not able to get a good first layer using 3PL and bed mesh

-

now with a drop off and pick up

M98 P"0:/macros/3 corner deveation"

G32 bed probe heights: 0.003 -0.003 0.006 0.003 -0.003 0.003 0.000 0.000 0.003 0.003 0.000 0.000, mean 0.001, deviation from mean 0.003

ProbeDropOff

12/20/2022, 9:10:04 AM Leadscrew adjustments made: -0.030 0.007 -0.006, points used 3, (mean, deviation) before (-0.009, 0.012) after (0.000, 0.000)

3PL finished -

im not sure if this is a valid test or not can someone let me know

also i have M561 to clear / disable bed mesh leveling.i added these lines to my gcode at the begining and end of the print file

M569 P0.4

M569 P0.5

M569 P0.6

to check to see if the stepper motors were moving during the printFinished printing file 0:/gcodes/300x300_0.25mm_PLA__3m.gcode, print time was 0h 6m

12/21/2022, 11:50:54 AM Drive 4 runs forwards, active low enable, timing fast, mode spreadCycle, ccr 0x00053, toff 3, tblank 0, hstart/hend/hdec 5/0/0, pos 680

Drive 5 runs in reverse, active low enable, timing fast, mode spreadCycle, ccr 0x00053, toff 3, tblank 0, hstart/hend/hdec 5/0/0, pos 264

Drive 6 runs forwards, active low enable, timing fast, mode spreadCycle, ccr 0x00053, toff 3, tblank 0, hstart/hend/hdec 5/0/0, pos 712

12/21/2022, 11:48:16 AM Drive 4 runs forwards, active low enable, timing fast, mode spreadCycle, ccr 0x00053, toff 3, tblank 0, hstart/hend/hdec 5/0/0, pos 104

Drive 5 runs in reverse, active low enable, timing fast, mode spreadCycle, ccr 0x00053, toff 3, tblank 0, hstart/hend/hdec 5/0/0, pos 828

Drive 6 runs forwards, active low enable, timing fast, mode spreadCycle, ccr 0x00053, toff 3, tblank 0, hstart/hend/hdec 5/0/0, pos 158the POS numbers are different , does this mean the stepper motors have been moving even though it was only printing a single layer?

-

@moth4017

I don't know what the POS number means, but it's much too short for a position variable or step counter. -

Reprinting parts for new x axis going to put them on the surface table before reinstalling to check for twist .

-

could not find a repeatable way to check the twist that i was happy with , so printed some more Y carrier parts as my others had cracks in them, reassembled did the 300 x 300 print test again, the same issue nozzle on the left-hand side of bed was further away then the right. look like about the same amount , not measured it yet

-

OK i think i have solved the issue :-

Its to do with 3PL , i have always measured 3 points in the 3PL , but have discovered today if you do a 4 points it levels much better .I now do this

;3PL

echo "3PL"

M561 ; cancels any bed-plane fitting as the result of probing

M564 S0 ; allow movement outside boundaries

G30 P0 X27 Y27 Z-99999 ; probe FR

G30 P1 X283 Y27 Z-99999 ; probe FL

G30 P2 X283 Y283 Z-99999 ; probe RL

G30 P3 X27 Y283 Z-99999 S3 ; probe RR S3 = 3 z axis

G90 ; Set to Absolute Positioning

echo "3PL finished" ;send Diagnose to console

-

@moth4017 thanks for updating us.

-

undefined dc42 marked this topic as a question

undefined dc42 marked this topic as a question

-

undefined dc42 has marked this topic as solved

undefined dc42 has marked this topic as solved

-

Whats best practice regarding this btw @dc42 ? To tram with 3 or 4 probe points on a bed with three points of pivot/adjustment?

-

@Exerqtor i used to probe 3 points but since going to 4 i can not get a good first layer doing a 300mm x 300mm print, my bed is supported on 3 points i would recommend it my bed is 320 x320 .

-

@Exerqtor said in not able to get a good first layer using 3PL and bed mesh:

Whats best practice regarding this btw @dc42 ? To tram with 3 or 4 probe points on a bed with three points of pivot/adjustment?

You can use between N points (where N = number of Z motors) and 32. RRF will minimise the RMS error over all the points. If the bed is flat and the gantry doesn't sag then 3 or 4 points should work well. If it isn't then a higher number may be better.

You may find it beneficial to run bed tramming more than once, if your mechanics don't match the model assumed by RRF. You can do this using a loop in the bed.g file.

-

Good point DC42 makes about the loop, i spent time on this yesterday now only probes the amount of times required to get within your desired tolerance.

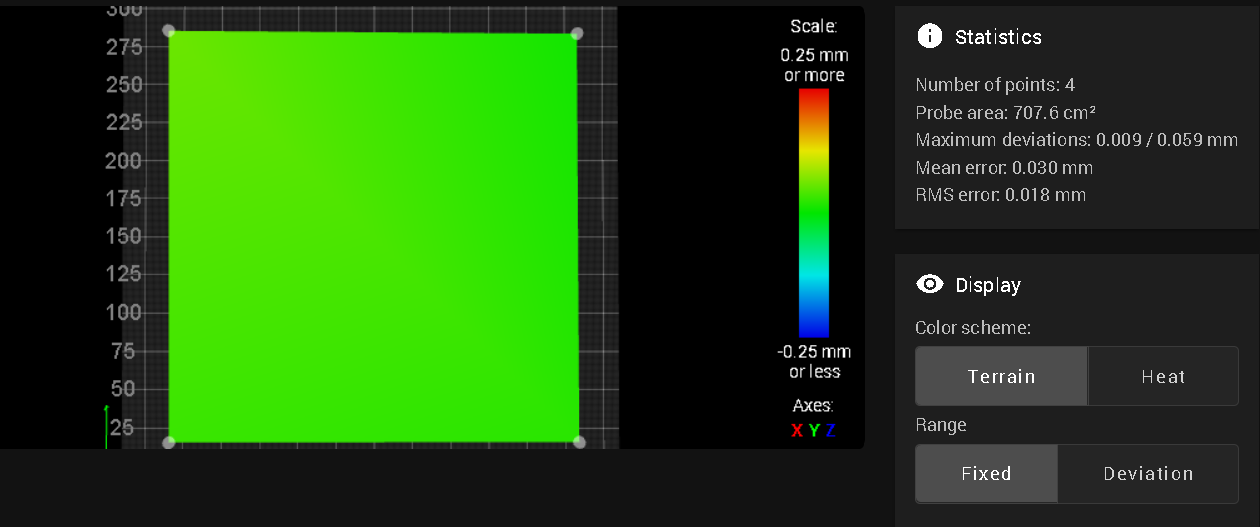

;G32 Auto calibration routine for large bed M561 ; clear any bed transform ; If the printer hasn't been homed, home it if !move.axes[0].homed || !move.axes[1].homed || !move.axes[2].homed G28 M98 P"/macros/ProbePickUp" ; probe pick up ; Probe the bed and do auto calibration G1 X14 Y44 Z25 F20000 ; go to just above the first probe point while true if iterations = 5 abort "Too many auto calibration attempts" G30 P0 X17 Y17 Z-99999 ; probe starboard bow if result != 0 continue G30 P1 X293 Y17 Z-99999 ; probe port bow if result != 0 continue G30 P2 X293 Y283 Z-99999 ; probe port stern if result != 0 continue G30 P3 X17 Y283 Z-99999 S3 ; probe starboard stern S3 = 3 z axis if result != 0 continue if move.calibration.initial.deviation <= 0.04 break echo "Repeating calibration because deviation is too high (" ^ move.calibration.initial.deviation ^ "mm)" ; end loop echo "Auto calibration successful, deviation", move.calibration.final.deviation ^ "mm" G1 F6000 X155 Y185 ; probe to center bed G30 F2000 ;Single Z-Probe M98 P"/macros/ProbeDropOff" ; probe drop off G10 Z30 F10000 ; get the head out of the wayinstead of having to always do x rounds of G32 i usually can get away with 2 , results like this

1/15/2023, 9:20:14 AM ProbeDropOff 1/15/2023, 9:20:06 AM Leadscrew adjustments made: -0.041 -0.023 0.019, points used 4, (mean, deviation) before (-0.008, 0.023) after (0.000, 0.008) Auto calibration successful, deviation 0.008mm 1/15/2023, 9:19:20 AM Leadscrew adjustments made: 2.404 -0.150 -0.937, points used 4, (mean, deviation) before (0.137, 1.350) after (0.000, 0.002) Repeating calibration because deviation is too high (1.350mm) 1/15/2023, 9:18:49 AM Probe Pickup complete -

@moth4017 it may be an artefact of inserting the file in your post, however it appears that the G28 command in line 6 may not be indented with respect to the if-command.

-

@moth4017 said in not able to get a good first layer using 3PL and bed mesh:

@Exerqtor i used to probe 3 points but since going to 4 i can not get a good first layer doing a 300mm x 300mm print, my bed is supported on 3 points i would recommend it my bed is 320 x320 .

I got the feeling you went from 3-probes to 4-probes, not the other way around?

😅

And that going to 4 solved the issues, not the other way around?🤔@dc42 said in not able to get a good first layer using 3PL and bed mesh:

@Exerqtor said in not able to get a good first layer using 3PL and bed mesh:

Whats best practice regarding this btw @dc42 ? To tram with 3 or 4 probe points on a bed with three points of pivot/adjustment?

You can use between N points (where N = number of Z motors) and 32. RRF will minimise the RMS error over all the points. If the bed is flat and the gantry doesn't sag then 3 or 4 points should work well. If it isn't then a higher number may be better.

You may find it beneficial to run bed tramming more than once, if your mechanics don't match the model assumed by RRF. You can do this using a loop in the bed.g file.

Ok, gotcha. I thought the number of probe points had to be equal to the number of pivot points/steppers for some reason.

Allready running two passes with the first being a coarse'n quick pass just to get it trammed-ish then a second run inside a loop that breaks when the deviation goes bellow aset tolerance or if it does more than a set number of iterations.

Sorry for the edit, managed to press "post" rather than "minimize" earlier so i only got the first line lol.

-

@Exerqtor i did go from 3 to 4 probes

my bed is on 3 points of support , (maxwell coupling )

-

@dc42 just a little change required in the next update when it does the bed adjustment and report "Leadscrew adjustments made: i dont have lead screws i have belts

can it be changed to Z adjustment or Bed or just something more generic. Cheers

can it be changed to Z adjustment or Bed or just something more generic. Cheers -

@moth4017

Yeah sorry posted the reply before i was done typing, I've edited the initial reply now!