488.207 Y581.793 Buffered code: G1 Z1 Buffered code: G1 E3 F6000 Buffered code: G1 F3360.595 Buffered codes: 1344 bytes total Code buffer space: 1800 Configured SPI speed: 8000000Hz, TfrRdy pin glitches: 0 Full transfers per second: 39.19, max time between full transfers: 40.8ms, max pin wait times: 38.7ms/0.5ms Codes per second: 0.21 Maximum length of RX/TX data transfers: 5240/1072M122 B1 Diagnostics for board 1: Duet EXP3HC rev 1.01 or earlier firmware version 3.6.0-rc.2 (2025-03-31 12:21:29) Bootloader ID: not available All averaging filters OK Never used RAM 168744, free system stack 182 words Tasks: Move(3,nWait 7,0.0%,134) TMC(2,nWait 6,7.3%,95) HEAT(2,nWait 6,0.1%,110) CanAsync(5,nWait 4,0.0%,66) CanRecv(3,nWait 1,0.0%,73) CanClock(5,nWait 1,0.0%,63) MAIN(1,running,91.5%,295) IDLE(0,ready,0.0%,39) AIN(2,delaying,1.1%,261), total 100.0% Owned mutexes: Last reset 00:12:31 ago, cause: software Last software reset at 2023-05-24 22:19, reason: StackOverflow, available RAM 158036, slot 1 Software reset code 0x0100 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x0048180e BFAR 0xe000ed38 SP 0x2002ffbc Task HEAT Freestk 44648 ok Stack: 200045c0 200045f4 00026599 00000000 20003c94 000000fa 00025c45 200047cc 20003c94 00000000 00f00000 e000e000 c0000000 00000006 00025d81 00025b00 21000000 ffffffff ffffffff ffffffff ffffffff ffffffff ffffffff ffffffff ffffffff ffffffff ffffffff Moves scheduled 5, hiccups 0 (0.00/12.06ms), segs 18, step errors 0 (types 0x0), maxLate 0 maxPrep 53, ebfmin 0.00 max 0.00 Peak sync jitter -7/5, peak Rx sync delay 212, resyncs 0/0, no timer interrupt scheduled, next step interrupt due in 4167254009 ticks, disabled VIN voltage: min 22.7, current 24.0, max 24.0 V12 voltage: min 12.3, current 12.3, max 12.3 MCU temperature: min 28.1C, current 30.4C, max 30.8C Driver 0: pos 10497, 490.0 steps/mm, standstill, SG min 0, mspos 1016, reads 21243, writes 19 timeouts 0 Driver 1: pos 0, 80.0 steps/mm, standstill, SG min n/a, mspos 8, reads 21251, writes 11 timeouts 0 Driver 2: pos 0, 80.0 steps/mm, standstill, SG min n/a, mspos 8, reads 21252, writes 11 timeouts 0 Last sensors broadcast 0x00000007 found 3 27 ticks ago, 0 ordering errs, loop time 0 CAN messages queued 15645, send timeouts 0, received 6770, lost 0, ignored 0, errs 0, boc 0, free buffers 38, min 38, error reg 0 dup 0, oos 0/0/0/0, rxMotionDelay 293, adv 35729/37075 === Filament sensors === Interrupt 5726621 to 0us, poll 1 to 254us Driver 0: okM122 B2 Diagnostics for board 2: Duet EXP3HC rev 1.01 or earlier firmware version 3.6.0-rc.2 (2025-03-31 12:21:29) Bootloader ID: not available All averaging filters OK Never used RAM 169692, free system stack 202 words Tasks: Move(3,nWait 7,0.0%,176) TMC(2,nWait 6,7.1%,95) HEAT(2,nWait 6,0.1%,117) CanAsync(5,nWait 4,0.0%,70) CanRecv(3,nWait 1,0.0%,73) CanClock(5,nWait 1,0.0%,63) MAIN(1,running,91.7%,321) IDLE(0,ready,0.0%,39) AIN(2,delaying,1.1%,261), total 100.0% Owned mutexes: Last reset 00:15:46 ago, cause: software Last software reset data not available Moves scheduled 0, hiccups 0 (0.00/12.06ms), segs 0, step errors 0 (types 0x0), maxLate 0 maxPrep 0, ebfmin 0.00 max 0.00 Peak sync jitter -6/5, peak Rx sync delay 213, resyncs 0/0, no timer interrupt scheduled, next step interrupt due in 3584711043 ticks, disabled VIN voltage: min 23.8, current 23.9, max 23.9 V12 voltage: min 12.2, current 12.2, max 12.2 MCU temperature: min 29.9C, current 30.4C, max 30.6C Driver 0: pos 0, 80.0 steps/mm, standstill, SG min n/a, mspos 8, reads 59275, writes 11 timeouts 0 Driver 1: pos 0, 80.0 steps/mm, standstill, SG min n/a, mspos 8, reads 59275, writes 11 timeouts 0 Driver 2: pos 0, 80.0 steps/mm, standstill, SG min n/a, mspos 8, reads 59276, writes 11 timeouts 0 Last sensors broadcast 0x00000038 found 3 11 ticks ago, 0 ordering errs, loop time 0 CAN messages queued 18822, send timeouts 0, received 8247, lost 0, ignored 0, errs 0, boc 0, free buffers 38, min 38, error reg 0 dup 0, oos 0/0/0/0, rxMotionDelay 0M122 B123 Diagnostics for board 123: Duet EXP1XD firmware version 3.6.0-rc.2 (2025-03-31 12:21:12) Bootloader ID: SAMC21 bootloader version 2.3 (2021-01-26b1) All averaging filters OK Never used RAM 9016, free system stack 75 words Tasks: Move(3,nWait 7,0.0%,92) HEAT(2,nWait 6,0.1%,124) CanAsync(5,nWait 4,0.0%,58) CanRecv(3,nWait 1,0.0%,70) CanClock(5,nWait 1,0.0%,58) MAIN(1,running,64.9%,420) IDLE(0,ready,0.0%,40) AIN(2,nWait 2,34.9%,112), total 100.0% Owned mutexes: Last reset 00:14:27 ago, cause: software Last software reset at 2024-10-09 17:58, reason: OutOfMemory, available RAM 8, slot 0 Software reset code 0x01c0 ICSR 0x00000000 SP 0x20004c98 Task Move Freestk 96 ok Stack: 20004ef8 00005a4b 00000000 36532722 00029e30 0000797b 00000000 000064ad 20007160 00000000 2fd75a5f b9b6dd11 fffffffd 00000496 b9b6ddaa 20004fe8 2000193f 20004d74 00029e30 20004a4c 20004990 bfa4c566 20004fe8 00000784 36532e2f 00006ab7 bf2a04ab Moves scheduled 29, hiccups 5 (0.25/12.06ms), segs 22, step errors 0 (types 0x0), maxLate 0 maxPrep 1245, ebfmin 0.00 max 0.00 Peak sync jitter 2/7, peak Rx sync delay 256, resyncs 0/0, no timer interrupt scheduled, next step interrupt due in 4080735155 ticks, disabled VIN voltage: min 23.7, current 23.8, max 23.9 MCU temperature: min 27.0C, current 27.2C, max 38.3C Driver 0: pos -4185, 100.0 steps/mm Last sensors broadcast 0x00000000 found 0 85 ticks ago, 0 ordering errs, loop time 0 CAN messages queued 6966, send timeouts 0, received 10909, lost 0, ignored 0, errs 0, boc 0, free buffers 18, min 18, error reg 0 dup 0, oos 0/0/0/0, rxMotionDelay 337, adv 34992/37159M122 B124 Diagnostics for board 124: Duet EXP1XD firmware version 3.6.0-rc.2 (2025-03-31 12:21:12) Bootloader ID: SAMC21 bootloader version 2.3 (2021-01-26b1) All averaging filters OK Never used RAM 9040, free system stack 75 words Tasks: Move(3,nWait 7,0.0%,90) HEAT(2,nWait 6,0.1%,124) CanAsync(5,nWait 4,0.0%,58) CanRecv(3,nWait 1,0.0%,70) CanClock(5,nWait 1,0.0%,58) MAIN(1,running,64.8%,420) IDLE(0,ready,0.0%,40) AIN(2,nWait 2,35.1%,112), total 100.0% Owned mutexes: Last reset 00:14:47 ago, cause: software Last software reset at 2024-10-09 17:58, reason: OutOfMemory, available RAM 8, slot 0 Software reset code 0x01c0 ICSR 0x00426000 SP 0x20004c98 Task Move Freestk 96 ok Stack: 20004ef8 00005a4b 00000000 365335b3 00029e30 0000797b 00000000 000064ad 20006c08 80000000 b021828c 3a08fff3 20004990 20006d28 365335b3 20006d28 00eedf29 20004d74 00029e30 20004a4c 20004990 3ff72819 20006d28 00000786 36533cc0 00006ab7 3f7f27c5 Moves scheduled 49, hiccups 167 (8.24/12.06ms), segs 21, step errors 0 (types 0x0), maxLate 0 maxPrep 1592, ebfmin 0.00 max 0.00 Peak sync jitter 1/6, peak Rx sync delay 265, resyncs 0/0, no timer interrupt scheduled, next step interrupt due in 4065336518 ticks, disabled VIN voltage: min 23.7, current 23.8, max 23.8 MCU temperature: min 26.7C, current 26.9C, max 37.9C Driver 0: pos 6441, 193.1 steps/mm Last sensors broadcast 0x00000000 found 0 169 ticks ago, 0 ordering errs, loop time 0 CAN messages queued 7130, send timeouts 0, received 11191, lost 0, ignored 0, errs 0, boc 0, free buffers 18, min 18, error reg 0 dup 0, oos 0/0/0/0, rxMotionDelay 471, adv 35006/37151M122 B125 Diagnostics for board 125: Duet EXP1XD firmware version 3.6.0-rc.2 (2025-03-31 12:21:12) Bootloader ID: SAMC21 bootloader version 2.3 (2021-01-26b1) All averaging filters OK Never used RAM 9064, free system stack 75 words Tasks: Move(3,nWait 7,0.0%,92) HEAT(2,nWait 6,0.1%,124) CanAsync(5,nWait 4,0.0%,58) CanRecv(3,nWait 1,0.0%,70) CanClock(5,nWait 1,0.0%,58) MAIN(1,running,64.2%,424) IDLE(0,ready,0.0%,40) AIN(2,nWait 2,35.6%,112), total 100.0% Owned mutexes: Last reset 00:15:11 ago, cause: software Last software reset data not available Moves scheduled 179, hiccups 71 (3.58/12.06ms), segs 20, step errors 1 (types 0x8), maxLate 0 maxPrep 1241, ebfmin 0.00 max 0.00 Peak sync jitter 1/6, peak Rx sync delay 255, resyncs 0/0, no timer interrupt scheduled, next step interrupt due in 4046779478 ticks, disabled VIN voltage: min 24.0, current 24.1, max 24.2 MCU temperature: min 26.3C, current 26.7C, max 36.9C Driver 0: pos -99650, 800.0 steps/mm Last sensors broadcast 0x00000000 found 0 24 ticks ago, 0 ordering errs, loop time 0 CAN messages queued 7318, send timeouts 0, received 11690, lost 0, ignored 0, errs 0, boc 0, free buffers 18, min 17, error reg 0 dup 0, oos 0/0/0/0, rxMotionDelay 324, adv 35305/37173 -

RE: [3.6.0-rc.2] Code 3 move errorposted in Beta Firmware

@dc42 said in [3.6.0-rc.2] Code 3 move error:

@MaxGyver said in [3.6.0-rc.2] Code 3 move error:

Last software reset at 2025-04-01 13:22, reason: MemoryProtectionFault mmarValid daccViol, Platform spinning, available RAM 108732, slot 1

I noticed the above in your M122 report. Do you know what provoked it?

Unfortunately not. I had the same error again while printing the firts layer.

M122 === Diagnostics === RepRapFirmware for Duet 3 MB6HC version 3.6.0-rc.2 (2025-03-31 12:17:13) running on Duet 3 MB6HC v1.01 (SBC mode) Board ID: 0JD2M-999AL-D25S4-7J1D2-3SJ6K-T51V3 Used output buffers: 1 of 40 (18 max) === RTOS === Static ram: 137420 Dynamic ram: 98656 of which 0 recycled Never used RAM 86548, free system stack 130 words Tasks: LASER(5,nWait 7,0.0%,167) SBC(2,nWait 7,0.9%,809) HEAT(3,nWait 6,0.0%,343) TMC(4,nWait 6,3.0%,375) CanReceiv(6,nWait 1,0.1%,770) CanSender(5,nWait 7,0.0%,327) CanClock(7,delaying,0.0%,348) MAIN(1,running,95.9%,500) IDLE(0,ready,0.1%,29) USBD(3,blocked,0.0%,149), total 100.0% Owned mutexes: HTTP(MAIN) === Platform === Last reset 00:51:27 ago, cause: software Last software reset at 2025-04-01 13:56, reason: User, Platform spinning, available RAM 85548, slot 2 Software reset code 0x2000 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x00400000 BFAR 0x00000000 SP 0x00000000 Task SBC Freestk 0 n/a === Storage === Free file entries: 20 SD card 0 not detected, interface speed: 37.5MBytes/sec SD card longest read time 0.0ms, write time 0.0ms, max retries 0 === Move === Segments created 893, maxWait 1145489ms, bed comp in use: mesh, height map offset 0.000, hiccups added 0/0 (0.00/22.42ms), max steps late 0, ebfmin 0.00, ebfmax 0.00 Pos req/act/dcf: 98537.00/98253/0.34 62047.00/62132/-0.86 2388.00/2389/-0.87 Next step interrupt due in 142 ticks, disabled Driver 0: standstill, SG min n/a, mspos 8, reads 15179, writes 22 timeouts 1 Driver 1: standstill, SG min n/a, mspos 8, reads 15179, writes 22 timeouts 1 Driver 2: standstill, SG min n/a, mspos 8, reads 15179, writes 22 timeouts 1 Driver 3: standstill, SG min n/a, mspos 8, reads 15179, writes 22 timeouts 1 Driver 4: standstill, SG min n/a, mspos 8, reads 15179, writes 22 timeouts 1 Driver 5: standstill, SG min n/a, mspos 8, reads 15179, writes 22 timeouts 1 Phase step loop runtime (us): min=0, max=46, frequency (Hz): min=205, max=10000 === DDARing 0 === Scheduled moves 4906, completed 4846, LaErrors 0, Underruns [0, 0, 0] Segments left 10, axes/extruders owned 0x80000007, drives owned 0x80000007 Code queue is empty === DDARing 1 === Scheduled moves 0, completed 0, LaErrors 0, Underruns [0, 0, 0] Segments left 0, axes/extruders owned 0x00000000, drives owned 0x00000000 Code queue is empty === Heat === Bed heaters -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1, chamber heaters 2 -1 -1 -1 -1 -1 -1 -1, ordering errs 0 === GCodes === Movement locks held by null, null HTTP* is doing "M122" in state(s) 0 Telnet is idle in state(s) 0 File* is idle in state(s) 3 USB is idle in state(s) 0 Aux is idle in state(s) 0 Trigger* is idle in state(s) 0 Queue* is idle in state(s) 0 LCD is idle in state(s) 0 SBC is idle in state(s) 0 Daemon is idle in state(s) 0 Aux2 is idle in state(s) 0 Autopause is idle in state(s) 0 File2 is idle in state(s) 0 Queue2 is idle in state(s) 0 === Filament sensors === Driver 31: no filament === CAN === Messages queued 30786, received 201368, lost 0, ignored 0, errs 0, boc 0 Longest wait 2ms for reply type 6013, peak Tx sync delay 386, free buffers 50 (min 46), ts 14635/14634/0 Tx timeouts 0,0,0,0,0,0 === SBC interface === Transfer state: 5, failed transfers: 0, checksum errors: 0 RX/TX seq numbers: 53220/53220 SPI underruns 0, overruns 0 State: 5, disconnects: 0, timeouts: 0 total, 0 by SBC, IAP RAM available 0x27a7c Buffer RX/TX: 864/2072-0, open files: 0 === Duet Control Server === Duet Control Server version 3.6.0-rc.2 (2025-03-31 10:50:27, 32-bit) HTTP+Executed: > Executing M122 File 0:/gcodes/LARGE SOFIA LAMPSHADE.gcode is selected, processing File: Buffered code: G3 X595.405 Y624.085 I-4.314 J1.866 E59.03433 Buffered code: G1 X595.555 Y625.451 E61.65082 Buffered code: G1 X595.363 Y626.871 E64.3791 Buffered code: G1 X595.253 Y627.261 E65.15063 Buffered code: G1 X594.762 Y628.389 E67.49298 Buffered code: G1 X594.557 Y628.731 E68.25217 Buffered code: G1 X593.692 Y629.799 E70.86893 Buffered code: G1 X530.615 Y691.023 E238.23745 Buffered code: G1 X529.101 Y692.304 E242.01349 Buffered code: G1 X527.47 Y693.353 E245.70575 Buffered code: G1 X525.685 Y694.194 E249.46271 Buffered code: G1 X523.985 Y694.745 E252.86527 Buffered code: G1 X522.022 Y695.116 E256.66898 Buffered code: G1 X520.059 Y695.221 E260.41187 Buffered code: G1 X518.125 Y695.07 E264.1054 Buffered code: G1 X516.185 Y694.66 E267.88074 Buffered code: G1 X444.689 Y674.356 E409.39167 Buffered code: G3 X442.260 Y671.078 I0.979 J-3.264 E417.70323 Buffered code: G1 F1290.186 Buffered code: G1 X442.218 Y670.833 E418.18384 Buffered code: G1 F1270.827 Buffered code: G1 X442.176 Y670.589 E418.66983 Buffered code: G1 F1252.039 Buffered code: G1 X442.134 Y670.344 E419.16508 Buffered code: G1 F1234.906 Buffered code: G1 X442.104 Y670.24 E419.38373 Buffered code: G1 F1218.236 Buffered codes: 1248 bytes total Code buffer space: 2024 Configured SPI speed: 8000000Hz, TfrRdy pin glitches: 0 Full transfers per second: 38.54, max time between full transfers: 362.2ms, max pin wait times: 73.7ms/16.9ms Codes per second: 1.65 Maximum length of RX/TX data transfers: 4604/1352 -

[3.6.0-rc.2] Code 3 move errorposted in Beta Firmware

I got the following error 15min into a printjob

Error: Code 3 move error: new: start=966631163 overlap=951 time now=966595179, existing: s=966587720 t=44394 d=1.24 u=2.7822e-5 a=0.0000e+0 f=08M122 === Diagnostics === RepRapFirmware for Duet 3 MB6HC version 3.6.0-rc.2 (2025-03-31 12:17:13) running on Duet 3 MB6HC v1.01 (SBC mode) Board ID: 0JD2M-999AL-D25S4-7J1D2-3SJ6K-T51V3 Used output buffers: 1 of 40 (18 max) Error in macro line 101 while starting up: in file macro line 101: M591: Switch-type filament monitor must be connected to same CAN board as extruder driver or to main board === RTOS === Static ram: 137420 Dynamic ram: 98656 of which 16 recycled Never used RAM 85548, free system stack 150 words Tasks: LASER(5,nWait 7,0.0%,167) SBC(2,nWait 7,0.9%,801) HEAT(3,nWait 6,0.0%,365) TMC(4,nWait 6,3.0%,375) CanReceiv(6,nWait 1,0.1%,770) CanSender(5,nWait 7,0.0%,327) CanClock(7,delaying,0.0%,352) MAIN(1,running,95.6%,500) IDLE(0,ready,0.3%,29) USBD(3,blocked,0.0%,149), total 99.9% Owned mutexes: HTTP(MAIN) === Platform === Last reset 00:21:56 ago, cause: power up Last software reset at 2025-04-01 13:22, reason: MemoryProtectionFault mmarValid daccViol, Platform spinning, available RAM 108732, slot 1 Software reset code 0x0160 HFSR 0x00000000 CFSR 0x00000082 ICSR 0x00400804 BFAR 0x00000000 SP 0x20415c18 Task MAIN Freestk 2282 ok Stack: 00000000 40826fe0 20412118 00000001 003ffff0 0049b499 0049b498 21070200 0049b499 20432f84 00000000 20432f84 00000000 204252a0 a5a5a5a5 204262a0 20420b94 00486a7b 20426390 00003466 00000001 00000184 00000065 00412ea9 00000000 00000000 003ffff0 === Storage === Free file entries: 20 SD card 0 not detected, interface speed: 37.5MBytes/sec SD card longest read time 0.0ms, write time 0.0ms, max retries 0 === Move === Segments created 934, maxWait 128061ms, bed comp in use: mesh, height map offset 0.000, hiccups added 0/0 (0.00/20.52ms), max steps late 0, ebfmin 0.00, ebfmax 0.00 Pos req/act/dcf: 91326.00/91430/-0.83 63682.00/63354/0.28 1788.00/1785/0.41 Next step interrupt due in 203 ticks, disabled Driver 0: standstill, SG min n/a, mspos 8, reads 11665, writes 22 timeouts 1 Driver 1: standstill, SG min n/a, mspos 8, reads 11665, writes 22 timeouts 1 Driver 2: standstill, SG min n/a, mspos 8, reads 11665, writes 22 timeouts 1 Driver 3: standstill, SG min n/a, mspos 8, reads 11665, writes 22 timeouts 1 Driver 4: standstill, SG min n/a, mspos 8, reads 11665, writes 22 timeouts 1 Driver 5: standstill, SG min n/a, mspos 8, reads 11665, writes 22 timeouts 1 Phase step loop runtime (us): min=0, max=60, frequency (Hz): min=236, max=10000 === DDARing 0 === Scheduled moves 3922, completed 3885, LaErrors 0, Underruns [0, 0, 0] Segments left 1, axes/extruders owned 0x80000007, drives owned 0x80000007 Code queue is empty === DDARing 1 === Scheduled moves 0, completed 0, LaErrors 0, Underruns [0, 0, 0] Segments left 0, axes/extruders owned 0x00000000, drives owned 0x00000000 Code queue is empty === Heat === Bed heaters -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1, chamber heaters 2 -1 -1 -1 -1 -1 -1 -1, ordering errs 0 === GCodes === Movement locks held by null, null HTTP* is doing "M122" in state(s) 0 Telnet is idle in state(s) 0 File* is idle in state(s) 3 USB is idle in state(s) 0 Aux is idle in state(s) 0 Trigger* is idle in state(s) 0 Queue* is idle in state(s) 0 LCD is idle in state(s) 0 SBC is idle in state(s) 0 Daemon is idle in state(s) 0 Aux2 is idle in state(s) 0 Autopause is idle in state(s) 0 File2 is idle in state(s) 0 Queue2 is idle in state(s) 0 === Filament sensors === Driver 31: no filament === CAN === Messages queued 19452, received 86251, lost 0, ignored 0, errs 0, boc 0 Longest wait 4ms for reply type 6061, peak Tx sync delay 384, free buffers 50 (min 46), ts 6241/6240/0 Tx timeouts 0,0,0,0,0,0 === SBC interface === Transfer state: 5, failed transfers: 0, checksum errors: 0 RX/TX seq numbers: 50065/50065 SPI underruns 0, overruns 0 State: 5, disconnects: 0, timeouts: 0 total, 0 by SBC, IAP RAM available 0x27a7c Buffer RX/TX: 1600/2632-0, open files: 0 === Duet Control Server === Duet Control Server version 3.6.0-rc.2 (2025-03-31 10:50:27, 32-bit) HTTP+Executed: > Executing M122 File 0:/gcodes/LARGE SOFIA LAMPSHADE.gcode is selected, processing File: Buffered code: G1 X495.945 Y664.02 E358.16503 Buffered code: G1 X495.564 Y664.136 E358.92333 Buffered code: G1 X494.023 Y664.389 E361.89667 Buffered code: G3 X493.237 Y664.311 I-0.249 J-1.495 E363.41372 Buffered code: G1 X491.775 Y663.761 E366.38782 Buffered code: G1 X491.424 Y663.573 E367.14595 Buffered code: G1 X457.275 Y639.076 E447.1649 Buffered code: G3 X456.100 Y635.169 I2.028 J-2.740 E455.47636 Buffered code: G1 F1290.183 Buffered code: G1 X456.143 Y634.924 E455.9573 Buffered code: G1 F1270.82 Buffered code: G1 X456.187 Y634.68 E456.44398 Buffered code: G1 F1252.029 Buffered code: G1 X456.23 Y634.436 E456.93761 Buffered code: G1 F1234.896 Buffered code: G1 X456.237 Y634.328 E457.15623 Buffered code: G1 F1218.226 Buffered code: G1 X456.245 Y634.22 E457.37798 Buffered code: G1 F1201.999 Buffered code: G1 X456.252 Y634.112 E457.60258 Buffered code: G1 F1186.199 Buffered code: G1 X456.259 Y634.004 E457.83017 Buffered code: G1 F1170.809 Buffered code: G1 X456.266 Y633.896 E458.06076 Buffered codes: 1056 bytes total Code buffer space: 1600 Configured SPI speed: 8000000Hz, TfrRdy pin glitches: 1 Full transfers per second: 24.81, max time between full transfers: 225.7ms, max pin wait times: 58.0ms/7.7ms Codes per second: 2.09 Maximum length of RX/TX data transfers: 4604/1092config.g

; Configuration file for Duet 3 MB 6HC (firmware version 3.3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.3.15 on Fri Dec 09 2022 19:49:12 GMT+0100 (Mitteleuropäische Normalzeit) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Duet 3" ; set printer name ;/// Global variables /// global minPrintX=0 global maxPrintX=950 global minPrintY=0 global maxPrintY=1200 ; Wait a moment for the CAN expansion boards to start G4 S1 M80 C"pson" ; allocates the pin and sets the pin in the power on state. ; Network ; Drives M569 P123.0 S1 R1 T5 ; physical drive 121.0 goes forwards M569 P124.0 S0 R1 T5 ; physical drive 122.0 goes forwards M569 P125.0 S0 R1 T5 ; physical drive 123.0 goes forwards M569 P10.0 S1 D2 ; driver 0.4 goes backwards (Extruder) M569 P1.0 S1 D2 ; Closed-Loop Drivers ;M569.1 P10.0 T3 E1000:100 R100 I2000 D0.1 V0 A0 ; Extruder M584 Y123.0 X124.0 Z125.0 E1.0 ; set drive mapping M350 X1 Y1 Z1 E16 I0 ; configure microstepping without interpolation M92 X193.05 Y100 Z800.00 E490 ; set steps per mm M906 E2500 ; set motor currents M201 X500 Y500 Z250 E3000 ; set maximum accelerations M203 X24000 Y24000 Z3000 E6000 ; set maximum speeds (mm/min) M205 X8 Y8 Z2 E10 ; M205 X5 Y5 Z2 E3 P0 ; set jerk;M566 X125 Y125 Z60 P0 ;set jerk M204 P250 T500 ; set printing and travel acceleration M84 S30 ; Set idle timeout ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X960 Y1500 Z1005 S0 ; set axis maxima ; Endstops M574 X1 S1 P"1.io1.in" ; configure switch-type (e.g. microswitch) endstop for low end on X via pin 1.io1.in M574 Y1 S1 P"0.io0.in" ; configure switch-type (e.g. microswitch) endstop for low end on Y via pin io2.in M574 Z2 S1 P"1.io0.in" ; configure switch-type (e.g. microswitch) endstop for high end on Z via pin io3.in ; Z-Probe M558 P8 C"1.io5.in" H5 S0.03 A5 R0.5 F300 T12000 ; set Z probe type to switch and the dive height + speeds G31 P1000 X-74 Y+17 Z0.8 ; set Z probe trigger value, offset and trigger height M557 X0:1000 Y0:1500 S200 ; define mesh grid ; Sensors M308 S0 P"1.temp0" Y"pt1000" A"Heizzohne 1" M308 S1 P"1.temp1" Y"pt1000" A"Heizzohne 2" M308 S2 P"1.temp2" Y"pt1000" A"Einzug" M308 S3 P"2.temp0" Y"thermistor" A"Gebläse" T100000 B3950 C7.06e-8 M308 S4 P"2.temp1" Y"thermistor" A"Luftheizung" T100000 B4725 C7.06e-8 M308 S5 P"2.temp2" Y"thermistor" A"Trockenluft" T100000 B4725 C7.06e-8 ; Heaters M950 H0 C"1.out0" T0 ; create nozzle heater output on out0 and map it to sensor 0 M307 H0 R1.120 K0.193:0.000 D10.84 E1.35 S1.00 B0 V23.0 M143 H0 S300 ; set temperature limit for heater 0 to 280C M950 H1 C"1.out1" T1 ; create nozzle heater output on out1 and map it to sensor 0 M307 H1 R1.120 K0.193:0.000 D10.84 E1.35 S1.00 B0 V23.0 M143 H1 S300 ; set temperature limit for heater 0 to 280C M950 H2 C"2.out2" T4 A"Luftheizung" ; create chamber heater output on out2 and map it to sensor 2 M307 H2 R2.598 K2.549:0.000 D3.91 E1.35 S1.00 B0 ; disable bang-bang mode for the chamber heater and set PWM limit M141 H2 ; map chamber to heater 2 M143 H2 S120 ; set temperature limit for heater 2 to 100C ; Fans M950 F0 C"1.out6" Q10000 M106 P0 H2 S0 B1 L0.5 T50:60 C"Extruder Cooling Fan" M950 F1 C"1.out3+out3.tach" M106 P1 S0 H-1 C"Part Cooling Fan" M950 F2 C"!2.out3+out3.tach" K3 Q25000 ; create fan #2 M106 P2 S0 B0 H-1 L0.4 C"Granulat Trockner Gebläse" M950 F3 C"1.out7" ; create fan #2 M106 P3 S1 H-1 B1 C"Extruder Motor Kühlung" ; Tools M563 P0 S"Extruder" D0 H0:1 F0:1 ; define tool 0 G10 P0 X80 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C M309 P0 S0.002 ;set heat feed forward M207 S6 R1.8 F8000 Z3 ;M572 P0 S0.005 ; set extruder 0 pressure advance to 0.1 seconds ;Valves M950 P0 C"2.out0" A"Ventil-Trichter" M950 P1 C"2.out1" A"Ventil-Schlauch" ; Filament monitor ;M591 P3 C"1.io4.in" S0 D0 R90:110 L28.8 ; filament monitor connected to 1.io.3 , pin is high when filament is present M591 D0 P1 C"1.io2.in" S1 ; Material monitor connected to 1.io.0 , pin is low when material is present ; Input/Output M950 J0 C"!io3.in" ; Input 3 uses io3.in.iso pin M581 P0 S1 T2 R0 ; run trigger2.g when io.3.in goes high M581 P0 S0 T3 R0 ; run trigger3.g when io.3.in goes low ; Custom settings are not defined T0 ; /// Input Shaping /// ;M955 P20.0 I45 ; ACC Z+ -> X+ Axis, ACC X+-> Y- Axis ; configure accelerometer M593 P"EI3" S0.05 F8.7 M569 P10.0 S1 D4 ; Miscellaneous M501 ; load saved parameters from non-volatile memory ;M595 P120 ;Set movement queue length -

RE: Broken documentantion links for Bookworm DuetPi 64-bit imagesposted in Documentation

Strange indeed, but it seems to be limited to Brave Browser. I have tried it again with Firefox where it works fine.

-

Broken documentantion links for Bookworm DuetPi 64-bit imagesposted in Documentation

The Bookworm DuetPi 64-bit images links in the section for the SBC-Setup are not working.

The links for the 32-bit images are working fine. -

[3.6.0-beta.4] H parameter in new M558.3 does nothingposted in Beta Firmware

I had the chance to test the new touch mode for analog Z probes. After a little trial and error, I got it working reliably enough. Unfortunately, the H parameter for Nozzle height to be assumed when touch is detected doesn't do anything in my case. I started with an H-parameter of zero until I got the probe triggering repeatably. When doing an G30 the nozzle height is alsways about 0.3mm too low no matter what H-parameter I use.

-

RE: Duet SZP nozzle probing like beacon contact?posted in Duet Hardware and wiring

I second this! The simplest way to determine when the nozzle is touching the bed, is to measure when the nozzle touches the bed.

I recon this feature could be used for Delta calibration since it requires a nozzle contact probe. -

RE: RepRapFirmware 3.6.0-alpha.4+3 available for testingposted in Beta Firmware

@dc42 I just had the same error as reported by @balajiramani . In my case, the error occurred during the first layer of a print job.

=== Diagnostics === RepRapFirmware for Duet 3 MB6HC version 3.6.0-alpha.5+1 (2024-08-31 17:51:17) running on Duet 3 MB6HC v1.01 (SBC mode) Board ID: 0JD2M-999AL-D25S4-7J1D2-3SJ6K-T51V3 Used output buffers: 1 of 40 (18 max) === RTOS === Static ram: 135136 Dynamic ram: 96472 of which 0 recycled Never used RAM 68768, free system stack 198 words Tasks: SBC(2,ready,0.8%,796) HEAT(3,nWait 6,0.0%,369) Move(4,nWait 6,0.0%,333) TMC(4,nWait 6,2.8%,353) CanReceiv(6,nWait 1,0.1%,794) CanSender(5,nWait 7,0.0%,334) CanClock(7,delaying,0.0%,353) MAIN(2,running,93.9%,440) IDLE(0,ready,2.4%,29), total 100.0% Owned mutexes: HTTP(MAIN) === Platform === Last reset 00:00:37 ago, cause: software Last software reset at 2024-09-18 18:45, reason: User, Expansion spinning, available RAM 65064, slot 0 Software reset code 0x6012 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x00400000 BFAR 0x00000000 SP 0x00000000 Task SBC Freestk 0 n/a Error status: 0x00 MCU temperature: min 33.9, current 34.3, max 34.5 Supply voltage: min 22.7, current 23.5, max 23.6, under voltage events: 0, over voltage events: 0, power good: yes 12V rail voltage: min 12.1, current 12.1, max 12.1, under voltage events: 0 Heap OK, handles allocated/used 99/4, heap memory allocated/used/recyclable 2048/88/40, gc cycles 0 Events: 0 queued, 0 completed Date/time: 2024-09-18 18:46:21 Slowest loop: 25.07ms; fastest: 0.07ms === Storage === Free file entries: 20 SD card 0 not detected, interface speed: 37.5MBytes/sec SD card longest read time 0.0ms, write time 0.0ms, max retries 0 === Move === Segments created 0, maxWait 0ms, bed comp in use: none, height map offset 0.000, hiccups added 0 (0.00/0.00ms), max steps late 0, ebfmin 0.00, ebfmax 0.00 Pos req/act/dcf: 0.00/0/0.00 0.00/0/0.00 0.00/0/0.00 next step interrupt due in 297 ticks, disabled Driver 0: standstill, SG min n/a, mspos 8, reads 8720, writes 11 timeouts 0 Driver 1: standstill, SG min n/a, mspos 8, reads 8720, writes 11 timeouts 0 Driver 2: standstill, SG min n/a, mspos 8, reads 8720, writes 11 timeouts 0 Driver 3: standstill, SG min n/a, mspos 8, reads 8720, writes 11 timeouts 0 Driver 4: standstill, SG min n/a, mspos 8, reads 8720, writes 11 timeouts 0 Driver 5: standstill, SG min n/a, mspos 8, reads 8720, writes 11 timeouts 0 Phase step loop runtime (us): min=0, max=2, frequency (Hz): min=1913, max=2089 === DDARing 0 === Scheduled moves 0, completed 0, LaErrors 0, Underruns [0, 0, 0] === DDARing 1 === Scheduled moves 0, completed 0, LaErrors 0, Underruns [0, 0, 0] === Heat === Bed heaters -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1, chamber heaters -1 -1 -1 -1, ordering errs 0 Heater 0 is on, I-accum = 0.0 Heater 1 is on, I-accum = 0.0 === GCodes === Movement locks held by null, null HTTP* is doing "M122" in state(s) 0 Telnet is idle in state(s) 0 File is idle in state(s) 0 USB is idle in state(s) 0 Aux is idle in state(s) 0 Trigger* is idle in state(s) 0 Queue is idle in state(s) 0 LCD is idle in state(s) 0 SBC is idle in state(s) 0 Daemon is idle in state(s) 0 Aux2 is idle in state(s) 0 Autopause is idle in state(s) 0 File2 is idle in state(s) 0 Queue2 is idle in state(s) 0 Q0 segments left 0, axes/extruders owned 0x80000003 Code queue 0 is empty Q1 segments left 0, axes/extruders owned 0x0000000 Code queue 1 is empty === Filament sensors === check 0 clear 0 Extruder 0 sensor: no filament === CAN === Messages queued 252, received 2403, lost 0, ignored 0, errs 315, boc 0 Longest wait 55ms for reply type 6041, peak Tx sync delay 50472, free buffers 50 (min 49), ts 187/186/0 Tx timeouts 0,0,0,0,0,0 === SBC interface === Transfer state: 5, failed transfers: 0, checksum errors: 0 RX/TX seq numbers: 1854/1854 SPI underruns 0, overruns 0 State: 5, disconnects: 0, timeouts: 0 total, 0 by SBC, IAP RAM available 0x2858c Buffer RX/TX: 0/0-0, open files: 0 === Duet Control Server === Duet Control Server version 3.5.2 (2024-06-12 07:09:26, 32-bit) HTTP+Executed: > Executing M122 Code buffer space: 4096 Configured SPI speed: 8000000Hz, TfrRdy pin glitches: 0 Full transfers per second: 60.06, max time between full transfers: 125.2ms, max pin wait times: 33.5ms/14.1ms Codes per second: 2.94 Maximum length of RX/TX data transfers: 4476/1040 -

RE: RepRapFirmware 3.6.0-alpha.4+3 available for testingposted in Beta Firmware

I just tested 3.6.0-alpha.5+1 on our 5meter printer. The "homing jolt" on our CAN-connected Servo Drives is strong enough to make the servo drives go into fault mode

Reducing the homing speed by 50% did help, but it still produces a loud "clonk"

Reducing the homing speed by 50% did help, but it still produces a loud "clonk"Everything else is working as expected

Setup: Duet MB6HC+ 3xEXP1XD+ EXP3HCMy small printer is flawlessly printing since an on our under 3.6.0-alpha.5+1

Setup: Duet MB6HC+ 3xEXP1HCL+TOOL1RRfour screw bed tramming and mesh probing with the SZP seems to be working as expected, I only had to reduce the pressure advance value by 50%.

I have noticed some short movement pauses during printing, these were also present in RRF 3.5.2, maybe increasing the movement queue length can help here? -

Run external Stepper driver with Duet PWM signalposted in General Discussion

Since setting up a "Continuous rotational axis" is not yet supported by RRF, I thought about a workaround to get a continuous rotational axis that won't interfere with the rest of the movement system...

To recap:

I use a stepper motor peristaltic pump on my CNC-Router to control the coolant flow while milling aluminum parts. My original Idea was to set up an extra Axis on the duet to control the stepper motor of the peristaltic pump. Right now this doesn't work since there is no option to run an axis continuously and progressing the axis in a loop would block other movements.Here is my Idea:

So I need a stepper motor that can basically be controlled like a Fan in DWC. So why not use one of the duet's PWM outputs to generate the step pulses for an external Stepper motor Driver? -

RE: steps per mmposted in CNC

Please check the following on the software side:

- The correct steps/mm are set for your ballscrews pitch in config.g

- If you had backlash compensation enabled for your old leadscrews, disable it for now. Ballscrews should have relatively low backlash.

- You have set the correct tool diameter in your program

- Confirm the diameter of the physical tool

Since the holes are spaced correctly, it is unlikely that you are loosing steps. But you can check the following to make sure it is not a mechanical issue:

-

See if the ballscrews are securely coupled to the motors

-

See if the ballscrew bearings have any play or are loose

-

Reduce your cutting feed and reduce your depth of cut to see if high feed speeds are bending your machine

-

Check if your motors are loosing steps: Position the spindle at a point outside your working area. Get something to mark this position. A dial indicator would be optimal. Mount the dial indicator so that it is stationary on your machine. Set the spindle against the dial indicator in die direction of the X or Y-Axis. Zero the dial indicator and note down the machine position. Then run your Program. When the Program is finished, move the spindle to the previously noted position. If the dial indicator is still close to zero, there should be no lost steps.

-

RE: [3.5.0-rc3+] M108 (cancel heating) is not working.posted in Beta Firmware

@droftarts said in [3.5.0-rc3+] M108 (cancel heating) is not working.:

If you run M109 et al in a macro, cancel it by sending M108 from the console in DWC; I think that shouldn’t be blocked.

Yes, that works. Thank you very much for clearing that up!

-

RE: [3.5.0-rc3+] M108 (cancel heating) is not working.posted in Beta Firmware

Okay now I am confused...

From the M108 description I understood that the purpose of this command is to break out of an M109, M116, M190 or M191 wait-for-temperature loop.When I send an M190 S60 over the console followed by an M108, the input channel is blocked until the bed reaches its set temperature of 60°.

The same goes for macros:

;M108 test echo "setting bed temp!" M140 S60 ; set bed temp G4 S1 echo "sending M108" M108Max

-

[3.5.0-rc3+] M108 (cancel heating) is not working.posted in Beta Firmware

I just noticed that the M108 command is not working... at least it does not work in RRF 3.5.0-rc3+. Unfortunately, I have no system running a stable version for testing if the problem is limited to the beta.

-

RE: Duet 3 Roto Toolboard peak current limit on high current outputposted in Duet Hardware and wiring

Thank you very much for your feedback! Just to be on the side of caution. The Roto Toolboard should be ok with the 115W nominal power of the pheatus rapido?

-

Duet 3 Roto Toolboard peak current limit on high current outputposted in Duet Hardware and wiring

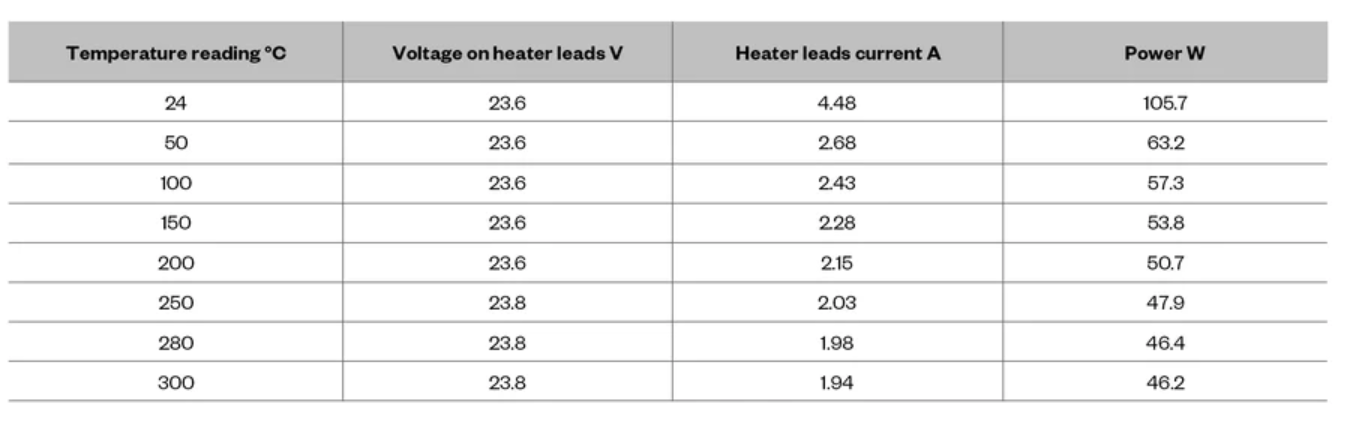

According to the docs the current limit on the high current output of the Revo toolboard is 3.4A (80W @ 24V).

While this is totally fine for the intended use of the Roto tool board with the E3D Revo system (max 60W), most high flow hotends are well above 80W or even around 115W.

Since the full output current is only drawn during the first few seconds during heatup, I was wondering if the revo toolboard might be capable of handling currents higher than 80W for a short amount of time without damaging the high current mosfet?I found this table for the phaetus rapido @24V. It illustrates the drop in current at different temperatures quite well: