Diagnosing poor print quality (wits end please!)

-

What print problems exactly are you seeing?

Can you also post the results of sending M122 and M98 P"config.g" in the gcode console?

What are you using for your start gcode?

These guides should be your first stop when having issues with a delta.

https://docs.duet3d.com/en/User_manual/Machine_configuration/Configuration_linear_delta

https://docs.duet3d.com/en/User_manual/Tuning/Delta_calibration

-

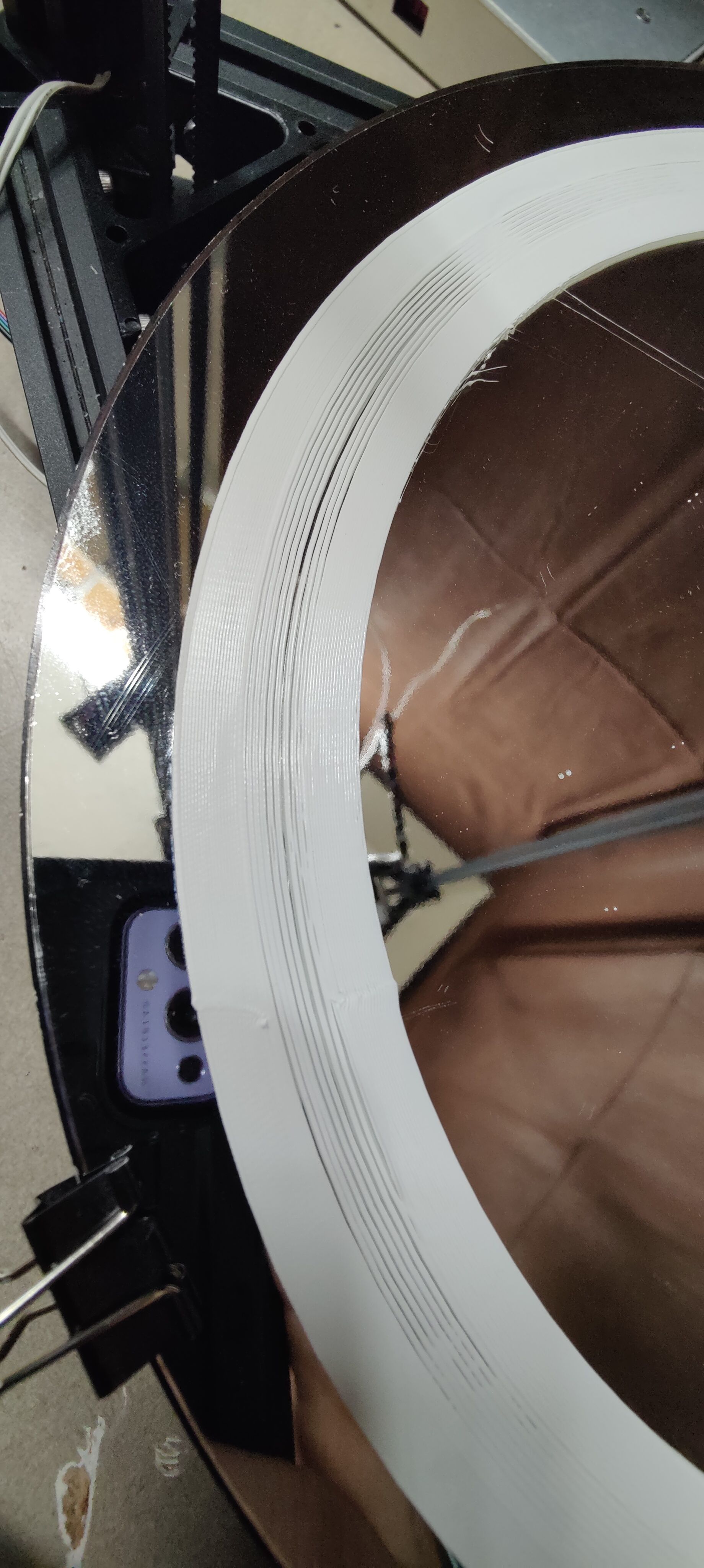

Very poor bed adhesion due to, I am assuming, an improper mesh compensation. I have already done both of those twice over with the same results. The config I have now was what was printing well then I started making slight changes after the effector rewiring and now I can't seem to get it to stabilize. I will post more tomorrow when I can.

-

This post is deleted! -

@Herve_Smith Thanks for the insight. I am still looking into this but I have tightened every bolt, leveled every tower, and made sure every rod is mounted correctly that I know of. The only result changes I get are adjusting the tower guide wheel tensions but it never truly improves and the heightmap only changes when I change tensions but probes the same every time. How do I interpret the height map when I see, seemingly random with no pattern, spikes and dives in the heightmap?

-

@sneakyferret said in Diagnosing poor print quality (wits end please!):

The only result changes I get are adjusting the tower guide wheel tensions but it never truly improves and the heightmap only changes when I change tensions but probes the same every time. How do I interpret the height map when I see, seemingly random with no pattern, spikes and dives in the heightmap?

Is a wheel slipping or is a bearing sticking?

-

@Phaedrux Not from anything I can tell. I have ordered new belts that I will be installing hopefully Friday and I hopefully will be finding someone local to 3d print better carriage adapters so I can properly adjust belt tension because the stock ones included with my K280 are, ahem, garbage.

-

@sneakyferret said in Diagnosing poor print quality (wits end please!):

then I decided to rewire the smart effector and then after that I started having a lot of issues.

Maybe some wires are too short and pull on the effector while probing? Never underestimate the effect of a stiff wiring loom.

There is another simple test for the Mag rods: while the effector is at 0,0, roll the rods of each side between your fingers.

Do you feel a difference in resistance?

The tighter rod is a tiny bit longer. Switch rods until all pairs roll with the same resistance.

I also had worn out Mag rods and the steel ball rubbed on the magnet. -

@o_lampe That's brilliant. Thank you! Doing that now.

-

@sneakyferret One thing I have recently noticed: When doing a mesh calibration run, some coords the smart effector makes a very audible but normal 'tap' sound as it contacts. Other spots, its either very muffled (like its tapping cloth) or not audible at all. THE PLOT THICKENS.

-

@o_lampe Interesting development. I did what you said and identified a single rod that was more loose than all the others. I swapped them around, no difference. Turns out, its that rod position that is more loose no matter which rod is in that place.