Hi

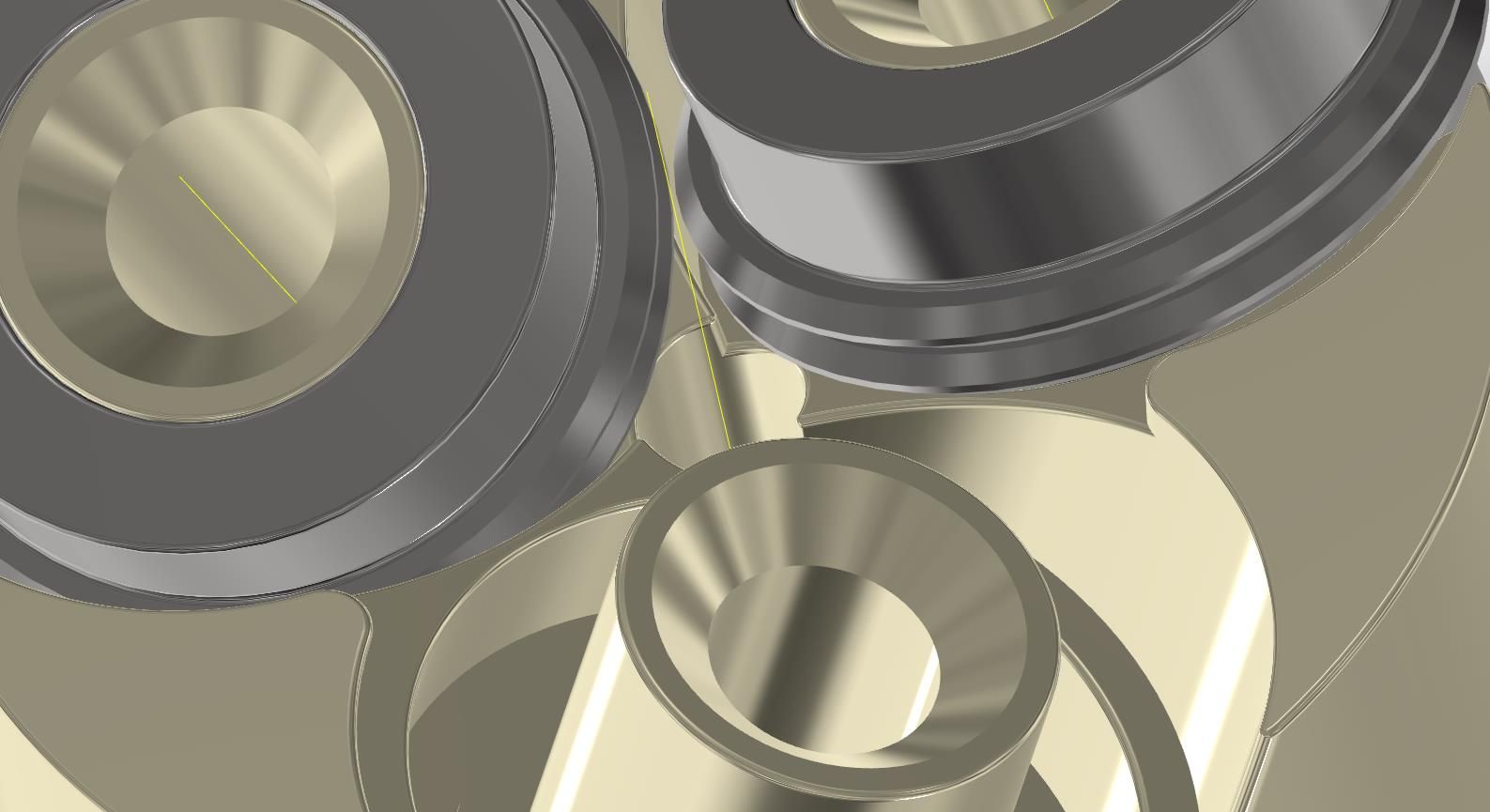

OK, compared with yours, it will be something like a monster hollow shaft extruder.

But the first step is done, some parts didn´t arrive yet, may be til next weekend.

Gruß, zero K

Hi

OK, compared with yours, it will be something like a monster hollow shaft extruder.

But the first step is done, some parts didn´t arrive yet, may be til next weekend.

Gruß, zero K

Hi, its my first printer building myself - my first was a kit to assemble

My actuel dual print head is about 1100 g.

If this new one is not as optimized in wight as yours, it´s not the end of the world for me.

Its a very nice project, I like the way filament ist moved and i can watch someting turning around and moving

It´s quite possible, if it works a little bit more as (with my skills) expected I will try to get 99%.

Thank you

zero K

@meatfest said in Erased Firmware now I cannot connect via USB:

@dc42 OK, good plan. I ordered a short (0.5M) USB cable with gold plated contacts. High transfer speed in spec... Hope it works, thanks for your kind help. I will post the results here.

Hi Meatfest

Not only a short wire ...

Have a look on diameter of the signaling wires.

Have a Look for AWG 24 or less - not AWG 26 or AWG 28 (American Wire Gauge - bigger number - less diameter)

Time ago I got an 1 m USB cabel with less than 0.1 mm (AWG 28 ?) - cheap but most useless.

Have a nice evening

May be PEEK countersunk head screws are an option for this.

Gruß, zero K

Hi

OK, compared with yours, it will be something like a monster hollow shaft extruder.

But the first step is done, some parts didn´t arrive yet, may be til next weekend.

Gruß, zero K

Thank You, now ist der Groschen gefallen - can´t explain in in english.

I think, I understand it and can find the starting for the setups.

Greetings

zero k

A way to increase the filament heating surface sems to be Bondtech/MicroSwiss CTH-Nozzle und e3D high speed Revo.

No one of my friend is printing 3 mm Filament - this time has gone.

Hi, its my first printer building myself - my first was a kit to assemble

My actuel dual print head is about 1100 g.

If this new one is not as optimized in wight as yours, it´s not the end of the world for me.

Its a very nice project, I like the way filament ist moved and i can watch someting turning around and moving

It´s quite possible, if it works a little bit more as (with my skills) expected I will try to get 99%.

Thank you

zero K

@tombrazier

I got two of this,

14HS14-1254H

from Stepper-Online, about 16 €, plus delivery and Tax.

It has 8 mm Shaft and 4 mm hole,

Hopefully the Power wil be OK.

Gruß zero K

Please, can some one explain (for me, suffering acute dyscalculia)

how many rotations of the shaft is needed for tom´s above linked FreeCad Model?

I´ m not an engineer

My Bearings MF-85-2RS have diameter of 9,14mm.

How do "pitch circle diameter" of the earing axes has to be set.

How deep should the sharpened flange cut in the Filament.

The Axes are in 20 ° .

15 ° would be very eng

Thank you,

Gruß, zero K

@o_lampe Thank you for your answer.

Phrozens Resin is cheap compared with them of our Formlabs printers.

I think, a foreign Resin can not be allowed in our Printers and post processing - not only because of bio compatibility - may be too - adjusting the parameters of Laser. For private use, some risk.

I will try it first with "Surgical Guide" - Only for testing I have sterilized parts out of this Resin 10 times 20 min at 134°C. I like this Resin very much. If a first try lasts 100 h printing, it would be a nice result because its quite brittle.

3D-printing is not my job - its like play ground and hobby.

I would let you know.

Gruß, zero K

@o_lampe Wich Resin did you use?

The Temperatur near the Extruders is about 60 °C, sometimes higher.

Thats why I ´m a little bit worried about fixturing the skrews in the plastic.

May be I can try it with Formlabs dental materials.

This is a very nice Project - sorry about my english

Gruß zero K