IR sensor to continuously monitor AND adjust pellet feed levles

-

Hello all. I am wanting to use an IR sensor that monitors feed levels in a hopper for my pellet extruder. What I want to do is basically poll the IR sensor and when it goes (high/low) in response to pellet levels, a stepper motor turns and releases more pellets from an external, larger container. Id imagine I would need to use the IO pins on the DUET3 board along with conditional gcode commands. I have not used those before but can quickly learn.

Any advice on how to approach this would be greatly appreciated. Thanks. FYI, this is the it sensor im planning on using https://www.elecbee.com/en-24833-3Pcs-IR-Infrared-Obstacle-Avoidance-Sensor-Module-For-Smart-Car-Robot-3-wire-Reflective-Photoelectric?utm_term=&utm_campaign=Shopping+加拿大+2021/4/21&utm_source=adwords&utm_medium=ppc&hsa_acc=9958698819&hsa_cam=12803474616&hsa_grp=126885124968&hsa_ad=516175968131&hsa_src=g&hsa_tgt=pla-1186173532455&hsa_kw=&hsa_mt=&hsa_net=adwords&hsa_ver=3&gclid=Cj0KCQjwz96WBhC8ARIsAATR252VFWZqBugtCZlYQZRkNhyrEcRIwRrM62GBoqadSUHFVj949qKsgrgaAtO4EALw_wcB

Thank you!

-

@ravs99

Wouldn't you need two sensors for upper/lower level? Or do you want to run the extra pellet feeder for a fixed time interval?

Be aware, that the sensor you've picked requires inverted logic for your task. ( no problem, but needs to be kept in mind)Nevertheless, combing a command for an extra stepper into the running print-queue can lead to unwanted behaviour.

I'd suggest to trigger an unused heater port instead and run the extra feeder from a common dc-motor. That'll work independent from the print queue. -

@ravs99 I am not sure if you could accomplish your goal with macros only. If not, then you need firmware modifications (could be easy for you if you are good in C++). But it definitely is very doable when using SBC with Duet, then you can just code up a python script that will read your sensor and send commands to the stepper.

-

@ravs99 I think you could accomplish that using the daemon.g file. https://docs.duet3d.com/en/User_manual/Reference/Gcode_meta_commands#daemong

-

@o_lampe this is a good alternate solution. instead of heater port, I can also just use any of the available GPIO pins correct?

-

@ravs99

With an external motor driver (3.3V signal level) it should be possible. -

@dc42 how would i go about rotating a stepper motor and X amount every 10secs or so in the daemon.g file? This stepper motor would be connected to the stepper drivers of the DUET3 and assigned an axis U let's suppose.

-

@ravs99

I imagine it would be very difficult to take an IR-Probe-Sensor for this action, since the measuring range is very small and the area to be measured is only a very small spot.

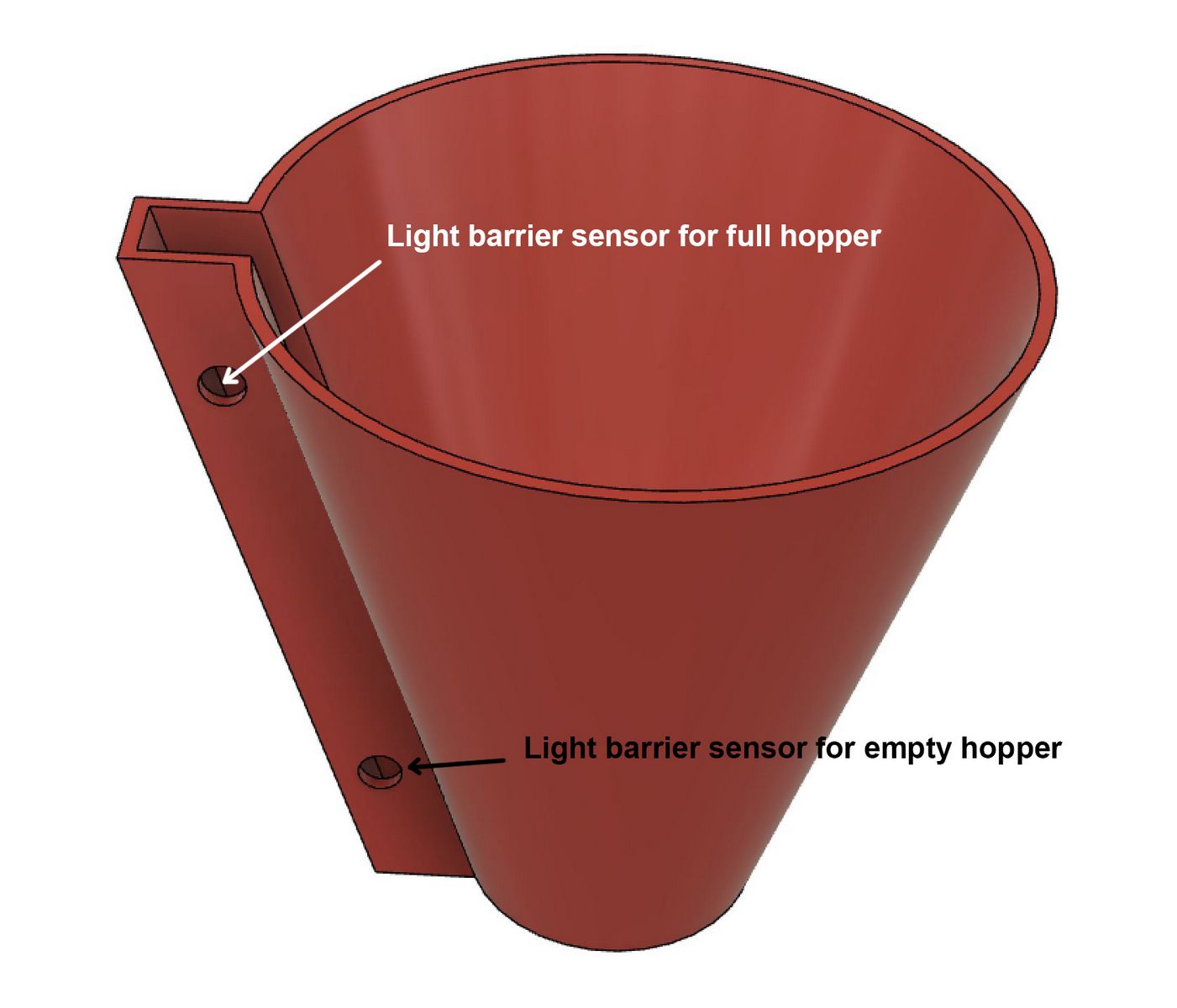

Once the auger is turning and the pellets are moving there will be constant on/off commands from the IR-Probe-Sensor, my guess.I would try to solve it with a light barrier.

Or with two light barriers... the lower light barrier says that new pellets are needed and the upper light barrier says when there are enough pellets in the hopper.Just a thought.

Google Translate

----- Original Text -----Ich stelle mir das sehr schwierig vor für diese Aktion einen IR-Probe Sensor zu nehmen, da der Messbereich nur sehr gering ist und die zu messende Fläche auch nur ein sehr kleiner Spot ist.

Sobald sich die Förderschnecke dreht und die Pellets sich bewegen wird es zu ständigen An / Aus Befehlen vom IR-Probe Sensor kommen, so meine Vermutung.Ich würde versuchen es mit einer Lichtschranke zu lösen.

Beziehungsweise mit zwei Lichtschranken... die untere Lichtschranke sagt das neue Pellets gebraucht werden und die obere Lichtschranke sagt wenn genug Pellets im Trichter sind.Nur so ein Gedanke.

P.S.:

Example... if the funnel itself can be printed.

The two holes are intended for the light barrier sensors.

Optical end stops for example.Maybe the "E18-D80NK" sensors will work with the Duet ?

@dc42 can definitely answer that !?

-

@norder Thank you for the advice. That does sound like a better option! However, I want to know how to actually drive the stepper motor that controls the release of pellets from the hopper to the extruder (not the auger motor) in the daemon.g file. Is it as simple as making a new axis and then adding the appropriate gcode to move the motor X amount every 10 seconds or so in incremental mode

Thanks

-

@ravs99

Sorry, I can't say how a pallet extruder is controlled because I don't have one or am not familiar with it.

But I think it's controlled like a motor by a normal extruder.

But how the steps are supposed to be calculated is a mystery to me.

Someone will definitely get in touch who can answer your question.

Post some photos, I'd be interested.Google Translate

----- Original Text -----Sorry, wie ein Pallet-Extruder gesteuert wird kann ich nicht sagen, weil ich keinen habe bzw mich damit nicht auskenne.

Aber ich denke der wird wie ein Motor von einem normalen Extruder angesteuert.

Aber wie die Steps berechnet werden sollen, ist mir ein Rätsel.

Es wird sich bestimmt jemand melden der Dir die Frage beantworten kann.

Poste gerne mal ein paar Fotos, es würde mich interessieren.