Driver 0 warning: over temperature warning"

-

Hello,

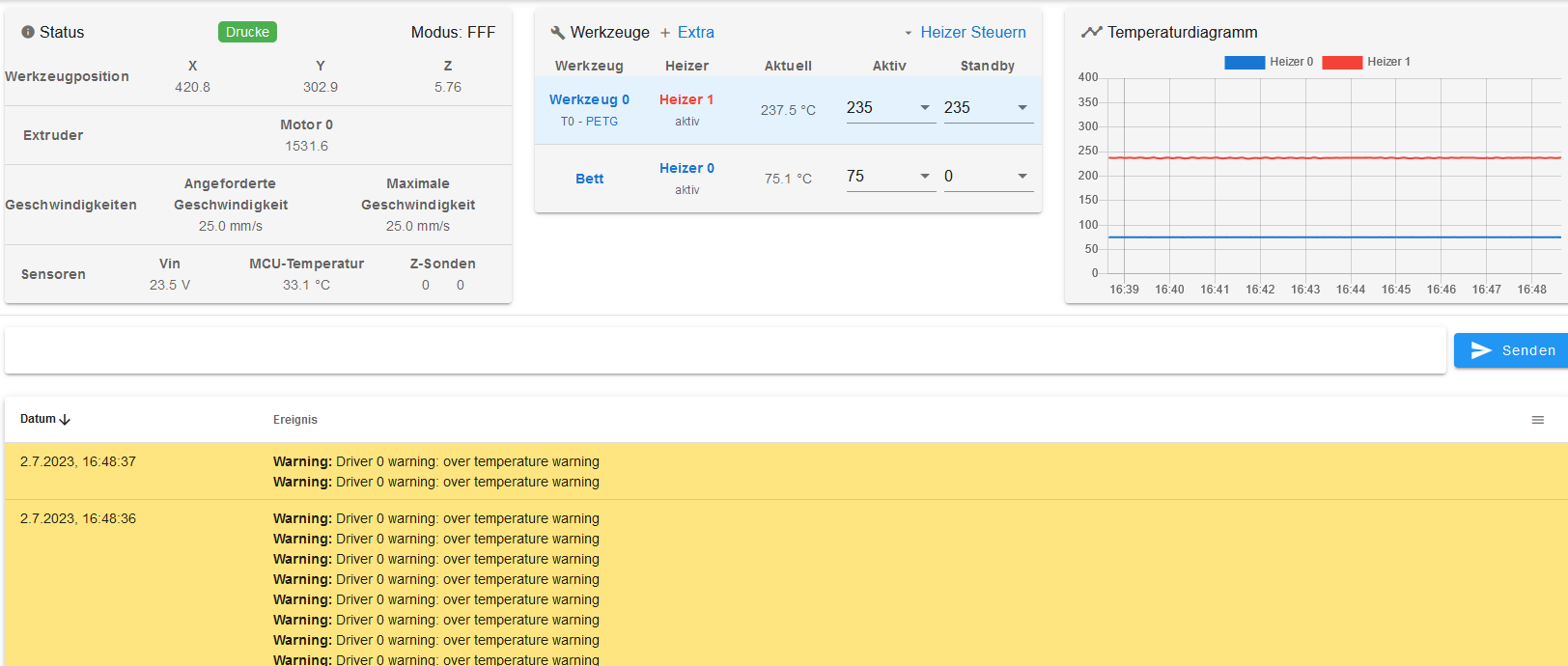

although temperatures etc. look quite good when printing, I get the message: "Warning: Driver 0 warning: over temperature warning"

what could be the cause and what can i do about it?

; generated by RepRapFirmware Configuration Tool v3.3.16 on Sun May 28 2023 15:23:44 GMT+0200 (Mitteleuropäische Sommerzeit); General preferences

M575 P1 S1 B57600 ; enable support for PanelDue

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"DUKA1300" ; set printer name; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S1 ; enable FTP

M586 P2 S1 ; enable Telnet; Drives

M569 P0 S1 ; physical drive 0 goes forwards

M569 P1 S1 ; physical drive 1 goes forwards

M569 P2 S1 ; physical drive 2 goes forwards

M569 P3 S1 ; physical drive 3 goes forwards

M584 X0 Y1 Z2 E3 ; set drive mapping

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

;M92 X80.00 Y80.00 Z400.00 E420.00 ; set steps per mm

M92 X80.09 Y80.00 Z640 E322.58 ; set steps per mm

;M92 X80.00 Y80.00 Z640.00 E322.58 ; set steps per mm

;M566 X900.00 Y900.00 Z60.00 E120.00 ; set maximum instantaneous speed changes (mm/min)

M566 X900.00 Y900.00 Z100.00 E120.00 ; set maximum instantaneous speed changes (mm/min)

;M203 X6000.00 Y6000.00 Z180.00 E1200.00 ; set maximum speeds (mm/min)

M203 X6000.00 Y6000.00 Z300.00 E1200.00 ; set maximum speeds (mm/min)

;M201 X500.00 Y500.00 Z20.00 E250.00 ; set accelerations (mm/s^2)

M201 X500.00 Y500.00 Z40.00 E250.00 ; set accelerations (mm/s^2)

M906 X2500 Y2100 Z1800 E1600 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X750 Y650 Z1255 S0 ; set axis maxima; Endstops

M574 X1 S1 P"xstop" ; configure switch-type (e.g. microswitch) endstop for low end on X via pin xstop

M574 Y1 S1 P"ystop" ; configure switch-type (e.g. microswitch) endstop for low end on Y via pin ystop

;M574 Z2 S1 P"zstop" ; configure switch-type (e.g. microswitch) endstop for high end on Z via pin zstop

;M574 Z2 S2 ; configure Z-probe endstop for high end on Z; Z-Probe

;M558 P1 C"!zprobe.in" H5 F120 T6000 ; set Z probe type to unmodulated and the dive height + speeds

;G31 P1000 X-1 Y-61 Z2 ; set Z probe trigger value, offset and trigger height

;M557 X0:740 Y-27:611 S30 ; define mesh grid; Z-Probe two of them

M558 K0 P1 C"!zprobe.in" H5 F120 T6000 ; set Z probe type to unmodulated and the dive height + speeds

M558 K1 P8 A2 S0.2 C"!zstop" H5 F80 T3000

G31 P1000 K0 X-1 Y-61 Z0.5; set Z probe trigger value, offset and trigger height

G31 P1000 K1 X0 Y0 Z12.664 ; Second Z-offset

M557 X0:740 Y-27:585 S35 ; define mesh grid; Heaters

; Bed

M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

;M307 H0 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit

M307 H2 R0.283 K0.463:0.000 D7.17 E1.35 S1.00 B0 ; enable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S280 ; set temperature limit for heater 0 to 120C;Hotend

M308 S1 P"e0temp" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin e0temp

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

;M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M307 H1 R1.797 K0.742:0.000 D7.57 E1.35 S1.00 B0 V23.8 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S400 ; set temperature limit for heater 1 to 400C; Fans

M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off

;M950 F1 C"fan1" Q700 ; create fan 1 on pin fan1 and set its frequency

;M106 P1 S1 H1 T60 ; set fan 1 value. Thermostatic control is turned on

M950 F2 C"fan2" Q350 ; create fan 2 on pin fan2 and set its frequency

M106 P2 S1 H1 T60 ; set fan 2 value. Thermostatic control is turned on; Tools

;M563 P1 S"Druckkopf 1" H1 F0 ; define tool 1

M563 P0 D0 H1 F0 ; define tool 1

G10 P0 X0 Y0 Z0 ; set tool 1 axis offsets

G10 P0 R0 S0 ; set initial tool 1 active and standby temperatures to 0C; Filamentsensor

M591 D0 P1 C"e1-stop" S1 ;R40:120 E3.0 S1 Filament Sensor;Auto Z-Offset

;M42 P3 C"e0-stop" S1

;M574 Z1 S2

;M558 C"e0-stop" S0

; Custom settings are not defined

M501 -

@axiom That usually means the driver is detecting it's over 100 degrees. Look at adding some cooling to blow across the underside of the board

-

@jay_s_uk Thanks, but if you look at the screenshot you can see that the MCU temperature is at 33.1 degrees...is there any other source?

-

@axiom The MCU is different to the driver.

-

@axiom Driver chips don't report their internal temperatures - just a digital high if it's too high. What I did on one of my machines was to fix a bead thermistor to some of the drivers with a small dab of epoxy and use these to control fans blowing cold air onto the back of the board.

-

@axiom said in Driver 0 warning: over temperature warning":

M584 X0 Y1 Z2 E3 ; set drive mapping

...

M906 X2500 Y2100 Z1800 E1600 I30 ; set motor currents (mA) and motor idle factor in per centYou are running driver 0 at 2.5A which is the maximum supported on your Duet 2. When running drivers at or near maximum current, fan cooling is required. Preferably, use a fan at the edge of the board, next to the VIN connector, to blow air across both sides of the board along the line of stepper drivers. See https://docs.duet3d.com/Duet3D_hardware/Duet_2_family/Duet_2_WiFi_Ethernet_Hardware_Overview#cooling.

-

I just ran into the same thing... 2 of my drivers were complaining about over heating...yikes!

This is on a Duet 3 Mini 5 with 6 active stepper motors.So, I'm off to print a backing plate with taller stand-offs and a mount for a blower fan. My stepper motors are all fairly cool, but the amperage draw makes sense. My FLIR ONE camera came in handy yet, again! ; )

- Cheers!