Play with Input Shaping

-

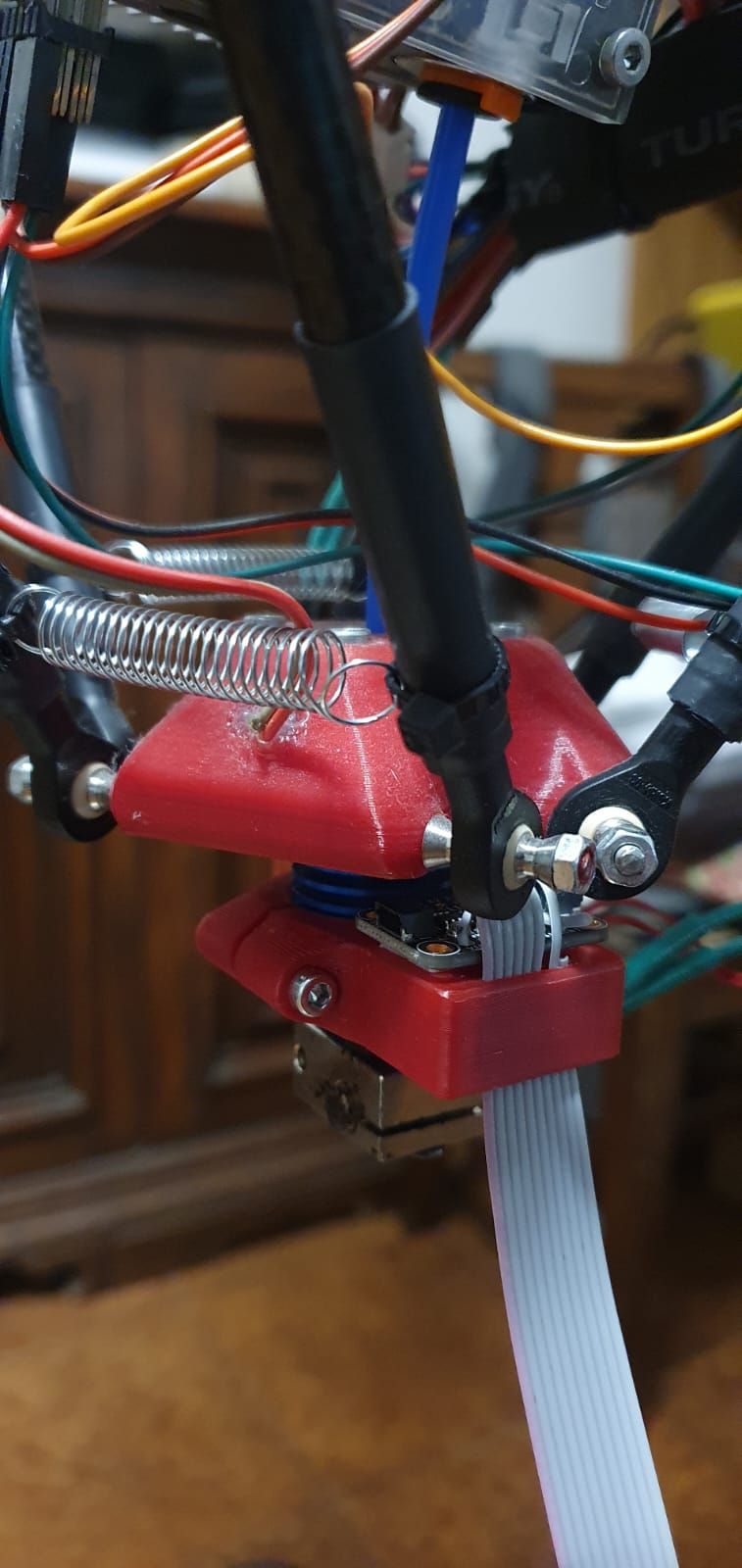

Hello I had install the accelerometer on my home made delta (R400 H500) printer:

Now I'm trying to understand how it works, This is without filter:

and this adding the filter that some testing I think have the better results:

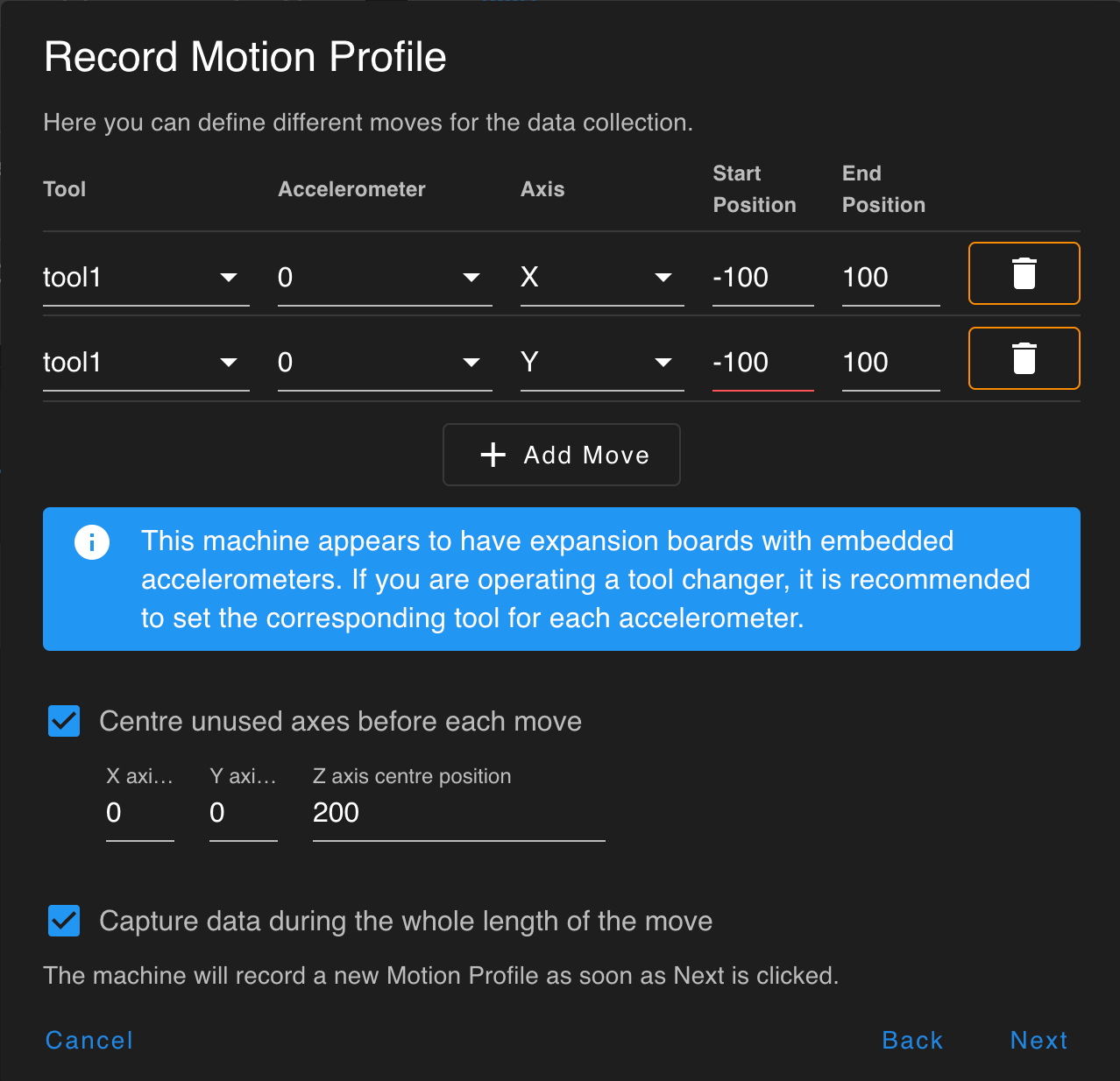

There is the movements:

My questions are:

- Why the does the filter acts so little?

- What is damping factor?

- How can I do to make better results?

Thansk!

-

@samu_87 what M566 settings do you have for X and Y in config.g? High values make input shaping less effective. The default value of 600 works well on most machines.

-

@dc42 i have X600 and Y600

I add my config.g maybe it can be useful

; executed by the firmware on start-up ; ; General preferences G90 ; Send absolute coordinates... M83 ; ...but relative extruder moves M665 R280.8 L515 B200 H574.800 X0.0 Y0.0 Z0.0 ; Set delta radius, diagonal rod length, printable radius and homed height M666 X0.0 Y0.0 Z0.0 A0 B0 ; Put your endstop adjustments here, or let auto calibration find them ; Network M550 P"Delta" ; Set machine name M551 P"NoPassword" ; Set password M552 S1 ; Enable network M586 P0 S1 ; Enable HTTP M586 P1 S0 ; Disable FTP M586 P2 S0 ; Disable Telnet ; Drives M569 P0 S1 ; Drive 0 goes forwards M569 P1 S1 ; Drive 1 goes forwards M569 P2 S1 ; Drive 2 goes forwards M569 P3 S1 ; Drive 3 goes forwards M584 X0 Y1 Z2 E3 M350 X16 Y16 Z16 E16 I1 ; Configure microstepping without interpolation M92 X200.00 Y200.00 Z200.00 E432 ; Set steps per mm M566 X600 Y600 Z2800 E6000.00 P1 ; Set maximum instantaneous speed changes (mm/min) M203 X18000.00 Y18000.00 Z18000.00 E900.00 ; Set maximum speeds (mm/min) M201 X3000.00 Y3000.00 Z3000.00 E5000.00 ; Set accelerations (mm/s^2) M906 X1600.00 Y1600.00 Z1600.00 E1000.00 I30 ; Set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 Z0 S1 ; Set minimum Z ; Endstops M574 X2 P"xstop" S1 M574 Y2 P"ystop" S1 M574 Z2 P"zstop" S1 ; Z-Probe M558 P1 C"!zprobe.in" R0.4 F240 H5 T4800 G31 X0 Y0 Z0.15 P500 M557 R160 S40 ; Define mesh grid ; Heaters M308 S0 P"e1temp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin e1temp M950 H0 C"e1heat" T0 ; create bed heater output on e1heat and map it to sensor 0 M307 H0 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M308 S1 P"spi.cs1" Y"rtd-max31865" ; configure sensor 1 as PT100 on pin spi.cs1 M950 H1 C"bedheat" T1 ; create nozzle heater output on bedheat and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S280 ; set temperature limit for heater 1 to 280C ; Fans M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off ;CPU Fan M308 S3 Y"mcu-temp" A"MCU" ; configure sensor 3 as on-chip MCU temperature sensor M950 F2 C"fan2" Q100 ; create fan 2 on pin fan2 and set its frequency M106 P2 H3 T20:70 ; set fan 2 value ; Tools M563 P0 S"tool1" H1 F0 D0 ; define tool 1 G10 P0 X0 Y0 Z0 ; set tool 1 axis offsets G10 P0 R0 S0 ; set initial tool 1 active and standby temperatures to 0C M204 P1800 M579 X1.004 Y1.01 M591 D0 P1 C"e0stop" S1 ;Sensore di Fine_Filo M572 D0 S0.05 M955 P0 C"spi.cs4+spi.cs3" I20 ;Accelerometer ;T0 ;Enable Extruder M501 ; Automatic saving after power loss is not enabled ; Custom settings are not configured