The most helpful post you'll read today

-

@zapta said in The most helpful post you'll read today:

@gnydick said in The most helpful post you'll read today:

That is wrong. You describe where the pivot point for each screw is. It makes a huge difference.

That makes sense. One difficulty I have is how to measure these offsets accurately. I wonder if the firmware could somehow measure them using the bed leveling sensor.

As I recall dc42 said that errors simply slowed the rate of convergence on a solution. But that was a long time ago and my recollection may be wrong.

I know my triple-Z machine levels fine and I didn't make any special effort to get the dimensions spot on.

Frederick

-

From the M671 documentation....

The X and Y coordinates in M671 are measured from the origin X0,Y0 set by M208. Measure to the pivot point of the bed where it connects to the Z axis. This is often each leadscrew, but may also be offset from the leadscrew if the bed rests on a carriage extending out from the leadscrew. -

@gnydick I think your argument is not correct. Leadscrew positions are the pivot points. I don't believe there is a setup where they cannot be. Also your 1km analogy would result in a large leadscrew adjustment, not small.

-

@bubblevisor said in The most helpful post you'll read today:

Leadscrew positions are the pivot points.

Only if your bed frame has no built in means of pivoting or flexing to account for misalignment. The frame will flex somewhere, and that's usually going to be in the lead screw nut since there is some slack there. But some printer designs have the pivot point elsewhere.

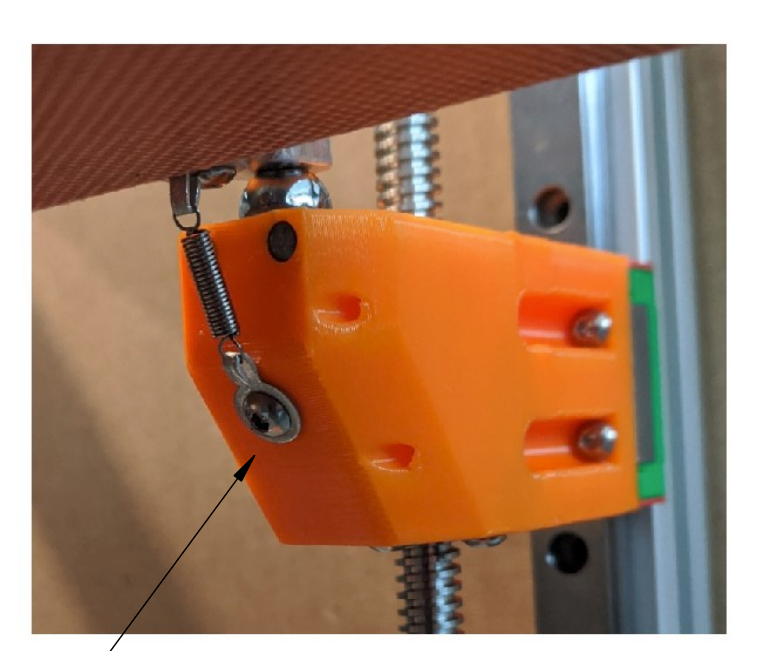

For instance the Jubilee printer uses a kinematic mount for the bed.

Screen Shot 2022-06-04 at 10.55.55 AM.png

Screen Shot 2022-06-04 at 10.55.55 AM.png -

@phaedrux Yep. Fair point. I stand corrected.

-

@gloomyandy oy, it used to say lead screw

I'm glad it's fixed now!!

I'm glad it's fixed now!! -

-

@zapta I've heard that too, but I don't know how it's supposed to converge if it over-shoots or under-shoots, depending on the inaccuracy.

-

Yep. That’s how I always had it set up. I didn’t realize that’s what was written down differed from that, because I just did what was logical

-

@gnydick said in The most helpful post you'll read today:

I'm trying to get my head around what is being discussed in this thread. But I'm coming from a position where my bed is mechanically flat and level and stays that way, so I don't use any form of firmware compensation myself. But just looking at those images, if the right hand edge of the build plate is low by say 1mm, and the bed is probed on that right hand edge, and those "arms" remain at 90 degrees to the lead screw, then moving the nut on the lead screw up by 1mm will raise the right hand edge of the build plate by 1mm, regardless of the length of the "arm" between the plate and the screw will it not? The only compensation that would be required is the relationship between the probe point and the attachment point if they are not the same. Is that what is being discussed? I don't understand what is being said about pivot point.

Edit. The pivot point for the bed is actually the attachment point on the left hand side. -

undefined deckingman referenced this topic

undefined deckingman referenced this topic

-

This post is deleted! -

@arnold_r_clark that's implied, isn't it?

-

@deckingman you're on the right track for the point of the post.

There are multiple pivot points. If you could probe exactly on the pivot points then you wouldn't need to know how far away the pivot points are from the probe points.

But since we are probing at offsets, we need to use trigonometry to figure out how much adjustment at the pivot point will translate to adjustment at the probe points.

-

This post is deleted!