Hi Guys,

I thought I will share with you unit that we developed

- 5 colours

- active heating

- rewind of the filament

Hi Guys,

I thought I will share with you unit that we developed

@Phaedrux I have been pining target and had disconnect - ping had no issues at all.

Hi,

has anyone used Duet boards to build a waterjet cutter?

@T3P3Tony you guys missed the fact where I say that the filament usage is reported correctly.

also the extruder drive was correct at the start.

I believe this is an error with the coding and the counter flips once it has reached certain distance

I believe it is a code bug with variable type definition - it simply cannot handle such a large number properly

@magnets99 it would be impossible to experiment due to the fact that it used over 12kg before it got to this point

@dc42 thanks a lot for the info.

I think i will give the macro a go

and no I am not using pogo pins - I am using USB cable.

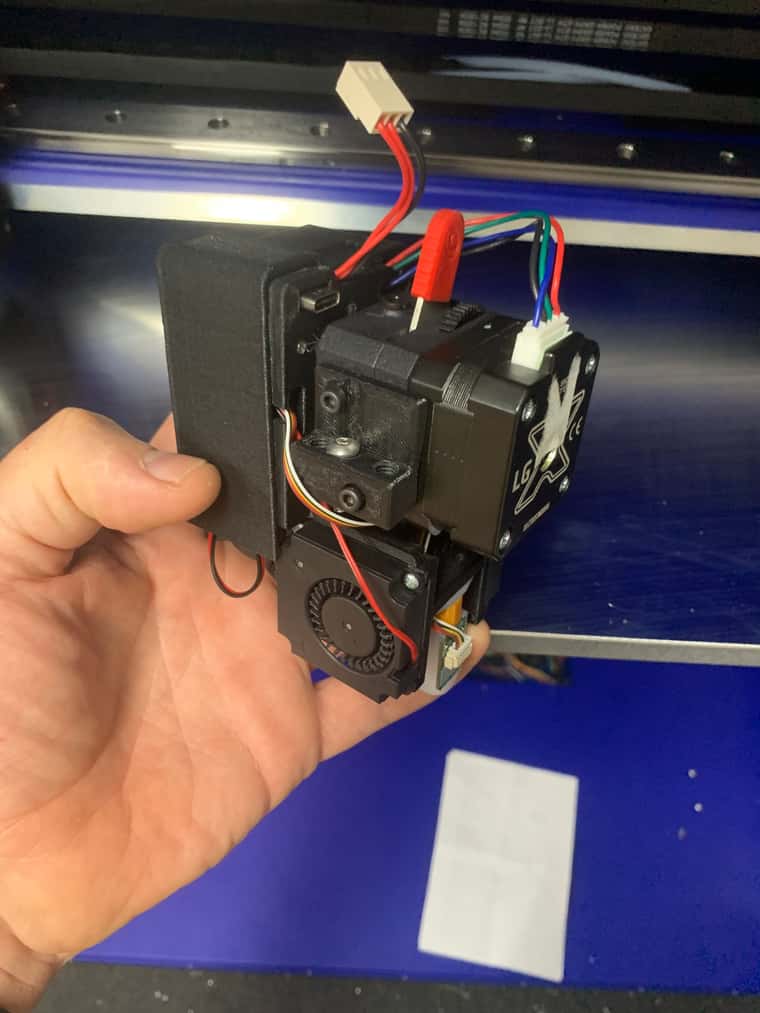

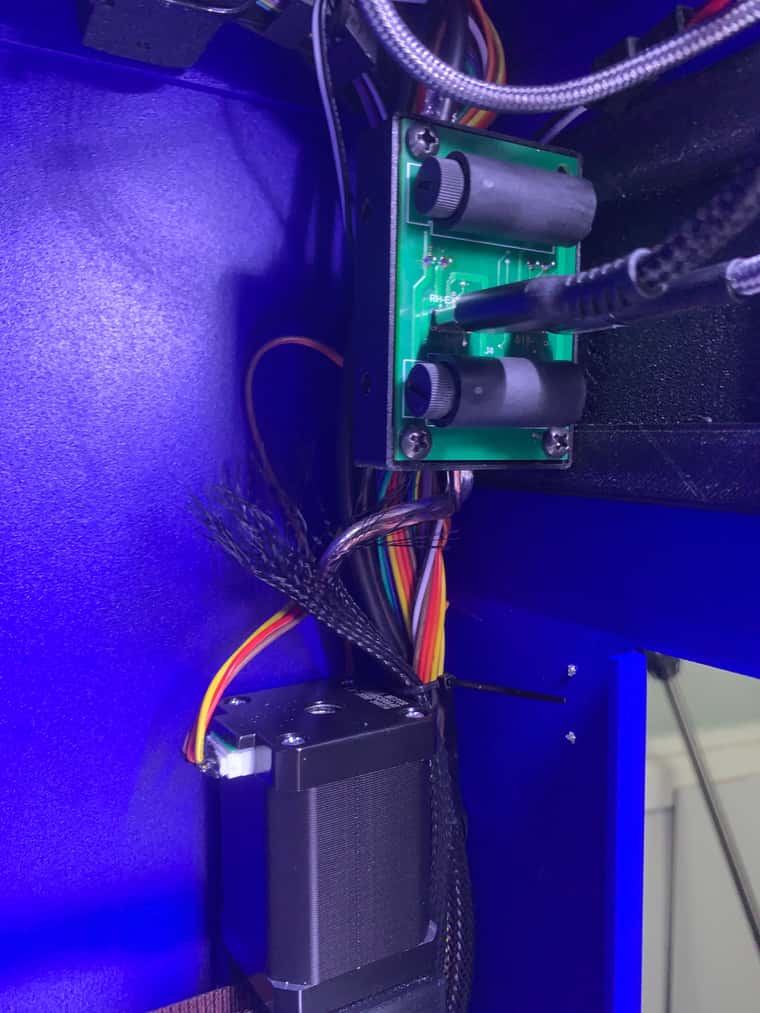

I made a small PCB board to go on the extruder and a distribution board to split can signal into two feeds.

by using USB C 3.2 i think I can supply ennough current at 24V

if anyone is interested I could share the designs

Hi again

so the setup is 1 tool with 4 heaters.

Tool is setup by assigning multiple heaters to it and it works fine once the temp is set all heaters would heat up and would control the temp.

the problem is that it would not give back control using either M104 or M116 - it just sits there

if the extra heaters are removed it will hand over the control once the heater reaches the temperature.

is there a magic trick to make it work? is it tolerance limits that need to be adjusted - maybe it is not exactly same temperature between the heaters and it is waiting for all of them to match exactly?

@Phaedrux do you know if Speed Factor overrides just the speed or acceleration too? especially m204?

@Phaedrux said in Speed factor doesn't honor M203:

Could you verify in 3.6 beta 4?

printer is running now - thats why I asked if anyone else has the same issue.

3.6.0-beta.2

i know i know it is beta, but before i start changing versions I was just wondering if it is actually the case

Hi,

can please anyone confirm that if you crank up speed factor it will not honor max M203 speeds?

I have this

M203 X20000.00 Y20000.00 Z150.00 E15000.00 ; set maximum speeds (mm/min)

and if i crank up the Speed factor it will got way over 333mm/s

@oliof pretty much all others use them. I use them with my custom setup too and it works great.

@T3P3Tony USB connectors would be nice option for CAN and Power transfer.

@wdenker Orca slicer works with Duet no problem at all. I am using it on multiple printers. Duet3 5 Mini boards on Wifi

@dc42 I am not sure I will be able to do that.

the issue was on the start of the printer and only seen it a couple of times.

sorry