@bearer its all inside a case  dangit... lol

dangit... lol

Posts made by dunginhawk

-

RE: Sleep, now I cant see duetposted in General Discussion

-

Sleep, now I cant see duetposted in General Discussion

Good morning... So yesterday as I was toying with ending gcode etc I think i wanted to try out the sleep command.

Woke up this morning after a print had finished and cant connect to my duet. Powered it off, back on again, nothing.

Is this normal behavior? Just curious as to why suddenly ive lost wifi access to it.

3.1 fw version , duet wifi board.

thanks -

RE: Fresh board, fresh upgrade. Heater issuesposted in Duet Hardware and wiring

well, the default is turds

that seemed to have resolved it. keep u posted.

that seemed to have resolved it. keep u posted. -

RE: Fresh board, fresh upgrade. Heater issuesposted in Duet Hardware and wiring

not sure how 4000 got put in there.. but that would explain why this thing when asked to move up 5mm goes up lets see about 10x that haha

-

RE: Fresh board, fresh upgrade. Heater issuesposted in Duet Hardware and wiring

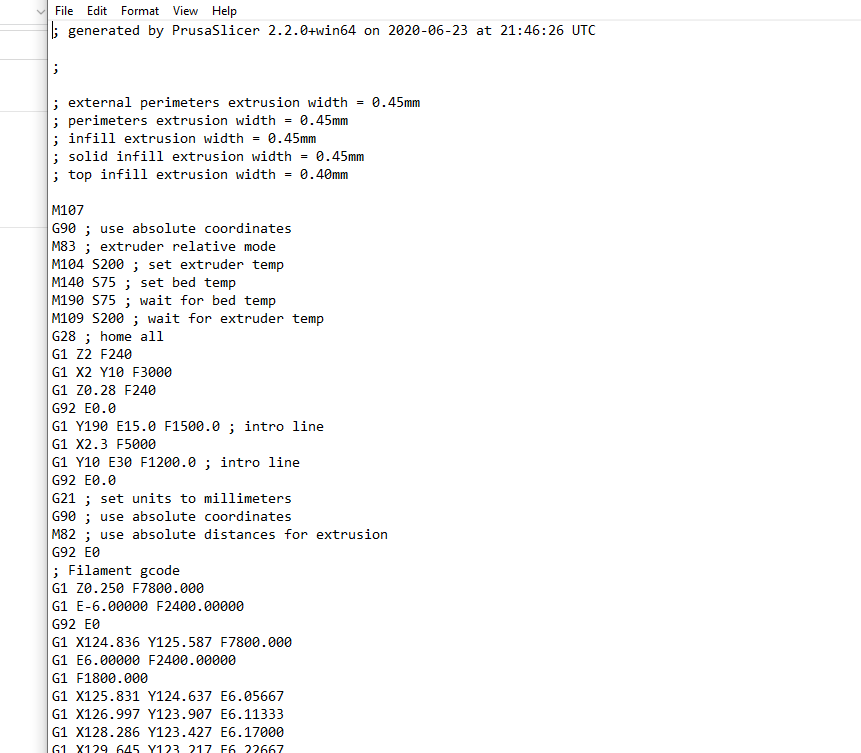

whats odd though is the nozzle is perfect when z is at 0. its only after the print starts does it raise up. Its like the gcode from the slicer is telling it to move up.

But here is the first bit of gcode.

-

RE: Fresh board, fresh upgrade. Heater issuesposted in Duet Hardware and wiring

I know its exactly -3 to where I need to print.

So can i just modify that G92 Z0 to be G92 Z-3?thank you kindly for the help

-

RE: Fresh board, fresh upgrade. Heater issuesposted in Duet Hardware and wiring

@Phaedrux i was missing the M501

printing happily away now..

printing happily away now..

The only outstanding issue now is the fact that my printer automatically goes up 3mm (default) before it starts printing. So its air printing.i can mod the Z offset in slicer settings, but id rather add it to firmware.

Should be fairly easy, but I am not smart in these ways haha

thanks for the 501 help -

RE: Fresh board, fresh upgrade. Heater issuesposted in Duet Hardware and wiring

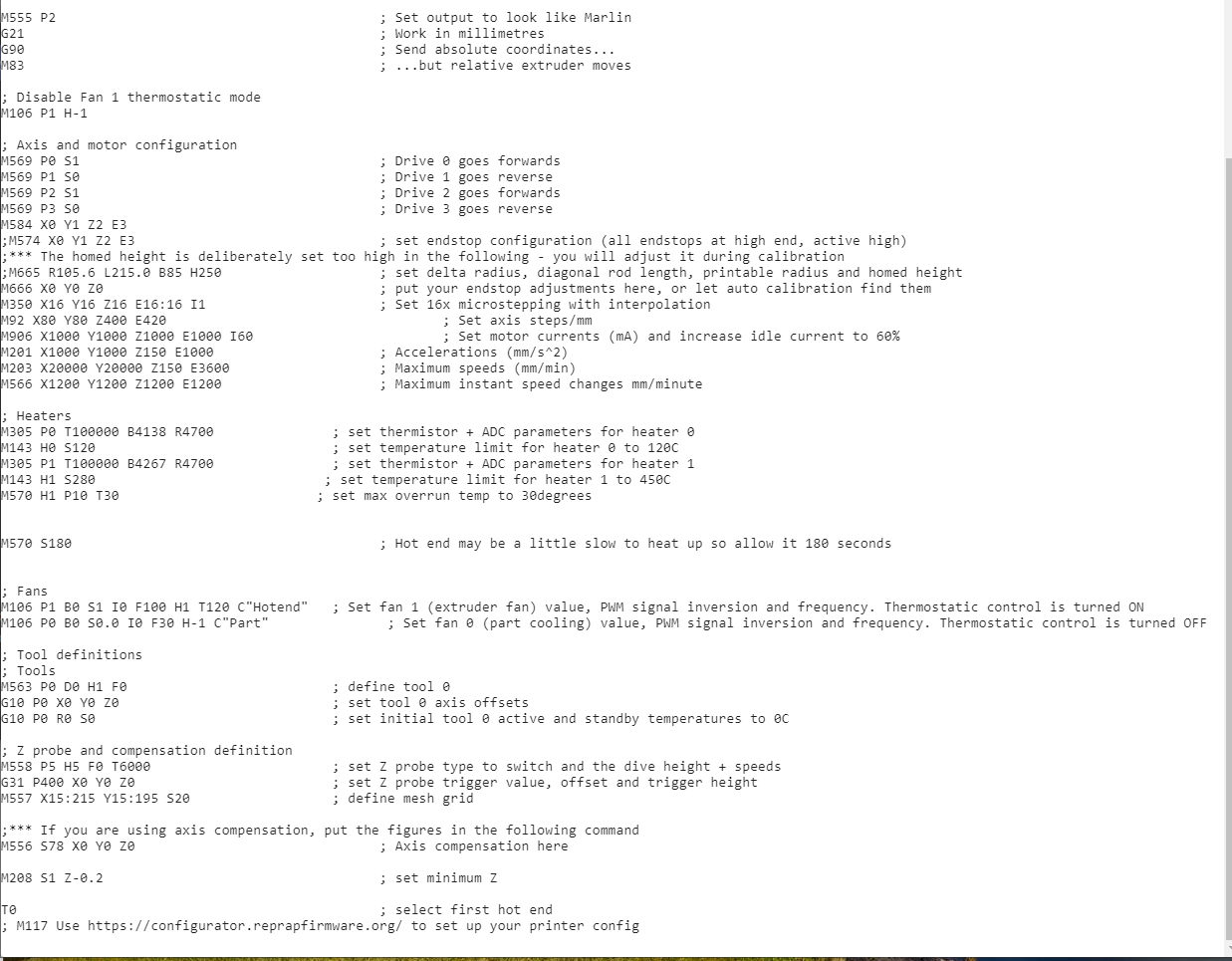

Ok, i went ahead and rebuilt it.

Everything wrks except the bed heater.

its a slow bed heater, so its throwing a fault.

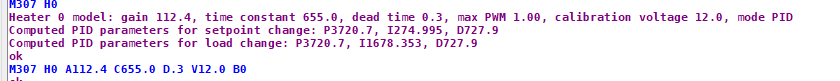

Ive tuned it, and made this change.

Still happening though... any ideas?

thanks

-

RE: Fresh board, fresh upgrade. Heater issuesposted in Duet Hardware and wiring

Yeah, i was afraid of that... I just have a problem knowing all the right stuff for the configurator...

The config I have there is mostly a copy/paste (to some extent) of my version 2 config.. so yeah clearly something is amiss. -

Fresh board, fresh upgrade. Heater issuesposted in Duet Hardware and wiring

So, I have a quick (hopefully) question.

I just replaced a thought to be bad duet board with a new one. Finally got the FW upgraded and am on 3.x.

I moved over some of the stuff from my old config.g and the axis are working great.

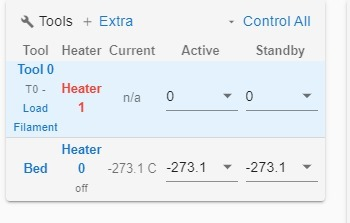

Everything is homing, times are good.However, when i try to heat up the bed, or the hotend, I have the bed at

-273.1 and the heater 1 basically MIA.

I am 99.9% sure I wired everything exactly the same as before. I am happy to provide any details to assist you in assisting me.

thank you all...

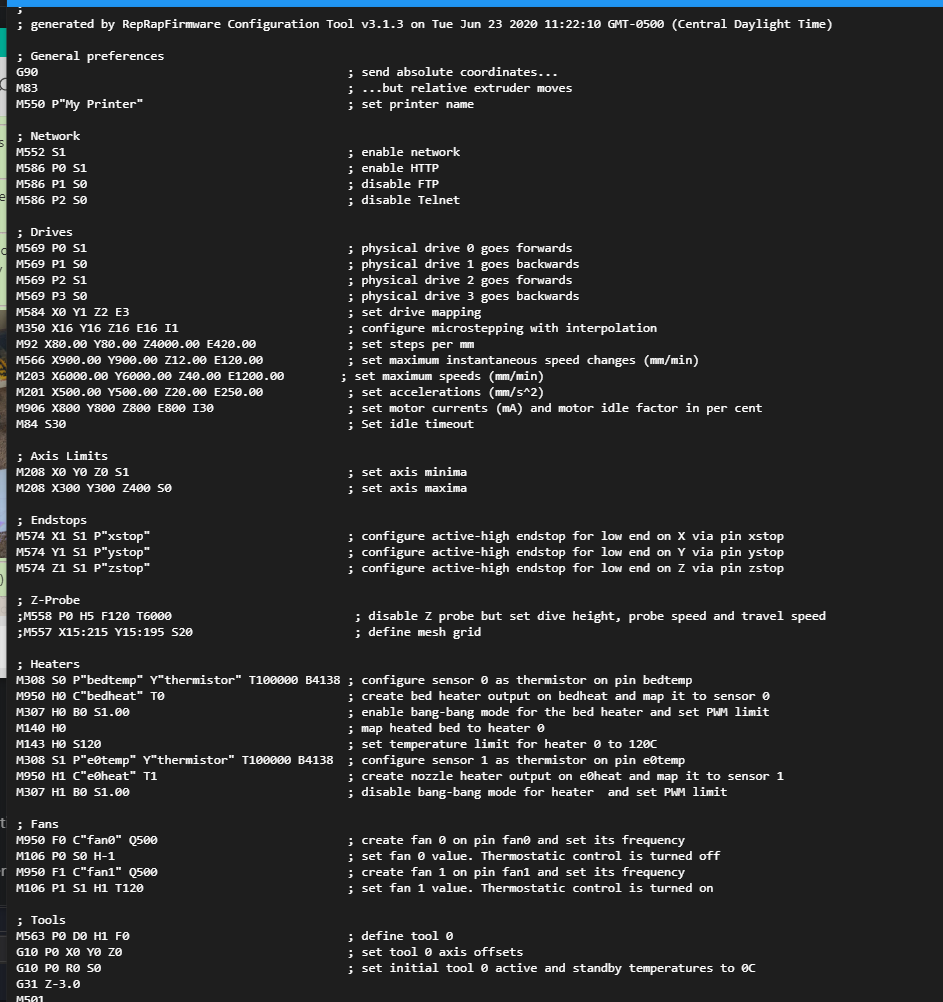

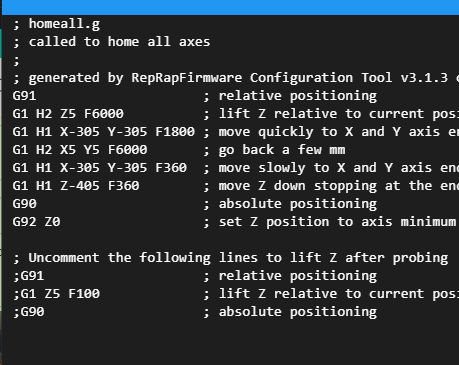

Here is a copy of my config.g

thank you

-

Is BL Touch the best option?posted in General Discussion

So I am running a duet wifi (and I love it) but I have considered adding ABL to my setup. Just curious is bl touch seems to be the best option?

I have a modded CR 10 which includes a Nova hot end with a duet board. Otherwise its fairly stock (i guess a new extruder too).

Just curious which kit to buy, or what I need to buy. It seems there are TONS of links on amazon to large kits, small kits, etc... Ive never bought a bl touch, so Im not sure how much of said kit I would need???

Thank you guys/gals. -

RE: Extruder skipping predictably???posted in General Discussion

so yeah, i think that fixed the issue... Ive been printing most of the day now without issue... Im doing retraction testing now...

-

RE: Extruder skipping predictably???posted in General Discussion

I think i have it resolved... THINK.

I have a line of code M106 P1 B0 X0.6 S0.3 I0 F100 H1 T120 C"Hotend" ; Set fan 1 (extruder fan) value, PWM signal inversion and frequency. Thermostatic control is turned ONbasically that turns on the fan when the hotend gets to 120C.

However that S.03 only runs it at a slow speed. Changing the S.03 to S1 made a HUGE difference.

Before I shot with a laser thermometer the heat sink at nearly 60 degrees C.

After the change to the fan speed, 27 C.Was just some confusion with my friend (inventor of nova) on different models of fan I got vs some others. Simple mixup. Ill report back on whether this is the fix for sure. but 1 hour in to a PLA print it appears to be the case.

-

RE: Extruder skipping predictably???posted in General Discussion

Retraction didnt seem to make a difference... 0 retraction or 5mm. no difference.

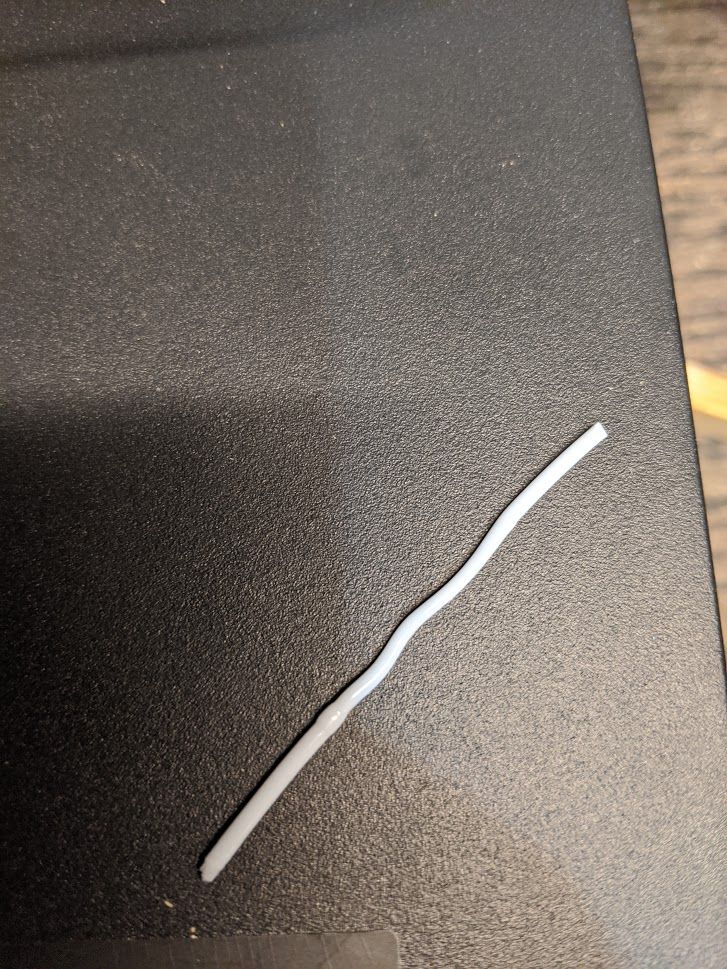

This is a picture of the issue in a nut shell. so I can manually push filament through, but as soon as I stop. then start a real print, its like the extruder itself cant push the filament through. Could I need a new gear? How likely is that?

You can see a bulge right there too, i THINK that is a ring inside the bowden fitting on the top of my hot end. if so, the heat is WAY higher than it should be.THoughts?

-

RE: Extruder skipping predictably???posted in General Discussion

So its happened with multiple PLA filaments

2 different PETG filaments as well.

It has not yet happened on ABS, but i think thats more likely because I havent tried printing anything large with it yet. ABS prints have all been small.

It MAY be heat creep. I will try a larger ABS print now to see what happens.I dont have any pics of failed prints, but i know all the answers.

Part fan is a BAF https://store.3dpassion.com/collections/store/products/baf

The fan blows directly on the part and I suppose the hot end as well... However the hotend maintains its temps just fine... Its a great hotend in that regard. I have even ramped PLA up to 220c to see if it was potentially cooling pre maturely, but no... it still occured.WHen it skips (the first few times) it was about layer 20 of a large print, and it basically just skipped back, and missed a tiny stretch of extrusion. Yes, inconsistent extrusion. Eventually after a little while of this behavior it just clogs or stops extruding...

Hobbed gear slipped on the filament. Not making any odd noises except for when it skips.

I am friends with the creator of Nova. we are working on it. Trying some diff things... kinda stuck at the moment.

Too much retraction would be how much? I had it set at .6mm, and 2mm (because it oozed a bit much with .6). Doesnt seem to be too much retraction... too low retraction causes major oozing... I guess I could try VERY low retraction .5 for example and lower the temp a bunch on the Hot End to control the oozing.

Part fan has no impact. Its happened in layers 1, 2, 3 before cooling fan, or at layer 20 when the fan is on.

Never heard of the cup of water test.

Layer height .2 .5 mm nozzle, speeds vary from 20 - 100mm/s mostly 40-60 during this time where its happening. Speed up , slow down doesnt seem to impact things. Gear is not loose (ill double check tho).

I am more than willing to swap the CR10 extruder, IF i know its the cause.

-

RE: Extruder skipping predictably???posted in General Discussion

I thought it might be a gap between my hot end and the PTFE fitting not being tight, but I remedied that and it still skips... Im really confused as to why this would be happening...

Any help would be appreciated.

thank you -

Extruder skipping predictably???posted in General Discussion

So My extruder (stock cr10) has been skipping at layer 19 roughly of a duet wifi CR10 case i am trying to print. Up until then, not a single skip.

Ok, I thought maybe a model issue or something...New model, sliced it up, and it started skipping in layer 1 this time. I am so freaking frustrated... Happens on PETG, or PLA, so I assume anything.

I am running a Nova Hot end, hence the fast speeds on X Y. The hotend is extremely capable of 200mm/s easy.

Regardless of that, when these issues are occuring I am printing less than 100mm/s or even slower..M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet; Drives

M569 P0 S1 ; physical drive 0 goes forwards

M569 P1 S0 ; physical drive 1 goes reverse

M569 P2 S1 ; physical drive 2 goes forwards

M569 P3 S0 ; physical drive 3 goes reverse

M584 X0 Y1 Z2 E3 ; set drive mapping

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X80.00 Y80.00 Z400.00 E93.00 ; set steps per mm

M566 X1200.00 Y1200.00 Z40.00 E150.00 ; set maximum instantaneous speed changes (mm/min)

M203 X24000.00 Y24000.00 Z100.00 E1200.00 ; set maximum speeds (mm/min)

M201 X1500.00 Y1500.00 Z150.00 E150.00 ; set accelerations (mm/s^2)

M906 X800 Y800 Z800 E800 I30 ; set motor currents (mA) and motor idle factor in per cent

M572 D0 S0.07

M84 S30 ; Set idle timeout; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X310 Y310 Z400 S0 ; set axis maxima; Endstops

M574 X1 Y1 Z1 S1 ; set active high endstops; Z-Probe

M558 P5 H5 F0 T6000 ; set Z probe type to switch and the dive height + speeds

G31 P400 X0 Y0 Z0 ; set Z probe trigger value, offset and trigger height

M557 X15:215 Y15:195 S20 ; define mesh grid; Heaters

M305 P0 T100000 B4138 R4700 ; set thermistor + ADC parameters for heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M305 P1 T100000 B4267 R4700 ; set thermistor + ADC parameters for heater 1

M143 H1 S450 ; set temperature limit for heater 1 to 450C; Fans

M106 P1 B0 X0.6 S0.3 I0 F100 H1 T120 C"Hotend" ; Set fan 1 (extruder fan) value, PWM signal inversion and frequency. Thermostatic control is turned ON

M106 P0 B0 S0.0 I0 F30 H-1 C"Part" ; Set fan 0 (part cooling) value, PWM signal inversion and frequency. Thermostatic control is turned OFF; Tools

M563 P0 D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C; Custom settings are not defined

-

RE: Z axis issues :) 0 - -405posted in General Discussion

the Y was just moving opposite when I homed it... so i reversed it..

we shall see prints are looking good though.

prints are looking good though.And yes, the bed is all the way back against endstop, and X is left, so 0 0 is front left