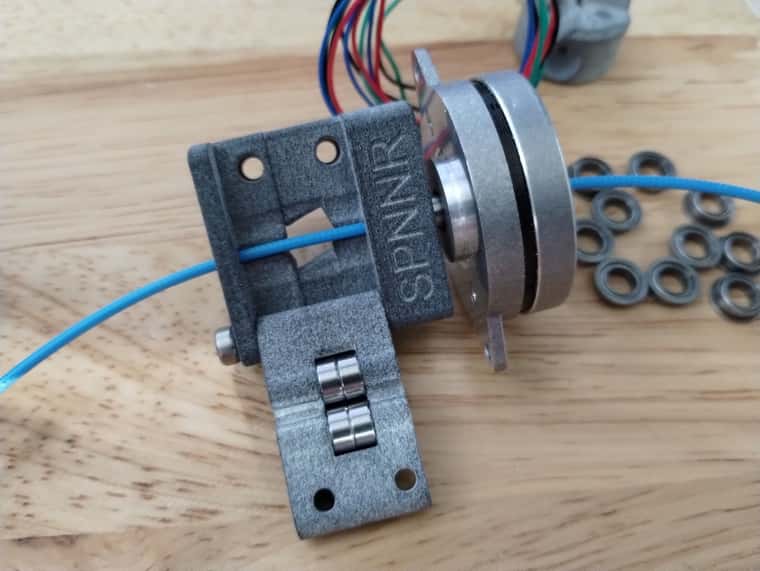

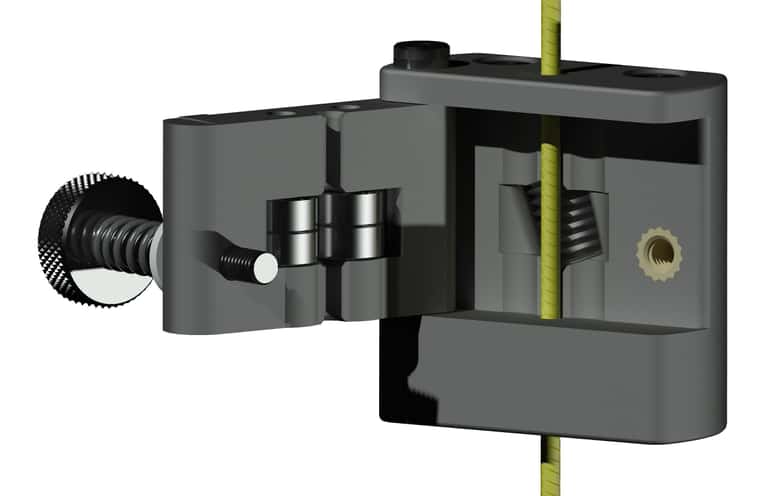

@o_lampe I didn't consider the filament path being a spot where it might flex, that's a good point. The non canted bearings in the door, I considered trying to find a way of adding a 20 degree angle, but then I got to thinking that would decrease the length that the filament is backed and pushed firmly into the groved roller. That length is already limited by the angle of the grooved roller. The shaft for the roller I was intending to be 3mm carbon rod. The bolt and spring for the door is offset because the outer frame is actually 2 pieces so the roller assembly can be inserted. I have a couple different designs I'm playing with in cad and have ordered some sls parts to mess with. Waiting currently on shoulder bolts from China, apparently the boat must be stuck in a canal somewhere. As far as balancing I could prob get it close by calculating up the individual pieces with their specifical gravity and get close. I don't know if I'll try and make this, I might, just figured I'd throw it out for people to think about.