That solved it thanks

Posts made by kickjaw

-

Whinning noise from heated bedposted in Duet Hardware and wiring

Hello,

I am trying to use a prusa Mk3 heated bed with the duet wifi. It works but I get this awful ringing/whining noise when it goes about 50C or so.

; General preferences G90 ; Set absolute coordinates M83 ; Set relative extruder moves M550 P"Prusa Duet" ; Set printer name ; Network M551 P"3D" ; Set password M552 S1 ; Enable network M586 P0 S1 ; Enable HTTP M586 P1 S1 ; Enable FTP M586 P2 S0 ; Disabled Telnet M575 P1 S1 B38400 ; Enable support for PanelDue ; Drive Mappings S0 = backwards, S1 = forwards M569 P0 S1 ; Drive 0 goes forwards: X Axis M569 P1 S0 ; Drive 1 goes forwards: Y Axis M569 P2 S0 ; Drive 2 goes forwards: Z Axis Left M569 P3 S1 ; Drive 3 goes backward: E Axis M569 P4 S0 ; Drive 4 goes forwards: Z Axis Right (using E1) M584 X0 Y1 Z2:4 E3 ; Motor Configuration ; M350 X16 Y16 Z16 I1 ; Set X, Y, and Z Microstepping with interpolation M350 E16 I0 ; Set Extruder Microstepping without interpolation M92 X100.00 Y100.00 Z400.00 E422 ; Steps per mm M566 X600.00 Y600.00 Z24.00 E300.00 P1 ; Set maximum instantaneous speed changes (mm/min) M203 X15000.00 Y15000.00 Z900.00 E2000.00 ; Set maximum speeds (mm/min) M201 X4000.00 Y4000.00 Z1000.00 E5000.00 ; Set accelerations (mm/s^2) M906 X750.00 Y850.00 Z750.00 E750.00 I10. ; Set motor currents (mA) and motor idle factor in percent M84 S1000 ; Set idle timeout before shifitng to idle-current ; Motor remapping for dual Z and axis Limits ; Set two Z motors connected to driver outputs Z and E1 M671 X-37:287 Y0:0 S10 ; Leadscrew at left connected to Z, leadscrew at right connected to E1 ; Set bed dimensions M208 X-13:240 Y-14:215 Z-0.1:205 ; X carriage moves from 0 to 250, Y bed goes from 0 to 210 M564 H0 ; Allow unhomed movement ; Endstops for each Axis M574 X1 S3 ; Set endstops controlled by the motor load detection M574 Y1 S3 ; Set endstops controlled by the motor load detection ; Stallgaurd Sensitivity M98 P"current-sense-homing.g" ; Set the current and sensitivity for normal routine, per the macro ; Z-Probe Settings for BLTouch M558 P9 C"^zprobe.in" H5 F200 T3000 G31 P1000 X58 Y-10 Z3.04 M950 S0 C"exp.heater3" M574 Z1 S2 M557 X-8:190 Y0:200 P8 ; Heatbed Heaters and Thermistor Bed M308 S0 P"bed_temp" Y"thermistor" A"Build Plate" T100000 C7.06e-8 R4700 ; Set thermistor + ADC parameters for heater 0 Bed M950 H0 C"bedheat" T0 Q40000 ; Creates Bed Heater frequency to try to stop buzzing M307 H0 A91.5 C264.0 D10.2 S1.00 V24.0 B0 ; Bed PID Calibration @ 75c - updated 11AUG2020 M140 H0 ; Bed uses Heater 0 M143 H0 S120 ; Set temperature limit for heater 0 to 120C Bed ; HotEnd Heaters and Thermistor HotEnd ; !!! Use this line for stock thermisotr: M308 S1 P"e0_temp" Y"thermistor" A"Nozzle" T100000 B4725 R4700 ; Set thermistor + ADC parameters for heater 1 HotEnd M308 S1 P"e_0temp" Y"thermistor" T100000 B4388 C7.06e-8 ; Set thermistor + ADC parameters for heater 1 HotEnd M950 H1 C"e0heat" T1 ; Create HotEnd Heater M307 H1 A311.0 C130.0 D4.3 S1.00 V24.1 B0 ; Hotend PID Calibration @ 240c - updated 09AUG2020 M143 H1 S300 ; Set temperature limit for heater 1 to 285C HotEnd M302 S190 R190 ; Allow cold extrudes, S-Minimum extrusion temperature, R-Minimum retraction temperature ; Fans M950 F1 C"Fan1" Q25000 ; Creates HOTEND Fan ; FAN 40X10MM 24VDC - 6.0 CFM (0.168m³/min). ; Digi-Key: G4010L24B-RSR M106 P1 T45 S255 H1 ; HOTEND Fan Settings M950 F0 C"Fan0" Q25000 ; Creates PARTS COOLING FAN ; BLOWER 50X15MM 24VDC - 5.0 CFM (0.140m³/min) ; Digi-Key: B5015E24B-BSR M106 P0 H-1 ; Set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned off PARTS COOLING FAN M950 F2 C"Fan2" Q25000 ; Creates PARTS COOLING FAN ; BLOWER 50X15MM 24VDC - 5.0 CFM (0.140m³/min) ; Digi-Key: B5015E24B-BSR M106 P2 H-1 ; Set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned off PARTS COOLING FAN ; The following lines are for auto case fan control, attached to 'fan2' header on duet board ;M308 S4 Y"drivers" A"TMC2660" ; Case fan - configure sensor 2 as temperature warning and overheat flags on the TMC2660 on Duet ; !!! Reports 0C when there is no warning, 100C if any driver reports over-temperature ; !!! warning , and 150C if any driver reports over-temperature shutdown ;M308 S3 Y"mcu-temp" A"Duet2Wifi" ; Case fan - configure sensor 3 as thermistor on pin e1temp for left stepper ;M950 F2 C"fan2" Q100 ; Case fan - create fan 2 on pin fan2 and set its frequency ;M106 P2 H4:3 L0.15 X1 B0.3 T40:70 ; Case fan - set fan 2 value ;M912 P0 S-5.5 ; MCU Temp calibration - default reads 5.5c higher than ambient ; Tools M563 P0 D0 H1 F0:2 ; Define tool 0 G10 P0 X0 Y0 Z0 ; Set tool 0 axis offsets G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C T0 ; Set Tool 0 active ; Relase X, Y, and E axis M18 XYZE ; Unlock the X, Y, and E axis M501 M302 P1 -

RE: Duet Wifi Crashes on Gcode startposted in General Discussion

@dc42 It crashed sometime right after the wait for temperatures. I will re run and get the M122

-

RE: Duet Wifi Crashes on Gcode startposted in General Discussion

@t3p3tony I have upgraded to 3.4.0 b6 and I tired running a different job with a lot of objects again and it still crashed. this on had 100. is there still a limit to how many objects can be on the build plate? I reduced it to 50 and it seems to be running fine.

-

RE: Duet Wifi Crashes on Gcode startposted in General Discussion

Thank you, is there a way to delete the labeling so it doesn't crash? I will upgrade to the beta either way.

-

RE: Duet Wifi Crashes on Gcode startposted in General Discussion

huh, no idea where that came from but that was not the issue as I ran a print with that same startup code just after this one with different models on the print surface.

-

RE: Duet Wifi Crashes on Gcode startposted in General Discussion

The full file is too large to upload. Here is the first 500 lines.

; generated by SuperSlicer 2.3.57 on 2021-11-30 at 20:29:15 UTC ; ; external perimeters extrusion width = 0.40mm ; perimeters extrusion width = 0.40mm ; infill extrusion width = 0.40mm ; solid infill extrusion width = 0.40mm ; top infill extrusion width = 0.40mm ; first layer extrusion width = 0.40mm ; object:{"name":"3mm_Top_Corner_Side_x2","id":"3mm_Top_Corner_Side_x2.stl id:0 copy 0","object_center":[29.788802,84.415552,0.000000],"boundingbox_center":[29.788802,84.415552,2.000000],"boundingbox_size":[31.500000,62.999992,4.000000]} ; object:{"name":"3mm_Top_Corner_Side_x2","id":"3mm_Top_Corner_Side_x2.stl id:0 copy 1","object_center":[28.132413,170.536152,0.000000],"boundingbox_center":[28.132413,170.536152,2.000000],"boundingbox_size":[31.500000,62.999992,4.000000]} ; object:{"name":"3mm_Top_Corner_Side_mirror_x1","id":"3mm_Top_Corner_Side_mirror_x1.stl id:1 copy 0","object_center":[67.866497,110.488844,0.000000],"boundingbox_center":[67.866497,110.488844,2.000000],"boundingbox_size":[31.500000,63.000000,4.000000]} ; object:{"name":"3mm_Top_Corner_Rear_x1","id":"3mm_Top_Corner_Rear_x1.stl id:2 copy 0","object_center":[117.025614,138.012939,0.000000],"boundingbox_center":[117.025614,138.012939,2.000000],"boundingbox_size":[31.500000,63.000000,4.000000]} ; object:{"name":"3mm_Top_Corner_Front_x1","id":"3mm_Top_Corner_Front_x1.stl id:3 copy 0","object_center":[50.979237,45.670760,0.000000],"boundingbox_center":[50.979237,45.670760,2.499999],"boundingbox_size":[31.500000,63.000000,4.999998]} ; object:{"name":"3mm_Middle_Clip_x9","id":"3mm_Middle_Clip_x9.stl id:4 copy 0","object_center":[187.692802,124.878069,0.000000],"boundingbox_center":[187.692802,124.878069,2.000000],"boundingbox_size":[15.000000,24.999985,4.000000]} ; object:{"name":"3mm_Middle_Clip_x9","id":"3mm_Middle_Clip_x9.stl id:4 copy 1","object_center":[42.204249,158.786459,0.000000],"boundingbox_center":[42.204249,158.786459,2.000000],"boundingbox_size":[15.000000,24.999985,4.000000]} ; object:{"name":"3mm_Middle_Clip_x9","id":"3mm_Middle_Clip_x9.stl id:4 copy 2","object_center":[145.119568,186.317705,0.000000],"boundingbox_center":[145.119568,186.317705,2.000000],"boundingbox_size":[15.000000,24.999985,4.000000]} ; object:{"name":"3mm_Middle_Clip_x9","id":"3mm_Middle_Clip_x9.stl id:4 copy 3","object_center":[185.521711,161.668573,0.000000],"boundingbox_center":[185.521711,161.668573,2.000000],"boundingbox_size":[15.000000,24.999985,4.000000]} ; object:{"name":"3mm_Middle_Clip_x9","id":"3mm_Middle_Clip_x9.stl id:4 copy 4","object_center":[61.533888,187.642719,0.000000],"boundingbox_center":[61.533888,187.642719,2.000000],"boundingbox_size":[15.000000,24.999985,4.000000]} ; object:{"name":"3mm_Middle_Clip_x9","id":"3mm_Middle_Clip_x9.stl id:4 copy 5","object_center":[106.450401,188.605946,0.000000],"boundingbox_center":[106.450401,188.605946,2.000000],"boundingbox_size":[15.000000,24.999985,4.000000]} ; object:{"name":"3mm_Middle_Clip_x9","id":"3mm_Middle_Clip_x9.stl id:4 copy 6","object_center":[166.924231,186.289387,0.000000],"boundingbox_center":[166.924231,186.289387,2.000000],"boundingbox_size":[15.000000,24.999985,4.000000]} ; object:{"name":"3mm_Middle_Clip_x9","id":"3mm_Middle_Clip_x9.stl id:4 copy 7","object_center":[84.942116,188.481209,0.000000],"boundingbox_center":[84.942116,188.481209,2.000000],"boundingbox_size":[15.000000,24.999985,4.000000]} ; object:{"name":"3mm_Middle_Clip_x9","id":"3mm_Middle_Clip_x9.stl id:4 copy 8","object_center":[125.888863,187.750513,0.000000],"boundingbox_center":[125.888863,187.750513,2.000000],"boundingbox_size":[15.000000,24.999985,4.000000]} ; object:{"name":"3mm_Hinge_Top_B_x1","id":"3mm_Hinge_Top_B_x1.stl id:5 copy 0","object_center":[78.087966,137.623091,0.000000],"boundingbox_center":[78.087966,137.623091,2.499527],"boundingbox_size":[34.999893,63.000000,4.999053]} ; object:{"name":"3mm_Hinge_Top_A_x1","id":"3mm_Hinge_Top_A_x1.stl id:6 copy 0","object_center":[96.514356,46.238788,0.000000],"boundingbox_center":[96.514356,46.238788,2.500000],"boundingbox_size":[34.000000,63.000000,5.000000]} ; object:{"name":"3mm_Bottom_Corner_Side_x2","id":"3mm_Bottom_Corner_Side_x2.stl id:7 copy 0","object_center":[72.981858,58.882453,0.000000],"boundingbox_center":[72.981858,58.882453,1.999999],"boundingbox_size":[32.000004,30.000000,3.999998]} ; object:{"name":"3mm_Bottom_Corner_Side_x2","id":"3mm_Bottom_Corner_Side_x2.stl id:7 copy 1","object_center":[133.173338,42.691611,0.000000],"boundingbox_center":[133.173338,42.691611,1.999999],"boundingbox_size":[32.000004,30.000000,3.999998]} ; object:{"name":"3mm_Bottom_Corner_Side_mirror_x1","id":"3mm_Bottom_Corner_Side_mirror_x1.stl id:8 copy 0","object_center":[139.335727,150.853850,0.000000],"boundingbox_center":[139.335727,150.853850,1.999999],"boundingbox_size":[32.000000,30.000000,3.999998]} ; object:{"name":"3mm_Bottom_Corner_Rear_x1","id":"3mm_Bottom_Corner_Rear_x1.stl id:9 copy 0","object_center":[171.664548,43.478435,0.000000],"boundingbox_center":[171.664548,43.478435,2.500000],"boundingbox_size":[32.000000,30.000000,5.000000]} ; object:{"name":"3mm_Bottom_Corner_Rear_mirror_x1","id":"3mm_Bottom_Corner_Rear_mirror_x1.stl id:10 copy 0","object_center":[159.878283,75.155802,0.000000],"boundingbox_center":[159.878283,75.155802,2.500000],"boundingbox_size":[32.000004,30.000000,5.000000]} ; object:{"name":"3mm_Bottom_Corner_Front_x1","id":"3mm_Bottom_Corner_Front_x1.stl id:11 copy 0","object_center":[125.558664,75.043969,0.000000],"boundingbox_center":[125.558664,75.043969,2.500000],"boundingbox_size":[32.000000,30.000008,5.000000]} ; object:{"name":"Door_Handle_x1","id":"Door_Handle_x1.STL id:12 copy 0","object_center":[138.319742,92.961334,0.000000],"boundingbox_center":[138.319742,92.961334,5.000000],"boundingbox_size":[104.243851,25.499999,10.000000]} ; object:{"name":"Door_Latch_x2","id":"Door_Latch_x2.STL id:13 copy 0","object_center":[22.172634,30.515469,0.000000],"boundingbox_center":[22.172634,30.515469,4.500000],"boundingbox_size":[15.000000,18.000000,9.000000]} ; object:{"name":"Door_Latch_x2","id":"Door_Latch_x2.STL id:13 copy 1","object_center":[22.861942,127.589356,0.000000],"boundingbox_center":[22.861942,127.589356,4.500000],"boundingbox_size":[15.000000,18.000000,9.000000]} ; Total objects to print: 25 M486 T25 ; plater:{"center":[103.787608,108.103454,0.000000],"boundingbox_center":[103.787608,108.103454,5.000000],"boundingbox_size":[182.810389,187.865389,10.000000]} M73 P0 R302 ;TYPE:Custom M862.3 P "MK2.5" ; printer model check M862.1 P0.4 ; nozzle diameter check M115 U3.10.0 ; tell printer latest fw version G90 ; use absolute coordinates M83 ; extruder relative mode M104 S250 ; set extruder temp M140 S110 ; set bed temp M190 S110 ; wait for bed temp M109 S250 ; wait for extruder temp G28 W ; home all without mesh bed level G80 ; mesh bed leveling G1 Y-3.0 F1000.0 ; go outside print area G92 E0.0 G1 X60.0 E9.0 F1000.0 ; intro line G1 X100.0 E12.5 F1000.0 ; intro line G92 E0.0 M107 G21 ; set units to millimeters G90 ; use absolute coordinates M83 ; use relative distances for extrusion ;LAYER_CHANGE ;Z:0.2 ;HEIGHT:0.2 ;BEFORE_LAYER_CHANGE G92 E0.0 ;0.2 G1 E-0.8 F2100 G1 Z0.4 F10800 ;AFTER_LAYER_CHANGE ;0.2 M204 P1500 G1 X6.625 Y9.805 M204 P1000 G1 X13.249 Y19.61 G1 Z0.2 G1 E0.8 F2100 ;TYPE:Skirt ;WIDTH:0.4 G1 F1500 G1 X13.877 Y19.292 E0.01923 G1 X38.275 Y11.832 E0.69692 G1 X38.822 Y11.778 E0.01501 G1 X60.901 Y11.778 E0.60309 G1 X112.321 Y12.37 E1.4047 G1 X172.848 Y26.204 E1.69597 G1 X173.908 Y26.606 E0.03098 G1 X174.425 Y26.93 E0.01666 G1 X174.9 Y27.331 E0.01698 G1 X188.783 Y41.213 E0.53628 G1 X189.444 Y42.069 E0.02956 G1 X189.841 Y42.945 E0.02626 G1 X190.036 Y43.883 E0.02615 G1 X197.577 Y117.942 E2.03346 G1 X197.583 Y131.671 E0.37504 G1 X195.389 Y168.809 E1.01621 M73 P0 R301 G1 X195.133 Y169.886 E0.03024 G1 X194.591 Y170.901 E0.03144 G1 X175.86 Y195.696 E0.84883 G1 X171.669 Y199.928 E0.1627 G1 X170.799 Y200.589 E0.02985 G1 X169.818 Y201.008 E0.02915 G1 X168.861 Y201.173 E0.02651 G1 X108.161 Y203.498 E1.6593 G1 X38.08 Y204.429 E1.9145 G1 X14.966 Y204.429 E0.63139 G1 X14.227 Y204.328 E0.02037 G1 X13.534 Y204.04 E0.02049 G1 X12.939 Y203.584 E0.02049 G1 X12.481 Y202.989 E0.02049 G1 X12.19 Y202.29 E0.02072 G1 X12.09 Y201.542 E0.02061 G1 X11.78 Y37.724 E4.47485 G1 X11.78 Y23.256 E0.3952 G1 X12.056 Y21.302 E0.0539 G1 X12.31 Y20.646 E0.01923 G1 X12.716 Y20.07 E0.01923 G1 X13.204 Y19.649 E0.0176 M204 P1500 G1 X13.319 Y19.784 F10800 M204 P1000 G1 X13.435 Y19.919 G1 F1500 G1 X13.457 Y19.901 E0.00078 G1 X14.011 Y19.623 E0.01694 G1 X38.354 Y12.18 E0.69533 G1 X38.823 Y12.135 E0.01288 G1 X60.9 Y12.135 E0.60307 G1 X112.272 Y12.724 E1.40337 G1 X172.767 Y26.552 E1.6951 G1 X173.74 Y26.921 E0.02843 G1 X174.217 Y27.22 E0.01537 G1 X174.655 Y27.591 E0.01569 G1 X188.526 Y41.462 E0.53585 G1 X189.133 Y42.245 E0.02705 G1 X189.501 Y43.055 E0.02431 G1 X189.681 Y43.919 E0.0241 G1 X197.22 Y117.956 E2.03287 G1 X197.226 Y131.656 E0.37422 G1 X195.034 Y168.765 E1.01545 G1 X194.8 Y169.757 E0.02783 G1 X194.3 Y170.693 E0.02899 G1 X175.578 Y195.478 E0.84848 G1 X171.424 Y199.668 E0.16114 G1 X170.624 Y200.278 E0.0275 G1 X169.716 Y200.666 E0.02696 G1 X168.842 Y200.816 E0.02424 G1 X108.16 Y203.141 E1.65882 G1 X38.076 Y204.072 E1.91458 G1 X14.975 Y204.072 E0.63103 G1 X14.325 Y203.985 E0.0179 G1 X13.716 Y203.733 E0.018 G1 X13.193 Y203.333 E0.018 G1 X12.792 Y202.814 E0.0179 G1 X12.535 Y202.199 E0.01822 G1 X12.447 Y201.541 E0.01813 G1 X12.137 Y37.724 E4.47483 G1 X12.137 Y23.268 E0.39489 G1 X12.401 Y21.392 E0.05175 G1 X12.626 Y20.814 E0.01694 G1 X12.986 Y20.304 E0.01704 G1 X13.39 Y19.958 E0.01452 M204 P1500 G1 X13.505 Y20.093 F10800 M204 P1000 G1 X13.62 Y20.228 G1 F1500 G1 X13.659 Y20.195 E0.0014 G1 X14.142 Y19.956 E0.0147 G1 X38.428 Y12.529 E0.69374 G1 X60.9 Y12.492 E0.61384 G1 X112.229 Y13.078 E1.40218 G1 X172.683 Y26.899 E1.69397 G1 X173.569 Y27.234 E0.02589 G1 X174.41 Y27.851 E0.02849 G1 X188.271 Y41.711 E0.53543 G1 X188.824 Y42.424 E0.02467 G1 X189.161 Y43.165 E0.02223 G1 X189.326 Y43.958 E0.02214 G1 X196.863 Y117.975 E2.03229 G1 X196.869 Y131.64 E0.37328 G1 X194.68 Y168.723 E1.01471 G1 X194.467 Y169.629 E0.02542 G1 X194.009 Y170.485 E0.02653 G1 X175.295 Y195.26 E0.84812 G1 X171.177 Y199.41 E0.15972 G1 X170.445 Y199.969 E0.02516 G1 X169.615 Y200.323 E0.02464 G1 X168.826 Y200.46 E0.02187 G1 X108.154 Y202.784 E1.65853 M73 P0 R300 G1 X38.072 Y203.715 E1.91453 G1 X14.979 Y203.715 E0.63081 G1 X14.416 Y203.64 E0.01549 G1 X13.896 Y203.424 E0.0154 G1 X13.445 Y203.08 E0.01549 G1 X13.101 Y202.634 E0.0154 G1 X12.88 Y202.107 E0.01559 G1 X12.804 Y201.54 E0.01563 G1 X12.494 Y37.724 E4.47481 G1 X12.494 Y23.274 E0.39471 G1 X12.747 Y21.483 E0.04941 G1 X12.941 Y20.981 E0.0147 G1 X13.25 Y20.545 E0.01461 G1 X13.575 Y20.267 E0.01167 ; INIT printing object 3mm_Top_Corner_Side_x2.stl id:0 copy 0 ;WIPE_START G1 F8640 G1 X13.659 Y20.195 E-0.02566 G1 X14.142 Y19.956 E-0.12429 G1 X16.668 Y19.184 E-0.61004 ;WIPE_END G1 E-0.04 F2100 G1 Z1 F10800 ; printing object 3mm_Top_Corner_Side_x2.stl id:0 copy 0 M486 S0 M204 P1500 G1 X25.357 Y62.664 M204 P1000 G1 X37.14 Y105.061 G1 Z0.2 G1 E0.8 F2100 ;TYPE:Internal perimeter G1 F1800 G1 X36.851 Y105.152 E0.00828 G1 X36.571 Y105.268 E0.00828 G1 X36.302 Y105.408 E0.00828 G1 X36.047 Y105.571 E0.00827 G1 X35.807 Y105.755 E0.00828 G1 X35.583 Y105.96 E0.00828 G1 X35.379 Y106.183 E0.00827 G1 X35.194 Y106.424 E0.00828 G1 X35.031 Y106.679 E0.00828 G1 X34.892 Y106.948 E0.00827 G1 X34.776 Y107.228 E0.00828 G1 X34.684 Y107.517 E0.00827 G1 X34.619 Y107.813 E0.00828 G1 X34.579 Y108.113 E0.00828 G1 X34.566 Y108.416 E0.00828 G1 X34.579 Y108.718 E0.00828 G1 X34.619 Y109.019 E0.00828 G1 X34.684 Y109.314 E0.00828 G1 X34.776 Y109.603 E0.00828 G1 X34.892 Y109.883 E0.00828 G1 X35.031 Y110.152 E0.00827 G1 X35.194 Y110.407 E0.00828 G1 X35.379 Y110.648 E0.00828 G1 X35.583 Y110.871 E0.00827 G1 X35.807 Y111.076 E0.00828 G1 X36.047 Y111.26 E0.00828 G1 X36.302 Y111.423 E0.00828 G1 X36.571 Y111.563 E0.00828 G1 X36.851 Y111.679 E0.00828 G1 X37.14 Y111.77 E0.00827 G1 X37.436 Y111.835 E0.00827 G1 X37.736 Y111.875 E0.00828 G1 X38.039 Y111.888 E0.00827 G1 X38.341 Y111.875 E0.00828 G1 X38.642 Y111.835 E0.00828 G1 X38.938 Y111.77 E0.00827 G1 X39.226 Y111.679 E0.00828 G1 X39.506 Y111.563 E0.00828 G1 X39.775 Y111.423 E0.00828 G1 X40.031 Y111.26 E0.00828 G1 X40.271 Y111.076 E0.00828 G1 X40.494 Y110.871 E0.00828 G1 X40.699 Y110.648 E0.00827 G1 X40.883 Y110.407 E0.00828 G1 X41.046 Y110.152 E0.00828 G1 X41.186 Y109.883 E0.00827 G1 X41.302 Y109.603 E0.00828 G1 X41.393 Y109.314 E0.00828 G1 X41.459 Y109.019 E0.00828 G1 X41.498 Y108.718 E0.00828 G1 X41.511 Y108.416 E0.00827 G1 X41.498 Y108.113 E0.00827 G1 X41.459 Y107.813 E0.00828 G1 X41.393 Y107.517 E0.00827 G1 X41.302 Y107.228 E0.00828 G1 X41.186 Y106.948 E0.00828 G1 X41.046 Y106.679 E0.00827 G1 X40.883 Y106.424 E0.00828 G1 X40.699 Y106.183 E0.00828 G1 X40.494 Y105.96 E0.00827 G1 X40.271 Y105.755 E0.00828 G1 X40.031 Y105.571 E0.00828 G1 X39.775 Y105.408 E0.00827 G1 X39.506 Y105.268 E0.00827 G1 X39.227 Y105.152 E0.00828 G1 X38.938 Y105.061 E0.00828 G1 X38.642 Y104.996 E0.00827 G1 X38.341 Y104.956 E0.00828 G1 X38.039 Y104.943 E0.00828 G1 X37.736 Y104.956 E0.00828 G1 X37.436 Y104.996 E0.00828 G1 X37.199 Y105.048 E0.00664 M204 P1500 G1 X37.237 Y105.223 F10800 M204 P1000 G1 X37.276 Y105.397 G1 F1767.5471 G1 X37.233 Y105.406 E0.00121 G1 X36.973 Y105.488 E0.00742 G1 X36.722 Y105.592 E0.00742 G1 X36.481 Y105.718 E0.00742 G1 X36.252 Y105.864 E0.00742 G1 X36.036 Y106.029 E0.00742 G1 X35.836 Y106.213 E0.00742 G1 X35.652 Y106.413 E0.00742 G1 X35.487 Y106.629 E0.00742 G1 X35.341 Y106.858 E0.00742 G1 X35.215 Y107.099 E0.00742 G1 X35.111 Y107.35 E0.00742 G1 X35.03 Y107.609 E0.00742 G1 X34.971 Y107.875 E0.00742 G1 X34.935 Y108.144 E0.00742 G1 X34.924 Y108.416 E0.00742 G1 X34.935 Y108.687 E0.00742 G1 X34.971 Y108.957 E0.00742 G1 X35.03 Y109.222 E0.00742 G1 X35.111 Y109.481 E0.00742 G1 X35.215 Y109.732 E0.00742 G1 X35.341 Y109.973 E0.00742 G1 X35.487 Y110.202 E0.00742 G1 X35.652 Y110.418 E0.00742 G1 X35.836 Y110.618 E0.00742 G1 X36.036 Y110.802 E0.00742 G1 X36.252 Y110.967 E0.00742 G1 X36.481 Y111.113 E0.00742 G1 X36.722 Y111.239 E0.00742 G1 X36.973 Y111.343 E0.00742 G1 X37.233 Y111.425 E0.00742 G1 X37.498 Y111.483 E0.00742 G1 X37.767 Y111.519 E0.00742 G1 X38.039 Y111.531 E0.00742 G1 X38.31 Y111.519 E0.00742 G1 X38.58 Y111.483 E0.00742 G1 X38.845 Y111.425 E0.00742 G1 X39.104 Y111.343 E0.00742 G1 X39.355 Y111.239 E0.00742 G1 X39.596 Y111.113 E0.00742 G1 X39.826 Y110.967 E0.00742 G1 X40.041 Y110.802 E0.00742 G1 X40.242 Y110.618 E0.00742 G1 X40.425 Y110.418 E0.00742 G1 X40.591 Y110.202 E0.00742 G1 X40.737 Y109.973 E0.00742 G1 X40.862 Y109.732 E0.00742 G1 X40.966 Y109.481 E0.00742 G1 X41.048 Y109.222 E0.00742 G1 X41.107 Y108.957 E0.00742 G1 X41.142 Y108.687 E0.00742 G1 X41.154 Y108.416 E0.00742 G1 X41.142 Y108.144 E0.00742 G1 X41.107 Y107.875 E0.00742 G1 X41.048 Y107.609 E0.00742 G1 X40.966 Y107.35 E0.00742 G1 X40.862 Y107.099 E0.00742 G1 X40.737 Y106.858 E0.00742 G1 X40.591 Y106.629 E0.00742 G1 X40.425 Y106.413 E0.00742 G1 X40.242 Y106.213 E0.00742 G1 X40.041 Y106.029 E0.00742 G1 X39.826 Y105.864 E0.00742 G1 X39.596 Y105.718 E0.00742 G1 X39.355 Y105.592 E0.00742 G1 X39.104 Y105.488 E0.00742 G1 X38.845 Y105.406 E0.00742 G1 X38.58 Y105.348 E0.00742 G1 X38.31 Y105.312 E0.00742 G1 X38.039 Y105.3 E0.00742 G1 X37.767 Y105.312 E0.00742 G1 X37.498 Y105.348 E0.00742 G1 X37.334 Y105.384 E0.00457 M204 P1500 G1 X37.373 Y105.558 F10800 M204 P1000 G1 X37.412 Y105.732 G1 F1599.1707 G1 X37.325 Y105.752 E0.00243 G1 X37.096 Y105.824 E0.00657 G1 X36.873 Y105.916 E0.00657 G1 X36.66 Y106.027 E0.00657 G1 X36.457 Y106.156 E0.00657 G1 X36.266 Y106.303 E0.00657 G1 X36.089 Y106.465 E0.00657 G1 X35.926 Y106.643 E0.00657 G1 X35.78 Y106.834 E0.00657 G1 X35.65 Y107.037 E0.00657 G1 X35.539 Y107.25 E0.00657 G1 X35.447 Y107.472 E0.00657 G1 X35.375 Y107.702 E0.00657 G1 X35.323 Y107.937 E0.00657 G1 X35.291 Y108.175 E0.00657 G1 X35.281 Y108.416 E0.00657 G1 X35.291 Y108.656 E0.00657 G1 X35.323 Y108.894 E0.00657 G1 X35.375 Y109.129 E0.00657 G1 X35.447 Y109.359 E0.00657 G1 X35.539 Y109.581 E0.00657 G1 X35.65 Y109.794 E0.00657 G1 X35.78 Y109.997 E0.00657 G1 X35.926 Y110.188 E0.00657 G1 X36.089 Y110.366 E0.00657 G1 X36.266 Y110.528 E0.00657 G1 X36.457 Y110.675 E0.00657 G1 X36.66 Y110.804 E0.00657 G1 X36.873 Y110.915 E0.00657 G1 X37.096 Y111.007 E0.00657 G1 X37.325 Y111.079 E0.00657 G1 X37.56 Y111.131 E0.00657 G1 X37.798 Y111.163 E0.00657 G1 X38.039 Y111.173 E0.00657 G1 X38.279 Y111.163 E0.00657 G1 X38.518 Y111.131 E0.00657 G1 X38.753 Y111.079 E0.00657 G1 X38.982 Y111.007 E0.00657 G1 X39.204 Y110.915 E0.00657 G1 X39.418 Y110.804 E0.00657 G1 X39.621 Y110.675 E0.00657 G1 X39.811 Y110.528 E0.00657 G1 X39.989 Y110.366 E0.00657 G1 X40.151 Y110.188 E0.00657 G1 X40.298 Y109.997 E0.00657 G1 X40.427 Y109.794 E0.00657 G1 X40.538 Y109.581 E0.00657 G1 X40.63 Y109.359 E0.00657 G1 X40.703 Y109.129 E0.00657 G1 X40.755 Y108.894 E0.00657 G1 X40.786 Y108.656 E0.00657 G1 X40.797 Y108.416 E0.00657 G1 X40.786 Y108.175 E0.00657 G1 X40.755 Y107.937 E0.00657 G1 X40.703 Y107.702 E0.00657 G1 X40.63 Y107.472 E0.00657 G1 X40.538 Y107.25 E0.00657 G1 X40.427 Y107.037 E0.00657 G1 X40.298 Y106.834 E0.00657 G1 X40.151 Y106.643 E0.00657 G1 X39.989 Y106.465 E0.00657 G1 X39.811 Y106.303 E0.00657 G1 X39.621 Y106.156 E0.00657 G1 X39.418 Y106.027 E0.00657 G1 X39.204 Y105.916 E0.00657 G1 X38.982 Y105.824 E0.00657 G1 X38.753 Y105.752 E0.00657 G1 X38.518 Y105.7 E0.00657 G1 X38.279 Y105.668 E0.00657 G1 X38.039 Y105.658 E0.00657 G1 X37.798 Y105.668 E0.00657 G1 X37.56 Y105.7 E0.00657 G1 X37.47 Y105.72 E0.00251 M204 P1500 G1 X37.509 Y105.894 F10800 M204 P1000 G1 X37.548 Y106.068 ;TYPE:External perimeter G1 F1236.2816 G1 X37.418 Y106.097 E0.00364 G1 X37.218 Y106.16 E0.00572 G1 X37.024 Y106.24 E0.00572 G1 X36.839 Y106.337 E0.00572 G1 X36.662 Y106.449 E0.00572 G1 X36.496 Y106.577 E0.00572 G1 X36.341 Y106.718 E0.00572 G1 X36.2 Y106.873 E0.00572 G1 X36.073 Y107.039 E0.00572 G1 X35.96 Y107.215 E0.00572 G1 X35.863 Y107.401 E0.00572 G1 X35.783 Y107.595 E0.00572 G1 X35.72 Y107.794 E0.00572 G1 X35.675 Y107.999 E0.00572 G1 X35.648 Y108.206 E0.00572 G1 X35.638 Y108.416 E0.00572 G1 X35.648 Y108.625 E0.00572 G1 X35.675 Y108.832 E0.00572 G1 X35.72 Y109.037 E0.00572 G1 X35.783 Y109.237 E0.00572 G1 X35.863 Y109.43 E0.00572 G1 X35.96 Y109.616 E0.00572 G1 X36.073 Y109.792 E0.00572 G1 X36.2 Y109.958 E0.00572 G1 X36.341 Y110.113 E0.00572 G1 X36.496 Y110.254 E0.00572 G1 X36.662 Y110.382 E0.00572 G1 X36.839 Y110.494 E0.00572 G1 X37.024 Y110.591 E0.00572 G1 X37.218 Y110.671 E0.00572 G1 X37.418 Y110.734 E0.00572 G1 X37.622 Y110.779 E0.00572 G1 X37.83 Y110.807 E0.00572 G1 X38.039 Y110.816 E0.00572 G1 X38.248 Y110.807 E0.00572 G1 X38.456 Y110.779 E0.00572 G1 X38.66 Y110.734 E0.00572 G1 X38.86 Y110.671 E0.00572I have uploaded the file to google drive if you want to see the whole file.

https://drive.google.com/file/d/1M-WPyHFmTdyF5wfY-rHaMmDVVsgNASb-/view?usp=sharing

If there is a better way to share it let me know. it is 13 kb.

-

Duet Wifi Crashes on Gcode startposted in General Discussion

I am trying to run a Gcode file that I sliced in Super slicer. Smaller files work but this one seems to crash the whole printer after it finishes waiting for the temps to reach the targets.

M122 output after crash

M122 === Diagnostics === RepRapFirmware for Duet 2 WiFi/Ethernet version 3.3 (2021-06-15 21:44:54) running on Duet WiFi 1.02 or later Board ID: 0JD0M-9P6M2-NW4SS-6JKDG-3S46J-TUYBM Used output buffers: 3 of 24 (20 max) === RTOS === Static ram: 23876 Dynamic ram: 75324 of which 116 recycled Never used RAM 15100, free system stack 184 words Tasks: NETWORK(notifyWait,13.2%,244) HEAT(delaying,0.0%,314) Move(notifyWait,0.1%,340) MAIN(running,86.1%,442) IDLE(ready,0.5%,29), total 100.0% Owned mutexes: WiFi(NETWORK) === Platform === Last reset 00:03:25 ago, cause: software Last software reset at 2021-11-30 15:42, reason: HardFault unaligned, none spinning, available RAM 14716, slot 1 Software reset code 0x4072 HFSR 0x40000000 CFSR 0x01000000 ICSR 0x0041f803 BFAR 0xe000ed38 SP 0x200031e8 Task NETW Freestk 352 ok Stack: a5a5a5a9 20009610 200034a8 00448f13 ffffffff 004064db 004060d8 810e0000 200034a8 20007688 200034a8 004110cd 20003230 20017ced 00000026 00000002 00474894 00000000 00000004 ffffa5a5 00000004 00000000 20007688 00406de5 20007688 004712af 00448f13 Error status: 0x08 Aux0 errors 0,0,0 Step timer max interval 0 MCU temperature: min 54.9, current 55.1, max 57.8 Supply voltage: min 12.0, current 12.0, max 12.1, under voltage events: 0, over voltage events: 0, power good: yes Heap OK, handles allocated/used 0/0, heap memory allocated/used/recyclable 0/0/0, gc cycles 0 Driver 0: position 0, standstill, SG min/max not available Driver 1: position 0, standstill, SG min/max not available Driver 2: position 0, standstill, SG min/max not available Driver 3: position 0, standstill, SG min/max not available Driver 4: position 0, standstill, SG min/max not available Driver 5: position 0 Driver 6: position 0 Driver 7: position 0 Driver 8: position 0 Driver 9: position 0 Driver 10: position 0 Driver 11: position 0 Date/time: 2021-11-30 15:45:36 Cache data hit count 4294967295 Slowest loop: 6.61ms; fastest: 0.17ms I2C nak errors 0, send timeouts 0, receive timeouts 0, finishTimeouts 0, resets 0 === Storage === Free file entries: 10 SD card 0 detected, interface speed: 20.0MBytes/sec SD card longest read time 52.4ms, write time 0.0ms, max retries 3 === Move === DMs created 83, maxWait 0ms, bed compensation in use: none, comp offset 0.000 === MainDDARing === Scheduled moves 0, completed moves 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === AuxDDARing === Scheduled moves 0, completed moves 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === Heat === Bed heaters = 0 -1 -1 -1, chamberHeaters = -1 -1 -1 -1 Heater 1 is on, I-accum = 0.0 === GCodes === Segments left: 0 Movement lock held by null HTTP is idle in state(s) 0 Telnet is idle in state(s) 0 File is idle in state(s) 0 USB is idle in state(s) 0 Aux is idle in state(s) 0 Trigger is idle in state(s) 0 Queue is idle in state(s) 0 LCD is idle in state(s) 0 Daemon is idle in state(s) 0 Autopause is idle in state(s) 0 Code queue is empty. === Network === Slowest loop: 57.59ms; fastest: 0.00ms Responder states: HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0), 0 sessions HTTP sessions: 1 of 8 - WiFi - Network state is active WiFi module is connected to access point Failed messages: pending 0, notready 0, noresp 0 WiFi firmware version 1.26 WiFi MAC address e8:db:84:f7:26:1a WiFi Vcc 3.33, reset reason Turned on by main processor WiFi flash size 4194304, free heap 22928 WiFi IP address 192.168.1.248 WiFi signal strength -70dBm, mode 802.11n, reconnections 0, sleep mode modem Clock register 00002002 Socket states: 0 0 0 0 0 0 0 0Let me know what other information would be helpful to diagnose.

-

Heated bed buzzingposted in Tuning and tweaking

Hi,

I have been modify my prusa mk2s to run off of a Duet wifi. The whole machine was working. I ordered Prusa's magnetic bed upgrade for this machine and plugged it in. I ran the PID bed tune with no issue to 70C. However, when I try to heat the bed past around 60C I get a strange buzzing sound. I don't think that the heated bed is defective as this is the second one I have tried and had the same issue, Prusa sent me a second after an hour of poking and prodding to try and solve the issue. I am wondering if there is some setting that is not correct for the new bed.

link to video with sound of buzzing

https://www.youtube.com/watch?v=nhisqatfQfM; 0:/sys/config.g ; Configuration file for MK3s Duet WiFi, firmware version 3.11 ; Go to https://github.com/rkolbi/RRF-machine-config-files/blob/master/Prusa%20MK3s/Duet-MK3s.pdf ; for corresponding wiring information. ; General preferences G90 ; Set absolute coordinates M83 ; Set relative extruder moves M550 P"Prusa Duet" ; Set printer name ; Network M551 P"3D" ; Set password M552 S1 ; Enable network M586 P0 S1 ; Enable HTTP M586 P1 S1 ; Enable FTP M586 P2 S0 ; Disabled Telnet M575 P1 S1 B38400 ; Enable support for PanelDue ; Drive Mappings S0 = backwards, S1 = forwards M569 P0 S0 ; Drive 0 goes forwards: X Axis M569 P1 S0 ; Drive 1 goes forwards: Y Axis M569 P2 S0 ; Drive 2 goes forwards: Z Axis Left M569 P3 S1 ; Drive 3 goes backward: E Axis M569 P4 S0 ; Drive 4 goes forwards: Z Axis Right (using E1) M584 X0 Y1 Z2:4 E3 ; Motor Configuration ; !!! For stock motors, use the following as a starting point: ; M906 X620.00 Y620.00 Z560.00 E650.00 I10. ; Set motor currents (mA) and motor idle factor in percent ; M350 X16 Y16 Z16 I1 ; Set X, Y, and Z Microstepping with interpolation ; M350 E32 I0 ; Set Extruder Microstepping without interpolation ; M92 X100.00 Y100.00 Z400.00 E409 ; Steps per mm ; !!! Also note that you should edit the current-sense-homing.g file and increase current to 50 on X and Y, 100 on Z. ; !!! M913 X20 Y20 Z60 ---> M913 X50 Y50 Z100 ; M350 X16 Y16 Z16 I1 ; Set X, Y, and Z Microstepping with interpolation M350 E16 I0 ; Set Extruder Microstepping without interpolation M92 X100.00 Y100.00 Z400.00 E409.00 ; Steps per mm M566 X600.00 Y600.00 Z24.00 E300.00 P1 ; Set maximum instantaneous speed changes (mm/min) M203 X15000.00 Y15000.00 Z900.00 E2000.00 ; Set maximum speeds (mm/min) M201 X4000.00 Y4000.00 Z1000.00 E5000.00 ; Set accelerations (mm/s^2) M906 X620.00 Y620.00 Z400.00 E750.00 I10. ; Set motor currents (mA) and motor idle factor in percent M84 S1000 ; Set idle timeout before shifitng to idle-current ; Motor remapping for dual Z and axis Limits ; Set two Z motors connected to driver outputs Z and E1 M671 X-37:287 Y0:0 S10 ; Leadscrew at left connected to Z, leadscrew at right connected to E1 ; Set bed dimensions M208 X0:250 Y-4:215 Z-0.1:205 ; X carriage moves from 0 to 250, Y bed goes from 0 to 210 M564 H0 ; Allow unhomed movement ; Endstops for each Axis ;M574 X1 S3 ; Set endstops controlled by the motor load detection ;M574 Y1 S3 ; Set endstops controlled by the motor load detection M574 X1 S1 P"xstop" ; physical endstops M574 Y1 S1 P"ystop" ; Stallgaurd Sensitivity M98 P"current-sense-homing.g" ; Set the current and sensitivity for normal routine, per the macro ; Z-Probe Settings for BLTouch M558 P9 C"^zprobe.in" H5 F200 T3000 G31 P1000 X-24.5 Y-44 Z1.65 M950 S0 C"exp.heater3" M574 Z1 S2 M557 X0:175 Y3:210 P7 ; Heatbed Heaters and Thermistor Bed M308 S0 P"bed_temp" Y"thermistor" A"Build Plate" T100000 C7.06e-8 R4700 ; Set thermistor + ADC parameters for heater 0 Bed M950 H0 C"bedheat" T0 ; Creates Bed Heater M307 H0 A91.5 C264.0 D10.2 S1.00 V24.0 B0 ; Bed PID Calibration @ 75c - updated 11AUG2020 M140 H0 ; Bed uses Heater 0 M143 H0 S120 ; Set temperature limit for heater 0 to 120C Bed ; HotEnd Heaters and Thermistor HotEnd ; !!! Use this line for stock thermisotr: M308 S1 P"e0_temp" Y"thermistor" A"Nozzle" T100000 B4725 R4700 ; Set thermistor + ADC parameters for heater 1 HotEnd M308 S1 P"e_0temp" Y"thermistor" T100000 B4388 C7.06e-8 ; Set thermistor + ADC parameters for heater 1 HotEnd M950 H1 C"e0heat" T1 ; Create HotEnd Heater M307 H1 A311.0 C130.0 D4.3 S1.00 V24.1 B0 ; Hotend PID Calibration @ 240c - updated 09AUG2020 M143 H1 S300 ; Set temperature limit for heater 1 to 285C HotEnd M302 S190 R190 ; Allow cold extrudes, S-Minimum extrusion temperature, R-Minimum retraction temperature ; Fans M950 F1 C"Fan1" Q25000 ; Creates HOTEND Fan ; FAN 40X10MM 24VDC - 6.0 CFM (0.168m³/min). ; Digi-Key: G4010L24B-RSR M106 P1 T45 S255 H1 ; HOTEND Fan Settings M950 F0 C"Fan0" Q25000 ; Creates PARTS COOLING FAN ; BLOWER 50X15MM 24VDC - 5.0 CFM (0.140m³/min) ; Digi-Key: B5015E24B-BSR M106 P0 H-1 ; Set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned off PARTS COOLING FAN M950 F2 C"Fan2" Q25000 ; Creates PARTS COOLING FAN ; BLOWER 50X15MM 24VDC - 5.0 CFM (0.140m³/min) ; Digi-Key: B5015E24B-BSR M106 P2 H-1 ; Set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned off PARTS COOLING FAN ; The following lines are for auto case fan control, attached to 'fan2' header on duet board ;M308 S4 Y"drivers" A"TMC2660" ; Case fan - configure sensor 2 as temperature warning and overheat flags on the TMC2660 on Duet ; !!! Reports 0C when there is no warning, 100C if any driver reports over-temperature ; !!! warning , and 150C if any driver reports over-temperature shutdown ;M308 S3 Y"mcu-temp" A"Duet2Wifi" ; Case fan - configure sensor 3 as thermistor on pin e1temp for left stepper ;M950 F2 C"fan2" Q100 ; Case fan - create fan 2 on pin fan2 and set its frequency ;M106 P2 H4:3 L0.15 X1 B0.3 T40:70 ; Case fan - set fan 2 value ;M912 P0 S-5.5 ; MCU Temp calibration - default reads 5.5c higher than ambient ; Tools M563 P0 D0 H1 F0:2 ; Define tool 0 G10 P0 X0 Y0 Z0 ; Set tool 0 axis offsets G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C T0 ; Set Tool 0 active ; Relase X, Y, and E axis M18 XYZE ; Unlock the X, Y, and E axis M501 ; config-override.g file generated in response to M500 at 2021-05-17 13:22 ; This is a system-generated file - do not edit ; Heater model parameters M307 H0 A116.4 C374.6 D9.4 S1.00 V12.0 B0 M307 H1 A361.1 C172.0 D4.2 S1.00 V12.1 B0 ; Workplace coordinates G10 L2 P1 X0.00 Y0.00 Z0.00 G10 L2 P2 X0.00 Y0.00 Z0.00 G10 L2 P3 X0.00 Y0.00 Z0.00 G10 L2 P4 X0.00 Y0.00 Z0.00 G10 L2 P5 X0.00 Y0.00 Z0.00 G10 L2 P6 X0.00 Y0.00 Z0.00 G10 L2 P7 X0.00 Y0.00 Z0.00 G10 L2 P8 X0.00 Y0.00 Z0.00 G10 L2 P9 X0.00 Y0.00 Z0.00 -

RE: When start a print the z axis goes up indefinately after homingposted in Tuning and tweaking

ok, im the idiot. Thanks so much for the help. the issue was the start.g and me not letting it go all the way up in the z axis. I have a print running thank you all for the help.

-

RE: When start a print the z axis goes up indefinately after homingposted in Tuning and tweaking

Hello,

Yes, its only when starting a print that it has this behavior. I can home everything normally. Also, it performs a home before in the gcode before it goes up the z axis.

Here is the M98

M98 P"config.g"

HTTP is enabled on port 80

FTP is enabled on port 21

TELNET is disabled

The other bit to look at that I just found that I had not seen before is this start.g file. I think the issue may reside in here.

Is the start.g necessary?; 0:/sys/start.g

; Executed before each print - BEFORE ANY SLICER CODE IS RAN

; This also loads the heightmap from the system's set filament type directory

; (0:/filaments/XXXX/heightmap.csv), if the heightmap does not exist, it will

; create one, and then save in the filament's directory. The HotMesh macro is

; a better choice to generate the heightmap as it performs a heat stabilization

; routine for ~5 minutes.M122 ; Clear diagnostic data to cleanly capture print evolution statistics.

T0 ; Ensure the tool is selected.

M280 P0 S160 ; BLTouch, alarm release.

G4 P100 ; BLTouch, delay for the release command.

M572 D0 S0.0 ; Clear pressure advance.

M220 S100 ; Set speed factor back to 100% in case it was changed.

M221 S100 ; Set extrusion factor back to 100% in case it was changed.

M290 R0 S0 ; Clear any baby-stepping.

M106 S0 ; Turn part cooling blower off if it is on.

M703 ; Execute loaded filament's config.g.

G28 ; Home all.;G1 Z5 X100 Y100 ; [PINDA] Place nozzle center of the bed, 5mm up.

G1 Z160 F300 ; [BLTouch] Last chance to check nozzle cleanliness.

M300 S4000 P100 G4 P200 M300 S4000 P100 ; Give a double beep.

M116 ; Wait for all temperatures.

M300 S4000 P100 ; Give a single beep.; [BLTouch] Start countdown - use Z as indicator

G91 ; [BLTouch] Set to Relative Positioning.

while iterations <=9 ; [BLTouch] Perform 10 passes.

G4 S12 ; [BLTouch] Wait 12 seconds.

G1 Z-15 F300 ; [BLTouch] Move Z 15mm down.

G90 ; [BLTouch] Set to Absolute Positioning.;G4 S120 ; [PINDA] wait an additional 2 minutes for the bed to stabilize.

G32 ; Level the gantry.

G29 S1 [P{"0:/filaments/" ^ move.extruders[0].filament ^ "/heightmap.csv"}] ; Load bed mesh for the system's set filament type.

if result > 1 ; If the file doesn't exist, perform mesh and save.

G29 ; Perform mesh now.

G29 S3 [P{"0:/filaments/" ^ move.extruders[0].filament ^ "/heightmap.csv"}] ; Save heightmap.csv to filament type's directory.M400 ; Finish all moves, clear the buffer.

G90 ; Absolute Positioning.

M83 ; Extruder relative mode.

M98 P"0:/sys/current-sense-normal.g" ; Ensure that motor currents and sense are set for printing.

G1 X0 Y0 F800 ; Final position before slicer's temp is reached and primeline is printed.

G1 Z2 F300 ; Final position before slicer's temp is reached and primeline is printed.; The primeline macro is executed by the slicer gcode to enable direct printing.

; of the primeline at the objects temp and to immediately print the object.

; following primeline completion.; Slicer generated gcode takes it away from here.

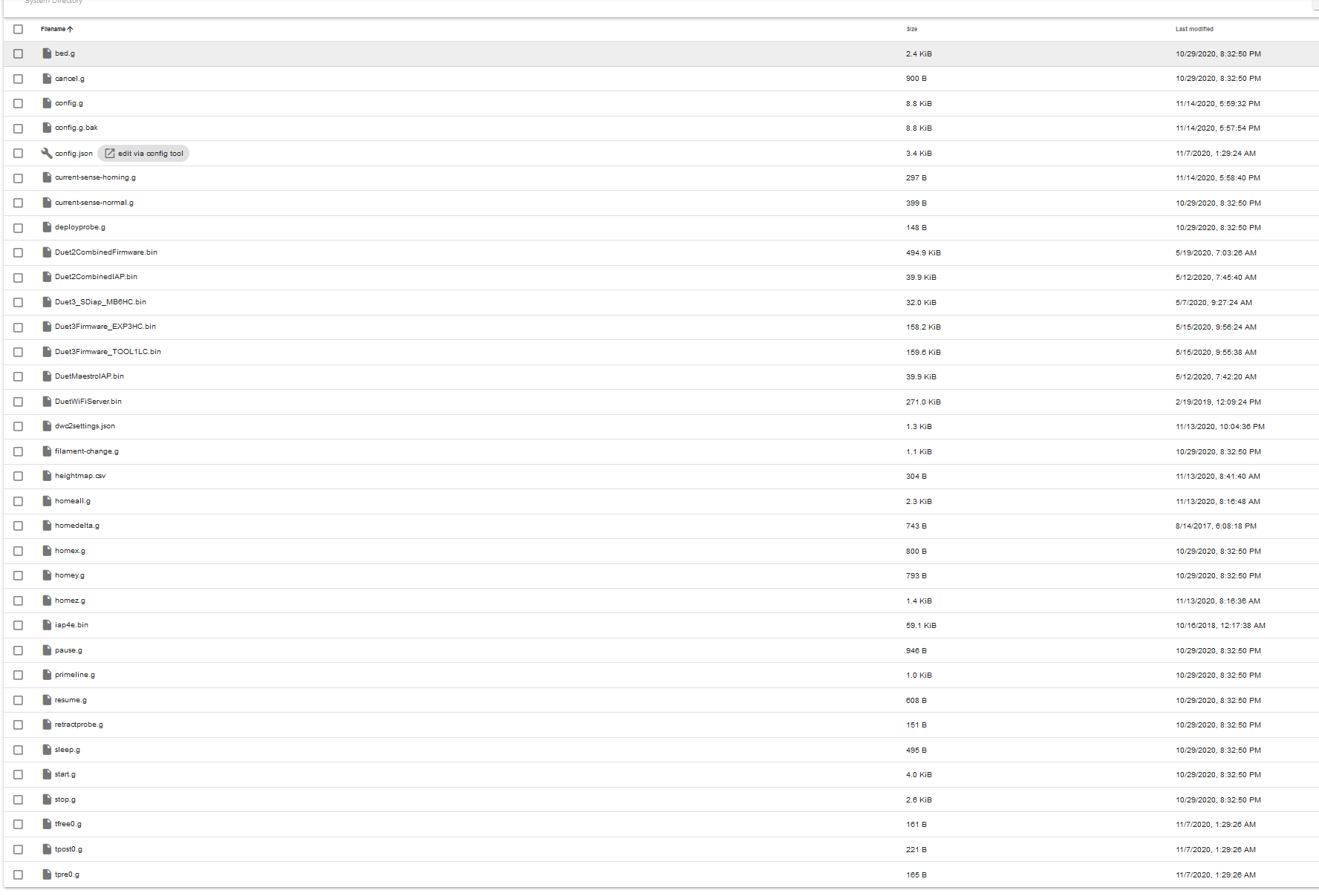

also here is the screen shot of the file system

-

RE: When start a print the z axis goes up indefinately after homingposted in Tuning and tweaking

I have made all the above changes and it still goes up after homing.

-

RE: When start a print the z axis goes up indefinately after homingposted in Tuning and tweaking

Here is the contents. Currently I dont think I am using it.

; 0:/sys/current-sense-homing.g

; Set the current and sensitivity for homing, non-printing, routinesM915 X S0 F0 H400 R0 ; Set the X axis sensitivity.

M915 Y S2 F0 H400 R0 ; Set the Y axis sensitivity.

M913 X50 Y50 Z100 -

RE: When start a print the z axis goes up indefinately after homingposted in Tuning and tweaking

I believe I have gone through and made the appropriate changes but i am still having the same issue. I think it has something to do with incorrectly setting the Z endstop. I am using a Pinde v1 probe for the z endstop which works correctly for the homing. Below is my new config.f

; 0:/sys/config.g

; Configuration file for MK3s Duet WiFi, firmware version 3.11

; Go to https://github.com/rkolbi/RRF-machine-config-files/blob/master/Prusa MK3s/Duet-MK3s.pdf

; for corresponding wiring information.; General preferences

G90 ; Set absolute coordinates

M83 ; Set relative extruder moves

M550 P"Prusa Duet" ; Set printer name; Network

M551 P"3D" ; Set password

M552 S1 ; Enable network

M586 P0 S1 ; Enable HTTP

M586 P1 S1 ; Enable FTP

M586 P2 S0 ; Disabled Telnet

M575 P1 S1 B38400 ; Enable support for PanelDue; Drive Mappings S0 = backwards, S1 = forwards

M569 P0 S0 ; Drive 0 goes forwards: X Axis

M569 P1 S0 ; Drive 1 goes forwards: Y Axis

M569 P2 S0 ; Drive 2 goes forwards: Z Axis Left

M569 P3 S1 ; Drive 3 goes backward: E Axis

M569 P4 S0 ; Drive 4 goes forwards: Z Axis Right (using E1); Motor Configuration

; !!! For stock motors, use the following as a starting point:

; M906 X620.00 Y620.00 Z560.00 E650.00 I10. ; Set motor currents (mA) and motor idle factor in percent

; M350 X16 Y16 Z16 I1 ; Set X, Y, and Z Microstepping with interpolation

; M350 E32 I0 ; Set Extruder Microstepping without interpolation

; M92 X100.00 Y100.00 Z400.00 E280.00 ; Steps per mm

; !!! Also note that you should edit the current-sense-homing.g file and increase current to 50 on X and Y, 100 on Z.

; !!! M913 X20 Y20 Z60 ---> M913 X50 Y50 Z100

;

M350 X16 Y16 Z16 I1 ; Set X, Y, and Z Microstepping with interpolation

M350 E32 I0 ; Set Extruder Microstepping without interpolation

M92 X100.00 Y100.00 Z400.00 E280.00 ; Steps per mm

M566 X600.00 Y600.00 Z24.00 E300.00 P1 ; Set maximum instantaneous speed changes (mm/min)

M203 X15000.00 Y15000.00 Z900.00 E2000.00 ; Set maximum speeds (mm/min)

M201 X4000.00 Y4000.00 Z1000.00 E5000.00 ; Set accelerations (mm/s^2)

M906 X620.00 Y620.00 Z560.00 E650.00 I10. ; Set motor currents (mA) and motor idle factor in percent

M84 S1000 ; Set idle timeout before shifitng to idle-current; Motor remapping for dual Z and axis Limits

M584 X0 Y1 Z2:4 E3 ; Set two Z motors connected to driver outputs Z and E1

M671 X-37:287 Y0:0 S10 ; Leadscrew at left connected to Z, leadscrew at right connected to E1; Set bed dimensions

M208 X0:250 Y-4:215 Z-0.1:205 ; X carriage moves from 0 to 250, Y bed goes from 0 to 210

M564 H0 ; Allow unhomed movement; Endstops for each Axis

;M574 X1 S3 ; Set endstops controlled by the motor load detection

;M574 Y1 S3 ; Set endstops controlled by the motor load detection

M574 X1 S1 P"xstop" ; physical endstops

M574 Y1 S1 P"ystop"; Stallgaurd Sensitivity

M98 P"current-sense-homing.g" ; Set the current and sensitivity for normal routine, per the macro; Z-Probe Settings for BLTouch

M558 P5 !C"^zprobe.in" H1 F1000 T6000 A20 S0.005

G31 P1000 X22 Y4 Z0.569 ; PEI Sheet (Prusa) Offset MICRO SWISS NOZZLE

M574 Z1 S2 ; Set Z axis endstop, controlled by probe

M557 X35:237 Y7:203 S99 ; Define mesh grid for probing; Z-Probe Setting for PINDA v2

; 1 - If using PindaV2, Remove above M558 & M950 lines, replace with the following M558 & M308 line

; 2 - Uncomment one of the Z-Offsets below, follow the wiki guide steps to get the proper Z-offset for your printer

; 3 - Comment out the 2 BLTouch lines in the homez and homeall files

;

; M558 P5 C"^zprobe.in" I1 H1 F1000 T6000 A20 S0.005 ; Prusa PindaV2

; M308 S2 P"e1_temp" A"Pinda V2" Y"thermistor" T100000 B3950 ; Prusa PindaV2

;

; Z-Offsets - Read here: https://duet3d.dozuki.com/Wiki/Test_and_calibrate_the_Z_probe

; G31 P1000 X23 Y5 Z0.985 ; PEI Sheet (Prusa) Offset Spool3D Tungsten Carbide

; G31 P1000 X23 Y5 Z0.440 ; PEI Sheet (Prusa) Offset MICRO SWISS NOZZLE

; G31 P1000 X23 Y5 Z1.285 ; Textured Sheet (Prusa) Offset MICRO SWISS NOZZLE

; G31 P1000 X23 Y5 Z0.64 ; Textured Sheet (thekkiinngg) Offset MICRO SWISS NOZZLE; Heatbed Heaters and Thermistor Bed

M308 S0 P"bed_temp" Y"thermistor" A"Build Plate" T100000 B4138 R4700 ; Set thermistor + ADC parameters for heater 0 Bed

M950 H0 C"bedheat" T0 ; Creates Bed Heater

M307 H0 A91.5 C264.0 D10.2 S1.00 V24.0 B0 ; Bed PID Calibration @ 75c - updated 11AUG2020

M140 H0 ; Bed uses Heater 0

M143 H0 S120 ; Set temperature limit for heater 0 to 120C Bed; HotEnd Heaters and Thermistor HotEnd

; !!! Use this line for stock thermisotr: M308 S1 P"e0_temp" Y"thermistor" A"Nozzle" T100000 B4725 R4700 ; Set thermistor + ADC parameters for heater 1 HotEnd

M308 S1 P"e0_temp" Y"thermistor" A"Nozzle" T100000 B4725 R4700 ; Set thermistor + ADC parameters for heater 1 HotEnd

M950 H1 C"e0heat" T1 ; Create HotEnd Heater

M307 H1 A311.0 C130.0 D4.3 S1.00 V24.1 B0 ; Hotend PID Calibration @ 240c - updated 09AUG2020

M143 H1 S285 ; Set temperature limit for heater 1 to 285C HotEnd

M302 S190 R190 ; Allow cold extrudes, S-Minimum extrusion temperature, R-Minimum retraction temperature; Fans

M950 F1 C"Fan1" Q1000 ; Creates HOTEND Fan

; FAN 40X10MM 24VDC - 6.0 CFM (0.168m³/min).

; Digi-Key: G4010L24B-RSR

M106 P1 T45 S255 H1 ; HOTEND Fan Settings

M950 F0 C"Fan0" Q5000 ; Creates PARTS COOLING FAN

; BLOWER 50X15MM 24VDC - 5.0 CFM (0.140m³/min)

; Digi-Key: B5015E24B-BSR

M106 P0 H-1 ; Set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned off PARTS COOLING FAN

; The following lines are for auto case fan control, attached to 'fan2' header on duet board

;M308 S4 Y"drivers" A"TMC2660" ; Case fan - configure sensor 2 as temperature warning and overheat flags on the TMC2660 on Duet

; !!! Reports 0C when there is no warning, 100C if any driver reports over-temperature

; !!! warning , and 150C if any driver reports over-temperature shutdown

;M308 S3 Y"mcu-temp" A"Duet2Wifi" ; Case fan - configure sensor 3 as thermistor on pin e1temp for left stepper

;M950 F2 C"fan2" Q100 ; Case fan - create fan 2 on pin fan2 and set its frequency

;M106 P2 H4:3 L0.15 X1 B0.3 T40:70 ; Case fan - set fan 2 value

;M912 P0 S-5.5 ; MCU Temp calibration - default reads 5.5c higher than ambient; Tools

M563 P0 D0 H1 F0 ; Define tool 0

G10 P0 X0 Y0 Z0 ; Set tool 0 axis offsets

G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C

T0 ; Set Tool 0 active; Relase X, Y, and E axis

M18 XYZE ; Unlock the X, Y, and E axis -

RE: When start a print the z axis goes up indefinately after homingposted in Tuning and tweaking

@Veti

thanks for pointing that out. I will try that and get back to you. -

RE: When start a print the z axis goes up indefinately after homingposted in Tuning and tweaking

Homeall.g

; 0:/sys/homeall.g

; Home X, Y, and Z axisM98 P"current-sense-homing.g" ; Ensure the current and sensitivity is set for homing routines.

; !!! If using Pinda, comment-out the following two lines

;M280 P0 S160 ; BLTouch, alarm release.

;G4 P100 ; BLTouch, delay for the release command.G91 ; Set relative positioning.

G1 Z3 F800 H2 ; Lift the Z axis 3mm.; HOME X

G1 H0 X5 F1000 ; Move slowly away.

G1 H1 X-255 F3000 ; Move quickly to the X endstop.

G1 H0 X5 F1000 ; Move slowly away.

G1 H1 X-255 F3000 ; Move quickly to the X endstop, a second check.; HOME Y

G1 H0 Y5 F1000 ; Move slowly away.

G1 H1 Y-215 F3000 ; Move quickly to the Y endstop.

G1 H0 Y5 F1000 ; Move slowly away.

G1 H1 Y-215 F3000 ; Move quickly to the Y endstops, a second check.; HOME Z

G1 H2 Z2 F2600 ; Raise the Z axis 2mm to ensure it is above the Z probe trigger height.

G90 ; Set absolute positioning mode.

G1 X8 Y4 F6000 ; Go to the sensor point closest to 0,0M558 F1000 A1 ; Set the Z-probe to fast for the first pass.

G30 ; Perform Z probing.

G1 H0 Z5 F400 ; Lift the Z axis to the 5mm position.M558 F50 A5 S-1 ; Set the Z-probe to slow for the second pass, take 5 probes and yield the average.

G30 ; Perform Z probing.

G1 H0 Z5 F400 ; Lift the Z axis to the 5mm position.M558 F200 A1 ; Set the Z-probe to normal speed.

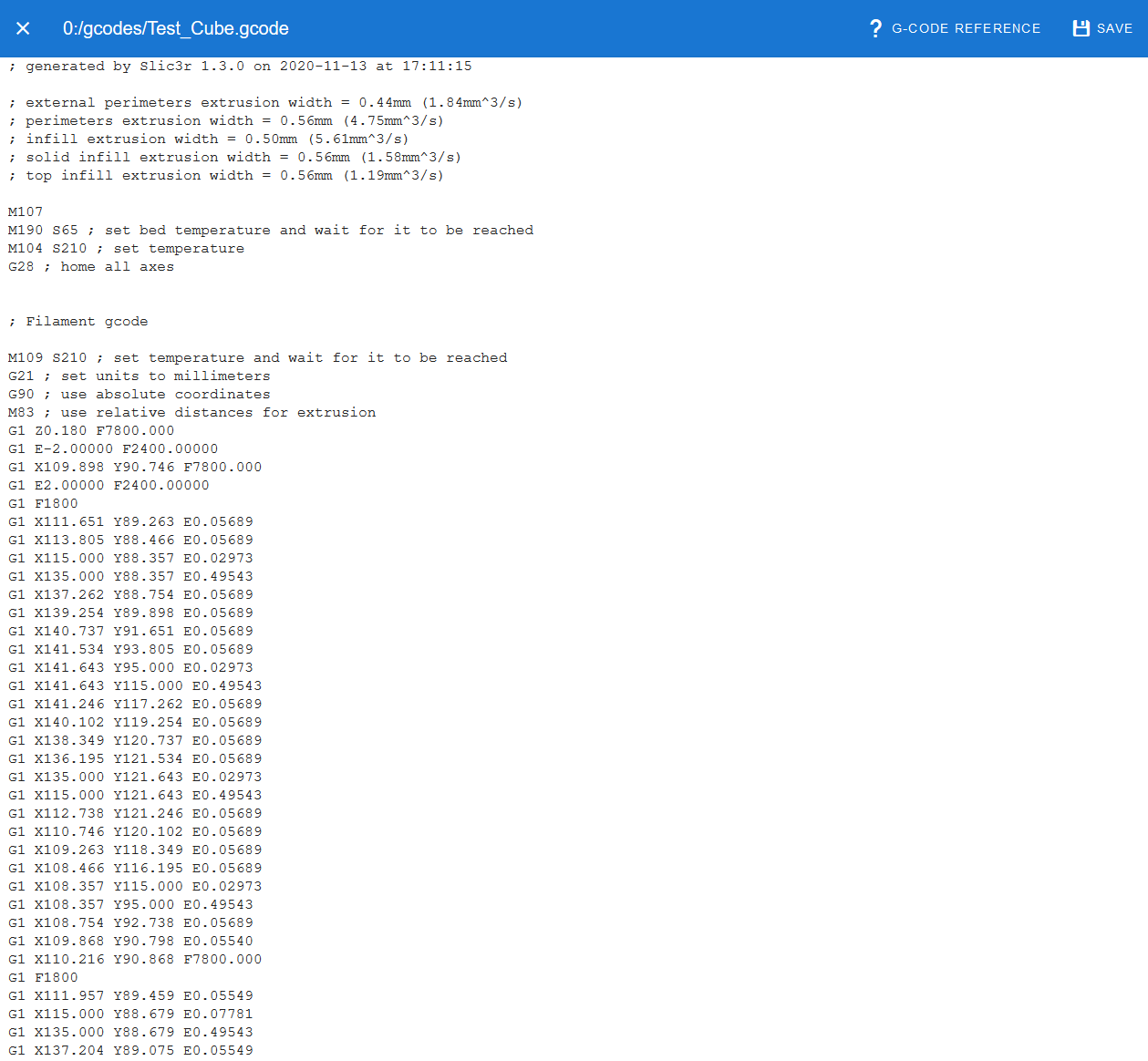

G Code file:

; generated by Slic3r 1.3.0 on 2020-11-13 at 17:11:15; external perimeters extrusion width = 0.44mm (1.84mm^3/s)

; perimeters extrusion width = 0.56mm (4.75mm^3/s)

; infill extrusion width = 0.50mm (5.61mm^3/s)

; solid infill extrusion width = 0.56mm (1.58mm^3/s)

; top infill extrusion width = 0.56mm (1.19mm^3/s)M107

M190 S65 ; set bed temperature and wait for it to be reached

M104 S210 ; set temperature

G28 ; home all axes; Filament gcode

M109 S210 ; set temperature and wait for it to be reached

G21 ; set units to millimeters

G90 ; use absolute coordinates

M83 ; use relative distances for extrusion

G1 Z0.180 F7800.000

G1 E-2.00000 F2400.00000

G1 X109.898 Y90.746 F7800.000

G1 E2.00000 F2400.00000

G1 F1800

G1 X111.651 Y89.263 E0.05689

G1 X113.805 Y88.466 E0.05689

G1 X115.000 Y88.357 E0.02973

G1 X135.000 Y88.357 E0.49543

G1 X137.262 Y88.754 E0.05689

G1 X139.254 Y89.898 E0.05689

G1 X140.737 Y91.651 E0.05689

G1 X141.534 Y93.805 E0.05689

G1 X141.643 Y95.000 E0.02973

G1 X141.643 Y115.000 E0.49543

G1 X141.246 Y117.262 E0.05689

G1 X140.102 Y119.254 E0.05689

G1 X138.349 Y120.737 E0.05689

G1 X136.195 Y121.534 E0.05689

G1 X135.000 Y121.643 E0.02973

G1 X115.000 Y121.643 E0.49543

G1 X112.738 Y121.246 E0.05689

G1 X110.746 Y120.102 E0.05689

G1 X109.263 Y118.349 E0.05689

G1 X108.466 Y116.195 E0.05689

G1 X108.357 Y115.000 E0.02973

G1 X108.357 Y95.000 E0.49543

G1 X108.754 Y92.738 E0.05689

G1 X109.868 Y90.798 E0.05540

G1 X110.216 Y90.868 F7800.000

G1 F1800M122

=== Diagnostics ===

RepRapFirmware for Duet 2 WiFi/Ethernet version 3.1.1 running on Duet WiFi 1.02 or later

Board ID: 08DGM-956GU-DGMSN-6JTDG-3SJ6Q-9AN3D

Used output buffers: 3 of 24 (20 max)

=== RTOS ===

Static ram: 27980

Dynamic ram: 93880 of which 44 recycled

Exception stack ram used: 264

Never used ram: 8904

Tasks: NETWORK(ready,384) HEAT(blocked,1224) MAIN(running,1824) IDLE(ready,80)

Owned mutexes: WiFi(NETWORK)

=== Platform ===

Last reset 04:43:42 ago, cause: software

Last software reset at 2020-11-13 17:20, reason: User, spinning module GCodes, available RAM 8496 bytes (slot 2)

Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x0441f000 BFAR 0xe000ed38 SP 0xffffffff Task MAIN

Error status: 0

MCU temperature: min 33.8, current 34.3, max 35.5

Supply voltage: min 12.0, current 12.2, max 12.4, under voltage events: 0, over voltage events: 0, power good: yes

Driver 0: standstill, SG min/max not available

Driver 1: standstill, SG min/max not available

Driver 2: standstill, SG min/max not available

Driver 3: standstill, SG min/max not available

Driver 4: standstill, SG min/max not available

Date/time: 2020-11-13 22:03:57

Cache data hit count 4294967295

Slowest loop: 7.43ms; fastest: 0.13ms

I2C nak errors 0, send timeouts 0, receive timeouts 0, finishTimeouts 0, resets 0

=== Storage ===

Free file entries: 10

SD card 0 detected, interface speed: 20.0MBytes/sec

SD card longest read time 3.9ms, write time 0.0ms, max retries 0

=== Move ===

Hiccups: 0(0), FreeDm: 169, MinFreeDm: 169, MaxWait: 0ms

Bed compensation in use: none, comp offset 0.000

=== MainDDARing ===

Scheduled moves: 0, completed moves: 0, StepErrors: 0, LaErrors: 0, Underruns: 0, 0 CDDA state: -1

=== AuxDDARing ===

Scheduled moves: 0, completed moves: 0, StepErrors: 0, LaErrors: 0, Underruns: 0, 0 CDDA state: -1

=== Heat ===

Bed heaters = 0 -1 -1 -1, chamberHeaters = -1 -1 -1 -1

Heater 1 is on, I-accum = 0.0

=== GCodes ===

Segments left: 0

Movement lock held by null

HTTP is idle in state(s) 0

Telnet is idle in state(s) 0

File is idle in state(s) 0

USB is idle in state(s) 0

Aux is idle in state(s) 0

Trigger is idle in state(s) 0

Queue is idle in state(s) 0

Daemon is idle in state(s) 0

Autopause is idle in state(s) 0

Code queue is empty.

=== Network ===

Slowest loop: 202.63ms; fastest: 0.09ms

Responder states: HTTP(2) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0), 0 sessions

HTTP sessions: 1 of 8- WiFi -

Network state is active

WiFi module is connected to access point

Failed messages: pending 0, notready 0, noresp 1

WiFi firmware version 1.23

WiFi MAC address 84:0d:8e:b2:f1:f1

WiFi Vcc 3.35, reset reason Unknown

WiFi flash size 4194304, free heap 22976

WiFi IP address 192.168.1.21

WiFi signal strength -49dBm, reconnections 0, sleep mode modem

Socket states: 0 0 0 0 0 0 0 0

M98 P"config.g"

HTTP is enabled on port 80

FTP is enabled on port 21

TELNET is disabled - WiFi -

-

When start a print the z axis goes up indefinately after homingposted in Tuning and tweaking

Hello,

I am having issues starting a print on my duet wifi. I have converted my prusa mk2 to use the duet wifi and I believe i have everything set up well. I have perform mesh leveling with the pinda probe and all the axis move in the direction i expect from the web terminal. However, when I try to run a part with G code it homes the axis and after homing successfully the goes up in the z direction with what looks like no intention of stopping. I have e stopped the printer before it reaches the top each time. I have tried to strip the beginning of the G code down to the bare minimum to try and eliminate anything there.

Here is the start of the g code for the print that i am trying to do.

M107

M190 S65 ; set bed temperature and wait for it to be reached

M104 S210 ; set temperature

G28 ; home all axes; Filament gcode

M109 S210 ; set temperature and wait for it to be reached

G21 ; set units to millimeters

G90 ; use absolute coordinates

M83 ; use relative distances for extrusion

G1 Z0.180 F7800.000

G1 E-2.00000 F2400.00000

G1 X109.898 Y90.746 F7800.000

G1 E2.00000 F2400.00000

G1 F1800

G1 X111.651 Y89.263 E0.05689Config.g

; 0:/sys/config.g

; Configuration file for MK3s Duet WiFi, firmware version 3.11

; Go to https://github.com/rkolbi/RRF-machine-config-files/blob/master/Prusa MK3s/Duet-MK3s.pdf

; for corresponding wiring information.; General preferences

G90 ; Set absolute coordinates

M83 ; Set relative extruder moves

M550 P"ZMK3-BMGm" ; Set printer name; Network

M551 P"3D" ; Set password

M552 S1 ; Enable network

M586 P0 S1 ; Enable HTTP

M586 P1 S1 ; Enable FTP

M586 P2 S0 ; Disabled Telnet

;M575 P1 S1 B38400 ; Enable support for PanelDue; Drive Mappings S0 = backwards, S1 = forwards

M569 P0 S0 ; Drive 0 goes forwards: X Axis

M569 P1 S0 ; Drive 1 goes forwards: Y Axis

M569 P2 S0 ; Drive 2 goes forwards: Z Axis Left

M569 P3 S1 ; Drive 3 goes backward: E Axis

M569 P4 S0 ; Drive 4 goes forwards: Z Axis Right (using E1); Motor Configuration

; !!! For stock motors, use the following as a starting point:

M906 X620.00 Y620.00 Z560.00 E650.00 I10. ; Set motor currents (mA) and motor idle factor in percent

M350 X16 Y16 Z16 I1 ; Set X, Y, and Z Microstepping with interpolation

M350 E32 I0 ; Set Extruder Microstepping without interpolation

M92 X100.00 Y100.00 Z400.00 E280.00 ; Steps per mm

; !!! Also note that you should edit the current-sense-homing.g file and increase current to 50 on X and Y, 100 on Z.

; !!! M913 X20 Y20 Z60 ---> M913 X50 Y50 Z100

;; Motor remapping for dual Z and axis Limits

M584 X0 Y1 Z2:4 E3 ; Set two Z motors connected to driver outputs Z and E1

M671 X-37:287 Y0:0 S10 ; Leadscrew at left connected to Z, leadscrew at right connected to E1; Set bed dimensions

M208 X0:250 Y-4:215 Z-0.1:205 ; X carriage moves from 0 to 250, Y bed goes from 0 to 210

M564 H0 ; Allow unhomed movement; Endstops for each Axis

;M574 X1 S3 ; Set endstops controlled by the motor load detection

;M574 Y1 S3 ; Set endstops controlled by the motor load detection

M574 X1 S1 P"xstop" ; configure active-high endstop for low end on X via pin xstop

M574 Y1 S1 P"ystop"; Stallgaurd Sensitivity

M98 P"current-sense-homing.g" ; Set the current and sensitivity for normal routine, per the macro; Z-Probe Settings for BLTouch

M558 P5 !C"^zprobe.in" H1 F1000 T6000 A20 S0.005

;M308 S2 P"e1_temp" A"Pinda V2" Y"thermistor" T100000 B3950

;G31 P1000 X22.8 Y3.8 Z1.32 ; BLTouch, Z offset with MICRO SWISS NOZZLE

;M574 Z1 S2 ; Set Z axis endstop, controlled by probe

M557 X35:237 Y7:203 S99 ; Define mesh grid for probing; Z-Probe Setting for PINDA v2

; 1 - If using PindaV2, Remove above M558 & M950 lines, replace with the following M558 & M308 line

; 2 - Uncomment one of the Z-Offsets below, follow the wiki guide steps to get the proper Z-offset for your printer

; 3 - Comment out the 2 BLTouch lines in the homez and homeall files

;

; M558 P5 C"^zprobe.in" I1 H1 F1000 T6000 A20 S0.005 ; Prusa PindaV2

; M308 S2 P"e1_temp" A"Pinda V2" Y"thermistor" T100000 B3950 ; Prusa PindaV2

;

; Z-Offsets - Read here: https://duet3d.dozuki.com/Wiki/Test_and_calibrate_the_Z_probe

; G31 P1000 X23 Y5 Z0.985 ; PEI Sheet (Prusa) Offset Spool3D Tungsten Carbide

G31 P1000 X22 Y4 Z0.569 ; PEI Sheet (Prusa) Offset MICRO SWISS NOZZLE

; G31 P1000 X23 Y5 Z1.285 ; Textured Sheet (Prusa) Offset MICRO SWISS NOZZLE

; G31 P1000 X23 Y5 Z0.64 ; Textured Sheet (thekkiinngg) Offset MICRO SWISS NOZZLE; Heatbed Heaters and Thermistor Bed

M308 S0 P"bed_temp" Y"thermistor" A"Build Plate" T100000 B4138 R4700 ; Set thermistor + ADC parameters for heater 0 Bed

M950 H0 C"bedheat" T0 ; Creates Bed Heater

M307 H0 A91.5 C264.0 D10.2 S1.00 V24.0 B0 ; Bed PID Calibration @ 75c - updated 11AUG2020

M140 H0 ; Bed uses Heater 0

M143 H0 S120 ; Set temperature limit for heater 0 to 120C Bed; Filament Sensor

;M591 D0 P2 C"e0stop" S1 ; Filament Runout Sensor; HotEnd Heaters and Thermistor HotEnd

; !!! Use this line for stock thermisotr: M308 S1 P"e0_temp" Y"thermistor" A"Nozzle" T100000 B4725 R4700 ; Set thermistor + ADC parameters for heater 1 HotEnd

M308 S1 P"e0_temp" Y"thermistor" A"Nozzle" T100000 B4725 R4700 ; Set thermistor + ADC parameters for heater 1 HotEnd

M950 H1 C"e0heat" T1 ; Create HotEnd Heater

M307 H1 A311.0 C130.0 D4.3 S1.00 V24.1 B0 ; Hotend PID Calibration @ 240c - updated 09AUG2020

M143 H1 S285 ; Set temperature limit for heater 1 to 285C HotEnd

M302 S190 R190 ; Allow cold extrudes, S-Minimum extrusion temperature, R-Minimum retraction temperature; Fans

M950 F1 C"Fan1" Q1000 ; Creates HOTEND Fan

; FAN 40X10MM 24VDC - 6.0 CFM (0.168m³/min).

; Digi-Key: G4010L24B-RSR

M106 P1 T45 S255 H1 ; HOTEND Fan Settings

M950 F0 C"Fan0" Q5000 ; Creates PARTS COOLING FAN

; BLOWER 50X15MM 24VDC - 5.0 CFM (0.140m³/min)

; Digi-Key: B5015E24B-BSR

M106 P0 H-1 ; Set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned off PARTS COOLING FAN

; The following lines are for auto case fan control, attached to 'fan2' header on duet board

;M308 S4 Y"drivers" A"TMC2660" ; Case fan - configure sensor 2 as temperature warning and overheat flags on the TMC2660 on Duet

; !!! Reports 0C when there is no warning, 100C if any driver reports over-temperature

; !!! warning , and 150C if any driver reports over-temperature shutdown

;M308 S3 Y"mcu-temp" A"Duet2Wifi" ; Case fan - configure sensor 3 as thermistor on pin e1temp for left stepper

;M950 F2 C"fan2" Q100 ; Case fan - create fan 2 on pin fan2 and set its frequency

;M106 P2 H4:3 L0.15 X1 B0.3 T40:70 ; Case fan - set fan 2 value

;M912 P0 S-5.5 ; MCU Temp calibration - default reads 5.5c higher than ambient; Tools

M563 P0 D0 H1 F0 ; Define tool 0

G10 P0 X0 Y0 Z0 ; Set tool 0 axis offsets

G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C

T0 ; Set Tool 0 active; Relase X, Y, and E axis

M18 XYZE ; Unlock the X, Y, and E axis