Spirograph emulator with Duet2

-

Hi guys,

after seeing a super cool video of a coffetable with a carved spirograph pattern, I want to build a CNC version in smaller scale. I found a different version with external gears, I want to emulate with geared steppers:

It almost looks like a 5-bar SCARA, but the motors moving the arms work with continuous rotation.

I thought of using the extruder mixing ratio for all three motors to get the typical spiro-patterns.But maybe there is a better solution to go beyond the spiro-world?

-

@o_lampe setting them up as a single mixing extruder should work. You may possibly get some rounding error resulting in the final pen position not quite lining up with the initial position. If that happens then I suggest you configure them as axes instead.

When I was a teenager I produced spirograph patterns on the screen of an old TV using two oscillators feeding modified audio amplifiers that drove the deflection coils of the CRT.

-

@dc42 said in Spirograph emulator with Duet2:

the final pen position not quite lining up with the initial position

Depending on how good the build will be, it will look wobbly anyway. Especially the joints and wrist bearings are giving me an headache. I want to use a Dremel grinder at least...

I thought of replacing the circular motion of the two arms with ballscrews going back and forth.

IMHO, the pattern is mostly related to different starting positions ( or different start-angles in the original toy-mechanic)But how could I mimic a sinusodial motion with a linear axis?

Do we have "s-curve" acceleration? -

@o_lampe said in Spirograph emulator with Duet2:

But how could I mimic a sinusodial motion with a linear axis?

You would need to generate small segments of GCode that move the linear axes in a sinusoidal manner.

@o_lampe said in Spirograph emulator with Duet2:

Do we have "s-curve" acceleration?

Experimental S-curve acceleration is under development, but I don't believe it will help in this case,

-

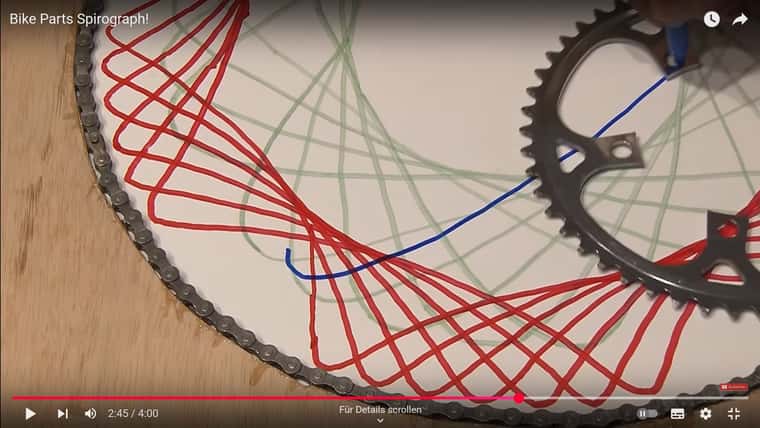

At work I started building a spirograph machine based on bicycle parts similar to this:

I then began to work out the basic math behind the pattern, which I now regret not have done earlier.

Turns out, the outer toothcount should better be a binary number. That way only the small sprockets define the number of revolutions to complete a pattern.

My chain counts 124 teeth, which leads to 31 * n revolution patterns.

I'd grind a wooden surface to dust...especially at the center.Good thing, the emulated CNC version can have any number of teeth. Plus I can vary the arm lengths and emulate non_circular sprockets.

If you're interested, there is this nice spirograph simulator. Just hit the demo button and get hypnotized

-

@o_lampe I saw this video the other day, not much left in the centre! https://youtu.be/zW5nZ0Hp95k

Ian

-

@droftarts That was the vid that got me started. All the 3D printed parts must have taken a long time...

and I thought: bike-parts?! Another guy had the same idea a while ago. It's a good starting point but not CNC-able.

The version I posted above is a better candidate. It could even work as a FDM printer.

Like a short range 5-bar SCARA with a rotary bed. I wonder if RRF supports such weird kinematics? -

@o_lampe See MakersMuse latest video where he converts rotary motion to linear motion to sine wave using a Scotch Yoke.

https://www.youtube.com/watch?v=wko3SWiV1DM

Not sure if it will be useful for you but might inspire some ideas.

-

@tas Quite the eye-opener! Thanks for posting.

I always thought that a crankshaft would create a sine wave. Now checking the above double-crank again, I'm sure the toolhead will draw an even weirder curve.Maybe I should invest some time and try to simulate it?

Would OpenScad be able to do it, or do I have to learn Blender or the like? -

@o_lampe OpenSCAD might be able to do it.

This link has an example file but it would require a lot of changes to simulate the Scotch Yoke.

https://www.instructables.com/Animating-with-OpenSCAD/

You can download their example at the bottom of the page.