Yes, I put R = 0,15 and I think is better, because my bed I think it has a low warm up rate.

Can have any sense?

Thansk!

Yes, I put R = 0,15 and I think is better, because my bed I think it has a low warm up rate.

Can have any sense?

Thansk!

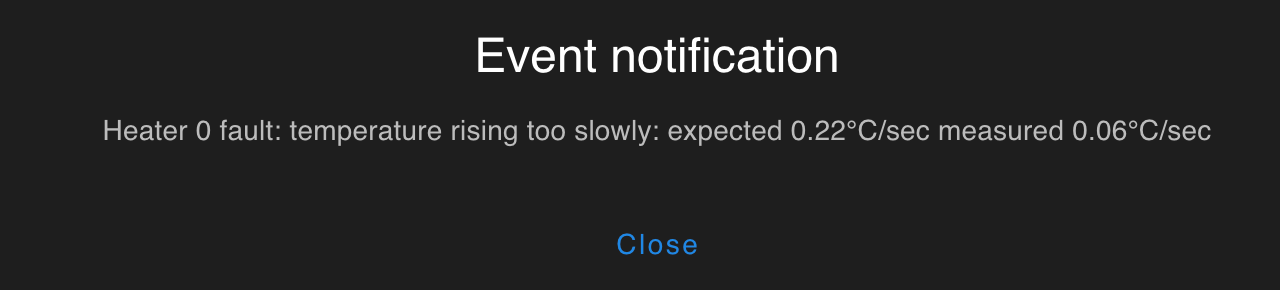

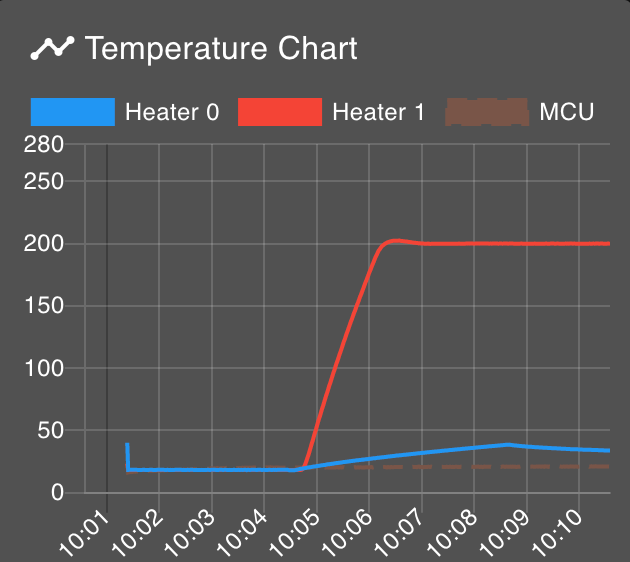

@Phaedrux Here we are, in this cold morning give me this error:

Which parameter is better to tweak?

Thanks!

@Phaedrux

Yes I will try! What change R and D?

Thanks!

M308 S0

Sensor 0 type Thermistor using pin e1temp, reading 82.2, last error: sensor not ready, T:100000.0 B:4138.0 C:0.00e+0 R:4700.0 L:0 H:0

Here the error... in a cold day the temperature rise slowly and the error appear.

Many thanks!

@Phaedrux As soon as the error occurs again I will give you the necessary data.

It usually comes back early in the morning when it's cold, I have a lot of mass to heat up so it takes a little longer than usual and gives an error. For now, thank you very much!

@Phaedrux

Hello, Thanks a lot because all work well now.

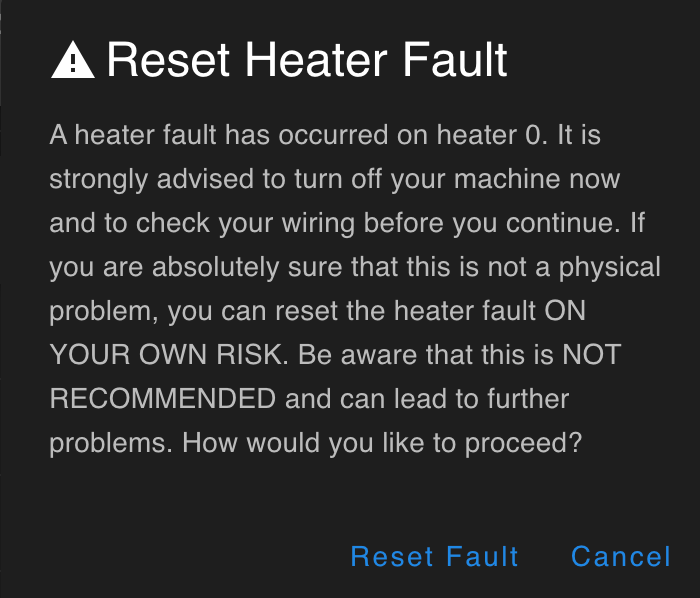

The heated bed sometimes give me this:

I'm sure that the wiring etc is all okay, I have a big heated bed with low power so it spend a lot of time to heating up.

how I can modify that to give them more time?

M307 H0 R0.186 K0.226:0.000 D1.09 E1.35 S1.00 B1

Thanks!!!

@dc42 i have X600 and Y600

I add my config.g maybe it can be useful

; executed by the firmware on start-up

;

; General preferences

G90 ; Send absolute coordinates...

M83 ; ...but relative extruder moves

M665 R280.8 L515 B200 H574.800 X0.0 Y0.0 Z0.0 ; Set delta radius, diagonal rod length, printable radius and homed height

M666 X0.0 Y0.0 Z0.0 A0 B0 ; Put your endstop adjustments here, or let auto calibration find them

; Network

M550 P"Delta" ; Set machine name

M551 P"NoPassword" ; Set password

M552 S1 ; Enable network

M586 P0 S1 ; Enable HTTP

M586 P1 S0 ; Disable FTP

M586 P2 S0 ; Disable Telnet

; Drives

M569 P0 S1 ; Drive 0 goes forwards

M569 P1 S1 ; Drive 1 goes forwards

M569 P2 S1 ; Drive 2 goes forwards

M569 P3 S1 ; Drive 3 goes forwards

M584 X0 Y1 Z2 E3

M350 X16 Y16 Z16 E16 I1 ; Configure microstepping without interpolation

M92 X200.00 Y200.00 Z200.00 E432 ; Set steps per mm

M566 X600 Y600 Z2800 E6000.00 P1 ; Set maximum instantaneous speed changes (mm/min)

M203 X18000.00 Y18000.00 Z18000.00 E900.00 ; Set maximum speeds (mm/min)

M201 X3000.00 Y3000.00 Z3000.00 E5000.00 ; Set accelerations (mm/s^2)

M906 X1600.00 Y1600.00 Z1600.00 E1000.00 I30 ; Set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout

; Axis Limits

M208 Z0 S1 ; Set minimum Z

; Endstops

M574 X2 P"xstop" S1

M574 Y2 P"ystop" S1

M574 Z2 P"zstop" S1

; Z-Probe

M558 P1 C"!zprobe.in" R0.4 F240 H5 T4800

G31 X0 Y0 Z0.15 P500

M557 R160 S40 ; Define mesh grid

; Heaters

M308 S0 P"e1temp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin e1temp

M950 H0 C"e1heat" T0 ; create bed heater output on e1heat and map it to sensor 0

M307 H0 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M308 S1 P"spi.cs1" Y"rtd-max31865" ; configure sensor 1 as PT100 on pin spi.cs1

M950 H1 C"bedheat" T1 ; create nozzle heater output on bedheat and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S280 ; set temperature limit for heater 1 to 280C

; Fans

M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off

;CPU Fan

M308 S3 Y"mcu-temp" A"MCU" ; configure sensor 3 as on-chip MCU temperature sensor

M950 F2 C"fan2" Q100 ; create fan 2 on pin fan2 and set its frequency

M106 P2 H3 T20:70 ; set fan 2 value

; Tools

M563 P0 S"tool1" H1 F0 D0 ; define tool 1

G10 P0 X0 Y0 Z0 ; set tool 1 axis offsets

G10 P0 R0 S0 ; set initial tool 1 active and standby temperatures to 0C

M204 P1800

M579 X1.004 Y1.01

M591 D0 P1 C"e0stop" S1 ;Sensore di Fine_Filo

M572 D0 S0.05

M955 P0 C"spi.cs4+spi.cs3" I20 ;Accelerometer

;T0 ;Enable Extruder

M501

; Automatic saving after power loss is not enabled

; Custom settings are not configured

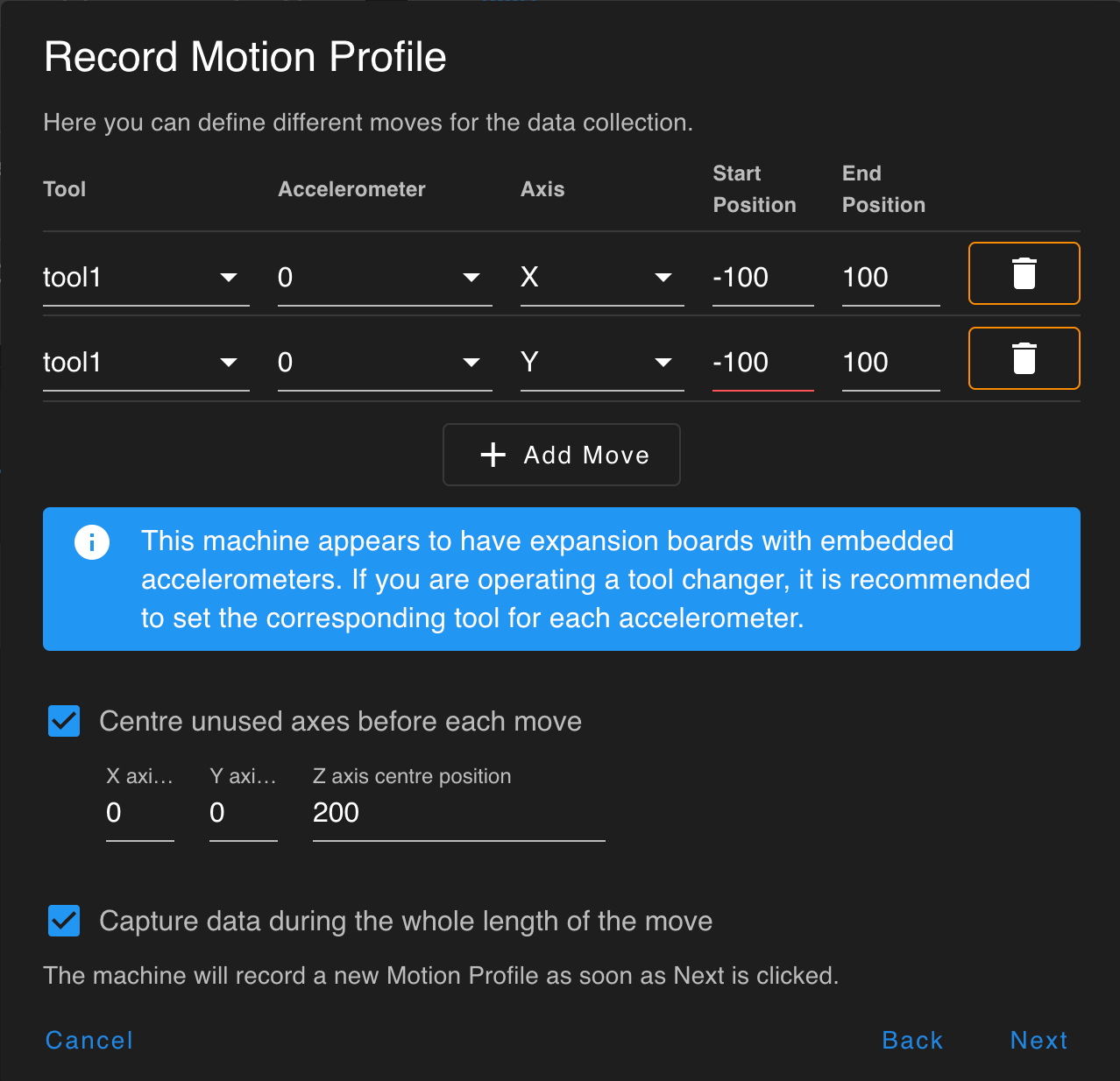

Hello I had install the accelerometer on my home made delta (R400 H500) printer:

Now I'm trying to understand how it works, This is without filter:

and this adding the filter that some testing I think have the better results:

There is the movements:

My questions are:

Thansk!

@Phaedrux said in Duet Wifi - Accel:

Active just means that it is the currently selected tool. If you don't want it active at startup you must remember to activate it manually by clicking on the tool or sending T0 in the slicer start gcode.

Now I have understand what do you mean, I'm used to the old graphics and every time I enable the Tool manually. I delete T0 in config.g and I'm okay

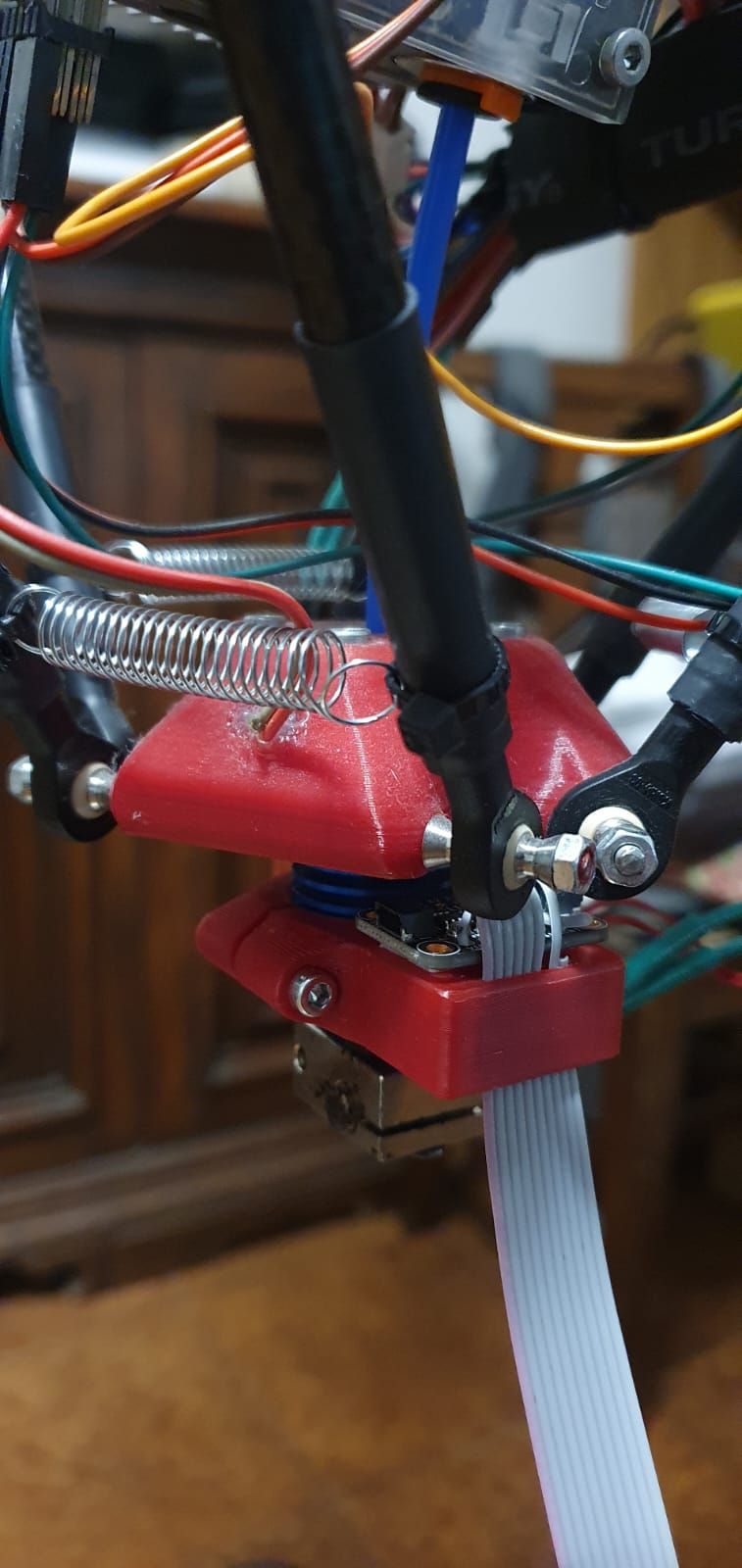

@Phaedrux Yes I have the hotend wired in that way:

Heated Bed:

This because i have a powerful heat cartiage on the extruder and a mosfet to control heated bed so i invert this because the bed mosfet on duet wifi handle more current.

Maybe is useless but I hope that don't make a problema,I've been using this for about 4 years.

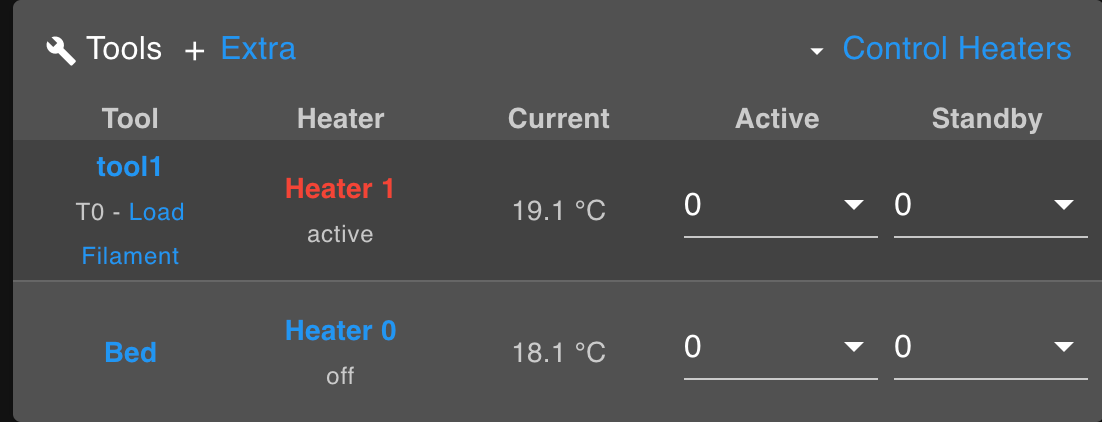

When i power on the printer I find the heater 1 active and not off like the bed, see this image: