Problems with new Laser Filament Monitor

-

I'm finding problems detecting eSun Yellow PLA also.

Duet3D laser filament monitor on endstop input 3, disabled, allowed movement 50% to 145%, check every 3.0mm, current position -6.8, brightness 92, shutter 17, measured minimum -15%, average 50%, maximum 130% over 479.8mm

@T3P3Tony can you tell me what the min, average and max percentages represent?

What causes a negative percentage?

Is the filament monitor still usable with numbers like this? -

@brunofporto Thanks, I'm starting with your design on my Ender 3 printed with eSun black PLA. I think you need a bit more surface area "bite" on the tubing.

-

@t3p3tony, @dc42

The last 2 days I've been printing with eSUN black PLA, not the PETG I've been having problems with but a filament that has worked ok.I have been getting value like:

minimum 83%, average 95%, maximum 112% mostly, I thought the sensor was working ok with this filament.Then today I tried a print and the print paused twice with "Extruder 0 reports too little movement".

I ran a M591 D0 I now get this and now it is

minimum 46%, average 71%, maximum 93%

with the same roll of black PLAWhy so inconsistent?

Do I have a faulty sensor?It doesn't work with some filaments and when it does it gives inconsistent result.

Did you have these problems in testing?

-

@insertnamehere said in Problems with new Laser Filament Monitor:

look, I'm a customer who is having problems with your product. I've been asking questions to help me determine if I have a faulty device. Two previous posts of mine have gone unanswered.

I would like to know if the inconsistent readings for the same filament over time (as much as 50% variability) were common in beta testing or if you think the sensor is faulty?

What do the the min, max and average percentages represent, and what values (I get some negative percentages) are unusable for sensing movement?

I get a lot of false detection even with quite wide M591 Raa:bb values. Was this seen in testing?

What should I do RMA for a replacement or get a refund?

-

How did you mount the filament monitor? Might dust have go on to the image sensor, reducing its sensitivity? The instructions on our wiki advise against mounting it with the image sensor facing upwards, to guard against dust building up on it.

-

@insertnamehere said in Problems with new Laser Filament Monitor:

What do the the min, max and average percentages represent

This one I can answer: these are statistical values representing the movement seen by the sensor vs. movement commanded by the firmware.

Example: minimum 83%, average 95%, maximum 112%

This means that on average the sensor saw 95% of movement distance that was commanded by the firmware. In case this would be totally accurate it means on average there would be 5% under-extrusion.

Minimum represents the lowest value seen compared to commanded movement and maximum of course the opposite.Negative values mean that the sensor saw a movement in reversed direction compared to what the firmware commanded. As an (arbitrary) example, the sensor saw forward movement where the firmware commanded a retraction.

Regarding the (possibly) inconsistent performance of the sensor with a filament working good previously: I had this issue twice in beta test where it paused due to too little movement - but in both cases when examining the print it turned out that the sensor was right and the print actually was under-extruded. So have you checked this particular print for signs of under-extrusion? Unfortunately, they might be hidden i.e. restricted to the infill portion of the print.

-

@wilriker The average is of good help for tunning extrusion. The blue ABS is perfected when tunned to 100% average.

But that is why I would like to have data from the entire print! Just Max and Min is a bad reference for decision or evaluate. A graphic view of the measurement versus gcode command over time would show events cristal clear.

-

@wilriker Thanks for the explanation.

I have 3 filaments that regularly give negative minimum percentages. I've also seen black PETG give a negative average percentage. I just wonder how effective a filament sensor is that gets the direction wrong on movement?

Does that make sense at all?

-

@dc42 said in Problems with new Laser Filament Monitor:

How did you mount the filament monitor? Might dust have go on to the image sensor, reducing its sensitivity? The instructions on our wiki advise against mounting it with the image sensor facing upwards, to guard against dust building up on it.

Thanks for the reply.

I've used 2 different mounts and currently using your the reference mount design. The sensor is mounted vertically, looking down. Checked for dust, nothing I can see.

I'm seeing wide variations of movement detected with some filaments showing negative values. Even the same filament on different days gives a huge difference in result.

I'm using a Bondtech BMG and I tried it with maximum tension on the filament. That extruder would literally pull the reel off the stand before slipping. I see no sign of under-extrusion on several 20mm test cubes printed during this process.

To me the sensor is either faulty or the design isn't reliable.

There are many things that you have to cope with and adjust for when printing, the filament sensor should not be one of them.

-

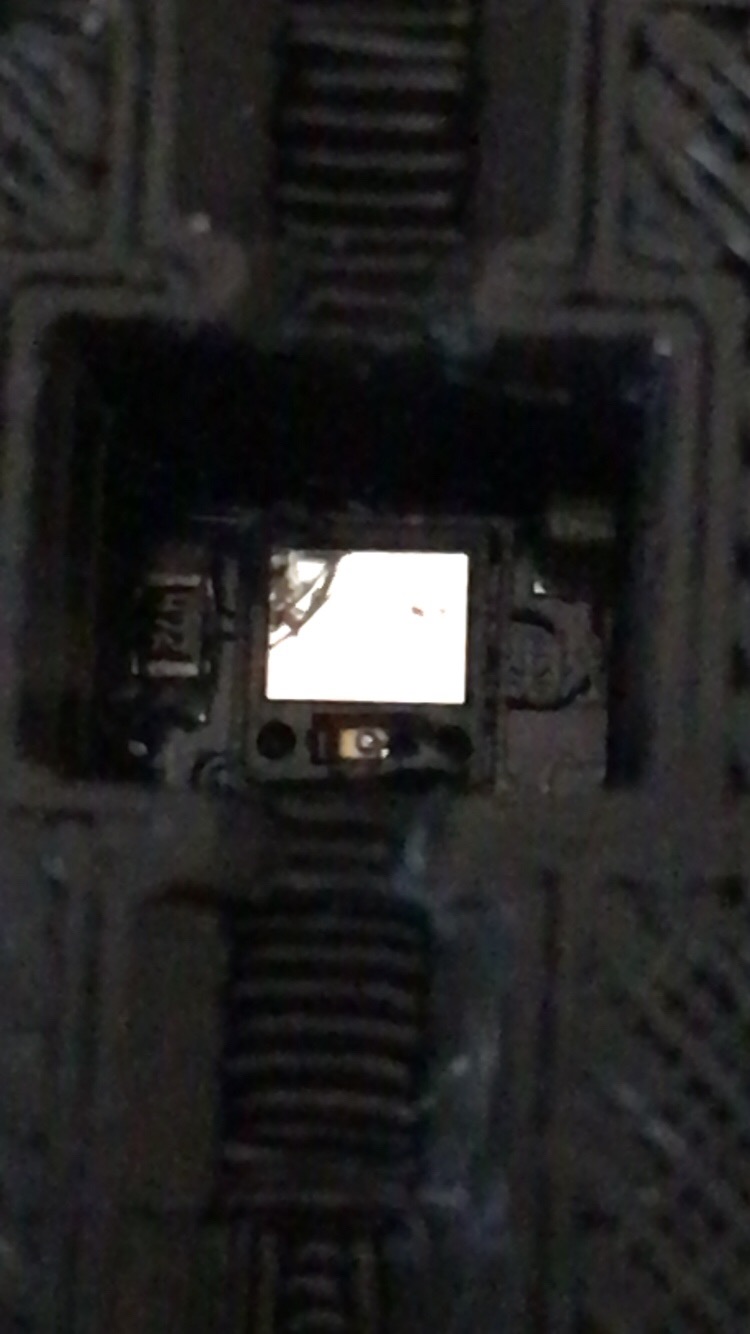

Well I found the likely cause. Clearly I have a faulty sensor.

This is an image showing the sensor through the mount aperture.

I don't know how this happened. I took great care in handling and mounting. It's been checked several times for dust and I certainly didn't see it.

My best guess is that because the reference mount design uses the mounting screws through the pcb to also provide tension on the bowden tube to clamp it tight, this tension cause the pcb to flex and cracked the sensor.

Clearly it could also be my fault, so I'll just forget about it.

Thanks for your help. -

@insertnamehere please can you submit a warranty claim:

https://www.duet3d.com/WarrantyReference this forum post in the comments.

Thanks for your patience. -

@insertnamehere, in addition to submit a warranty claim, please can you:

-

Check the printed parts that the filament monitor PCB fits between, to make sure that the surfaces that mate with the PCB are flat, and there are no blobs or other blemishes that might stress the PCB when the screws are tightened.

-

Tell us what material you printed them in.

I have just added a note in the fitting instructions to advise looking for blobs that might stress the PCB. It may be that we also need to increase the thickness of the lower printed part, perhaps depending on what material it is printed with.

-

-

I couldn't see any blobs or contamination on the surface.

I used eSun PLA+ with 100% infill.

Honestly, I took all care, but I can't be sure it wasn't something I did that damaged the sensor. Are you sure you want me to claim warranty?

-

We don't know whether the cracked sensor is our fault because of a manufacturing defect or because we didn't make the printed part thicker in our housing design, or something you did. In these cases we give the customer the benefit of the doubt. So please make a warranty claim.

-

@dc42

Thanks you. -

Printing with eSun olive green PLA tonight. Pretty crap numbers.

Duet3D laser filament monitor on endstop input 3, disabled, allowed movement 40% to 120%, check every 3.0mm, current position -7.3, brightness 91, shutter 17, measured minimum 27%, average 81%, maximum 204% over 4232.4mm

-

Back to eSun yellow PETG, and my average was 84%. My minimum was -1%.

-

Regarding the filament monitor, can we use Prusa MK3 filament sensor as well? Can it be connected to E0 end stop?

-

@shawnc said in Problems with new Laser Filament Monitor [SOLVED]:

Regarding the filament monitor, can we use Prusa MK3 filament sensor as well? Can it be connected to E0 end stop?

No it cannot be used because it does not have the control circuitry on it.

-

@shawnc said in Problems with new Laser Filament Monitor [SOLVED]:

Regarding the filament monitor, can we use Prusa MK3 filament sensor as well? Can it be connected to E0 end stop?

No. The Prusa filament monitor uses a raw I2C interface to communicate between the sensor and the processor (and it's level shifted to 5V). We rejected that approach because I2C is a bad choice for connecting devices over more than a few cm, because of its poor noise immunity, the lack of any error detection, and the difficulty of recovering from I2C protocol errors. It may be possible to get it working reliably enough in a closely controlled system like a genuine Prusa i3, but it would be a support nightmare if used more widely, e.g. in home-build printers.