It looks like the SD card managed to corrupt itself. We managed to recover most of the data on it but had to recreate the config.g file.

Lesson learned to keep good backups and perhaps the SD card is due for replacement.

It looks like the SD card managed to corrupt itself. We managed to recover most of the data on it but had to recreate the config.g file.

Lesson learned to keep good backups and perhaps the SD card is due for replacement.

We were adjusting the Z-offset value for the BLTouch probe in the config file when upon rebooting the mainboard the PanelDue went blank and DWC would not connect. I can connect through pronterface but the Duet will not respond to a ping and the PanelDue is just black (backlight is on).

I have tried the following so far:

Verified the SD card using M122 and M39 and M122 P104 S10. All worked fine.

I checked the diag LED, it comes on for about 0.5 seconds as expected and goes off. All voltage LEDs are lit as well.

I think I've exhausted all of the troubleshooting steps I found on the wiki. Any ideas?

Thank you,

Ian

@OwenD I do have bearings on my filament spool. The issue is getting the spool moving each time the filament retracts and then pulls again.

@dc42 I am using 3.3. Perhaps I should try the 3.4 update?

Anyone?

This issue stems from using 10kg spools with this printer and the initial inertia of getting the spool rotating trips the filament sensor. I'm open to other suggestions on solving this.

I've noticed (at least for my printer) that about 90% of filament too little movement errors can simply be resumed and the printer keeps working. My thought is to create some conditional G code that will automatically resume the printer once. If it pauses again within 5 seconds or so after resuming, then it will stay paused. If the printer keeps printing after auto resuming, then this cycle can reset and repeat for future errors.

However, I'm not much of a programmer and am trying to figure out how to implement this. I'll have to initialize some variables in my start G code and I imagine filament-error0.g will have some sort of test to see whether it has just paused within the last 5 seconds or so.

Any suggestions would be greatly appreciated!

I'd love to see this implemented. I have a Modix printer that uses Duet hardware and prints are regularly 24 hours or longer. Being able to set up preventive maintenance based on clocked print hours would be extremely useful. All of our other printers have this feature! (Craftbot, Flashforge, Stratasys)

@zapta Yes kind of - some connectors are ultrasonic welded.

Most definitely not something available to the hobbyist nor necessary for a 3D printer.

Pretty cool process nonetheless:

http://www.bluejeanscable.com/articles/ultrasonic-welding.htm

I decided to try and decipher the OpenSCAD model and came up with this model that isn't full detailed but should be sufficient for anyone trying to design mounting provisions above an extruder.

@t3p3tony I see that. Attempted to go through FreeCAD to get a .step file but that's proving tricky. Looking like I'll reverse engineer it from the .stl file and remake it in SW.

@thatninthguy Thanks but I need the magnetic filament monitor version. I'm trying to incorporate solid mounting for it in an extruder bracket im designing.

I could use the .stl files but SW hates modelling with meshes.

The github only has .stl files for the magnetic filament monitor enclosure v2. Is it possible to upload CAD files that are solid bodies?

For some reason, Solidworks won't open the step files here either:

https://github.com/Duet3D/FilamentMonitors/tree/master/Filament_Monitor_Magnetic/enclosure

@dc42 Sure thing

M115

FIRMWARE_NAME: RepRapFirmware for Duet 2 WiFi/Ethernet FIRMWARE_VERSION: 2.05.1 ELECTRONICS: Duet Ethernet 1.02 or later + DueX5 FIRMWARE_DATE: 2020-02-09b1

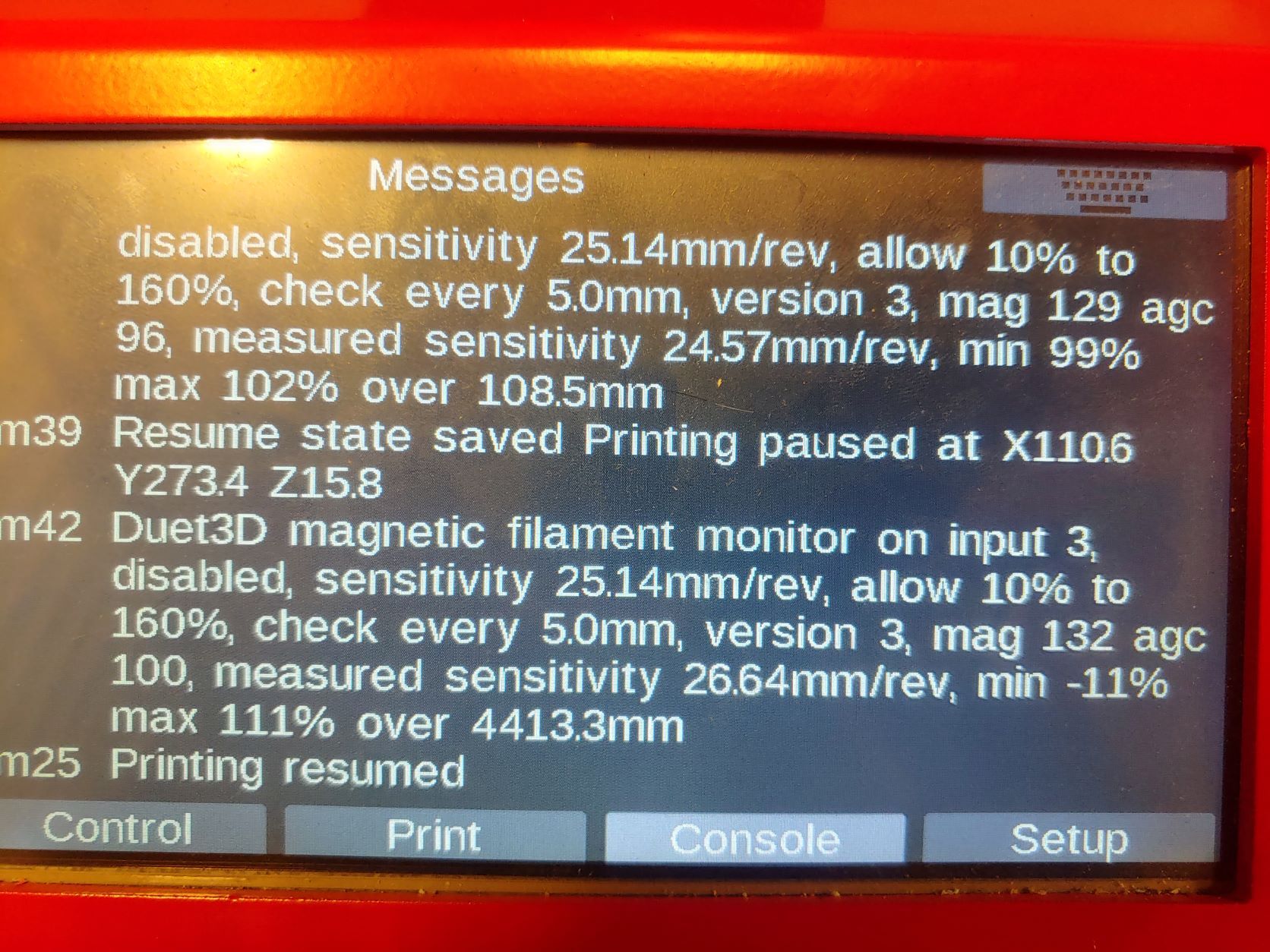

See the picture below from the printer console. This is the output of M591 D0.

It correctly says disabled but it still seems to be pausing prints when outside of the allowed error range.

Also how does the math work out to a negative percentage error? Is this related to retractions not registering correctly? I'm thinking I need to more securely mount the sensor above the extruder. Right now its just sitting on the PTFE tube about 25mm above the feed wheels.

Thanks!!!

Got the sensor working but I'm getting a lot of reporting too little movement errors. The sensor is located immediately above a Titan Aero extruder so theres maybe 25 mm of filament between the sensor and the extruder drive. All is contained in ptfe tubing.

My current M591 output is:

M591 D0

Duet3D magnetic filament monitor on input 3, enabled, sensitivity 25.14mm/rev, allow 90% to 110%, check every 15.0mm, version 3, mag 131 agc 92, measured sensitivity 25.67mm/rev, min 91% max 104% over 45.1mm

I'm confused on why it paused at 91% when my threshold is set for 90%?

Regardless, I'm still getting instances where the percentage is down to 20% or so but no issues in filament movement.

Any suggestions would be greatly appreciated!

I was misunderstanding the meaning of "Reporting No Data" to mean that I was having a bad connection on the signal output. I sanded down my housing and things seem to be working now.

I guess the tolerance for the magnet distance is really tight!

My agc is reading 128, is it worth sanding down the housing to get this value to the 80-105 range?

@alankilian

M591 reports no data received. The duet 2 is not talking to the filament sensor and I'm trying to figure out why.

Just hooked up a magnetic filament sensor to the E0 input, my M591 command in the config file is:

M591 D0 P3 C3 S1 R70:130 L28.4 E3.0 A0

I get a red solid LED on the Duet board but the filament sensor LED flashes red 7 times.

M591 D0 reports:

Duet3D magnetic filament monitor on input 3, enabled, sensitivity 28.40mm/rev, allow 70% to 130%, check every 3.0mm, no data received

I've triple checked that I am actually connected to the E0 input on the duet. I have two filament sensors and both perform identically.

Any ideas?

@nightlonk42 I've been waiting on them for about a year now and unfortunately, last time I talked to Filastruder, they had no parts at all. I also wanted to SLA print my own housing but they didn't have any electronics.

Re: Stock Shortages

Is it possible to get the electronics for the filament sensor? Last I heard the issue was related to getting the cases injection molded. I can resin print the enclosure so I would just need the electronics and hardware.