Problems with new Laser Filament Monitor

-

I am having issues using the sensor... It does do a lot of false errors as it detects and pause the print even when there is no issue and with a very broad tolerance (0% to 200%!!!!)

For example... it ALWAYS pauses with my start g code, does not matter the filament:

G32 G29 G1 X17 Y0 F10000 M116 M98 P/macros/SubMacros/beep.g G4 P30000 G1 Z0.2 ; G92 E0 G1 Y5 E10 F1000 ; Purge 1 G1 X77 E9 F1000 ; Purge 2 G1 X107 E12.5 F1000; Purge 3 G92 E0 -

@brunofporto You try to push 10mm of filament into the hotend which only moves 5mm on the line saying "Purge 1". These are about 24mm³ of plastic spread on a 0.2mm layer height makes for an extrusion width of 24mm - I have a feeling that your hotend is not able to comply to this command.

The second purge tries to create an extrusion width of 1.8mm which is again quite something to ask for.

The third one wants to go with a 5mm extrusion width.

I don't see a way how your extruder would be able to press this much plastic out though I might have an error in my math.

-

@wilriker I was pretty sure it is my fault

Your answer solves this part lol

But still: how to avoid so much false detections during print?

-

@brunofporto, I have a firmware update on the way that may help, provided the problem isn't that the sensor can't see that particular filament clearly enough.

Have you made sure that there is a only very short piece of PTFE tubing between the filament monitor and the extruder inlet, secured at both ends, so that when the extruder reverses the filament is forced to run back through the sensor, and not bunch up between the sensor and the extruder?

-

For the record in my case lashing down the sensor made a big difference. Of course many filaments simply don't work with this sensor. But keeping the sensor from moving around was very important. I don't know how it even works with a bowden

-

@dc42 said in Problems with new Laser Filament Monitor:

Have you made sure that there is a only very short piece of PTFE tubing between the filament monitor and the extruder inlet, secured at both ends, so that when the extruder reverses the filament is forced to run back through the sensor, and not bunch up between the sensor and the extruder?

Yes, that is for sure

Almost touching the extruder. And great to know that there is a firmware update related to the sensor. Thank you very much! You also made me remember that there is a loooong time since the last time I checked for debris over the sensor. I'll check on that.

Almost touching the extruder. And great to know that there is a firmware update related to the sensor. Thank you very much! You also made me remember that there is a loooong time since the last time I checked for debris over the sensor. I'll check on that.Also...

@3dmntbighker said in Problems with new Laser Filament Monitor:

For the record in my case lashing down the sensor made a big difference. Of course many filaments simply don't work with this sensor. But keeping the sensor from moving around was very important. I don't know how it even works with a bowden

The sensor casing IS moving due to a bad positioning - it is perpendicular from where the filament comes and it surely started to get worst readings after that... I do not know why I did not correlate this before

thank you!

thank you! -

And there was A LOT of dirt inside the casing and the sensor was really nasty with it.... I'll test it tomorrow with some simple parts to check. If a single hair make my optical mouse going havoc imagine with a ball of dirt rolling over the sensor

I am pretty sure that it was the main responsible for the issue.

-

What about somehting like this: https://www.thingiverse.com/thing:3091625

the part in that thing is just an interposer... but, the skelestruder project has the other parts.

sensing off of a rotating bearing kinda sorta makes sense to me. -

@madhunm said in Problems with new Laser Filament Monitor:

What about somehting like this: https://www.thingiverse.com/thing:3091625

the part in that thing is just an interposer... but, the skelestruder project has the other parts.

sensing off of a rotating bearing kinda sorta makes sense to me.Fantastic idea

-

@3dmntbighker I am working on a modified version of my casing with this purpose

-

@brunofporto said in Problems with new Laser Filament Monitor:

@3dmntbighker I am working on a modified version of my casing with this purpose

When I print your current version I find the PTFE clamping is marginal at best. I have had to drill deeper into the housing to find some purchase for the tube. My printer is partially to blame. While you are at the redesign can I suggest a longer surface area for clamping the PTFE tube. I am using Capricorn tubing now. Actually I may switch to cheap PTFE tube because in this application the Capricorn is actually a detriment. It's more particular about out of tolerance filament and it's not as if it's a bowden tube.

-

@3dmntbighker Actually a short piece of Capricorn tube was recommended coming into and going out the sensor housing because this will better constrain the filament passing over the center of the sensor. But it is hard to use only a short amount if you need longer distances.

Reg. fixing the tube inside the housing the approach used in this housing by @punamenon might be very interesting. @brunofporto what do you think?

-

@wilriker said in Problems with new Laser Filament Monitor:

@3dmntbighker Actually a short piece of Capricorn tube was recommended coming into and going out the sensor housing because this will better constrain the filament passing over the center of the sensor. But it is hard to use only a short amount if you need longer distances.

Reg. fixing the tube inside the housing the approach used in this housing by @punamenon might be very interesting. @brunofporto what do you think?

Thanks, I'll stick with the Capricorn. I'm fortunate I don't need a long section. I think I have no more than 20mm on either end.

Yeah, that looks like a much better way to capture the tube. I actually don't have issues with the tube coming out, but it's very poorly held in place now.

-

@wilriker said in Problems with new Laser Filament Monitor:

@brunofporto what do you think?

Nice idea!

An M4 nut may hold that nicely!

An M4 nut may hold that nicely! -

@3dmntbighker said in Problems with new Laser Filament Monitor:

@brunofporto said in Problems with new Laser Filament Monitor:

@3dmntbighker I am working on a modified version of my casing with this purpose

When I print your current version I find the PTFE clamping is marginal at best. I have had to drill deeper into the housing to find some purchase for the tube. My printer is partially to blame. While you are at the redesign can I suggest a longer surface area for clamping the PTFE tube. I am using Capricorn tubing now. Actually I may switch to cheap PTFE tube because in this application the Capricorn is actually a detriment. It's more particular about out of tolerance filament and it's not as if it's a bowden tube.

I have the same issue... It keeps falling when I am messing with it sometimes. Thank you! I'll increase the length of the hold and also make it tighter a little.

Besides the centering the Capricorn tube is also opaque and prevents the light to interfere with the sensor.

But If I use the bearing solution there is no problem as the sensor will be shielded by the bearing.

-

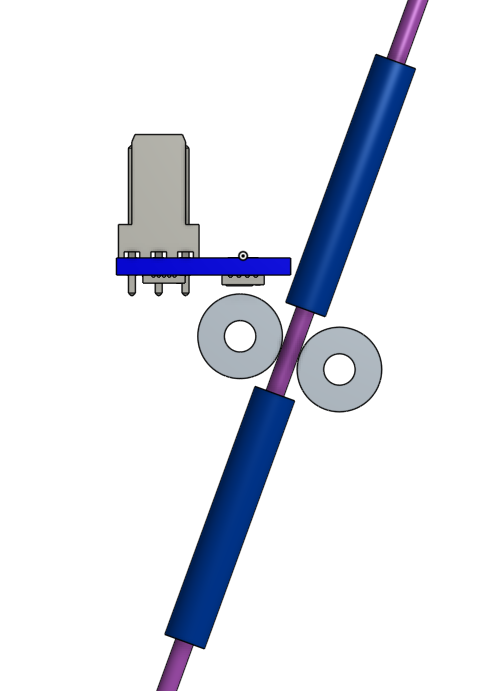

Something like this

Now I need to think the thing around the concept

-

That Prusa one on Thingy manages with one bearing. And weirdly it seems to read the side of the bearing instead of the circumference. Presumably you will want some kind of weak spring in there somewhere keeping tension on the filament without wearing out the tubing.

-

@3dmntbighker yes... I'll leave the "reading" bearing fixed and the second bearing will press against the filament with some type of spring system - like the one used with bmtech extruders.

-

would lightly sanding the bearing also help with the sensor pickup more light?

-

@nikker Not needed for the sensor as it is perfect for the type of surface the bearing offers. What concerns me is the possibility of the filament slipping the bearing somehow. If this starts happening then the sanding will help.