Printer won't extrude walls of prints.

-

Try reslicing the file with the same speed for walls and infills.

-

@Phaedrux said in Printer won't extrude walls of prints.:

; Extruders M584 E0.0 ; set extruder mapping M350 E1 I1 ; configure microstepping with interpolation M906 E1100 ; set extruder driver currents M92 E562 ; configure steps per mm M566 E3000 ; set maximum instantaneous speed changes (mm/min) M203 E12000 ; set maximum speeds (mm/min) M201 E5000 ; set accelerations (mm/s^2)This is a very strange extruder setup. What kind of extruder is this?

Are you able to extrude in free air from the DWC extrusion commands?

What is strange about the extruder setup? It's the Bondtech LGX Lite V2. It extrudes fine in free air through the DWC, even on the infill of prints, just not the outer walls for some reason.

I'm currently warming up my printer to try reprinting with all of the speeds set to 45mm/s to see if that helps.

-

@Phaedrux said in Printer won't extrude walls of prints.:

Try reslicing the file with the same speed for walls and infills.

Just tried this and still the same behaviour as the video. It also won't extrude while printing out the skirt either, which it has done this whole time I just forgot to mention it...

-

Why 1x micro stepping?

Have you tried with pla instead of tpu?

-

@Phaedrux I think that may have been the default when I used the firmware configurator but I can't remember.

I tried printing the same part with a 8mm Brim and the printer doesn't extrude when going around the rim except for a small section of the brim. The small bit that does extrude always occurs at the same spot in the brim.

I really think this is a slicer or firmware issue, but I don't have any PLA to try right now. I could try with CF Nylon but I have never printed with that so it may just be adding another variable.

If anyone else is running the LGX lite V2 and has firmware settings that work for them please share them with me.

-

@Phaedrux said in Printer won't extrude walls of prints.:

Why 1x micro stepping?

I just tried 16x microstepping and there was no change, I also tried 32X microstepping with 1124 steps per mm and still no change.

-

@MurphDurtay if it helps here are my settings but not a V2:

Duet 2 Wifi, Bondtech LGX Lite, E3DV6 hotend, 0.4mm NozzleX.M584 E3;

M350 E16 I1;

M906 E400;

M92 E568.3 ; (eSun PLA+)

M566 E8000.00;

M203 E6000.00;

M201 E5000.00;Your current is way too high. The Bondtech specs state 550-650 mA.

-

TPU is hard to print with to begin with. Testing with PLA would be my next step.

When was the last time prints were working correctly?

I doubt it's a firmware issue, but it could be related to your configuration. 16x microstepping is the norm. If your steps per mm are way out of whack for 1x microstepping no wonder things aren't extruding well.

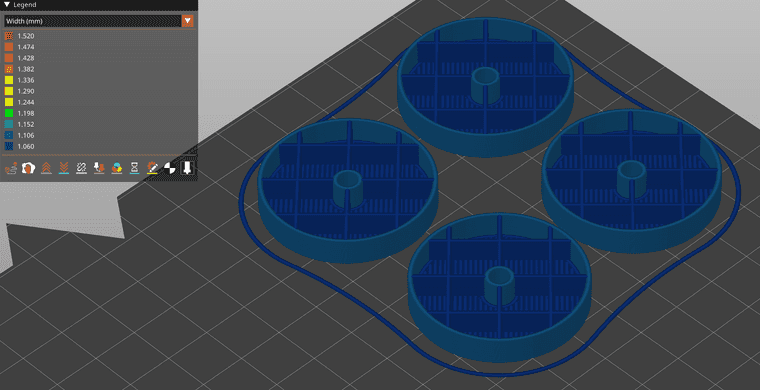

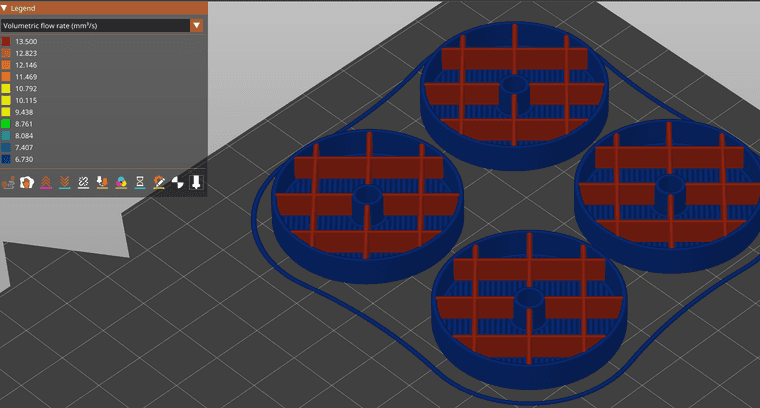

The sliced gcode file you shared shows nothing out of the ordinary when previewed in prusa slicer gcode viewer.

-

@tas I just tried your exact settings but it still won't extrude along walls, brims, or skirts. As for the current I just went off of the datasheet for the stepper which is rated at 1 amp. I didn't consider that the stepper datasheet could be peak current and the config is in RMS so that would be a max in the config of 707ma so I turned it down to 700, but still having issue.

Can anyone see if the G-code I posted extruder should be extruding while tracing the wall?

-

The only difference between the walls and infill is the extrusion width. Though the volumetric flow is lower on the walls than infill due to being slower.

That still may be too high for TPU. Try dropping the print speed by half.

-

@Phaedrux said in Printer won't extrude walls of prints.:

TPU is hard to print with to begin with. Testing with PLA would be my next step.

When was the last time prints were working correctly?

I doubt it's a firmware issue, but it could be related to your configuration. 16x microstepping is the norm. If your steps per mm are way out of whack for 1x microstepping no wonder things aren't extruding well.

The sliced gcode file you shared shows nothing out of the ordinary when previewed in prusa slicer gcode viewer.

-I'll have to wait to get some more PLA but I don't think it's a material or bed adhesion issue

-The last time prints were working correctly was before moving my printer, I had to move the printer and make a new SD card with the firmware because the old one got broken in the move. These are my first prints on the new SD card.

-I have changed the settings to 16x micro-stepping and 564 steps per mm which came from the bondtech website

-

Try prusa slicer as a sanity check?

How fast are you extruding into free air when you're testing? Are you actually matching the feed rates that would be used during the print?

-

@Phaedrux Yeah I'll try that next

-

@Phaedrux said in Printer won't extrude walls of prints.:

Try prusa slicer as a sanity check?

How fast are you extruding into free air when you're testing? Are you actually matching the feed rates that would be used during the print?

Same behavior with prusa slicer, I'm Extruding at 2mm/s in DWC however it doesn't have a problem extruding anything but walls, brim or skirt.

-

I just tried downloading a fresh benchy STL and sliced in Cura and it still only prints a sliver of the brim.

-

I think I figured out what is going on, I slowed the print down to 10mm/s and set the nozzle to 255 and now it is printing the brim! I'm thinking the only reason it extruded on just the inside is the frequent retractions gave the filament enough time to heat. It would appear I drastically underestimated how much extra temperature you need for 0.8 and 1.0mm nozzles. I just swapped to a 0.4mm nozzle because even the brim it printed with the big nozzle was pretty ugly. Right now I'm going to try 30mm/s with a 0.4mm nozzle and the temp at 245C.

-

Everything seems to be working as usual now with the 0.4mm nozzle. Could I just ratchet up the nozzle temp to like 270 to print with the 0.8 and 1.0mm nozzles?

-

This can be marked as solved at this point, thanks for the help everyone!

-

@MurphDurtay said in Printer won't extrude walls of prints.:

Everything seems to be working as usual now with the 0.4mm nozzle. Could I just ratchet up the nozzle temp to like 270 to print with the 0.8 and 1.0mm nozzles?

You can try that, but you may also want to look at https://docs.duet3d.com/en/User_manual/Reference/Gcodes#m309-set-or-report-heater-feedforward.

-

undefined dc42 marked this topic as a question

undefined dc42 marked this topic as a question

-

undefined dc42 has marked this topic as solved

undefined dc42 has marked this topic as solved