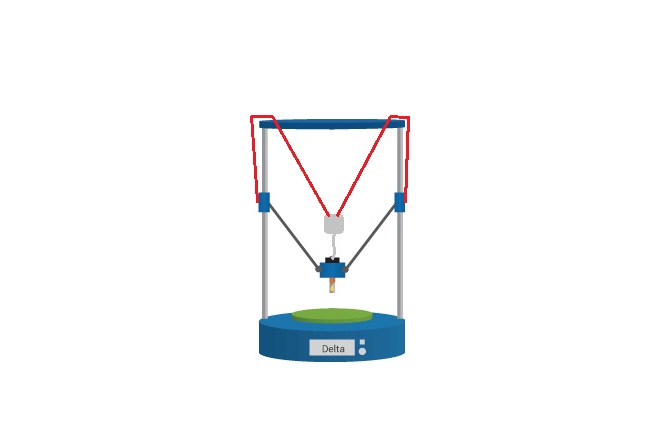

Flying extruder with 4th axis

-

@dc42 Other towers do act as you mentioned.

But U_axis doesn't seem to revert to the standard position.

It acts like -15mm offset. If I adopt a magnetic end_stop to avoid a collision, I could even set a positive offset I suppose. -

I'll extend M666 to allow UVW endstop offsets in the next beta release.

Could you make a video of your machine printing, that I can share with others?

-

@dc42

I will in the future.

Currently, I am not prepared for the heat bed. So actual printing is not ready to show. And the 4th tower is a bit ugly.

I can take a video of bed leveling(G32,G29) though.

Is there some dryrun G_code in Reprap firmware? I can't find it. -

I do dry runs simply by not putting any filament in the extruder.

-

@deckingman said in Flying extruder with 4th axis:

So for me on my CoreXY (actually CoreXYUV now) having an actively driven extruder gantry is a better solution than a passive one. I would imagine that would be the case for Deltas too but I know next to nothing about them. If the existing motors will accelerate the print head as fast as you want, while still passively dragging extruders around, and there is no danger of the mechanism causing the effector to tilt, then there is probably no point in motorising the extruder gantry/tower. If on the other hand, the coupling to the extruder carriage could cause the effector tilt, or acceleration is being limited by the motor/mass combination, then using a motor to power the extruder gantry/tower will be beneficial.

Right, I hadn't considered the XY movement. Having the motor quietly resting above the effector makes sense.

I had considered building a scaffold on top of the delta, so the extruder gets strung up by only one tether, but that would maybe lead to more wobbling since 3 tethers with their friction can calm down XY motion better than just one.

As it is, I dont see an issue. Since my frame is weak im accelerating not that hard, but it could become in issue adding more inertia to moves at higher speeds.As a third option i also had thought about fixing the extruder to the carriages, but that would have meant not decoupling the extruder weight from the carriages.

Would be interesting to see if one can add a rod on top of the printer parallel to the towers that is still counter balanced but doesnt allow the extruder to move in XY.

In any case: a good opportunity for @ander to put together a upgrade kit

-

@dc42 I made some video of 4th axis flying extruder.

Because I am not used to video editing, I uploaded 4 separate videos on youtube. sorry about that. Pls, visit followings.- 4th axis flying extruder overview... https://youtu.be/Ig0k9NiVD94

- Side view ... https://youtu.be/hCjmkRbwGWc

- Top view ... https://youtu.be/Z_L8L-FmCf0

- Carriage view ... https://youtu.be/bgNJpSbPvUQ

If you need other scenes, just ask.

-

Your last 2 links are the same. But the second link shows the 4th axis very well. May I post it on other sites?

-

@dc42, Of course, you can post it on other sites.

The PTFE tube length is 280mm from extruder fitting to effector fitting.

This is significant improvement comparing to my mini KOSSEL's 450mm.I corrected the link of the carriage view, the 4th video.

I attached a metric ruler on the 4th rail. So you can see how far and fast the extrude carriage moves up and down when effector is traveling the same z_height XY plane.My current setup is as follows

U_axis rod Length is 300, U_tower position M669 X0 Y-100.The carriage moves dully relative to XY position if the U_axis rod length

is set high(ex. X665 L358:358:358:600), whereas the movement is very rapid and far when U_axis rod length is set low (ex. X665 L358:358:358:300).

If I set the rod length too short (for example 200mm), the effector cannot reach U_axis' opposite(diagonal) edge. And the carriage moves too fast enough to skip steps. Firmware restricts the movement.The ideal U_tower position seems to be the center[M669 X0 Y0] given that fitting do not wear out and the PTFE tube don't flex too much. I will try this when I am ready for gimbals similar to ZATSIT's FlyStruder.

-

hi there!!!

Sorry i was kind of busy with work and disconected from all this proyect, i still didn´t make any video(i will) but it is working fine so far...but i have a little problem using slic3r prusa edition. If i generate the gcode with simplify3D there is no problem, but with the prusa edition it goes so slow that it looks it is not even moving, i mean all the movements, homing, auto level, printing...i tried to higher all the speed settings that the slicer brings but the result is the same. the simplify version i´m using is 2 years old and the prusa slic3r is the latest. i was wondering if the 4th axis´s speed is limiting here because in the slicer i have no option to change it -

I don't think it's related to the 4th axis. I suggest you check whether the slicer has inserted any M203 commands in the GCode file that you are trying to print.

Did you choose the correct GCode flavour in the slicer?

-

Hi there, i don´t really know what you mean by flavour, the prusa slicer just has a button that gives you the g file and that´s it. i kind a feel like i´ve tried every setting now, dunno what happens

-

@ander said in Flying extruder with 4th axis:

Hi there, i don´t really know what you mean by flavour, the prusa slicer just has a button that gives you the g file and that´s it. i kind a feel like i´ve tried every setting now, dunno what happens

On PE Slic3R go to the "Printer Settings" tab, then click "General" which you will find at the top of the list on the left hand side. The on the right hand pane you'll find a section entitled "Firmware" and under that is "G-code flavour" with a drop down box. Select "RepRap/Sprinter" from the list. Then save the change.

-

Which version of slicer PE specifically?

In the print settings tab under speed, there is an acceleration control. I believe it's hidden now by default in the latest 1.42 beta and only visible when set to advanced/expert view.

Perhaps you can post the gcode file that has this problem?

-

Hi there!!

you guys were right, i´m used to program in Marlin for arduino, and i put marlin instead of reprap, thanks for helping. i couldn´t post earlier because for some reason the forum was blocking my messages again, it looks that works fine now. -

Hi there!!!

a bit late but here goes my setup:

https://www.youtube.com/watch?v=ToBLN7YHWt4 -

I found the section about "additional towers to carry flying extruders" in the wiki, when I define the 4th like this does that in include the behavior that the 4axis moves up and down depending on where the x/y position of the effector is? or does this need to be added as an extra command?

-

@sungod3k said in Flying extruder with 4th axis:

I found the section about "additional towers to carry flying extruders" in the wiki, when I define the 4th like this does that in include the behavior that the 4axis moves up and down depending on where the x/y position of the effector is? or does this need to be added as an extra command?

That's automatic, you just need to define the XY position of the extruder outlet and the distance you want to maintain between the extruder output and the hot end input.

-

Hi there!

i had an issue with the duet wifi...i don´t know how happened but i tried to update it to 3.0 firmware and died.

So i´m installing from 0 the 3.0 now in a new board, and seems like i have some issues with endstops, i tried to copy all the 4th axis comands in the config file from the old version but doesnt seem to work

i manually push the effectors endstop switch and the 4th axis endstop swicth and neither of them show any change in the duet web interface, but in the board i clearly see the led switching off in both . pushing x,y, and z works fine

, here i leave the config file so you can have a look and hopefully find a solution.

config.g -

@ander You haven't defined where the U axis endstop switch connects. What does it connect to? RRF3 doesn't have default assignments for anything, so you need to define everything.

Also, you have default thermistors set, T100000 B4138. Best to find what thermistors you are actually using and set values correctly, for temperatures to be accurate.

Ian

-

Hi there!

Thanks for the quick response, can you tell me where exactly and how should i put the endstop info?

i´m using E1 endstop conector for the effector switch and E0 conector for the 4th axis´s endstop