Diagnosing poor print quality (wits end please!)

-

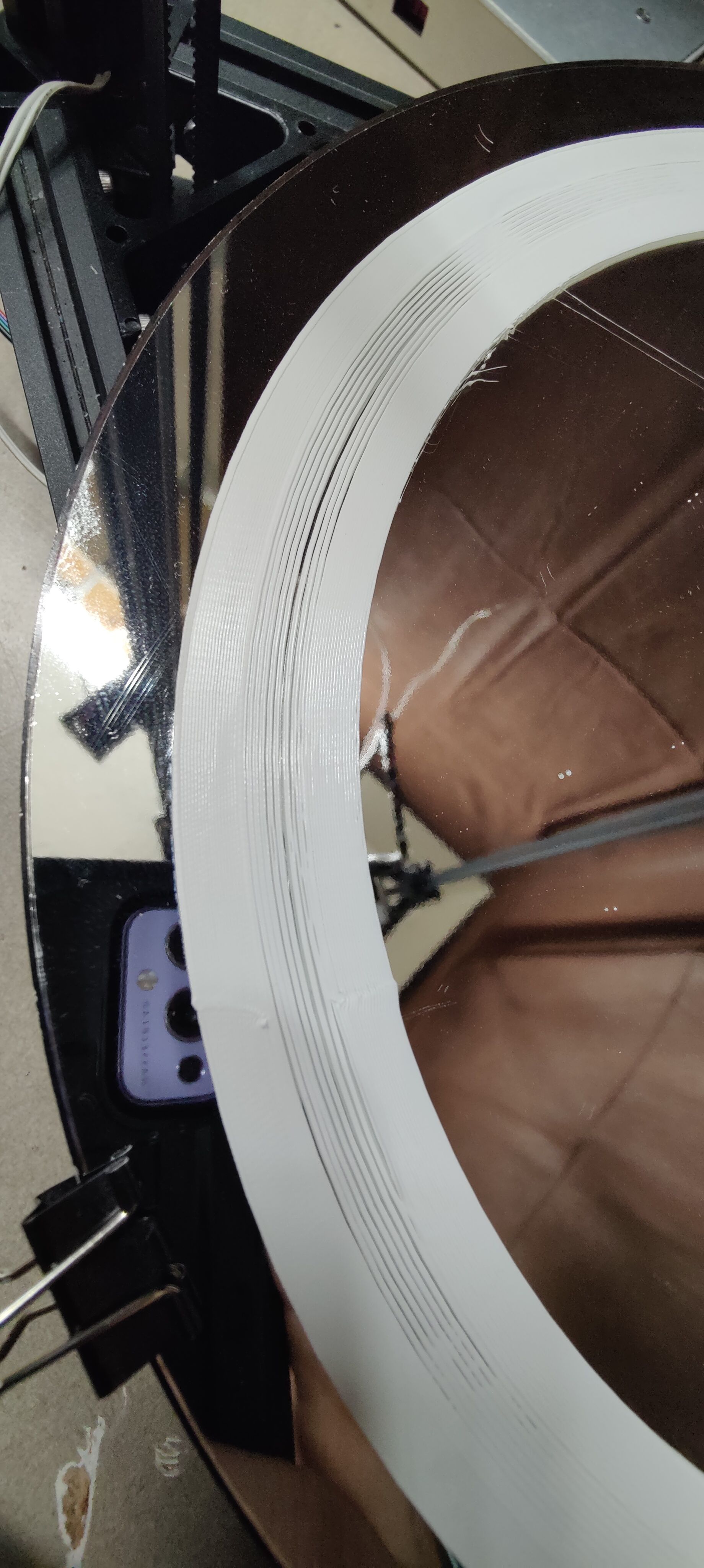

Hello everyone. It's a tale as old as time: my printer is doing very poorly. I had it printing very well for the longest time but then I decided to rewire the smart effector and then after that I started having a lot of issues. I have double checked all the connections and made sure they were tight and well crimped so maybe I changed something in settings.

I am running a HE3D k280 delta printer with a duet 2 wifi board and smart effector with magball end rods. Here are my codes:

bed.g

; called to perform automatic delta calibration via G32 ; ; generated by RepRapFirmware Configuration Tool v2.1.8 on Sun Feb 02 2020 21:40:17 GMT-0500 (Eastern Standard Time) ; 13 points, 7 factors, probing radius: 138, probe offset (0, 0) M561 ; clear any bed transform G28 G30 P0 X0.00 Y130.00 Z-99999 H0 G30 P1 X83.56 Y99.59 Z-99999 H0 G30 P2 X128.03 Y22.57 Z-99999 H0 G30 P3 X112.58 Y-65.00 Z-99999 H0 G30 P4 X44.46 Y-122.16 Z-99999 H0 G30 P5 X-44.46 Y-122.16 Z-99999 H0 G30 P6 X-112.58 Y-65.00 Z-99999 H0 G30 P7 X-128.03 Y22.57 Z-99999 H0 G30 P8 X-83.56 Y99.59 Z-99999 H0 G30 P9 X0.00 Y65.00 Z-99999 H0 G30 P10 X56.29 Y-32.50 Z-99999 H0 G30 P11 X-56.29 Y-32.50 Z-99999 H0 G30 P12 X0 Y0 Z-99999 S6 ; G29 S1 M500 ; I believe this saves the mesh to EPROMConfig.g

; Configuration file for Duet WiFi (firmware version 2.03) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v2.0.3 on Thu Sep 05 2019 15:50:44 GMT-0400 (Eastern Daylight Time) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Tall Printer" ; set printer name M665 R180 L160 B130 H580 ; Set delta radius, diagonal rod length, printable radius and homed height M666 X0 Y0 Z0 ; put your endstop adjustments here, or let auto calibration find them M575 P1 S1 B57600 ; Network M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0 S0 ; physical drive 0 goes backwards M569 P1 S0 ; physical drive 1 goes backwards M569 P2 S0 ; physical drive 2 goes backwards M569 P3 S1 ; physical drive 3 goes forwards M584 X0 Y1 Z2 E3 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X80.00 Y80.00 Z80.00 E410.00 ; set steps per mm M566 X1200.00 Y1200.00 Z1200.00 E1200.00 ; set maximum instantaneous speed changes (mm/min) M203 X18000.00 Y18000.00 Z18000.00 E1200.00 ; set maximum speeds (mm/min) M201 X1000.00 Y1000.00 Z1000.00 E1000.00 ; set accelerations (mm/s^2) M906 X1100 Y1100 Z1100 E900 I50 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 Z0 S1 ; set minimum Z ; Endstops M574 X2 S1 P"!xstop" ; X active low and disabled endstop M574 Y2 S1 P"!ystop" ; Y active low and disabled endstop M574 Z2 S1 P"!zstop" ; Z active low and disabled endstop ; Z-Probe M558 P8 C"zprobe.in+zprobe.mod" R0.4 H10 F1200 T6000 ; set Z probe type to effector and the dive height + speeds G31 P100 X0 Y0 Z-.22 ; set Z probe trigger value, offset and trigger height M557 R85 S20 ; define mesh grid ; Temperature Sensors M308 S0 P"bed_temp" Y"thermistor" T100000 B3950 ; define bed temperature sensor M308 S1 P"e0_temp" Y"thermistor" T100000 B4725 C7.06e-8 ; define E0 temperature sensor ; Heaters M950 H0 C"bed_heat" T0 ; heater 0 uses the bedheat pin, sensor 0 M950 H1 C"e0_heat" T1 ; heater 1 uses the e0_heat pin and sensor 1 M307 H0 B0 S1.00 M140 H0 ; Fans M950 F2 C"fan2" Q500 ; Hot end fan M106 P2 T45 H1 M950 F0 C"fan0" Q500 ; Part Cooling fan M106 C"PartFan" P0 S0 H-1 B1 M307 H0 ; report the process parameters for heater 0 M307 H0 R2.186 K0.17:0.11 D5.67 S1.00 V24.0 ; set the process parameters for heater 0 ; Tools M563 P0 H1 F0 D0 T0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings are not defined M501 ; recall last used parametershomedelta.g

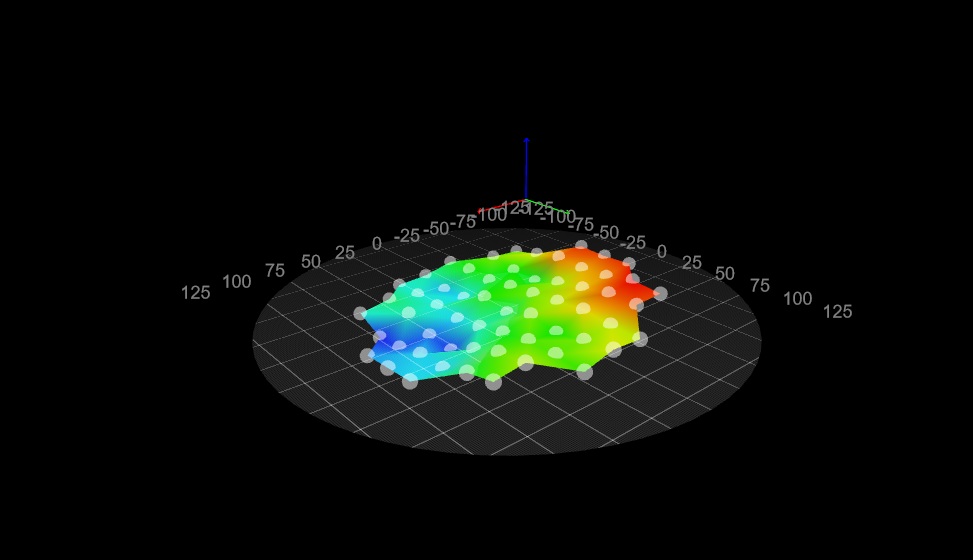

; homedelta.g ; called to home all towers on a delta printer ; ; generated by RepRapFirmware Configuration Tool v2.1.8 on Sun Feb 02 2020 21:40:18 GMT-0500 (Eastern Standard Time) G91 ; relative positioning G1 H1 X605 Y605 Z605 F1800 ; move all towers to the high end stopping at the endstops (first pass) G1 H2 X-5 Y-5 Z-5 F1800 ; go down a few mm G1 H1 X10 Y10 Z10 F1800 ; move all towers up once more (second pass) G1 Z-10 F6000 ; move down a few mm so that the nozzle can be centred G90 ; absolute positioning G1 X0 Y0 F6000 ; move X+Y to the centreI, for the life of me, cannot get my height map to look correctly after squaring the towers, making sure the end stops are all at the same height, etc. My bed is non adjustable (previous owner decision that I plan to fix).

PLEASE for the love of God anyone see anything obvious? I love you guys and appreciate you looking out for us newbs. -

Also, I have made sure everything is at 90 degree angles, my top supports are parallel to the bed, and my end stops are all at the same height.

-

What print problems exactly are you seeing?

Can you also post the results of sending M122 and M98 P"config.g" in the gcode console?

What are you using for your start gcode?

These guides should be your first stop when having issues with a delta.

https://docs.duet3d.com/en/User_manual/Machine_configuration/Configuration_linear_delta

https://docs.duet3d.com/en/User_manual/Tuning/Delta_calibration

-

Very poor bed adhesion due to, I am assuming, an improper mesh compensation. I have already done both of those twice over with the same results. The config I have now was what was printing well then I started making slight changes after the effector rewiring and now I can't seem to get it to stabilize. I will post more tomorrow when I can.

-

This post is deleted! -

@Herve_Smith Thanks for the insight. I am still looking into this but I have tightened every bolt, leveled every tower, and made sure every rod is mounted correctly that I know of. The only result changes I get are adjusting the tower guide wheel tensions but it never truly improves and the heightmap only changes when I change tensions but probes the same every time. How do I interpret the height map when I see, seemingly random with no pattern, spikes and dives in the heightmap?

-

@sneakyferret said in Diagnosing poor print quality (wits end please!):

The only result changes I get are adjusting the tower guide wheel tensions but it never truly improves and the heightmap only changes when I change tensions but probes the same every time. How do I interpret the height map when I see, seemingly random with no pattern, spikes and dives in the heightmap?

Is a wheel slipping or is a bearing sticking?

-

@Phaedrux Not from anything I can tell. I have ordered new belts that I will be installing hopefully Friday and I hopefully will be finding someone local to 3d print better carriage adapters so I can properly adjust belt tension because the stock ones included with my K280 are, ahem, garbage.

-

@sneakyferret said in Diagnosing poor print quality (wits end please!):

then I decided to rewire the smart effector and then after that I started having a lot of issues.

Maybe some wires are too short and pull on the effector while probing? Never underestimate the effect of a stiff wiring loom.

There is another simple test for the Mag rods: while the effector is at 0,0, roll the rods of each side between your fingers.

Do you feel a difference in resistance?

The tighter rod is a tiny bit longer. Switch rods until all pairs roll with the same resistance.

I also had worn out Mag rods and the steel ball rubbed on the magnet. -

@o_lampe That's brilliant. Thank you! Doing that now.

-

@sneakyferret One thing I have recently noticed: When doing a mesh calibration run, some coords the smart effector makes a very audible but normal 'tap' sound as it contacts. Other spots, its either very muffled (like its tapping cloth) or not audible at all. THE PLOT THICKENS.

-

@o_lampe Interesting development. I did what you said and identified a single rod that was more loose than all the others. I swapped them around, no difference. Turns out, its that rod position that is more loose no matter which rod is in that place.