I extensively use self adhesive foiled rubber foam. Its the stuff that comes sometimes with heated beds for insulation. Its actually manufactured as automotive engine bay sound and heat insulation. In my opinion this knocks the socks off all other options. Easy to install, cheap and very effective. My enclosures are all passively heated and achieve 74degrees consistently. Heres the aliexpress link. https://www.aliexpress.com/item/1005001475455913.html?spm=a2g0o.order_list.0.0.21ef1802dXxfYm

Best posts made by bubblevisor

-

RE: What Insulation do you use?posted in General Discussion

-

RE: Random additional steps - interference?posted in Tuning and tweaking

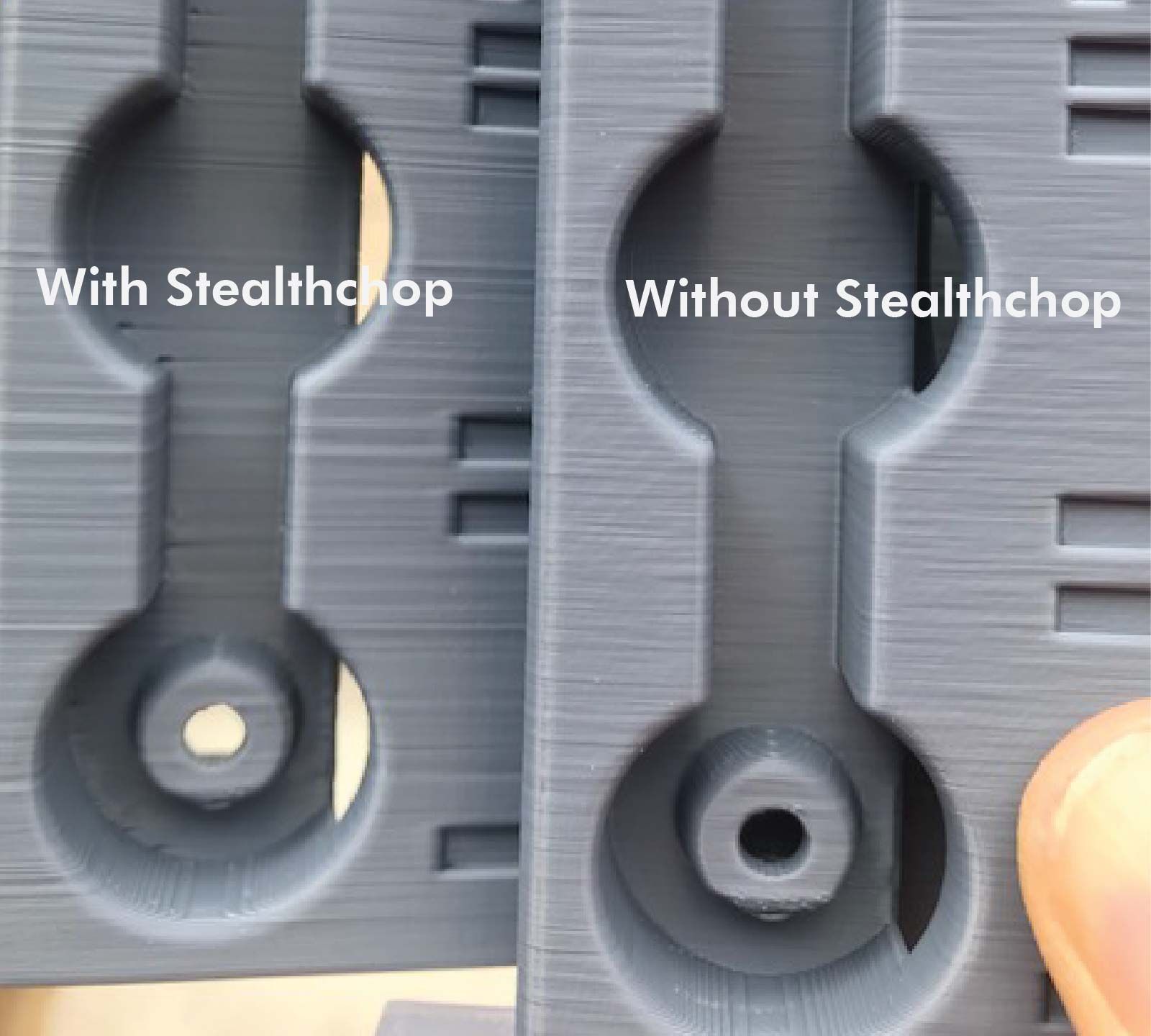

@phaedrux The stealth chop point seems potentially likely as the good printer is running RRF3.3 on Duet 2 spreadcycle and bad printer is 3.4 on big dipper TMC2209 defaulting to stealthchop with a weird speed threshold that switches to spreadcycle. This sounds like it can give rise to inconsistencies.

I'll change the M569 to enforce spreadcycle and report back. Fingers crossed.

-

RE: Tool Length Switchposted in General Discussion

@phaedrux said in Tool Length Switch:

ou should be using the probe to set the Z position

I'm a little confused. I am trying to achieve a setup that ignores the induction probe z offset entirely and relies only on the tool length switch. Indeed the voron guys don't even bother accurately setting the induction probe trigger height in the config as they don't use it. The probe is just used to create the contour (delta z) map and the switch to set the global height. My goal is to avoid the heat drift problem with probes.

-

RE: Random additional steps - interference?posted in Tuning and tweaking

BINGO! I turned off the default stealthchop and enabled spreadcycle via M569. Completeley solved the problem.

Default Stealthchop switches back and forth between spreadcycle and stealthchop when the speed is low. This seems to create a print blemish when this happens. My advice is STICK TO SPREADCYCLE!

-

RE: Glass 3D printing featuring RRFposted in General Discussion

@oliof That's incredible. I'm more thinking of the engineering applications more than art though!

Latest posts made by bubblevisor

-

End stop indicators on DWC?posted in Duet Hardware and wiring

Is there a live way of showing the end stop status on DWC. I realise there are LEDs on the board but it once installed in a housing at the bottom of your printer they're not much help. I am trying to diagnose a problem whereby the x axis is intermittently not homing. It behaves as is the end stop is already triggered.

-

RE: Stops dead randomlyposted in Duet Hardware and wiring

@jay_s_uk I've just been trying to update the firmware. But no matter which .zip firmware I upload the installed version remains at 3.4.0beta.

-

RE: Stops dead randomlyposted in Duet Hardware and wiring

@jay_s_uk Here is the M122. It has done a few successful prints but just now it stopped just before it started laying the first layer:

m122

=== Diagnostics ===

RepRapFirmware for big-dipper version 3.4.0beta5+1 (2021-10-23 18:16:14) running on Duet 3 big-dipper WiFi (standalone mode)

Board ID: RZAN1-D2401-8D3J0-40188-K3T0Z-7YR20

Used output buffers: 3 of 40 (12 max)

=== RTOS ===

Static ram: 102180

Dynamic ram: 101368 of which 0 recycled

Never used RAM 38164, free system stack 198 words

Tasks: NETWORK(ready,15.8%,249) HEAT(notifyWait,0.0%,343) Move(notifyWait,0.0%,338) CanReceiv(notifyWait,0.0%,941) CanSender(notifyWait,0.0%,371) CanClock(delaying,0.0%,338) TMC(notifyWait,1.2%,114) MAIN(running,82.0%,425) IDLE(ready,0.1%,30) AIN(delaying,0.8%,264), total 100.0%

Owned mutexes: WiFi(NETWORK)

=== Platform ===

Last reset 00:04:14 ago, cause: software

Last software reset at 2023-10-21 16:25, reason: HardFault imprec, Display spinning, available RAM 37884, slot 2

Software reset code 0x406f HFSR 0x40000000 CFSR 0x00000400 ICSR 0x0047d803 BFAR 0xe000ed38 SP 0x20003f18 Task MAIN Freestk 1066 ok

Stack: 00000000 200290a8 00000571 00000570 00000348 00076857 00076872 61030000 00000000 00000000 369dc3a0 3edb75d2 3331bb4c 41880000 3e178897 3e1cd04f be09b238 3e3a3fd4 3e639b49 00000000 00000000 412ccccd 3f800000 00000000 60000010 a5a5a5a5 0000000f

Error status: 0x00

Aux0 errors 0,0,0

MCU revision 0, ADC conversions started 254285, completed 254285, timed out 0, errs 0

Step timer max interval 752

MCU temperature: min 44.6, current 44.8, max 45.4

Supply voltage: min 23.9, current 23.9, max 24.0, under voltage events: 0, over voltage events: 0, power good: yes

Heap OK, handles allocated/used 0/0, heap memory allocated/used/recyclable 0/0/0, gc cycles 0

Driver 0: pos 0, standstill, SG min/max 10/10, read errors 0, write errors 1, ifcnt 22, reads 23088, writes 9, timeouts 0, DMA errors 0

Driver 1: pos 0, standstill, SG min/max 0/0, read errors 0, write errors 1, ifcnt 22, reads 23088, writes 9, timeouts 0, DMA errors 0

Driver 2: pos 0, standstill, SG min/max 0/0, read errors 0, write errors 1, ifcnt 21, reads 23088, writes 9, timeouts 0, DMA errors 0

Driver 3: pos 0, standstill, SG min/max 14/14, read errors 0, write errors 1, ifcnt 21, reads 23087, writes 9, timeouts 0, DMA errors 0

Driver 4: pos 0, standstill, SG min/max 14/14, read errors 0, write errors 1, ifcnt 22, reads 23088, writes 9, timeouts 0, DMA errors 0

Driver 5: pos 0, standstill, SG min/max 0/0, read errors 0, write errors 1, ifcnt 20, reads 23088, writes 9, timeouts 0, DMA errors 0

Driver 6: pos 0, standstill, SG min/max 0/0, read errors 0, write errors 1, ifcnt 19, reads 23087, writes 9, timeouts 0, DMA errors 0

Date/time: 2023-10-21 16:29:37

Cache data hit count 436204769

Slowest loop: 2.92ms; fastest: 0.12ms

=== Storage ===

Free file entries: 10

SD card 0 detected, interface speed: 22.5MBytes/sec

SD card longest read time 0.5ms, write time 0.0ms, max retries 0

=== Move ===

DMs created 83, segments created 0, maxWait 0ms, bed compensation in use: none, comp offset 0.000

=== MainDDARing ===

Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1

=== AuxDDARing ===

Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1

=== Heat ===

Bed heaters = 0 -1, chamberHeaters = -1 -1

Heater 1 is on, I-accum = 0.0

=== GCodes ===

Segments left: 0

Movement lock held by null

HTTP is idle in state(s) 0

Telnet is idle in state(s) 0

File is idle in state(s) 0

USB is idle in state(s) 0

Aux is idle in state(s) 0

Trigger is idle in state(s) 0

Queue is idle in state(s) 0

LCD is idle in state(s) 0

Daemon is idle in state(s) 0

Aux2 is idle in state(s) 0

Autopause is idle in state(s) 0

Code queue is empty

=== Filament sensors ===

Extruder 0 sensor: ok

=== CAN ===

Messages queued 2288, received 0, lost 0, longest wait 0ms for reply type 0, peak Tx sync delay 0, free buffers 17 (min 17), ts 1272/0/0

Tx timeouts 0,0,1271,0,0,1015 last cancelled message type 30 dest 127

=== Network ===

Slowest loop: 15.37ms; fastest: 0.00ms

Responder states: HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0), 0 sessions

HTTP sessions: 1 of 8- WiFi -

Network state is active

WiFi module is connected to access point

Failed messages: pending 0, notready 0, noresp 0

WiFi firmware version 1.25

WiFi MAC address bc:ff:4dxxxxxxxx

WiFi Vcc 3.38, reset reason Power up

WiFi flash size 2097152, free heap 25600

WiFi IP address 192.168.1.xxx

WiFi signal strength -64dBm, mode 802.11n, reconnections 0, sleep mode modem

Clock register 00002002

Socket states: 0 0 0 0 0 0 0 0

- WiFi -

-

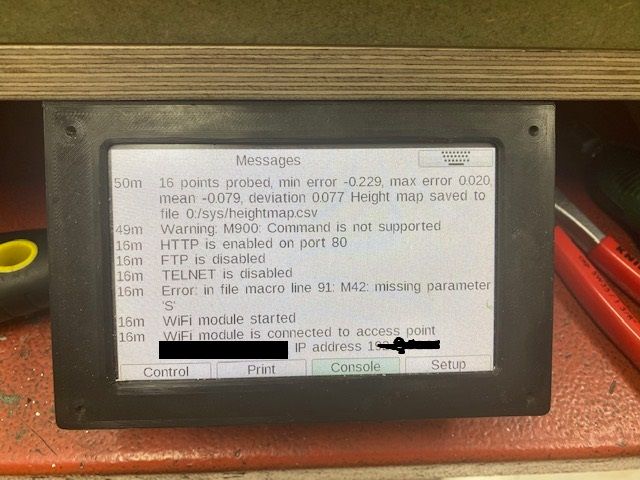

Stops dead randomlyposted in Duet Hardware and wiring

My duet 2 mini 5+ controlled printer has recently developed a problem whereby it stops dead randomly. I have yet to catch it when the failure occurs but it appears as though someone just cut the power momentarily. Could it literally be a fault with the power supply? I have attached a shot of the console that may indicate something. Any ideas?

-

RE: RRF on Bambu Labs etc.?posted in General Discussion

@oliof Is there a thread here somewhere that describes implementing strain gauges?

-

RE: RRF on Bambu Labs etc.?posted in General Discussion

@oliof Yes, I hear what you are saying with regards merits of semi industrial type machines. Cost is a big factor however. I need maximum user serviceability, ability to print ABS in a 65degree chamber and strong mechanics/motion system for print quality and reliability. Speed is irrelevant.

-

RRF on Bambu Labs etc.?posted in General Discussion

I was wondering if it would be possible to run consumer machines such bambu Labs P1P or Creality K1 with RRF. I run a small printer farm based on my own custom printers and prefer the total control of RRF. Of course I would expect you will need to replace the board and screen with say duet 3 mini but can reprap be used to control all the hardware including strain gauges etc?

-

RE: PL-05 Type induction probe with BAT85 diodeposted in Duet Hardware and wiring

@dc42 Yes that's correct. The PL05 does not work with less than 5v hence using the expansion port. Does it matter where I connect to GND? I was wondering if it made a difference using the GND on the z probe port or the pin2 GND on expansion.

Although it seems to work ok on the 5v so far, I was thinking of taking 24v directly from the power supply as the probe does indicate 6v - 30v. Are there any issues doing this? Which GND should you use in this setup? -

RE: PL-05 Type induction probe with BAT85 diodeposted in Duet Hardware and wiring

@dc42 Hmm. Does that apply if I use the 5v and GND from the expansion but signal goes to z probe in. I have a v1.04 duet 2 wifi.

-

RE: PL-05 Type induction probe with BAT85 diodeposted in Duet Hardware and wiring

@dc42 That's very helpful David, thanks. Can you also confirm if all the duet 3 boards also have that protection?