With belts removed from x and y stepper motors the motors turn choppy and not smooth. The motors are rated at 2Amp. I've tried changing current up to 2000MA and same. Test stepper motors on diffrent hypercube and work good. Z axis works great. Just X and Y pulsate during movment in Y direction.

Firmware 3.5.1

Duet 2 wifi

Hypercube evolution

Latest posts made by BlitzReg

-

X and Y axis steppers choppy hypercubeposted in General Discussion

-

RE: Software bundle 3.5.0rc.4 now availableposted in Firmware installation

3.5rc4

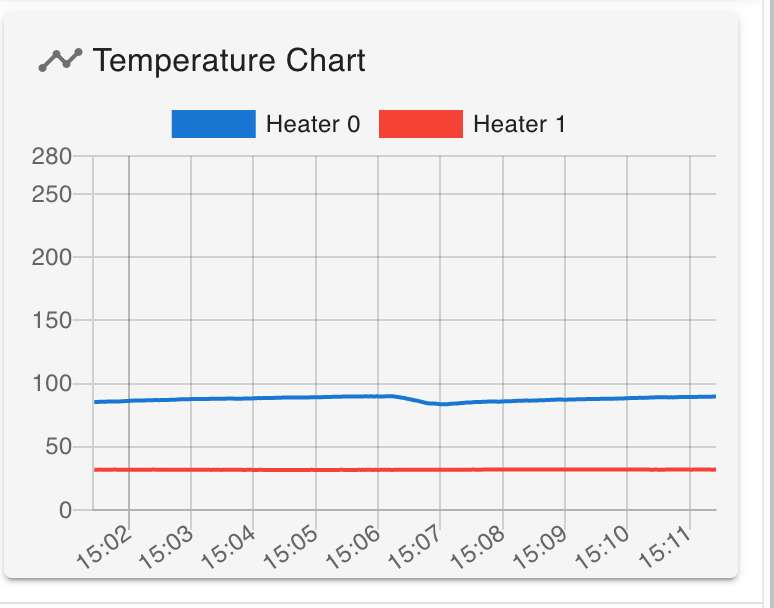

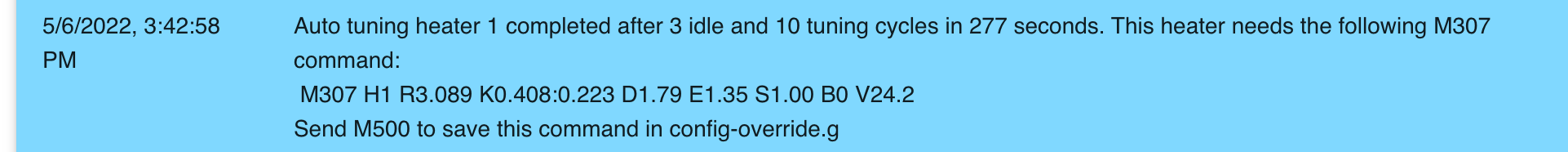

I'm getting H1 Heater faults which I had no issues with my hypercube. I have to clear out the faults and then H1 heats up and I have no problems during print. The faults only happen when I try try to prewarm the bed and extruder. I ran M303 on both the bed and the extruder. No problem on the extruder but I do get a yellow warning on the bed. I even tried tuning at a lower temp and same thing on the bed. When I updated my firmware the wifi quit working and I had to use the terminal software with cable to get it working again. when I watch the graph during print the temps are staying in a straight line. -

RE: PID problemsposted in Tuning and tweaking

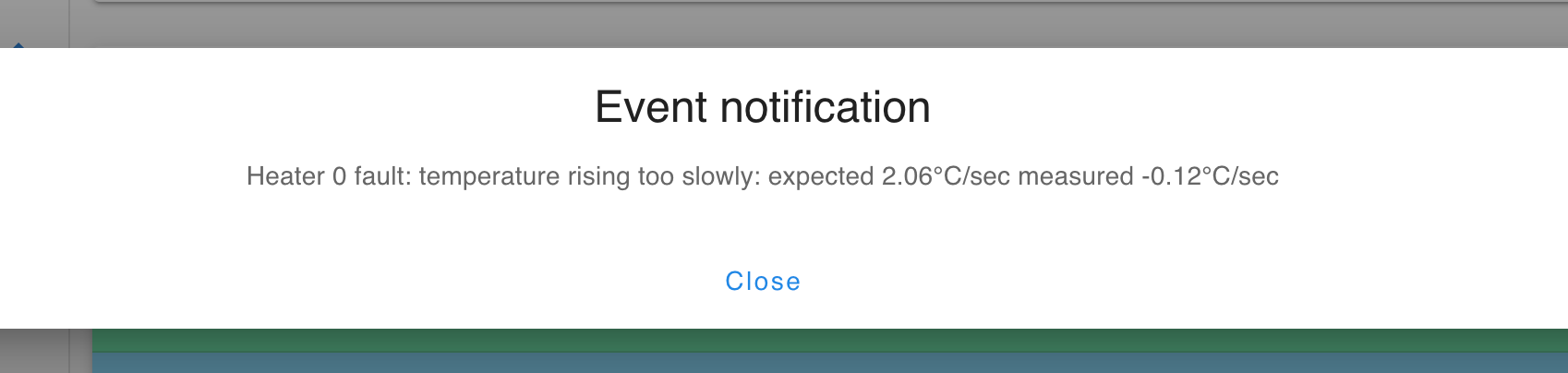

@phaedrux Why is it saying Heater 0 when the fault happens on heater 1 the extruder? Not sure what is happening here!

-

RE: PID problemsposted in Tuning and tweaking

@phaedrux Hi, the problem was the thermistor in the bed. I swapped it out and now the temps are almost the same between the panel and the IR Gun. Now the gremlin has move to the extruder. I have a REVO Hermera direct drive and it keeps getting heater faults. I have ver 3.4.0 and ran M303 T0 S240 and it tunes fine. But I noticed the the temp rises above the print temperature I set and keeps going until there is a heater fault.

-

REVO Hemera Heater Faultsposted in Tuning and tweaking

- list itemRevo Hemera direct drive

duet wifi 2 - firmware 3.4.0

Problem - multiple heater faults

extruder temp goes above set temp from slicer and keeps climbing until a heater fault occurs.Sometimes the temperature is correct and stats to print and during print a heater fault occurs. The 3D print surface indicates that the model is being printed much higher then what it should be.

; Configuration file for Duet WiFi (firmware version 3.3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.3.10 on Thu Jan 27 2022 07:58:07 GMT-0800 (Pacific Standard Time); General preferences

M575 P1 S1 B57600 ; enable support for PanelDue

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"EVO2" ; set printer name

M669 K1 ; select CoreXY mode; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet; Drives

M569 P0 S0 ; physical drive 0 goes forwards

M569 P1 S0 ; physical drive 1 goes forwards

M569 P2 S1 ; phys4cal drive 2 goes backwards

M569 P3 S0 ; physical drive 3 goes forwards

M584 X0 Y1 Z2 E3 ; set drive mapping

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

;M92 X81.41 Y81.41 Z394.7 E400 ; set steps per mm

M92 X79.85 Y79.85 Z400.04 E392.47 ; set steps per mm

M566 X900.00 Y900.00 Z12 E300 ; set maximum instantaneous speed changes (mm/min)

M203 X6000.00 Y6000.00 Z3000.00 E1000.00 ; set maximum speeds (mm/min)

M201 X300 Y300 Z250 E1500 ; set accelerations (mm/s^2)

M906 X850 Y850 Z650 E850 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout

; Axis Limit

M208 X0 Y0 Z-10.0 S1 ; set axis minima

M208 X250 Y260 Z180 S0 ; set axis maxima; Endstops

M574 X1 S1 P"xstop" ; configure switch-type (e.g. microswitch) endstop for low end on X via pin xstop

M574 Y1 S1 P"ystop" ; configure switch-type (e.g. microswitch) endstop for low end on Y via pin ystop

M574 Z1 S2 ; configure Z-probe endstop for low end on Z

;M574 X1 Y2 S1 ; X home to min. Y home to max. Normally Closed limit switches.

;M574 Z1 S2 ; Define Z to use Probe. Home to Min; Z-Probe

M950 S0 C"exp.heater7" ; create servo pin 0 for BLTouch

M558 P9 C"^zprobe.in" H5 F500 T6000 ; set Z probe type to bltouch and the dive height + speeds

G31 P500 X7 Y-50 Z2.675 ; set Z probe trigger value, offset and trigger height

M557 X30:250 Y15:210 S20 ; define mesh grid;BLTouch Heater

M307 H7 A-1 C-1 D-1 ; Disable the 7th Heater to free up PWM channel 5 on the Duex board.; Heaters

M308 S0 P"bedtemp" Y"thermistor" T100000 B3950 C0 R4700 ; configure sensor 0 as thermistor on pin bedtemp b4138

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M308 S1 P"e0temp" Y"thermistor" T100000 B4725 C7.060000e-8 ; configure sensor 1 as thermistor on pin e0temp

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S280 ; set temperature limit for heater 1 to 280C; Fans

M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off

M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency

M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on; Tools

M563 P0 D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C; Custom settings are not defined

; Miscellaneous

M912 P0 S-12.6

M501 ; load saved parameters from non-volatile memory

M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss

T0 - list itemRevo Hemera direct drive

-

RE: PID problemsposted in Tuning and tweaking

@phaedrux Almost 1 hour on phase 3. My other hypercube has already tuned using firm ware 1.21. now I'm wondering when I tell the extruder to heat to 220C its actually 220C. My first prints off them looked like they got pretty hot. I am using the e3d hemeria w/volcano direct drive. I also have their REVO

-

RE: PID problemsposted in Tuning and tweaking

@phaedrux no, I actually testing it all 4 corners and in the middle where the thermistor is located

-

RE: PID problemsposted in Tuning and tweaking

@phaedrux right now the thermistor in phase 3 reads 84 and the IR gun shows 96. Makes me wonder if the thermistor is bad