Extruder Heater overshoots target temperature, M307 questions

-

Hi,

I am using a 50W heater with Biqu H2 extruder. I am able to auto-tune heater at different part cooling fan speeds. (tried from 20% to 100% fan speed). But when I set temperature, even with 100% fan ON, I see extruder overshoots the target temperature by >15degC .

I found few links, but there is some ambiguity in the documentation literature & the forum link.following links, David asks to increase 'R' paramater.

https://forum.duet3d.com/topic/31038/overshoot-and-really-unstable-hotend-temperature/2?=1721909615387

https://forum.duet3d.com/topic/31038/overshoot-and-really-unstable-hotend-temperature/2?=1721909615382But literature says, to decrease in case of overshoot:

https://docs.duet3d.com/User_manual/Connecting_hardware/Heaters_tuning-

Can you please confirm whether to increase or decrease?

-

I have tried increasing R parameter, still the problem of overshoot persists.

-

Should I try tuning to 90% PWM?

@droftarts , @dc42 : What do you suggest?

NOTE: I am using latest firmware & didn't face such problem with Bondtech extruders & slice engineering heaters.

-

-

@JayT what command are you sending to auto tune?

Can you post a photo of your hotend+fan setup? -

M303 H1 S300 P1

If I keep cooling fan at 0% fan during autotune, then I get the learned values as below & temperature with these values overshoots only by 6degC. BUT, the moment FAN starts, temperature drops by 5degC & I get a warning that predicted temperature can go beyond 500degC/700degC at times.

The values I get are:

M307 H1 R2.876 C238.464:338.464 D10.36 S1.00 V23.4 B0 I0- If I auto-tune with FAN on in 2 phases & off in last two as per the procedure, Then the learned values cause an effect of overshooting by 15degC.

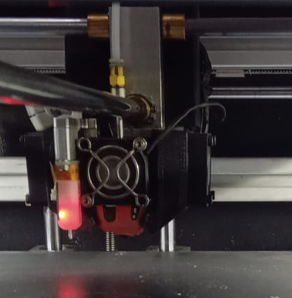

Image of hotend:

-

@JayT Try tuning as a tool.

soM303 T0 S300assuming your hotend is set as tool 0 -

Thanks.

I tried this "M303 T0 S300".

values after tune : M307 H1 R1.991 K0.759:0.048 D11.88 S1 B0 V23.9 E1.35.On power up, prediction warning no longer appears.

On setting 210degC for PLA, temperature still, at first overshoots by 14degC but stabilizes after 2 mins. And on switching on Cooling fan, temperature drops by 5degC but heater manages to pick up. (in a nutshell, the I no longer get any heater warnings.The question I have is :

- What does this feedforward method really does in the code to tune different than M303 H1 command?

- I have saved values in config-override.g, If I re-tune will the values be same or will it optimize further?

- Is this overshoot of 14degC due to thermal mass & sensor being little farther from heater area?

-

@JayT said in Extruder Heater overshoots target temperature, M307 questions:

What does this feedforward method really does in the code to tune different than M303 H1 command?

It takes into account the expected temperature drop from fan cooling.

@JayT said in Extruder Heater overshoots target temperature, M307 questions:

I have saved values in config-override.g, If I re-tune will the values be same or will it optimize further?

No, the tuning isn't cumulative. You can retune it if you wish, but the values will largely remain the same (with some noise leading to slight variation).

@JayT said in Extruder Heater overshoots target temperature, M307 questions:

Is this overshoot of 14degC due to thermal mass & sensor being little farther from heater area?

Larger heaters with larger thermal mass are harder to tune especially if there is a loose connection between the heater and the sensor. You can manually adjust the values if you want to try and reduce the overshoot.

https://docs.duet3d.com/en/User_manual/Connecting_hardware/Heaters_tuning

-

For manual adjustment, it brings me back to the 1st post in this thread. Can you answer the following for me to try :

following links,

David suggests to increase 'R' paramater.

https://forum.duet3d.com/topic/31038/overshoot-and-really-unstable-hotend-temperature/2?=1721909615387

https://forum.duet3d.com/topic/31038/overshoot-and-really-unstable-hotend-temperature/2?=1721909615382But literature says, to decrease in case of overshoot:

https://docs.duet3d.com/User_manual/Connecting_hardware/Heaters_tuningCan you please confirm whether to increase or decrease "R" value ?

- Should I reduce P value ?

- Should I try tuning to 90% PWM?

-

@JayT if you consistently see overshoot, try increasing the R value. Start by increasing it by about 10%.

-

@dc42 :

Increasing R parameter, in my case, does not change the overshoot problem.

I tried decreasing R parameter, by 20-40%, then overshoot only reduces by 2 degC. i.e. earlier overshoot was 14degC, then it changed to 12degC, but cooling rate reduced.

What to do further , any suggestion?Printer1:

M307 H1 R1.991 K0.759:0.048 D11.88 S1 B0 V23.9 E1.35 P7.5 I0.120 D44

This printer, does not give any warning on power up pf prediction, though overshoots at first by 14degC, but settles & then on fan on, temperature drop seen is just 4-5degC but manages reach target.Printer2, same extruder, Biqu.

M307 H1 R2.457 K0.290:0.132 D11.88 S1 B0 V24.1 E1.35 P5.1 I0.0.085 D43.8This printer, on power on, gives predicted temperature warning (511degC), temperature overshoots only by 6degC, but settles & on fan on, temperature drop behaviour is same as that of printer 1.

Why same sensor & heater type in same extruder type, behave so differently ? One overshoots only by 6degC, but other overshoots by 14degC.

note: Both tuned at same ambient, using "M303 T0 S300".

-

-

@droftarts : I understand your suggestion; for abs I might need 260degC.However, if I want to claim 300degC of extruder, I must tune it to that max limit. If I just tune to 210degC, then at times it will struggle to even reach 280/290degC . I plan to include chamber heater too.

My only concern is to understand this tuning well, so that there are not heater warnings/faults ., other wise on power up this predicted warning generates a doubt to user.

(I don't face this with bondtech set up, but with biqu extruder only).- Does the position of heater & sensor matter?, Is it supposed to be completely inline with heater/sensor boundaries or a little protruding ? (I have used borosilica paste to fit the sensor well.)

NOTE: I user Duet 2 wifi board.

-

I further checked the setup & realize that the PT1000 sensor is 30mm in length with 4mm diameter. But the Biqu extruder slot for hotend & sensor is of 15mm.

This means half the sensor is outside sensor slot & not in contact with hotend.Shouldn't this affect the PID learning & heater behaviour?