New beta firmware 2.02beta1

-

@zerspaner_gerd said in New beta firmware 2.02beta1:

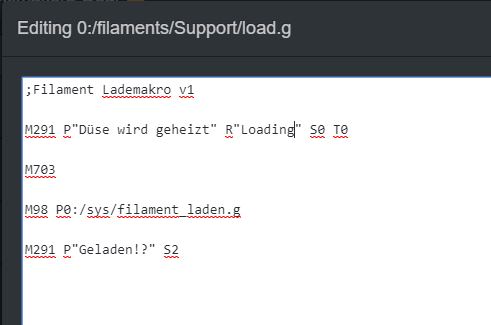

I just mentioned that unfortunately it does not work in "Load Filament" Macro!

Do you mean that in the

load.gmacro for the filament (configured via context-menu for this filament in DWC) you are loading you want to addM703to immediately also load the same filament'sconfig.g? -

@wilriker Here is a picture of my attempt:

But yes, I think we mean the same! -

@zerspaner_gerd Coincidently my loading macro looks exactly like your third line.

Anyway, the problem here certainly is that at this point in time the filament is not completely loaded in regards to firmware so it would not know whichconfig.gto load withM703.@dc42 and @chrishamm should this be like that? Is there a case where loading a filament (in software) could fail/abort? Otherwise the info about which filament is loaded could be saved as the very first step and this would resolve this race. I could look into changing this most likely on Monday.

-

Chrishamm wrote and maintains the filament management code, so I'll leave this for him to answer.

-

At present it is not intended to use M703 in the load.g macro because DWC already sends it after the filament has been loaded and because the filament name is NOT assigned until the load.g macro has finished AFAIR. A better place for M703 would be your tpost*.g macro because you usually want to apply different settings when you select a tool that is loaded with a different material.

At present DWC does the following when you load/change a filament:

- A tool is selected using a T-code (if the selected tool is different)

- If a filament is already assigned to the tool, it is unloaded via M702 which runs the unload.g macro of the old filament

- M701 is invoked with the corresponding filament name, which runs the corresponding load.g. Do only the loading here (e.g. set temperatures, ask the user to insert filament and eventually load it)

- M703 is invoked which runs config.g of the corresponding filament (if present). There you can set extrusion factors, pressure advance, temperatures and possibily the speed factor to use

-

@chrishamm said in New beta firmware 2.02beta1:

M703 is invoked which runs config.g of the corresponding filament (if present). There you can set extrusion factors, pressure advance, temperatures and possibily the speed factor to use

Would be interesting to call the config.g for filaments with another name to avoid consfusion. Something like fconfig.g

-

@dc42 great work on adding S parameter to control laser PWM

I have a suggestion to make it more compatible with other laser engravers and Laserweb software:

When S parameter is not provided it should keep the previous PWM value instead of turning off the laser, the G0 should turn off the laser

Example output from Laserweb:G0 X86.61 Y21.34

G1 X86.61 Y21.34 S255.00 F1300

G1 X86.61 Y21.33

G1 X86.62 Y21.33

G1 X86.62 Y21.33

G1 X86.62 Y21.33

G1 X86.62 Y21.33G0 X91.07 Y16.73

G1 X91.07 Y16.73 S255.00 F1300

G1 X91.07 Y16.73

G1 X91.07 Y16.73

G1 X91.06 Y16.73

G1 X91.06 Y16.73

G1 X91.06 Y16.72

G1 X91.06 Y16.72 -

@spw, it's a shame they chose to make it work that way. It would have been much safer to default to zero power. Anyway, I'll change it. I'll also need to make sure that the laser is turned off at pause and on again at resume. Tedious...

-

Hi everyone,

I upgraded to this version a week back as I was having issues with the official release before this. One thing I have noticed with this is that the extruder temperature is not always set when loading the GCode. I am using Cura 3.4.1 and printing directly to the printer via the plugin. Looking at the start of the g code it is setting the temperature, but when you start a print, the bed heats up and the extruder is set to 0 degrees.

Here is the start of the gcode file:

;FLAVOR:RepRap

;TIME:6266

;Filament used: 11.8932m

;Layer height: 0.2

;Generated with Cura_SteamEngine 3.4.1

T0

M190 S50

M104 S200

M109 S200

M82 ;absolute extrusion mode

; Startup Gcode

G91 ; Relative Positioning

G1 Z5 ; Move Z down 1mm

G90 ; Absolute Positioning

G28 XY ; Home XY

M561 ; Clear any bed transform

G32 ; Start 3-point probe sequence

G28 Z ; Home Z

M375 P"heightmap.csv" ; Load heightmap

G1 Z20.0 F6000 ; Move Z to 20

G1 X10 Y10 ; Move Head to front left

M582 T1 ; check levels of inputs that give rise to trigger #1

G92 E0 ; Zero Extruder

G1 F200 E30 ; Prime the extruder

G92 E0 ; Zero Extruder

M83 ;relative extrusion modeCan anyone shed any light on this? Is it the plugin or the firmware?

Kind Regards,

Sam -

If you upload the file directly and print it from the DWC does it set the temp properly?

If you set your temp manually from the DWC does it heat up?

-

Hi @Phaedrux,

I will try printing off a file this morning. I can manually change the temp on the dwc.

Will get back to you shortly.

Kind Regards,

Sam -

Hi @Phaedrux

I tried uploading the file directly to the DWC and it still does not bring the extruder temperature through.

Kind Regards,

Sam -

@samlogan87 just to test, try reverting back to your previous firmware version and try again.

-

@phaedrux said in New beta firmware 2.02beta1:

@samlogan87 just to test, try reverting back to your previous firmware version and try again.

Or even go forward to 2.02RC1.

P.S.: I use the same Cura version and used 2.02beta1 since it was released never experiencing your issue. This should not mean you don't have it I just want to say it is not happening for everyone.

P.P.S.: You mentioned "the plugin". Can you be a bit more specific? Do you mean Kriechi's Cura-DuetRRFPlugin? At least based on the avatar that would be @resam here in the forums.

-

The previous stable version did not work for me as the printer would buffer between moves all the time, hence why I was put on to this version. I will try upgrading to the new release but unfortunately it won’t be for a few days as I have just packed up the laptop and am about to head out the door for a work trip for a couple of days. Hopefully should be back on Thursday night.

Kind Regards,

Sam

-

Hi, just want to see if its possible for you and your team to come up with a layer height pause option on the LCD. I have Afinia H800+ printers and there is an option in their software to pause at different layer heights but just clicking on a numbered spot and giving it a layer height. Would be neat if you could click on pause button and enter a layer height or heights that you want to pause at so you can easily change out colors of filament. Insteady of having to put in script files in S3D. This would make the duetwifi even more powerful. I'm currently using the M266 in my script files. Larry