Tuning Macros Menus (Accel, Jerk, Retraction, Pressure Advance)

-

@Phaedrux This sounds really helpful as I am now at the stage of fine tuning my 3D printer. When you say "install them is to put the SD card into your computer and extract the zip file into the /macros folder" do you mean the SD card you can run in a Panel Due as I am not running one in mine. I tried uploading the the Zip file into the DWC however it just did not seem to work.

Any Advice on how to go forwards would be great Thank You. -

@900turbo said in Tuning Macros Menus (Accel, Jerk, Retraction, Pressure Advance):

When you say "install them is to put the SD card into your computer and extract the zip file into the /macros folder" do you mean the SD card you can run in a Panel Due

No I mean the SD card that goes in the Duet itself. That's where the macros folder is.

-

There is an error in the retraction section that I was able to isolate. The retract command for .2 under direct drive needs to be S 0.2, not R 0.2. I was having a rough time trying to figure out why it was changing the unretract and not the entire retract setting whenever I selected that.

-

@br7408 Sorry about that. Which file specifically?

-

@Phaedrux said in Tuning Macros Menus (Accel, Jerk, Retraction, Pressure Advance):

@br7408 Sorry about that. Which file specifically?

No worries... I certainly appreciate the macros, they have been of great help. The file in the: Set Retraction Distance/Direct Drive/Less Than 1mm/Retract 0.20.mm.g file. It is listed as R 0.2 instead of S 0.2.

I fixed it in my own folder but figured I'd let you know.

-

@Phaedrux Could you please specify what is the bad or good Extruder acceleration or jerk settings? I mean how does it look during the printing process if extruder accel is too low for example?

-

@Arminas said in Tuning Macros Menus (Accel, Jerk, Retraction, Pressure Advance):

@Phaedrux Could you please specify what is the bad or good Extruder acceleration or jerk settings? I mean how does it look during the printing process if extruder accel is too low for example?

that is hard to quantify. You want to have quick retractions that aren't causing pauses on layer change or travels. I would suggest starting low and increasing it until it seems smooth and responsive. If you go too high you may notice the extruder become jerky or loud.

It also depends a lot on if it's direct drive or bowden, etc.

You'll just have to experiment.

-

@Arminas Just to add to what @Phaedrux has said - with regard to extruder jerk, setting it too low can slow down any XYE moves because each axis and extruder have to be synchronised. So a low extruder jerk value could effectively cap the X and Y jerk values for a print move. You can set extruder jerk as high as you like with no adverse consequences.

-

@deckingman @Phaedrux Do I understand it right - first of all I have to tune acceleration and then jerk?

-

as @deckingman alluded, just set extruder jerk to infinity (not a real value, just more than X and Y), and then tune acceleration by increasing it until your extruder starts making unwarranted noises; then back off 10%

-

@Arminas said in Tuning Macros Menus (Accel, Jerk, Retraction, Pressure Advance):

@deckingman @Phaedrux Do I understand it right - first of all I have to tune acceleration and then jerk?

If we are talking about acceleration and jerk in general terms, then I don't think it matters much but it's probably best to tune acceleration before jerk. If we are talking about extruder acceleration and jerk exclusively, then I can't think of any extruder only move where jerk applies. Extruder only moves are retraction and un-retraction moves which start at zero speed so jerk is not normally applied. But for a print move using one or more axes as well as the extruder, then the jerk setting for that move would be the lowest of the axes or extruder - hence my recommendation to simply set extruder jerk high value where it will do no harm (I use 3600mm/minute for my extruders). For extruder acceleration, this will apply to retractions and un-retractions as well as any XYE move if it's low. So it needs to be brisk to give a rapid release of pressure. There is a school of thought that says if extruder acceleration is too high, then it will cause the molten filament to "break" rather than retract but I'm not sure that I believe that. One thing to note is that retraction moves are generally very short (unless you have an extremely long Bowden tube) so the time available to accelerate up to speed then decelerate down to standstill is very limited, meaning that you would need a high acceleration rate in order to attain the desired speed.

-

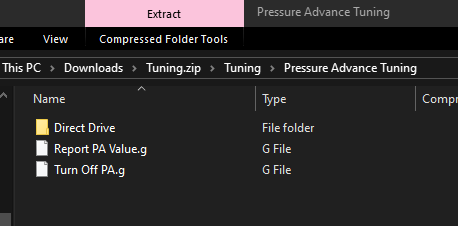

@Phaedrux Hey thanks for these! Just FYI I see in your screenshot for Pressure Advance Tuning you have a folder for Bowden, but in the zip file it appears to be missing. I was able to find it in an older commit for this file at least.

-

undefined droftarts referenced this topic

undefined droftarts referenced this topic

-

undefined moth4017 referenced this topic

undefined moth4017 referenced this topic

-

These macros have been a great aid. I wrote additional macros for all of the IS algorithms in single steps 30-50 Hz. I found it useful for real-time tweaking freqs during actual printing. I can upload them somewhere if anyone wants them.

-

undefined Inlinebrother referenced this topic

undefined Inlinebrother referenced this topic

-

undefined Inlinebrother referenced this topic

undefined Inlinebrother referenced this topic