Auto pressure advance turning by hotend pressure

-

@penguinya what inductance are they measuring to determine pressure for pressure advance calibration?

-

@T3P3Tony

It's probably the filament that bends in a certain direction when pressure increases. They could design the filament path in such way, that it bends in a predictable way.

But that would highly depend on the stiffness of the filament and would need a calibration with temp-compensation -

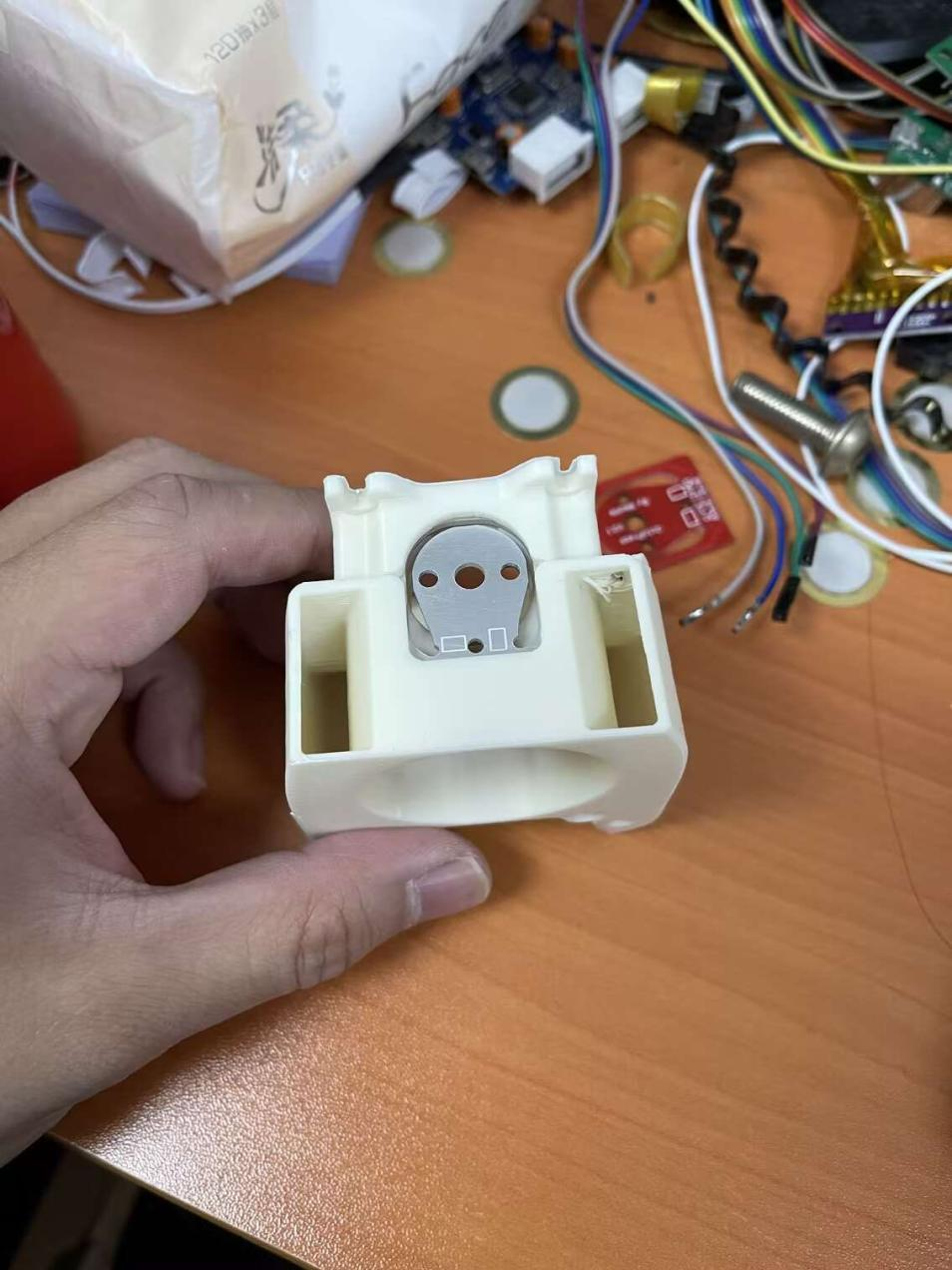

@T3P3Tony Same as the string gauge, it looks like the hotend can move up and down

-

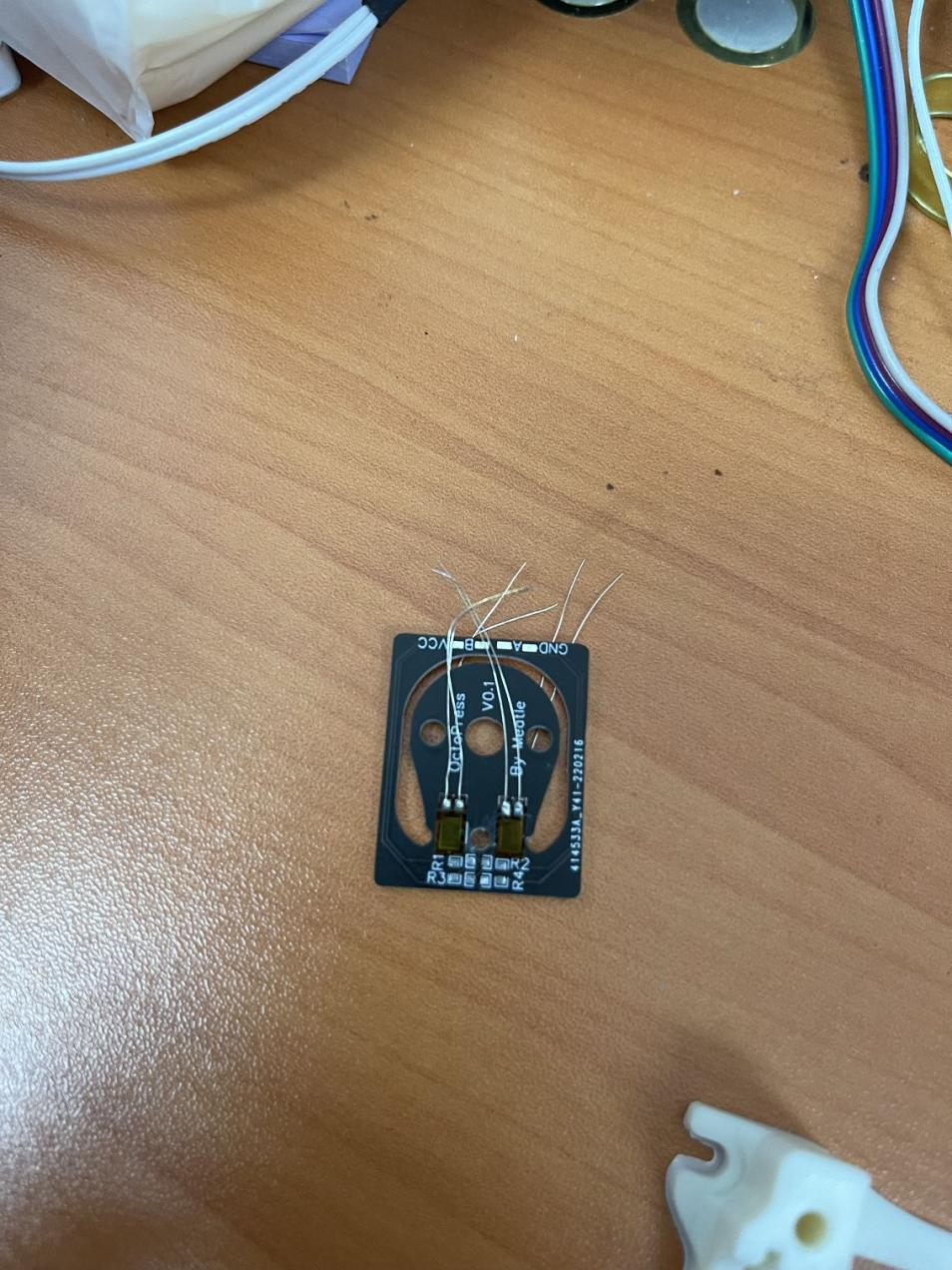

RP2040 have two core and fust enough ADC to measure string gauge.

I think it can save pressure data to calculate pressure curve

-

@penguinya

-

-

15 minutes, 16 seconds to 17 seconds, the hotend moves up and down.

https://www.youtube.com/watch?v=EZ3BtQ7k9Ak -

I love the idea!

I guess you could write a gcode snippet in daemon.g which continously reads straingauge values and adjusts pressure advance values?

Duet can read sensors via SPI, maybe a dedicated "strain gauge sensor" option would be possible? One could also put together a small PCB that amplifies the strain gauge reading into a voltage that can just be read by a linear analog sensor on the Duet? -

@nikscha macro not fast enough, and this is my idea https://forum.duet3d.com/post/324006

-

Automated PA testing is still an early idea. I hope to implement z probe and collect enough PA pressure data for research.

-

@penguinya I think it would be fast enough. Just put a "while true" into daemon.g and then a G4 P50 in the body to execute your script every 50ms. (Edit: this wouldn't actually run that frequent, more like 3-6 times a second)

I don't think pressure advance needs to be adjusted that often, right?

-

@nikscha Bambu Lab tests pa every print, and 50ms really slow, HX711 can reach 80HZ, Prusa using HX717 320HZ, higher the sampling frequency, the more beneficial for auto PA testing.

-

find a better chip for load cell.

CS1237 http://www.asidesigner.com/Files/PartFiles/15315/222/cs1237_datasheet.pdf

spi bus 1.28kHz ADC and PGA -

@nikscha Here is a post about sampling speed

https://forum.duet3d.com/post/251488 -

-

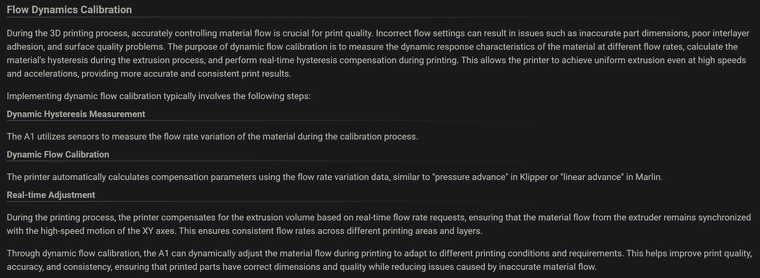

@penguinya The introduction of bambulab confirmed my guess.

-

Correct me if Im wrong, but I feel like this sensor could also be used for filament runout/jam detection as well. Like if the force expected by feeding the filament is not produced, it could indicate that there is some filament error.

-

@Charlie Yes prusa has implemented it

-

@Charlie would a mouse optical sensor work to monitor filament

do we need more than this for a run out trigger

-

@Richard-F that's the simple runout switch that you find on many printers. There are other filament failures you'd want to catch.