Hi,

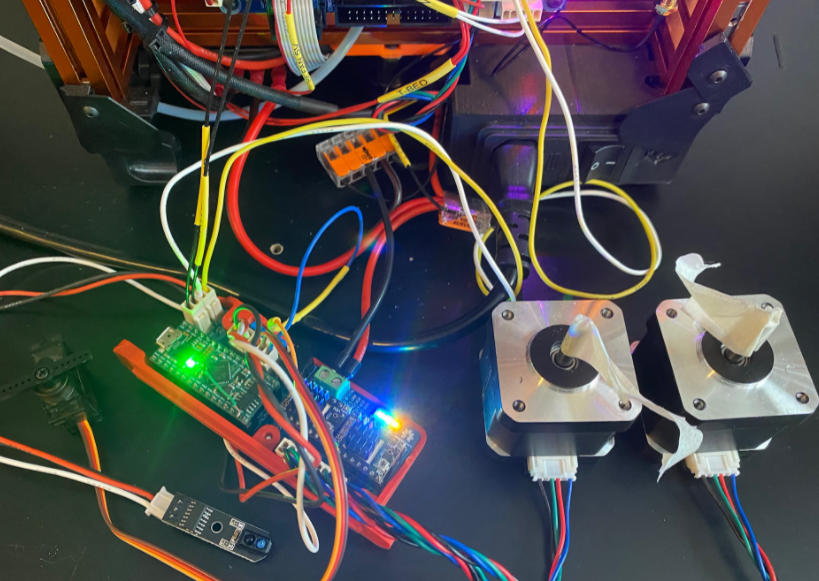

I'm tinkering with a little project where I'm using the Sammy C21 and I want to enable support for two TMC2209 drivers with serial communication/configuration.

It was fairly straightforward to modify the Sammy C21 firmware so that I can have two drivers with step/dir control. However when I want to enable UART/sercom things get a bit more complicated.

Part of it is probably because I don't know what I'm doing

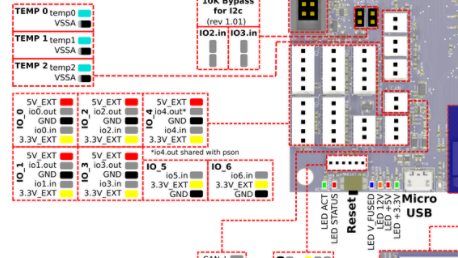

These are the defines I'm using at the moment

#define BOARD_TYPE_NAME "SAMMYC21"

#define BOOTLOADER_NAME "SAMMYC21"

// General features

#define HAS_VREF_MONITOR 0 // Nope no VREF-monitor

#define HAS_VOLTAGE_MONITOR 0 // Nope, this wil break the build!

#define HAS_12V_MONITOR 0

#define HAS_CPU_TEMP_SENSOR 1

#define HAS_ADDRESS_SWITCHES 0 // What is this?

#define HAS_BUTTONS 0 // Nope

// Drivers configuration

#define SUPPORT_DRIVERS 1

#define HAS_SMART_DRIVERS 1

#define HAS_STALL_DETECT 0

#define SINGLE_DRIVER 0 // UE

#define SUPPORT_SLOW_DRIVERS 0 // UE

#define SUPPORT_DELTA_MOVEMENT 0

#define USE_EVEN_STEPS 0 // UE

//------------------------------------------------------------------

#define ACTIVE_HIGH_STEP 1 // 1 = active high, 0 = active low

#define ACTIVE_HIGH_DIR 0 // 1 = active high, 0 = active low

#define SUPPORT_TMC51xx 0

#define SUPPORT_TMC2160 0

#define SUPPORT_TMC2660 0

#define SUPPORT_TMC22xx 1

constexpr size_t NumDrivers = 2;

constexpr size_t NumSmartDrivers = NumDrivers;

constexpr size_t MaxSmartDrivers = NumDrivers;

#define TMC22xx_USES_SERCOM 1 // UE

#define TMC22xx_HAS_MUX 1 // I don't have a MUX but if I set this everything gets easier it seems

#define TMC22xx_SINGLE_DRIVER 0 // UE

#define TMC22xx_HAS_ENABLE_PINS 0 // <- Am I supposed to set this ?

#define TMC22xx_VARIABLE_NUM_DRIVERS 0 // No, it's fixed to two

#define TMC22xx_USE_SLAVEADDR 1 // What does this mean ?

#define TMC22xx_DEFAULT_STEALTHCHOP 0 // No thanks

constexpr Pin GlobalTmc22xxEnablePin = PortAPin(9);

constexpr uint8_t TMC22xxSercomNumber = 4;

Sercom * const SERCOM_TMC22xx = SERCOM4;

//Sercom * TMC22xxSercoms[NumDrivers] = {SERCOM3, SERCOM3};

constexpr Pin TMC22xxSercomTxPin = PortAPin(22);

constexpr GpioPinFunction TMC22xxSercomTxPinPeriphMode = GpioPinFunction::C;

constexpr Pin TMC22xxSercomRxPin = PortAPin(20);

constexpr GpioPinFunction TMC22xxSercomRxPinPeriphMode = GpioPinFunction::D;

constexpr uint8_t TMC22xxSercomRxPad = 2;

Does the defines above look right for a simple TMC2209 board?

I now have a few build errors left

../src/Platform.cpp: In function 'void Platform::Spin()':

../src/Platform.cpp:983:21: error: 'powered' was not declared in this scope

983 | SmartDrivers::Spin(powered);

| ^~~~~~~

../src/Platform.cpp: In function 'void Platform::SetOrResetEventOnStall(DriversBitmap, bool)':

../src/Platform.cpp:1814:3: error: 'eventOnStallDrivers' was not declared in this scope

1814 | eventOnStallDrivers |= drivers;

| ^~~~~~~~~~~~~~~~~~~

../src/Platform.cpp:1818:3: error: 'eventOnStallDrivers' was not declared in this scope

1818 | eventOnStallDrivers &= ~drivers;

| ^~~~~~~~~~~~~~~~~~~

src/subdir.mk:24: recipe for target 'src/Platform.o' failed

The first is because I don't have a voltage monitoring so the variable is never defined.

The second is about the same but for stallguard.

As you can see I'm testing my way forward

I know that you guys have probably a lot of more urgent things to handle but I would appreciate a nudge in the right direction if possible.