All_surface scanning z-probe

-

Hi guys,

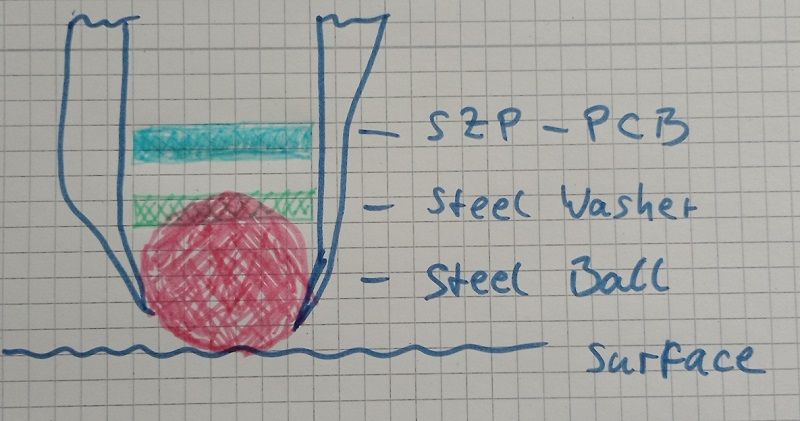

while other people discuss the neccessity of mesh-levelling in general, I thought of a way to use inductive sensors on any surface.

That should work with a Pinda probe or the new SZP-board intruduced by Duet3D lately.

The steel washer will provide a flat solid surface for analog sensors, but for a switching probe it would be interesting to see it's behavior when it probes only the spheric shape of the steel ball. I expect a much sharper transition zone for on/off detection.

-

The idea might work but you may need a cylinder with a round end (as opposed to a ball) to get enough travel to take the inductive sensor from off to on.

Frederick

-

@o_lampe if you go this route then no need to stick with inductive, you can use any sensing technology that works on the ball. That means you could pick something less temperature dependent

-

@o_lampe Given that this will need to be in contact with the bed surface you would need to have some way to deploy it and it will need sufficient "travel" to cope with any reasonable variance in the bed height (which may be tricky to arrange depending upon the size of the steel ball you had in mind).

Perhaps something like "pin" that can be deployed by allowing it to drop to the bed surface and which is then free to move up and down would be easier?

-

@gloomyandy said in All_surface scanning z-probe:

you would need to have some way to deploy it

Aside from some wear on the build surface what would be the downside to the "ball" always touching it?

Frederick

-

@fcwilt Well assuming this is mounted alongside a nozzle (if it is not then you have an entirely different set of "deployment" methods), what's going to happen when print something? To enable the ball to touch the print surface it will need to be lower then the nozzle tip (unless you want the nozzle to be dragging along the bed as well). Won't the ball constantly be hitting whatever is being printed?

-

-

@gloomyandy I'd probably consider something a little more like the Euclid probe where you can pick up and drop off. Would be neat to see especially for folks who use glass/mirror beds.

-

Also a ball is not necessarily the optimal contact shape. even a relatively large radius ball is going to have minimal contact area so you are either going to have to scan many close together lines, miss areas, or have a huge ball. probably a roller is better as scanning only needs to be on one axis. Manufacturing and mounting a smooth and concentric roller is its own challenge!

-

@Sindarius Euclid is how I do it

-

Thanks for the interesting replies. They made me think...

IMHO a small contact area would be best to find the lowest valley in the surface. A roller or cylinder would average out what's underneath.

OTOH a ball might miss the highest point, but that's less of a problem when it comes to 1st layer adhesion.Retracting the ball is a thing I haven't thought about. It would be like a BLtouch, but here the sensor board would need an actor to lift the ball.

Maybe a parking macro for the probe could retract/unretract the probe. Like with the oldfashioned allen key switch probes.If we'd use a capacitive sensor the ball could be made of POM, which is lighter. And has less impact, if we don't retract it and it bumps into the print.

A magnetic sensor (*) would need a mechanic to translate the vertical motion into rotational. (maybe backlash problems)

*) the new MT6835 has a super high resolution of 21 bit = 0,00017 degree/step and has an SPI clock of 16MHz -

@T3P3Tony

I just read the discussion in the official thread about the need of a separate Z-probe for calibration...

What if outside of the coil are two protruding contacts and the steel washer is used to close the contact? Voilá, z=0 datum set -

@o_lampe You could retract/deploy the ball with an electromagnet. Altough I wouldn't use a ball but a rod with a spherical end. I don't think this kind of zprobe needs a "rolling" element.

-

@o_lampe I was considering mechanical devices that could be used for non-metallic build plates, like glass.

You could use a FSR or a load cell on a ballpoint pen style roller, this would probably cause issues with heat drift.

You could use some style of linear potentiometer/hall effect. This would probably drift with temp also.

You could use an optical gauge with a slider. This would probably drift with temp too.

I think the biggest issue is eliminating the temp drift.

-

@Surgikill Temp drift can be an issue, but when we scan the bed really fast and contact material has a low thermal conductivity (ceramic ball or POM) it won't matter.

The inductive probe is especially sensitive, but some other sensors just expand a tiny bit. The range of motion we have to deal with is so small, their thermal expansion is below the radar.

Other issues like AD-conversion noise and interface delay can also mess up the result. -

What about adapting a digital dial gauge? Something like https://github.com/stawel/dialIndicatorToSerial ... I assume the challenges are a) getting readings fast enough, and b) finding a digital dial gauge that's precise enough without costing an arm and a leg.

-

@oliof There are linear hall sensors, but I don't know how sensitive they are. Passing a small magnet along the sensor would act like the rotary mag-sensors, but without the need of a motion translation.