interesting. i didnt think of that. how would i check it? it happen during bed probing cycle

Posts made by BenDiesel

-

RE: heater faultposted in Duet Hardware and wiring

-

heater faultposted in Duet Hardware and wiring

so this has poped up a few times. keep getting a random heater fault. i thought it was the old heater chartrage or thermsistor. so i replace the 30w heater with a new 40w and a new heat block, thermsistor, nozzle and heat break.

it happen again. it didnt seem to want to try to heat the heater after i stopped the print and homed the machine

any idea why this happens? frist time with the new heater

-

RE: rail core 2 300zl cloneposted in My Duet controlled machine

@samlogan87 thank you for the reply. We have the bed leveling working. The problem is were getting inconsistent probing. Are you saying that it could be because each motor is out of sync of some sort?

-

RE: rail core 2 300zl cloneposted in My Duet controlled machine

Update. Still having problems with probing with the precision piezo

At first we thought it was the boden tube causing a error so we removed it. Didn't help

Hoping the piezo guy could help with this.

We reduced the probe speed aswell but no avail.

-

Mpcnc plasma tableposted in My Duet controlled machine

So I have a extra duet wifi bord I been trying to figure out what to do with.

So I have been looking at building th mpcnc as a 4x4 plasma table. I was pondering if the duet could be configured to work with a torch height controller like this one

http://proma-elektronika.com/index.php/en/products/thc-torch-height-control/compact-thc-150

It has 3 outputs that should be monitored. Up down and ark ok -

RE: Multi color printing with Prusa's MMU V2 & Duet?posted in General Discussion

Looks like prusa released a promotion video

https://youtu.be/E1ZxTCApLrs -

RE: Palette 2 / Canvas Hub Announcement -- Duet compatible?posted in General Discussion

Maybe the mosaic setup might be better for a duet 3. Which I think I heard is supposed to have a USB host?

What about the prusa multi material mk2? I think it communicates over spi or can bus and is half the price? -

Pallet 2 or Prusa multi mk2posted in Third-party add-ons

Has there been any thought given to being a leader to implement either of these options? I know the filament sensor would likely be a requirement for the Prusa multi material.

-

RE: rail core 2 300zl cloneposted in My Duet controlled machine

So we got it up and running. Were having a weird increasing z offset each time we probe. Any ideas?

-

Marlin and panel dueposted in PanelDue

Looks like the marlin guys are working on getting the panel due going for their firmware

https://youtu.be/QJx75PWE6dQ

At 13:20ish -

RE: rail core 2 300zl cloneposted in My Duet controlled machine

im hoping he dose.

i should also state we are useing a precision peizo -

rail core 2 300zl cloneposted in My Duet controlled machine

hi im part of a group who are building a core xy based on the railccore 2 300zl from parts leftover from other printers and a few new parts.

right now im trying to figure out how to set up the config.g to get it to work correctly.

we have both motors on the left side of the machine. most corexy i have seen have been on the back or front. is there any special compinsation we need for this?

are the cordinates needed for the 3 z motors in referance to home position or ?heres my current config.g i havent set up bed.g yet

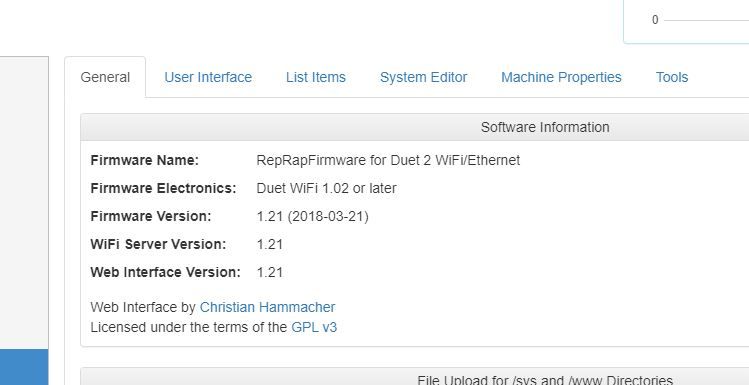

; Configuration file for Duet WiFi (firmware version 1.20 or newer)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool on Mon Jul 16 2018 15:02:06 GMT-0700 (Pacific Daylight Time); General preferences

G90 ; Send absolute coordinates...

M83 ; ...but relative extruder movesM667 S1 ; Select CoreXY mode

; Network

M550 Pcorexy ; Set machine name

M552 S1 ; Enable network

;*** Access point is configured manually via M587

M586 P0 S1 ; Enable HTTP

M586 P1 S0 ; Disable FTP

M586 P2 S0 ; Disable Telnet; Drives

M569 P0 S1 ; Drive 0 goes forwards

M569 P1 S1 ; Drive 1 goes forwards

M569 P2 S1 ; Drive 2 goes forwards

M569 P3 S1 ; Drive 3 goes forwards

M569 P4 S1 ; Drive 4 goes forwards

M350 X16 Y16 Z16 E16 I1 ; Configure microstepping with interpolation

M92 X80 Y80 Z4000 E420 ; Set steps per mm

M566 X900 Y900 Z12 E120 ; Set maximum instantaneous speed changes (mm/min)

M203 X6000 Y6000 Z180 E1200 ; Set maximum speeds (mm/min)

M201 X500 Y20 Z250 E250 ; Set accelerations (mm/s^2)

M906 X800 Y800 Z800 E800 I30 ; Set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout

M584 X0 Y1 Z2:3:4 ; three Z motors connected to driver outputs 2, 5 and 6

M671 X387.3:387.3:-80.3 Y302.5:-2.5:150.1 S0.5 ; leadscrews at rear left, front middle and rear right; Axis Limits

M208 X0 Y0 Z0 S1 ; Set axis minima

M208 X300 Y300 Z300 S0 ; Set axis maxima; Endstops

M574 X1 Y2 S1 ; Set active high endstops; Z-Probe

M574 Z1 S2 ; Set endstops controlled by probe

M558 P1 H5 F120 T6000 ; Set Z probe type to unmodulated and the dive height + speeds

G31 P500 X0 Y0 Z2.5 ; Set Z probe trigger value, offset and trigger height

M557 X15:285 Y15:285 S20 ; Define mesh grid; Heaters

M307 H0 B0 S1.00 ; Disable bang-bang mode for the bed heater and set PWM limit

M305 P0 T100000 B4138 C0 R4700 ; Set thermistor + ADC parameters for heater 0

M143 H0 S120 ; Set temperature limit for heater 0 to 120C

M305 P1 T100000 B4138 C0 R4700 X4 ; Set thermistor + ADC parameters for heater 1 and remap it to channel 4

M143 H1 S280 ; Set temperature limit for heater 1 to 280C; Fans

M106 P0 S1 I0 F500 H1 T45 ; Set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned on

M106 P1 S1 I0 F500 H-1 ; Set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned off

M106 P2 S1 I0 F500 H-1 ; Set fan 2 value, PWM signal inversion and frequency. Thermostatic control is turned off; Tools

M563 P0 D0 H1 ; Define tool 0

G10 P0 X0 Y0 Z0 ; Set tool 0 axis offsets

G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C; Automatic saving after power loss is not enabled

; Custom settings are not configured

; Miscellaneous

T0 ; Select first toolpic is taken looking at front of machine

-

RE: Strange x shiftingposted in Tuning and tweaking

It was I had checked it like 3 times but the 4th showed the y axis pulley was loose.

-

RE: Strange x shiftingposted in Tuning and tweaking

so now im confused. you can see in the pics that the first part that had the problem was bigger then the test cube i just printed. it was a file i sliced a while ago while setting up the printer. the slot is supposed to be straight up not at the angle.

the test block was a file i sliced a while ago. it has the problem for the first half and then it straightens up. it seems to be most pronounced in x and only slightly in y

im confused now.

-

RE: Strange x shiftingposted in Tuning and tweaking

heres my config.g sory i dont know how to put it in a little windown like the others are. i dont see a m556 any were in it

on a side note i printed a test cube that i had sliced before the problem aroused. the problem is still there.the cant is toward the left in the x axis it not angled toward any tower.

would updating the firmware erase my config and network informations?; Configuration file for Duet WiFi (firmware version 1.20 or newer)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool on Mon May 21 2018 14:48:27 GMT-0700 (Pacific Daylight Time); General preferences

G90 ; Send absolute coordinates...

M83 ; ...but relative extruder moves;*** The homed height is deliberately set too high in the following - you will adjust it during calibration.

M665 R162.78 L400.21 B170 H530 ; Set delta radius, diagonal rod length, printable radius and homed height

M666 X0 Y0 Z0 ; Put your endstop adjustments here, or let auto calibration find them; Network

M550 PBigBen ; Set machine name

M552 S1 ; Enable network

M586 P0 S1 ; Enable HTTP

M586 P1 S0 ; Disable FTP

M586 P2 S0 ; Disable Telnet; Drives

M569 P0 S1 ; Drive 0 goes forwards

M569 P1 S1 ; Drive 1 goes forwards

M569 P2 S1 ; Drive 2 goes forwards

M569 P3 S0 ; Drive 3 goes forwards

M350 X16 Y16 Z16 E16 I1 ; Configure microstepping with interpolation

M92 X80 Y80 Z80 E2571.42 ; Set steps per mm

M566 X1200 Y1200 Z1200 E40 ; Set maximum instantaneous speed changes (mm/min)

M203 X18000 Y18000 Z18000 E1200 ; Set maximum speeds (mm/min)

M201 X1000 Y1000 Z1000 E120 ; Set accelerations (mm/s^2)

M906 X1000 Y1000 Z1000 E800 I30 ; Set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 Z0 S1 ; Set minimum Z; Endstops

M574 X2 Y2 Z2 S1 ; Set active high endstops; Z-Probe

M558 P5 R0.4 H5 F1000 T6000 ; Set Z probe type to effector and the dive height + speeds

G31 P100 X0 Y0 Z-0.25 ; Set Z probe trigger value, offset and trigger height

M557 R165 S20 ; Define mesh grid; Heaters

M301 H0 S1.00 P10 I0.1 D200 T0.4 W180 B30 ; Use PID on bed heater (may require further tuning)

M305 P0 T100000 B4138 C0 R4700 ; Set thermistor + ADC parameters for heater 0

M143 H0 S120 ; Set temperature limit for heater 0 to 120C

M305 P1 T100000 B4725 C7.06e-8 R4700 ; Set thermistor + ADC parameters for heater 1

M143 H1 S280 ; Set temperature limit for heater 1 to 280C; Fans

M106 P0 S0.0 I0 F2500 H-1 ; Set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off

M106 P1 S1 I0 F500 H1 T45 ; Set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on

M106 P2 S1 I0 F500 H1 T45 ; Set fan 2 value, PWM signal inversion and frequency. Thermostatic control is turned on; Tools

M563 P0 D0 H1 ; Define tool 0

G10 P0 X0 Y0 Z0 ; Set tool 0 axis offsets

G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C; Automatic saving after power loss is not enabled

; Custom settings are not configured

; Miscellaneous

M501 ; Load saved parameters from non-volatile memory

T0 ; Select first tool -

RE: Strange x shiftingposted in Tuning and tweaking

All good suggestions I'll look into when I get a chance. It dose not align up.with a tower but it dose ling up with true x axis. I have sliced 2 files separate and has done this. I'll have to reprint a older file to.see if it dose it.

-

RE: Strange x shiftingposted in Tuning and tweaking

Well it's a delta so no real x motor. And it started randomly after one print.

-

Strange x shiftingposted in Tuning and tweaking

Trying to print on my tevo and the whole part prints in a strange way. It is printing up and to the right. Any ideas

-

RE: Rc speed controllerposted in Duet Hardware and wiring

Interesting.

My understanding was that the remote transmitter the "arm" feature.