Auto pressure advance turning by hotend pressure

-

Bambu lab release new the A1 mini, using hotend pressure.

I think this is light enough on the MCU

bambulab a1 mini measure Inductance for pressure advanced auto calibration

Prusa mk4‘s hardware can do same thing.

I’m interested in how they do auto Pressure Advanced

without computer vision -

-

@penguinya

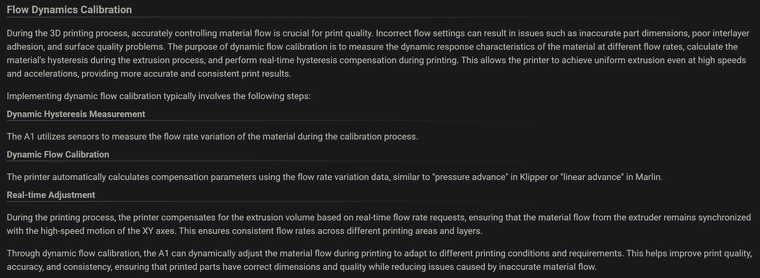

a1 mini use pcb coil -

@penguinya what inductance are they measuring to determine pressure for pressure advance calibration?

-

@T3P3Tony

It's probably the filament that bends in a certain direction when pressure increases. They could design the filament path in such way, that it bends in a predictable way.

But that would highly depend on the stiffness of the filament and would need a calibration with temp-compensation -

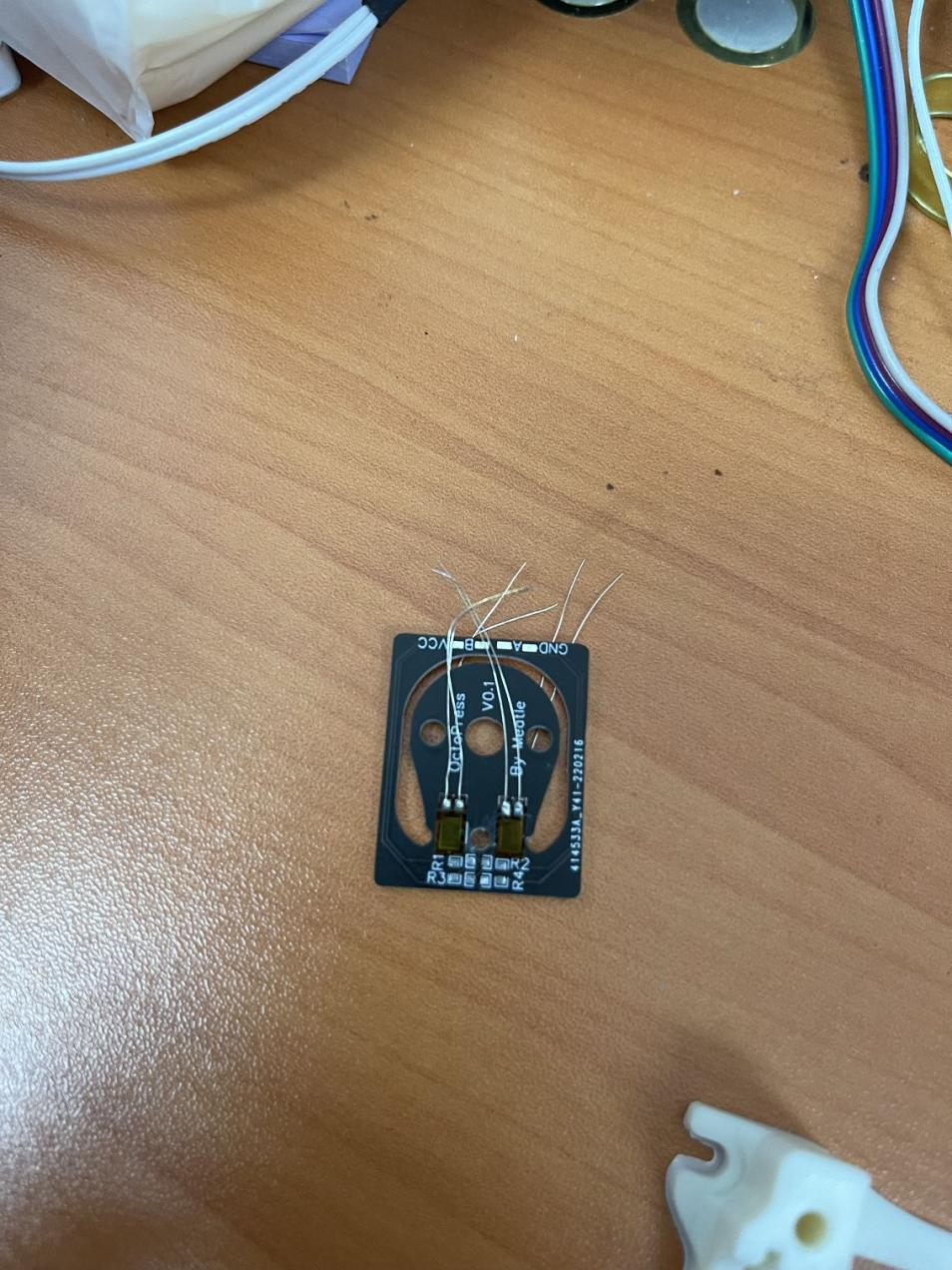

@T3P3Tony Same as the string gauge, it looks like the hotend can move up and down

-

RP2040 have two core and fust enough ADC to measure string gauge.

I think it can save pressure data to calculate pressure curve

-

@penguinya

-

-

15 minutes, 16 seconds to 17 seconds, the hotend moves up and down.

https://www.youtube.com/watch?v=EZ3BtQ7k9Ak -

I love the idea!

I guess you could write a gcode snippet in daemon.g which continously reads straingauge values and adjusts pressure advance values?

Duet can read sensors via SPI, maybe a dedicated "strain gauge sensor" option would be possible? One could also put together a small PCB that amplifies the strain gauge reading into a voltage that can just be read by a linear analog sensor on the Duet? -

@nikscha macro not fast enough, and this is my idea https://forum.duet3d.com/post/324006

-

Automated PA testing is still an early idea. I hope to implement z probe and collect enough PA pressure data for research.

-

@penguinya I think it would be fast enough. Just put a "while true" into daemon.g and then a G4 P50 in the body to execute your script every 50ms. (Edit: this wouldn't actually run that frequent, more like 3-6 times a second)

I don't think pressure advance needs to be adjusted that often, right?

-

@nikscha Bambu Lab tests pa every print, and 50ms really slow, HX711 can reach 80HZ, Prusa using HX717 320HZ, higher the sampling frequency, the more beneficial for auto PA testing.

-

find a better chip for load cell.

CS1237 http://www.asidesigner.com/Files/PartFiles/15315/222/cs1237_datasheet.pdf

spi bus 1.28kHz ADC and PGA -

@nikscha Here is a post about sampling speed

https://forum.duet3d.com/post/251488 -

-

@penguinya The introduction of bambulab confirmed my guess.

-

Correct me if Im wrong, but I feel like this sensor could also be used for filament runout/jam detection as well. Like if the force expected by feeding the filament is not produced, it could indicate that there is some filament error.