Why the slowdown?

-

Hi all,

I've been tuning my machine for a while and I can't seem to figure out why my machine is a lot slower since moving from Marlin to RRF.

Usually, on Marlin, when slicing my prints with PrusaSlicer and running it, would result in around correct slicing estimates. It normally only took one or two minutes longer than the slicer had ancitipated.

Since I moved to RRF with around the same or faster settings, my prints take around more than twice the time estimate and this is absolutely driving me nuts. Especially since I also moved to a 0.6mm nozzle (previously had a 0.4mm nozzle equipped).

These are the values currently in my config.g:

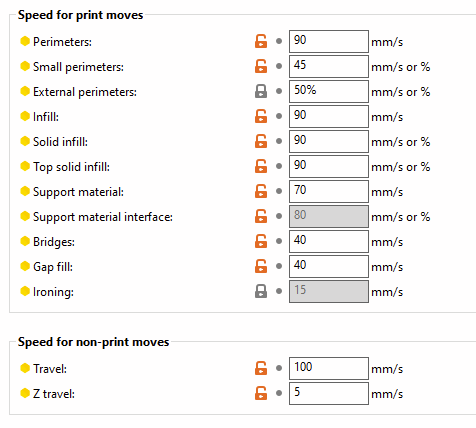

M566 X350.00 Y350.00 Z50.00 E300.00 ; set maximum instantaneous speed changes (mm/min) M203 X18000.00 Y18000.00 Z300.00 E6500.00 ; set maximum speeds (mm/min) M201 X4000.00 Y4000.00 Z20.00 E4000.00 ; set accelerations (mm/s^2)And these are my PS values for printing PETG:

I'm using an Orbiter v2 extruder with a bowden setup and I use both PA and IS:

IS is using ZVD at 40Hz

PA is set to 1.35I've been trying to tune it a bit in the past two weeks but I have not been able to find the reason why the estimates are so off. I also have put my RRF speed settings into PS in order to help it make a better time estimate.

En example would be that a simple benchy would take 38 minutes to print according to PS. In reality after 57 minutes, the print is only at 58% finished. This would mean that the print time is around 100 minutes total. This is an increase of roughly 260% of the estimates print time. And to be honest, isn't 100 minutes for a benchy with 0.6 nozzle and an Orbiter v2 extruder a little slow?

The sole reason why I went through all the trouble of converting to IS, PA, 0.6mm nozzle and a better extruder was to get better print times. But instead the print times have increased 'super drastically'. Maybe I'm missing something in my tuning that is causing this slowdown and I can't seem to find it on my own so I am asking the community to think along with me as I don't know what else to do.

The machine was tuned with this guide and is otherwise working well: https://ellis3dp.com/Print-Tuning-Guide/

Thanks in advance for your perspectives.

-

What were your speeds in Merlin. Was your conversion (I believe Merlin uses mm/min and RRF uses mm/s) done correctly?

Your non print moves seem relatively slow. Your other moves might be a bit slow too depending on the capabilities of your printer.

There was another thread recently about the tie estimate being off in PS. -

@Acid please check that PrusaSlicer has not inserted M201 or M203 commands into the GCode file that you are trying to print. It tends to do that if you are not careful. Also look out for M204 commands, which limit the printing and travel accelerations - which is OK if that is what you wanted for that print.

-

@dc42 said in Why the slowdown?:

@Acid please check that PrusaSlicer has not inserted M201 or M203 commands into the GCode file that you are trying to print. It tends to do that if you are not careful. Also look out for M204 commands, which limit the printing and travel accelerations - which is OK if that is what you wanted for that print.

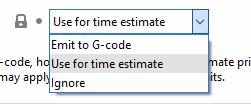

Hi, thanks for the hint. This should not be possible since this option was chosen:

But I checked it just to be sure (you never know). Luckily that wasn't the issue.

I did some more testing, like changing the PA settings (by setting it to 0) during a print and that made the print speed up a lot so I think the issue is with PA.

From what I gather the only way to speed up the printer is to raise the extruder jerk, but this becomes problematic because the extruder starts making a lot of noise when I raise the jerk and accel settings for the extruder. I don't want to damage the extruder.

My previous extruder could go a lot higher with jerk and accel and still wouldn't produce nearly as much noise but it was also less powerful so that's why I got an Orbiter. I've seen so many people on youtube with RRF that run their printer very fast with an Orbiter v2. Can it be that they are running without pressure advance and that I have unrealistic expectations?

I just don't understand how E-jerk in combination lowers the print speed by so much. It's logical that it has influence on the print speed because it takes control of the extrusion. Are there other things I can try?

-

This is pretty common with the orbiter and other small drive and remote extruders.

You may need to experiment with your jerk and acceleration setting for all axis to find a happy medium.

For instance, your jerk on XYE is very low, but your acceleration is very high.

Give these settings a try.

M566 X700 Y700 Z60 E900 ; set maximum instantaneous speed changes (mm/min) M203 X18000 Y18000 Z600 E6000 ; set maximum speeds (mm/min) M201 X2000 Y2000 Z200 E2000 ; set accelerations (mm/s^2) -

@Acid when pressure advance is used, sudden changes in extrusion speed are needed in order to apply it. In practice this means that extruder acceleration during printing moves (not retraction or reprime moves) can't exceed the extruder jerk in mm/sec

timesdivided by the pressure advance factor. -

@Phaedrux said in Why the slowdown?:

This is pretty common with the orbiter and other small drive and remote extruders.

You may need to experiment with your jerk and acceleration setting for all axis to find a happy medium.

For instance, your jerk on XYE is very low, but your acceleration is very high.

Give these settings a try.

M566 X700 Y700 Z60 E900 ; set maximum instantaneous speed changes (mm/min) M203 X18000 Y18000 Z600 E6000 ; set maximum speeds (mm/min) M201 X2000 Y2000 Z200 E2000 ; set accelerations (mm/s^2)Thanks for the suggestion, I'm giving it a try now. Seems like it's going a lot faster already. The only thing is that the extruder is giving off a distinct whine at these speeds but only due to PA. On longer moves the extruder is inaudible.

I guess lowering extruder jerk a little might help with the whine?

The official website for Orbiter v2 recommends a max of 600mm/min for E-jerk. Can I change this value during a print, or actually is it possible to change any of the M566, M203 and M201 values during a print via DWC?

Edit:

I just read that stealthchop is recommended to be turned off for the Orbiter v2, yet I see a lot of people run it with stealthchop. Does this have to do with the crossover speed where it transitions from stealthchop to spreadcycle?Edit #2:

Okay, I tried it and it turns out I can even tune these settings on the fly which makes tuning a lot easier. I didn't know this before!The settings I'm running with now are:

M566 X700 Y700 Z60 E700 ; set maximum instantaneous speed changes (mm/min) M203 X18000 Y18000 Z600 E6000 ; set maximum speeds (mm/min) M201 X2000 Y2000 Z200 E4500 ; set accelerations (mm/s^2)These speeds are still somewhat noisy, but I don't want to lower them any further as that will increase print times. Trying a benchy now to see how long it takes. I do see that with the higher print speeds my part cooling fan isn't fast enough. Also, sometimes the extruder sounds like it's doing a very fast retraction, like a zipper that you pull really fast. It's almost as if it skips steps, but I can't quite make out if that it true or not. Is there any smart way to check if it skips steps? I'm assuming since I now run the motor in stealthchop it doesn't register a stall because the signal is too noisy for the TMC2209 to distinguish the move noise from a stall back-EMF or however it does that (I'm not yet that familiar with the techniques it uses to detect stalls).

It's now also time to probably start tuning from the beginning again since I changed a bunch of parameters and I also still need to find a good way to tune retraction.

One other thing I'd like to start tuning is extrusion width. Since the Orbiter v2 should be able to handle some pressure and I'm currently extruding at 0.6mm like a good boy, I'm thinking to take this a bit higher. My goal was faster prints, so increasing the extrusion width will help with that as well. I understand that 0.72mm (120%) is a good amount for the 0.6mm nozzle.

Would my current speed/jerk settings need to be tuned further when changing the extrusion width, or will this be less of an issue?

-

@Acid said in Why the slowdown?:

The official website for Orbiter v2 recommends a max of 600mm/min for E-jerk. Can I change this value during a print, or actually is it possible to change any of the M566, M203 and M201 values during a print via DWC?

Yes you can change all of them (and the pressure advance) on-the-fly in DWC. In most cases the change won't take effect for a few seconds, until moves already in the movement buffer have been completed.

-

Give this a look for tuning your extrusion system to match speed. The key thing to know is the volumetric flow rate of your hotend. If you can maximize that with a combination of extrusion width, layer height, and print speed, the rest will follow easier. You may not need to move as fast if you're extruding more.

https://forum.duet3d.com/topic/14250/tuning-jerk-accel-speed-settings?_=1671825688469