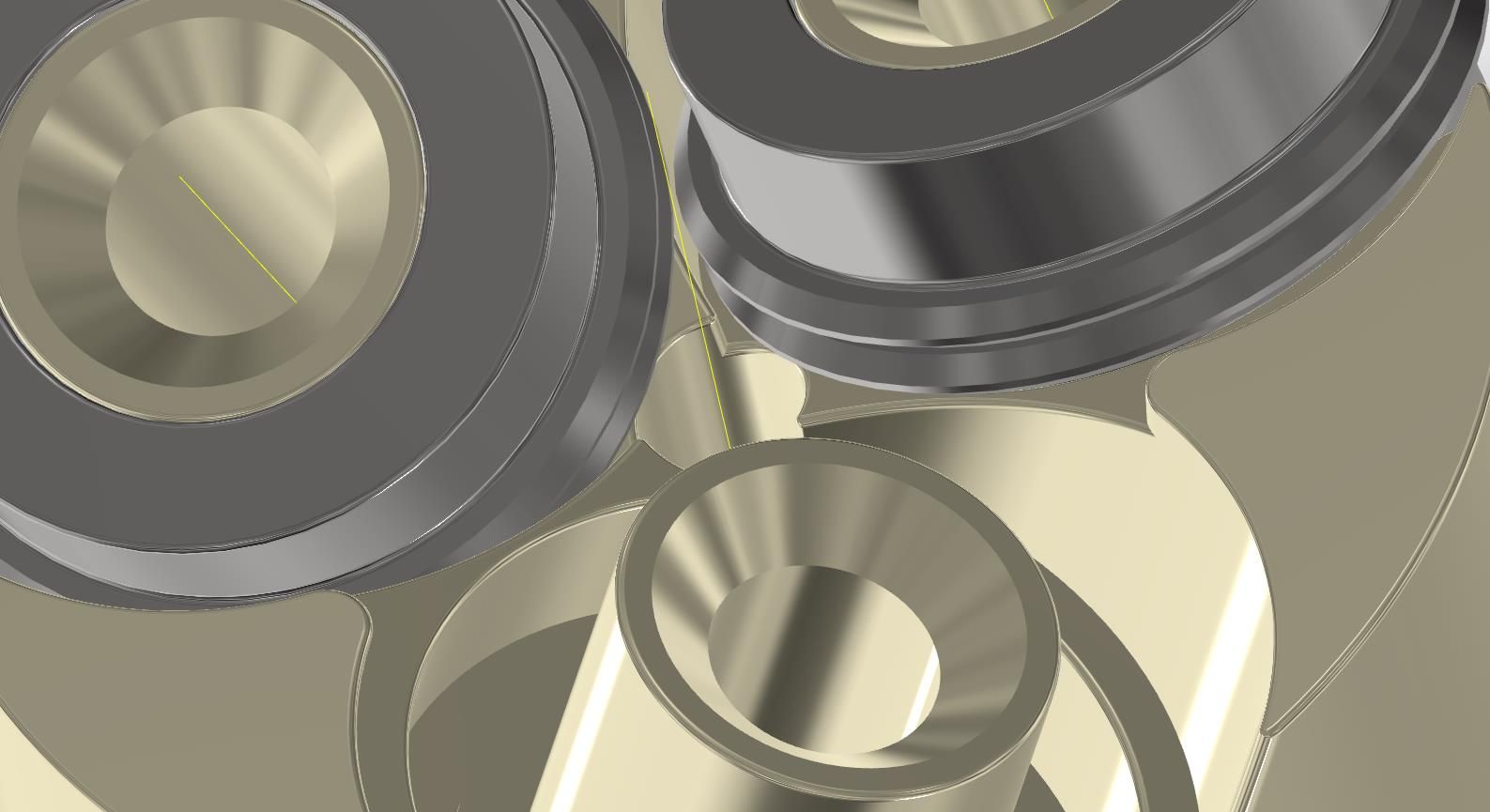

Hollow shaft extruder

-

@tombrazier It was during COVID but don't remember when it was. I don't think it was that early I'm gonna guess late 2020 early 2021. It was originally for the anycubic predator which came out 2019 I think. It's basically a thread less ballscrew.

-

@tombrazier I made an extruder that used counter rotating nuts to move the filament. The problem with that was the two counter rotating nuts (or whatever cuts threads into the filament) will never grip the filament at exactly the same strength, so one will dominate and the filament will try to twist with it. I found it mainly to be a problem with retracting the filament. If the filament rotates a little when you do a retraction, you won't get the retraction you are expecting. I think you need a bend in the filament path at the input of the extruder to minimize that problem.

See https://drmrehorst.blogspot.com/2021/08/an-old-project-snakebite-extruder.html

-

@mrehorstdmd that looks alot like I was designing originally. Except it had double 3 screw assemblies inside of the bevel gears. I ran with it in cad for a bit but it ended up so big and more than twice as heavy. I was just looking for a vertical extruder with a small foot print to fit on the smart effector. I had double timing belt design I started also that had a fairly small foot print but I felt like the torque required to run it would require too big a motor and defeat the purpose. I'm really excited about the work these guys are doing on this VDE100. The going to a low count of "threads" by using the flange bearings allows a high lead angle that would not be possible on a normal threaded screw without scrubbing. Plus with the high lead the rpms come down into the realm of a regular stepper. The math on the screw design I was working on originally was like 6 revolutions per mm or something like that. Which is possible with bldc motor and I originally was trying to do the flex shaft remote direct drive thing I had first seen at Mrrf2019 which would like the high rpm low torque thing. I was worried though if the filament would carry enough heat away or if it would gum up the screw.

-

Does anyone still print with 3mm filament? Why? Why not? Seems to me like the VDE100 would be a little easier to make if the parts were a little bigger. It would potentially take longer to melt I guess but it seems as if hotend tech has outstripped extruder and cooling techniques at this point.

-

Please, can some one explain (for me, suffering acute dyscalculia)

how many rotations of the shaft is needed for tom´s above linked FreeCad Model?

I´ m not an engineer

My Bearings MF-85-2RS have diameter of 9,14mm.

How do "pitch circle diameter" of the earing axes has to be set.How deep should the sharpened flange cut in the Filament.

The Axes are in 20 ° .

15 ° would be very engThank you,

Gruß, zero K -

@o_lampe I've been thinking about what questions I have for the BLDC mounter VDE. In the end I reckon it all comes down to one question: how fast can it push filament through a hotend before the motor stalls assuming you run the motor at low enough current that it does not become too hot and (for me at least) with a 12V supply voltage.

-

@mrehorstdmd I have seen a number of posts and videos of the snakebite extruder in recent days. It looks like it was a great contribution to the rapidly growing pool of FDM designs and ideas in the last decade. Nice work IMHO.

The key difference, I think, between VDE-like designs and the screw designs of 10 years ago is that the screws freely roll over the filament in these designs, thereby almost eliminating torque on the filament. In principle, one might even be able to drive the screw at the right speed that torque on the filament is entirely removed but I suspect that would be overengineering.

-

@breed A 3mm hollow shaft stepper motor would be harder to source but many gimbal BLDCs would be be great. 3mm would also mean you could use larger flanged bearings and get more overlap with the filament for each bearing. For me the main reason not to try 3mm is everything else in my system assumes 1.75mm.

-

@zero-K Short answer: you get about 1.55mm of filament feed per rotation at 20° and 1.75mm filament. But depending on the specifics of your actual system, it will vary slightly. I find it's best just to measure it experimentally.

Long answer: will have to wait, I don't have the time to answer it right now unfortunately.

-

@tombrazier I only tested the sFOC setup for a few short prints. But I can tell, it doesn't get hot because of the close loop. There is no excess energy, like with static current steppers.

For 12V you should look for a motor with ~300kV. Mine has 140kV and runs on 24V. I had luck with it, because it also has low rotor cogging.

The rpm-limit is also determined by the sensor and the MCU clock. I can tell more, when the optical-disk sensor arrives. -

@tombrazier said in Hollow shaft extruder:

you get about 1.55mm of filament feed per rotation

That's about 2065 steps/mm for a regular stepper setup. Three times more than the 710 step/mm on the Sherpa mini and other extruders with the round NEMA14.

Maybe the stepper can be much smaller then? I have a super small NEMA08 stepper with hollow shaft. -

@tombrazier

I got two of this,

14HS14-1254H

from Stepper-Online, about 16 €, plus delivery and Tax.

It has 8 mm Shaft and 4 mm hole,

Hopefully the Power wil be OK.Gruß zero K

-

-

@tombrazier that 1.55 mm of lead is interesting. Should be more like 1.91mm. I wonder why? Are you finding that your thread pitch on the filament is staying consistent with varied speeds and loads?

-

@o_lampe That little nema8 is neat. What's that weigh?

-

@o_lampe "Haltemoment: 16 mNm" is not enough for high speed extrusion. You need to be able to drive against a back pressure which results in about 50N on the filament. I have specced a 50mNm motor from LDO.

-

@breed Theoretically it should be tan(20) * 1.75mm * pi which is about 2mm. The pitch does reduce with load but I have a design where that effect is not too bad. Nonetheless this is part of the reason. Another part is probably that the pitch diameter is less than 1.75mm because of the bite into the filament. And another is that the bearings are not perfectly tight so the cant angle is slightly reduced. That's as far as I have got with my reasoning on the subject.

-

@o_lampe said in Hollow shaft extruder:

That's about 2065 steps/mm for a regular stepper setup.

Rq3 who first pioneered the VDE-100 says he once completed a 5nm layer height print. Apparently it took a very long time but came out very smooth.

-

@zero-K As @o_lampe says, this is a much heavier stepper than needed. However it should do the job even with a 12V PSU. It will need something like 500mA to accelerate really well, by which I mean 1000mm/s^2 E feed acceleration.

I have a script that generates speed vs acceleration graphs for steppers. I'll try to post it at some point along with an explanation.

-

@breed 3mm filament takes longer to melt all the way through, and everyone wants to push print speeds faster and faster. 3mm filament is much stiffer than 1.75 so you need bigger, heavier motors to move it for most extruder designs.

I suspect we'll end up with 1mm dia filament in the not too distant future to allow the hot end to keep up with the rest of the mechanism.