6th-order jerk-controlled motion planning

-

For the issue of commanding instantaneous speed changes between the segments of a curve, what is needed is to deliberately change the motion path to be different from what the slicer specified in the GCode. This will involve putting extra acceleration/deceleration segments at the end of the first move and the start of the next, without changing the overall number of steps.

For S-curve acceleration, there are some algorithms that modify the trapezoidal speed curve by using slightly higher acceleration than commanded in the middle so that the acceleration can be tapered at the start and end. This is what marlin appears to be using. Complications arise when there are several accelerating or decelerating moves in a row, because the total number of steps must be kept correct. I am not sure that the Marlin implementation gets this right. The comments suggest that it may assume zero acceleration at the start and end of each move, and at first glance the code changes don't appear to involve the planner at all - but for sequences of accelerating and decelerating moves the planner should be involved.

-

@dc42

I think it might actually be better if you "deliberately change the motion path to be different from what the slicer specified in the GCode".

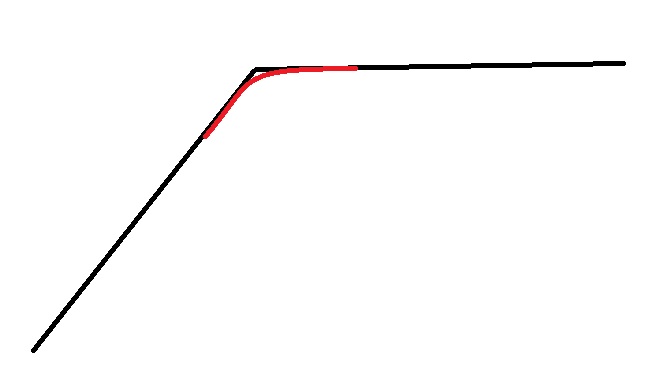

Instead of going along the black line as gcode instructs. It might be better to go along the red line. It will not only result in smoother motion, it might actually produce a better representation of the actual gcode path due to inertia of the print head. So basicly it's like a "pressure advance" for the XY motion. -

Is it not what CNC do?

-

@shen

I would avoid even to suggest such a behavior unless it is made optional. The image actually depicts a corner replaced by an arc. This is a decision to be made when generating the GCode for a job (3D printing or milling) and not to be done by the controller in the machine. Just imagine items with sharp edges that must mate properly. With the suggested path that might no longer happen.If the path smoothing is desired because of the STL 3D models, why not look for a slicer that supports arc fitting and generates G2/G3 commands? Why not looking for a GCode processor that reads the file produced by the slicer and changes it to G2/G3 commands where possible? In the end the controller should do exactly what it is instructed to do.

As a side note, it might be more interesting to do a side-by-side comparison between Duet and some board that supports a firmware with higher order motion planning. Is there any difference? Is it really worth the effort?

-

In a world with inertia, no controller can do exactly what it is instructed to do, at anything above the very lowest cutting speeds. This truth has been accepted in the CNC world for decades, because the gantry of a CNC may weigh many kilos. Going all the way back to proprietary controllers, and MACH in all its incarnations, several of the many tuning parameters traded "accuracy to g-code" vs. "speed".

Path accuracy vs. speed is part of "tuning a machine to its controller" during initial setup, AND tuning individual cuts for repetitive production runs.

3D printing seems to have avoided the nuances of this, through a combination of lighter gantries and not caring as much about the actual path. Sorry, but it is true. The "ringing" that is currently considered acceptable after turning a corner in most 3D prints is absolutely intolerable in the CNC world. I realize there are printers that have no visible ringing... but, current state of the art, they are the exception, not the rule.

Having said all of that, I don't really want to steer the debate down a bunch of anecdotal judgement calls of what is acceptable or not.

Instead, let me convey a data point:

I have several CNC rigs. One of them is a router, with 24" (600mm) by 60" (1500mm close enough) cut area. Uses Nema25s at 70v driven by "Gecko" drivers and a honking big 'toroidal' transformer based power supply. Tons of muscle.

I've used it to cut many things in "repetitive production". That is tens to dozens of repeats out of a sheet of material. Tens to dozens of sheets to produce hundreds of parts. Mostly cutting FR4 (think circuit board material, without the copper). Difficult stuff to cut accurately, due to the fibers inside.

This machine started with a MACH3 controller and a "parallel port" break out board driven by a "smoothstepper" board. Tuning for "looks like" the desired path, and note, NOT "exactly like"... just visually close enough to see no defects, tuning for that vs. tuning for "a tiny bit of visual oddity where a direction change occurs" makes HOURS of difference in a full sheet cut (faster). Hours.

Later changed that same machine to a TinyG, specifically for the "Constant Jerk" motion algorithm. Shaved tons of time off of many cuts.

There are so many variables in any cut it is very hard to give a factual comparison... what I can tell you is how it changed rapids (fast moves while not cutting). With Mach, the fastest rapids that did not cause mechanical issues were about 90 to 100 inches per second. With TinyG on the exact same mechanics, rapids of 300 IPS became normal, and really much smoother.

By the way, TinyG has several known flaws, and its developers have moved on to G2, and these flaws have not been fixed in the last couple of years. I find it worthwhile to work around these, simple because of the goodness of the constant jerk.

Summary: My hands on experience with larger heavier machines (than most 3D printers), and with Mach3 vs. TinyG, tells me that Constant Jerk is VERY VERY VERY VERY VERY worth pursuing.

Perhaps my experiences do not apply... nonetheless, a long post with a hard data point or two for people to mull over.

-

First of all the graph is exaggerated. In practice it would be a much smaller amount. When you make a corner at a high speed, the nozzle would go over the instructed position, as in the picture below.

It compensate for that. Also I would imaging this work the similar to pressure advance, it would have a constant k to decide the amount of compensation, and the compensation is proportional to the acceleration the nozzle experiences. So when you print at slow speed, or when the cornering angle is small, the acceleration/deceleration would be small, which results in less compensation.Also I can't agree with you that the controller should do exactly what the gcode instructed it to do. I my opinion, gcode is the theoretical motion path and speed, but in reality you have acceleration/jerk/pressure advance to try to compensate for physical effects and generate the best representation of the gcode.

-

If such feature can be activated/deactivated with G-Codes, slicers could choose to let the firmware correct paths or not, depending on its needs.

-

A controller CANNOT "Do what the gcode says". Gcode says "move along path to point x,y at feedrate f", and the next gcode says "now, point x2y2". This involves "turning a corner". Changing the mechanics to that path CANNOT happen at feedrate f.

The planner must accelerate, decelerate, etc. The amount that it does so is ALWAYS a compromise.

That compromise can be planned in dozens of ways. Sixth order is one of those many ways.

"Turn it on or off"? What you really mean is "Select this planning/accel/jerk algorithm over that one". Don't think for a second that the one currently embodied in any given firmware is perfect.

-

I know, but as you say, it is compromises. So, if one could choose one or the other, it is better. For example, reduce ringing but rounded corners, or sharp corners but ringing... Just an idea...

-

There seems to be a misinterpretation of the graphs shown in the page explaining higher order motion planning. Those have nothing to do with automatically replacing corners with arcs, on the contrary. With higher order motion planning the controllers try to reduce the motion related artifacts (missed steps, ringing etc.) as much as possible, while also indirectly reducing other problems (like cutting tool bending, especially on straights as the tool goes slow enough to bend less when getting close to the final position).

I don't have Danal's experience (never really used any large CNC or one with a gantry exceeding 15kg), but I still consider that purposely replacing corners with arcs is not good, at least now without the possibility of disabling it! My message was mostly about "path smoothing".

Another thing that the 3D printing world knows nothing about is the two separate passes when milling - roughing and finishing. Corners rounding might be OK when roughing with some left over material for the finishing pass, but most CAM tools used for milling already do that.

Now on the Mach3 vs TinyG comparison, I can't comment on that matter. But it would be interested to know overall results when using TinyG with and without "constant jerk" algorithm (if there is a way to disable it!). There might be many more differences making TinyG better than Mach3 for your specific situation. I have first hand experience with GRBL vs Duet. I have found out that G2/G3 should be limited on my current setup to 2100mm/min with Duet while with GRBL I can go up to 2500mm/min (maximum mechanically possible). If beyond 2100mm/min (like 2140mm/min, so just 2% faster) the machine sounds like breaking into pieces when executing some of the G2/G3 commands. Overall Duet is much better, but for this particular task GRBL beats it, for now! That is why I consider that pure Mach3 vs TinyG comparison is not correct as we are discussing motion planning algorithms, so we should rely more on comparisons done on the same controller.

-

The rounding of corners I proposed is on a very small scale just to counter the effect of flexibility and inertia. The distance nozzle overshoot on a 90 degree corners is usually between 0.05 to 0.1mm. So I won't only add a arc with that radius to just counter the overshoot, and while it does that it also proves a smoother motion. And the rounding compensation should be proportional to the acceleration experienced by the nozzle, so when you draw perimeter with a slower speed, the amount of compensation would be less.

-

Catalin_RO,

I completely agree that there are many more differences between MACH and TinyG than just the philosophy behind the motion algorithm.

At the same time... watch this video:

https://www.youtube.com/watch?v=Uq1Hawd6ONE&feature=youtu.be&t=6

Nothing special is being done to bring the weight to a stop at the end of each cycle... except "constant jerk".

-

I must admit it is pretty impressive, though it would have been even more impressive to see a side-by-side comparison with the same movement with simple, constant acceleration, solution.

But, again, it is all about higher order motion planning and not path smoothing. If path smoothing is just a side effect of motion planning, so be it. But doing it on purpose is still the thing I disagree with. In the end, if I want to machine sharp edges, I can go for something like 100mm/min and avoid all artifacts. With automatic replacing of corners with circles, those sharp edges are no longer possible.

Also, if TinyG does that only with 3rd order motion planning, why not implementing that first and only afterwards go for higher order algorithms?

-

+1 to S-Curve implementation. This video is the perfect demonstration for an enhanced quality (noticeably less ringing in the print). https://www.youtube.com/watch?v=C0XjXqO6Ji8

I have been looking at the implementation of the S-Curve motion control in Marlin and TinyG. It oly works on 32bit CPUs as AVR simply does not have enough processing power for this.

TinyG implementation is well explained nd has references to some papers with the maths behind the code: (https://github.com/synthetos/TinyG/blob/master/firmware/tinyg/plan_exec.c#L243).They're using 5th-order Bezier velocity curves to get 6th-order position planning. When planning each velocity change, the math assumes that acceleration and jerk start at zero, which allows to significantly simplify the math.

Note that both solutions are still using trapezoids to drive overall velocity changes, it's just that the velocity changes are smoothed using the 5th-order Bezier curves.

The logic is also very clearly explained at https://github.com/MarlinFirmware/Marlin/pull/10337.

-

I've been trying to avoid getting involved with this discussion on the grounds that it's bad for my blood pressure

, but anyway…..

, but anyway…..So aside from the technicalities, what is the big problem with the current motion system that this proposed variable rate of acceleration is going to cure? Where are all the real world prints that every FDM printer suffers from because of imperfections in the current motion system? I look on line and see some pretty amazing things that people are making so where is this problem that needs solving?

Also, where are the real world prints that have been produced with every parameter unchanged apart from implementing variable acceleration? Where are the back to back, real world tests? Where is there any scientific analysis of a) the problem as it manifests itself in FDM printing and b) the solution to this problem?

I see videos of moving glasses full of liquid in a straight line. So what? How does that relate to improved print quality with real prints? What happens when that same motion system is applied to short moves or segmented arcs? What happens to the extruded filament under those conditions? What happens to pressure inside the melt chamber? etc etc...

I see a picture of an imperfectly printed test cube, then a “reason” for the imperfection being some sort of overshoot which variable acceleration will correct. Come one…….I've printed much better test cubes than that, and just look on line and you'll see many other examples of test cubes without these defects. All of which have been printed with the current motion system.

I see statements like “the distance nozzle overshoot on a 90 degree corner is usually between 0.05 and 0.1mm”. Really? For every printer? For every speed? Where are the test results? How was that number derived? Where is the evidence to back up that statement?

Come on guys. Lets have some real world test results and some sort of proper analysis. All I hear is conjecture and hypothesis based on theory, YouTube videos of beer glasses, and pictures of imperfect prints which can in fact be printed without those imperfections. Show me real evidence that a problem exists and that variable acceleration on it's own with all other parameters unchanged, gives some improvement in 3D printing, then I'll start to believe.

The big thing that everyone forgets or chooses to ignore with these discussions is that we are using what is in effect a robot controlled glue gun. That is to say, we are squeezing hot sticky filament out of a nozzle. No matter how precisely we control the movement of the print head, the filament will to some extent “do it's own thing” and in general, it will always lag slightly behind the print head as it gets dragged across the bed or previously printed layer. If we accelerate the print head in X and or Y we need to accelerate the rate that we push filament into the hot end (and melt it) by the same proportion. The trouble is, it just acts like a sponge and damps out a great deal of that acceleration or deceleration. All we get is rapid pressure changes followed by much slower increases in feed rate. So the rate of change that we can extrude filament will never closely follow the rate of change that we can apply to the print head position. Coupled with other factors such as filament type, hot end temperature, layer height (and width), imperfect gcode and numerous other variables, this means that very fine control of the rate of change of the tool path position is largely a waste of time and effort IMO.

-

@deckingman Ian I agree with you about this not necessarily being something that is required for 3d printing. What is interesting is that for CNC firmware variations on this theme appear to be more common.

Now that David has migrated to an RTOS, it might be possible for someone to write an alternative motion planner based on one of these algorithms and then run true side by side tests. I would be very wary of switching permanently but having an alternative that could be selected via gcode might work, especially if this is a bigger issue for CNC machines.

-

Why heaving less vibrations should not be an advantage for 3d printing? The psychics behind it is simple. Maybe many users will not see a difference because they jerk and acl settings a quite low. But I like to push my printer to the limits.

-

@dragonn The point is that it has not been definitively shown to have less vibrations in 3d printing. We need to have some comparisons with everything else held equal.

-

A lot of this comes down to - "how fast do you want or need to print?" If you need accuracy over speed, and that's the position most people eventually come to rest at, then slow everything down, lower XY acceleration to the point where you are not making your mechanics follow anything but the true path the gcode contains.

If however you want to push a machine to the limits of speed then perhaps having some sort of compensation for the inertia of the print head and the axes supporting it makes sense. There is no doubt that good software, especially RRF, can create much better prints than less good software, using things we already have like pressure advance and non-linear extrusion which for all intents and purposes can be seen as either fudges which do yield better results, or compensations to allow the imperfect machinery to produce nearer the desired output.

How you go about tuning it and deciding how much "inertia-compensation" or whatever you end up calling it, to apply is something to be determined.

-

@t3p3tony I know without an video and rely on one opinion isn't an 100% confirmation but I will quote from first link with I posted (https://github.com/MarlinFirmware/Marlin/pull/10337) :

"The result is mostly incredible: There is no vibration of the machine itself while printing. You have to see in action to believe it! :D"