Toolboard 1LC troubles

-

@oliof it's Bondtech BMG with Bondtech pancake motor (https://www.bondtech.se/product/nema17-pancake-stepper-25mm/). Never had issue with it, but now motor does not extrude consistently.

; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"V-Core - 1" ; set printer name M669 K1 ; CoreXY G21 ; Set Units to Millimeters G4 S2 ; wait for expansion boards to start ; Network M552 S1 ; enable network and acquire dynamic address via DHCP M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0.0 S0 D3 ; physical Z1 drive 0 goes forwards M569 P0.1 S0 D3 ; physical Z2 drive 1 goes forwards M569 P0.2 S0 D3 ; physical Z3 drive 2 goes forwards M569 P0.3 S1 D3 ; physical Y1 drive 3 goes backwards M569 P0.4 S1 D3 ; physical X1 drive 4 goes backwards M569 P121.0 S0 D3 ; physical E drive 121.0 goes forwards M584 X0.4 Y0.3 Z0.0:0.1:0.2 E121.0 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X80.00 Y80.00 Z800.00 E415.00 ; set steps per mm M906 X1700 Y1700 Z1700 E700 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout M205 X5.00 Y5.00 Z1.00 E60.00 P1 ; set maximum instantaneous speed changes (mm/s) M203 X30000.00 Y30000.00 Z3600.00 E10800.00 ; set maximum speeds (mm/min) M201 X6000.00 Y6000.00 Z100.00 E10000.00 ; set maximum accelerations (mm/s^2) M204 P3000 T6000 ; set printing and travel acceleration ; Axis Limits M208 X0 Y0 Z-1 S1 ; set axis minima M208 X413 Y405 Z405 S0 ; set axis maxima M671 X0:203.5:408.7 Y0.5:409:0.5 S5 ; define positions of Z leadscrews or bed levelling screws M556 S100 X0.45 Y0 Z0 ; axis skew compensation ; Endstops M574 X1 S1 P"121.io2.in" ; configure active low endstops M574 Y2 S1 P"io0.in" ; configure active high endstops M574 Z1 S2 ; configure Z-probe endstop for low end on Z ; Heaters M308 S0 P"temp0" Y"thermistor" T100000 B3950 A"Bed" ; configure sensor 0 as thermistor on pin temp0 M950 H0 C"out0" T0 Q50 ; create bed heater output on out0 and map it to sensor 0 M307 H0 R0.698 K0.390:0.000 D5.08 E1.35 S1.00 B0 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S110 ; set temperature limit for heater 0 to 110C ; Tools M563 P0 D0 H1 F1 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C M308 S1 P"121.temp0" Y"thermistor" T100000 B4725 C7.060000e-8 A"Hotend" M950 H1 C"121.out0" T1 ; create nozzle heater output on out2 and map it to sensor 1 M307 H1 R1.774 K0.362:0.276 D6.68 E1.35 S1.00 B0 V23.9 ; disable bang-bang mode for heater and set PWM limit M143 H1 S285 ; set the maximum temperature in C for heater ; Fans M950 F0 C"121.!out1+out1.tach" Q500 ; create fan 1 on pin out4 and set its frequency M106 P0 C"Layer Fan" S0 H-1 ; set fan 1 name and value. Thermostatic control is turned off M950 F1 C"121.out2" Q500 ; create fan 0 on pin out3 and set its frequency M106 P1 C"Hotend Fan" S1 H1 T45 ; set fan 0 name and value. Thermostatic control turned on for Hotend M950 F2 C"out6" Q500 ; create fan 2 on pin out6 and set its frequency M106 P2 C"Duet fan" S1 H-1 ; set fan 2 value. Thermostatic control is turned off ; BLTouch M950 S0 C"121.^io0.out" ; Create a servo pin on 121.io0 M558 P9 C"121.^io0.in" H5 F240 T10800 A5 ; set Z probe type to unmodulated and the dive height + speeds G31 P25 X-30 Y-14.50 Z1.9 ; set Z probe trigger value, offset and trigger height, more Z means closer to the bed ; Accelerometer LIS3DH and Input shaping M955 P121.0 I05 ; specify orientation of accelerometer on Toolboard 1LC with CAN address 121 M593 P"zvd" F50 M404 N1.75 D0.4 ; Filament width and nozzle diameter T0 ; Pressure Advance M572 D0 S0.04 -

@Arminas the TDS gives peak value of 0.7A, so I would set it to something from 550 to 600 mA in RRF. If that does not improve its behavior, measure the resistance of both phases; if they differ too much the motor may be toast.

-

@oliof both phases has 4.6 ohms, although it's written that it should be 4.2. Is that an issue?

-

@oliof But if I connect the wire and measure phase on the loose end of wire, one phase is 4.6, another is 4.9

-

@oliof After a few layers extruder starts to skip the steps, and it gets extremely hot, I can't keep my fingers on it. So I guess it's motor fault?

I tried to swap to another motor, will see how it goes.

-

@oliof @droftarts same issue with other motor - during the print, something happened and blower fan started to blow 100% instead of 20% and I got an error "M106 board 121 does not have fan 0".

Here is m122:

m122 === Diagnostics === RepRapFirmware for Duet 3 Mini 5+ version 3.4.6 (2023-07-21 14:09:13) running on Duet 3 Mini5plus WiFi (standalone mode) Board ID: U51SX-F396U-D65J0-40KMW-M603Z-ZFNKD Used output buffers: 1 of 40 (24 max) === RTOS === Static ram: 103712 Dynamic ram: 110488 of which 36 recycled Never used RAM 23804, free system stack 118 words Tasks: NETWORK(notifyWait,14.3%,240) HEAT(notifyWait,0.0%,336) Move(notifyWait,1.5%,235) CanReceiv(notifyWait,0.0%,796) CanSender(notifyWait,0.0%,325) CanClock(delaying,0.0%,349) TMC(notifyWait,0.7%,106) MAIN(running,82.5%,417) IDLE(ready,0.1%,30) AIN(delaying,0.9%,263), total 100.0% Owned mutexes: WiFi(NETWORK) === Platform === Last reset 00:47:07 ago, cause: software Last software reset at 2024-04-07 22:10, reason: User, GCodes spinning, available RAM 27692, slot 0 Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x00000000 BFAR 0xe000ed38 SP 0x00000000 Task MAIN Freestk 0 n/a Error status: 0x00 MCU revision 3, ADC conversions started 2827072, completed 2827071, timed out 0, errs 0 Step timer max interval 1490 MCU temperature: min 28.0, current 35.4, max 37.4 Supply voltage: min 23.5, current 23.9, max 24.1, under voltage events: 0, over voltage events: 0, power good: yes Heap OK, handles allocated/used 99/1, heap memory allocated/used/recyclable 2048/12/0, gc cycles 0 Events: 0 queued, 0 completed Driver 0: standstill, SG min 0, read errors 0, write errors 1, ifcnt 41, reads 17656, writes 15, timeouts 0, DMA errors 0, CC errors 0 Driver 1: standstill, SG min 0, read errors 0, write errors 1, ifcnt 41, reads 17656, writes 15, timeouts 0, DMA errors 0, CC errors 0 Driver 2: standstill, SG min 0, read errors 0, write errors 1, ifcnt 41, reads 17655, writes 15, timeouts 0, DMA errors 0, CC errors 0 Driver 3: standstill, SG min 0, read errors 0, write errors 1, ifcnt 41, reads 17655, writes 15, timeouts 0, DMA errors 0, CC errors 0 Driver 4: standstill, SG min 0, read errors 0, write errors 1, ifcnt 41, reads 17656, writes 15, timeouts 0, DMA errors 0, CC errors 0 Driver 5: not present Driver 6: not present Date/time: 2024-04-07 22:58:07 Cache data hit count 4294967295 Slowest loop: 219.05ms; fastest: 0.07ms === Storage === Free file entries: 9 SD card 0 detected, interface speed: 22.5MBytes/sec SD card longest read time 6.4ms, write time 2.1ms, max retries 0 === Move === DMs created 83, segments created 34, maxWait 130698ms, bed compensation in use: mesh, comp offset 0.000 === MainDDARing === Scheduled moves 17036, completed 17036, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 2], CDDA state -1 === AuxDDARing === Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === Heat === Bed heaters 0 -1 -1 -1, chamber heaters -1 -1 -1 -1, ordering errs 0 Heater 0 is on, I-accum = 0.2 === GCodes === Segments left: 0 Movement lock held by null HTTP is idle in state(s) 0 Telnet is idle in state(s) 0 File is idle in state(s) 0 USB is idle in state(s) 0 Aux is idle in state(s) 0 Trigger is idle in state(s) 0 Queue is idle in state(s) 0 LCD is idle in state(s) 0 SBC is idle in state(s) 0 Daemon is idle in state(s) 0 Aux2 is idle in state(s) 0 Autopause is idle in state(s) 0 Code queue is empty === CAN === Messages queued 41267, received 55885, lost 0, boc 0 Longest wait 2ms for reply type 6026, peak Tx sync delay 6729, free buffers 18 (min 17), ts 14136/14135/0 Tx timeouts 0,0,0,0,0,0 === Network === Slowest loop: 183.57ms; fastest: 0.00ms Responder states: HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0) HTTP sessions: 2 of 8 = WiFi = Interface state: active Module is connected to access point Failed messages: pending 0, notready 0, noresp 0 WiFi firmware version 1.26 WiFi MAC address f0:08:d1:03:81:a2 WiFi Vcc 3.38, reset reason Power up WiFi flash size 2097152, free heap 25616 WiFi IP address 192.168.32.177 WiFi signal strength -56dBm, mode 802.11n, reconnections 0, sleep mode modem Clock register 00002002 Socket states: 0 0 0 0 0 0 0 0 -

@Arminas what does M122 B121 report when the fan goes missing?

-

@oliof So I tried to print one more time. This time there is no fan error, but extruder motor started to skip steps and it's over extruding a lot, line width looks at least 2x wider than it should be. Now I am thinking that it skips steps because of the huge over extrusion.

M122 B121:

M122 B121 Diagnostics for board 121: Duet TOOL1LC rev 1.1 or later firmware version 3.4.6 (2023-07-21 14:17:33) Bootloader ID: SAMC21 bootloader version 2.4 (2021-12-10) All averaging filters OK Never used RAM 2532, free system stack 41 words Tasks: Move(notifyWait,0.2%,99) HEAT(notifyWait,0.5%,83) CanAsync(notifyWait,0.0%,61) CanRecv(notifyWait,0.0%,74) CanClock(notifyWait,0.0%,65) ACCEL(notifyWait,0.0%,61) TMC(notifyWait,3.0%,57) MAIN(running,91.2%,351) IDLE(ready,0.0%,26) AIN(delaying,5.0%,142), total 100.0% Last reset 00:24:55 ago, cause: power up Last software reset data not available Driver 0: pos 1710258, 415.0 steps/mm,ok, SG min 0, read errors 0, write errors 2, ifcnt 78, reads 15080, writes 6499, timeouts 35, DMA errors 0, CC errors 6477, failedOp 0x6a, steps req 2007480 done 2007461 Moves scheduled 6321, completed 6320, in progress 1, hiccups 2, step errors 0, maxPrep 690, maxOverdue 115, maxInc 113, mcErrs 0, gcmErrs 0 Peak sync jitter -3/10, peak Rx sync delay 215, resyncs 0/0, next step interrupt due in 439 ticks, enabled VIN voltage: min 7.7, current 23.7, max 24.3 MCU temperature: min 45.8C, current 67.7C, max 70.7C Last sensors broadcast 0x00000002 found 1 161 ticks ago, 0 ordering errs, loop time 1 CAN messages queued 29964, send timeouts 0, received 19829, lost 0, free buffers 37, min 36, error reg 0 dup 0, oos 0/0/0/0, bm 0, wbm 0, rxMotionDelay 537, adv 18383/74651 Accelerometer: LIS3DH, status: 00 I2C bus errors 0, naks 3, other errors 0 -

@dc42 maybe you have any insights?

-

@Arminas is the blower fan that goes to 100% the hot end heatsink fan, or the print cooling fan? If there is a temperature reading error on the hot end then it's normal for the hot end heatsink fan to go to 100%. The firmware does that because it doesn't know what the temperature is, and having the heatsink fan on may prevent the hot end from clogging or getting damaged.

My best guess is that either there is a problem with the temperature sensor, or the temperature reading input on the tool board has been damaged by either a short circuit between the thermistor and heater wires, or by electrostatic discharge. So I suggest you start by checking the thermistor using a multimeter. Check that its resistance at room temperature is as expected, and check that there is no continuity between it and the heater wires. If that looks OK, try using the second temperature connector on the tool board. Make sure that the hot end metalwork is connected to Duet ground, either directly or through a resistor, to prevent static charge from building up.

-

@dc42 it's the blower fan. Temp sensor is good by checking it with multimeter. Is it possible that toolboard temp reading input is damaged and it causes the toolboard to do weird things, like over extrusion and etc.?

What do you mean by checking the continuity between temp sensor and heater wires?

Hot end metalwork is not grounded I guess. How do I do that?

-

@dc42 Same happens with second temperature connector. It just starts over extruding out of nowhere..

idk if this helps, but here is M122 B121:

M122 B121 Diagnostics for board 121: Duet TOOL1LC rev 1.1 or later firmware version 3.4.6 (2023-07-21 14:17:33) Bootloader ID: SAMC21 bootloader version 2.4 (2021-12-10) All averaging filters OK Never used RAM 2532, free system stack 31 words Tasks: Move(notifyWait,3.1%,99) HEAT(notifyWait,10.7%,75) CanAsync(notifyWait,0.0%,59) CanRecv(notifyWait,0.8%,74) CanClock(notifyWait,0.5%,65) ACCEL(notifyWait,0.0%,61) TMC(delaying,84.4%,57) MAIN(running,22.1%,351) IDLE(ready,0.0%,26) AIN(delaying,138.0%,142), total 259.6% Last reset 28:02:20 ago, cause: software Last software reset data not available Driver 0: pos 7263403, 415.0 steps/mm,standstill, SG min 0, read errors 3, write errors 2, ifcnt 20, reads 18793, writes 6440, timeouts 12343, DMA errors 0, CC errors 6419, failedOp 0x06, steps req 17729885 done 17729885 Moves scheduled 269100, completed 269100, in progress 0, hiccups 13, step errors 0, maxPrep 747, maxOverdue 130, maxInc 67, mcErrs 0, gcmErrs 0 Peak sync jitter -5/13, peak Rx sync delay 225, resyncs 0/0, no step interrupt scheduled VIN voltage: min 20.9, current 23.7, max 24.3 MCU temperature: min 41.9C, current 71.1C, max 76.4C Last sensors broadcast 0x00000002 found 1 157 ticks ago, 0 ordering errs, loop time 1 CAN messages queued 2019442, send timeouts 0, received 1178017, lost 0, free buffers 37, min 34, error reg 110000 dup 0, oos 0/0/0/0, bm 0, wbm 0, rxMotionDelay 974, adv 15860/74653 Accelerometer: LIS3DH, status: 00 I2C bus errors 0, naks 3, other errors 0 -

@Arminas said in Toolboard 1LC troubles:

MCU temperature: min 41.9C, current 71.1C, max 76.4C

Are you using a heated chamber?

-

@Phaedrux no, this printer is not enclosed. And I have one more RatRig Vcore 400 printer with 1LC, but this one is enclosed and there are no problems

1LC temp readings on enclosed printer are the same:

MCU temperature: min 19.6C, current 72.4C, max 75.2C -

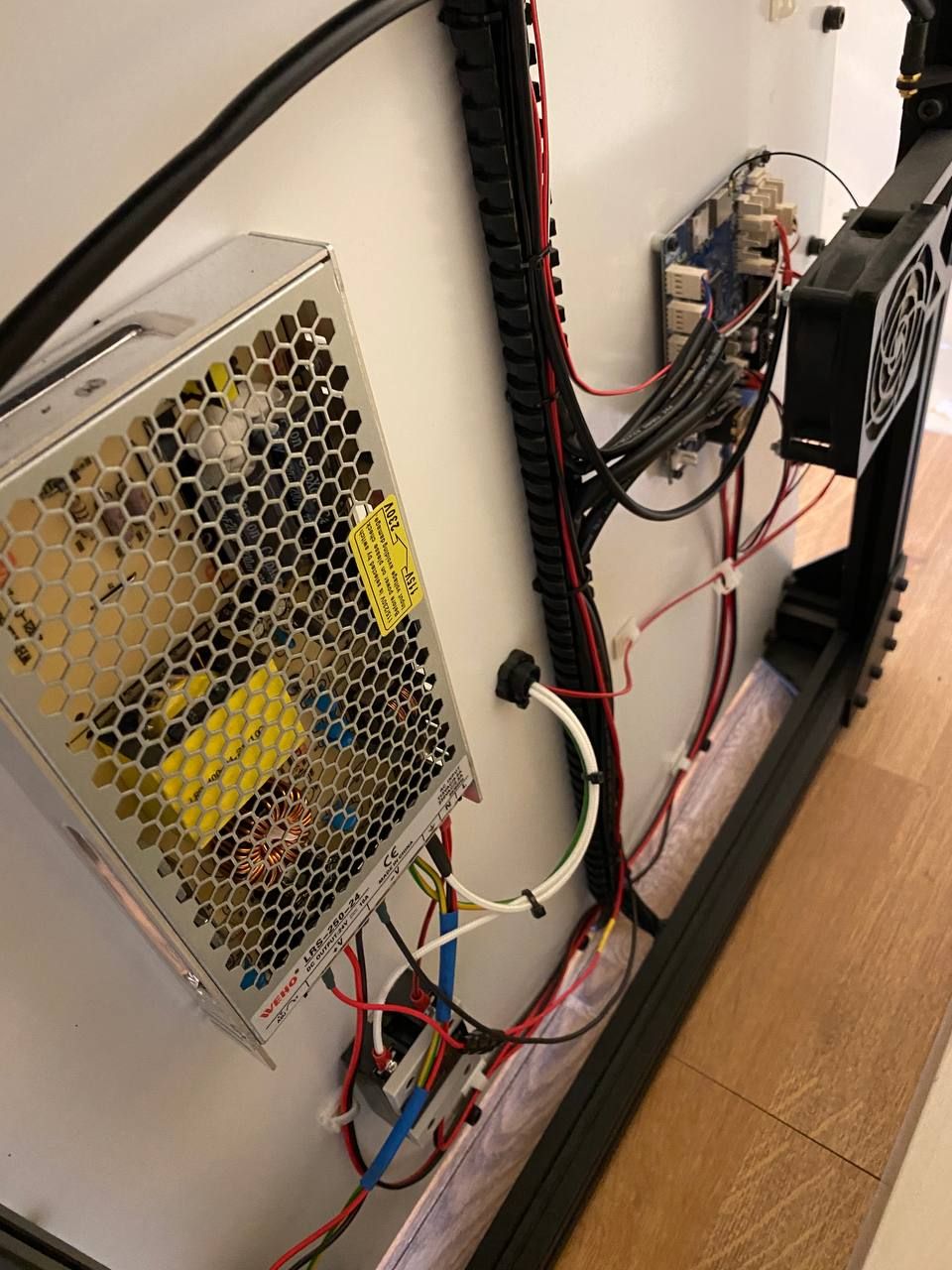

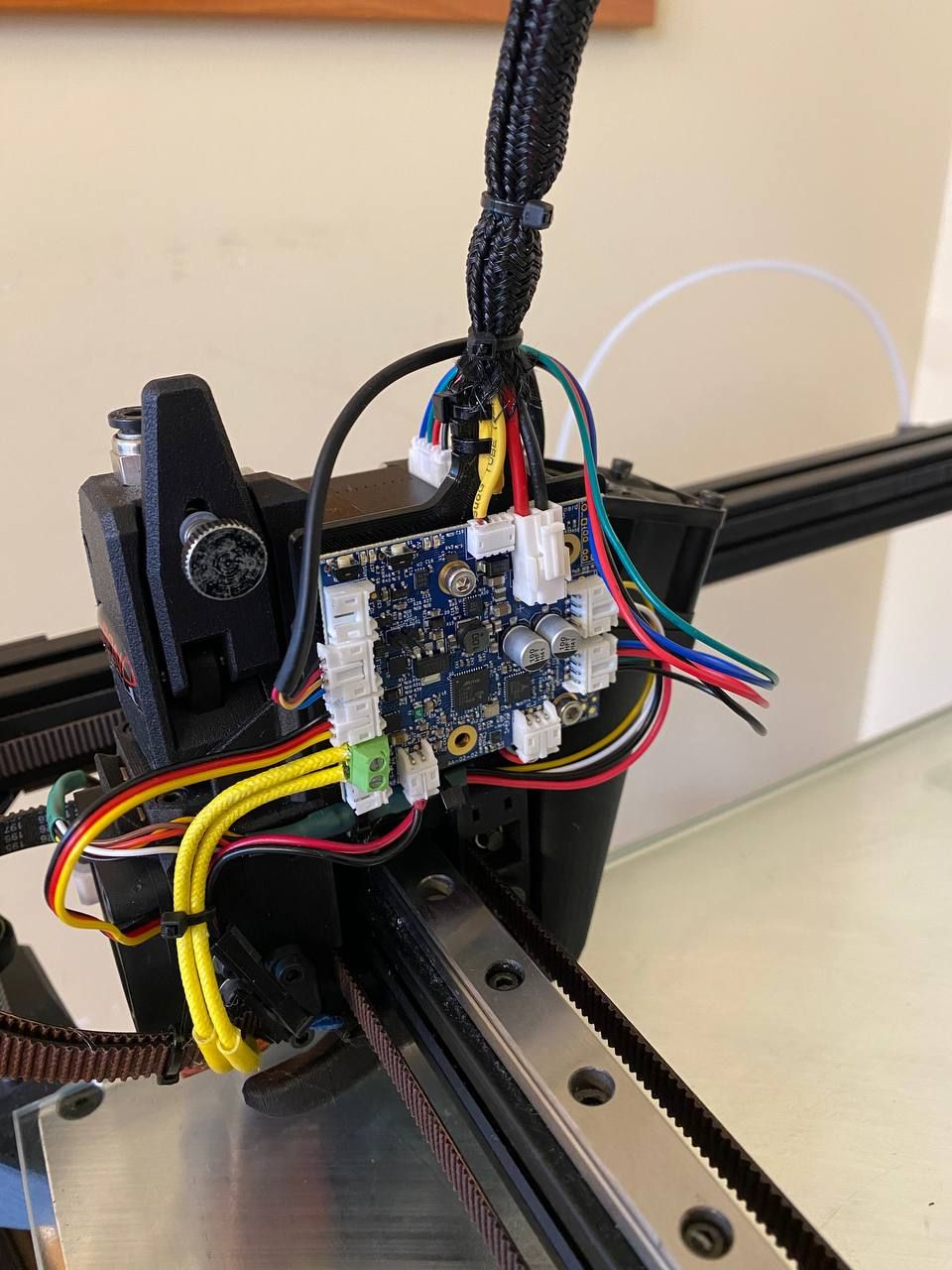

Those temps seem very high for a non-enclosed printer. Can you share some photos of the setup?

-

@Phaedrux Sure, here it is.

-

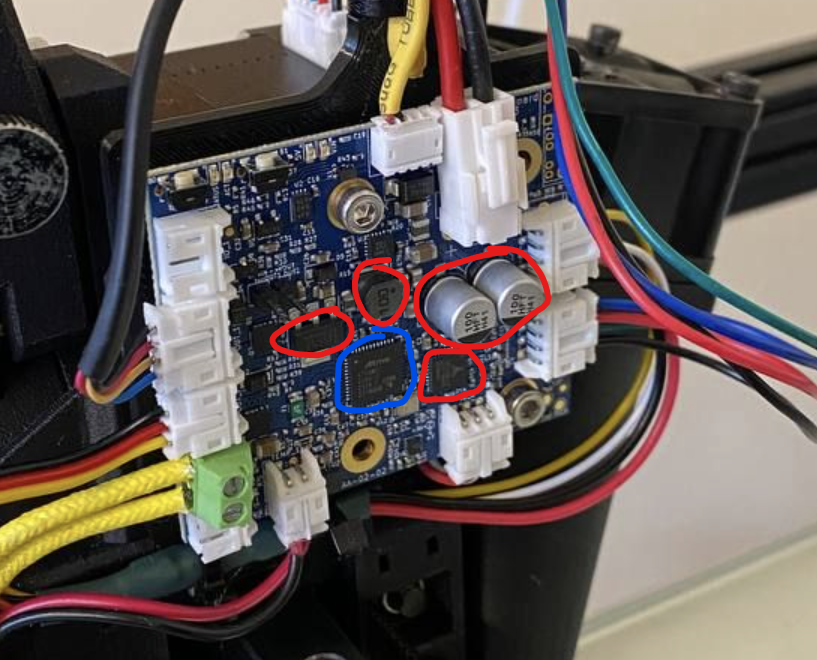

Can you tell if there are any components on the board getting very hot?

-

@Phaedrux Blue - cold, Red - hot (I don't feel comfortable touching it more than 3 seconds). And extruder motor is very very hot

-

Can you disconnect the motor and anything connected to the IO connectors, and see if it still gets hot?

-

@Phaedrux one of IO is used for BLTouch, I can't start the print without it. Maybe it's not a big deal if I leave this one connected?