Any advise to improve print quality :)

-

Hi guys! I wanted to ask for some help here to the speed gods

I am tuning the printing parameters in my printer, a corexy with a duet wifi. I did printing tests to setup the accelerations and jerks after I tuned properly the input shaping and the presure advance. I recorded the next parameters after trials:M204 P3000 T1000 ;accelerations

M566 X480.00 Y300.00 Z420.00 E600.00 ;jerks(instant speeds)

M572 D0 S0.0375 ; pressure advace

M593 P"mzv" F42.50 ;input shaping

Temp 200

PLA Smartfill.And this are the results:

From left to right is front x axis, right y axis, rear x axis and left y axis. Also from top to bottom is from 250mmxs to 50mmxs

At 50mxs there is very VFA visible apart from that ringing. But don't know how to improve that ringing 🥲

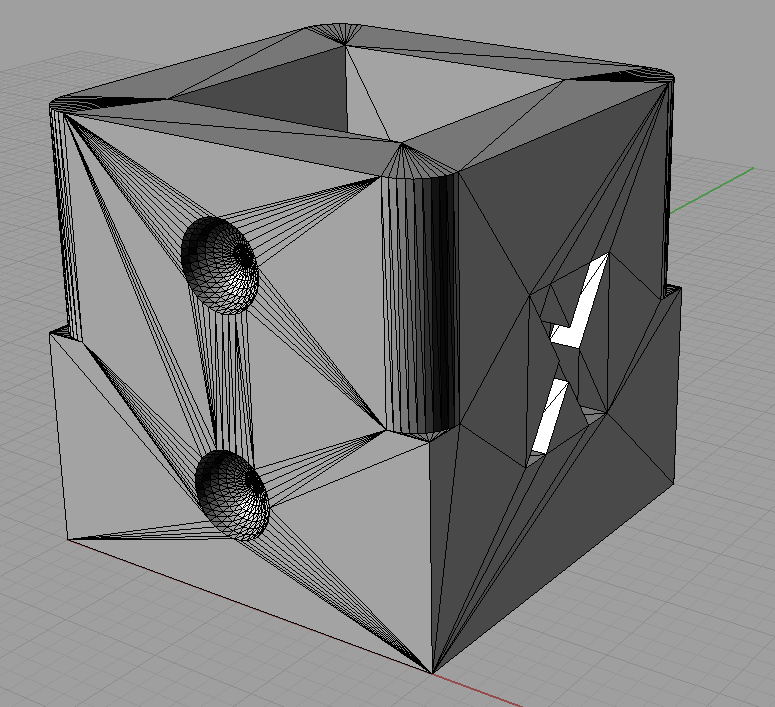

The machine has an aluminum 4040 structure so is pretty solid as you can see:

The linear rails in x and y are usongshine MGN9H with Z1 preload, there was no Z0 availables.

Forget to say the retractions are them all in the corner between tha face with the x and the y in the model 0.8mm at 900mmxm retraction speed. The hotend is a Phaetus Rapido with a 0.4 CHT nozzle. -

Very nice build. I am not an expert but from what I gathered from the voron community, a mgn9 with no additional support is not stiff enough for x rail. They use a mgn12 backed by an extrusion.

Again, I am not an expert.

-

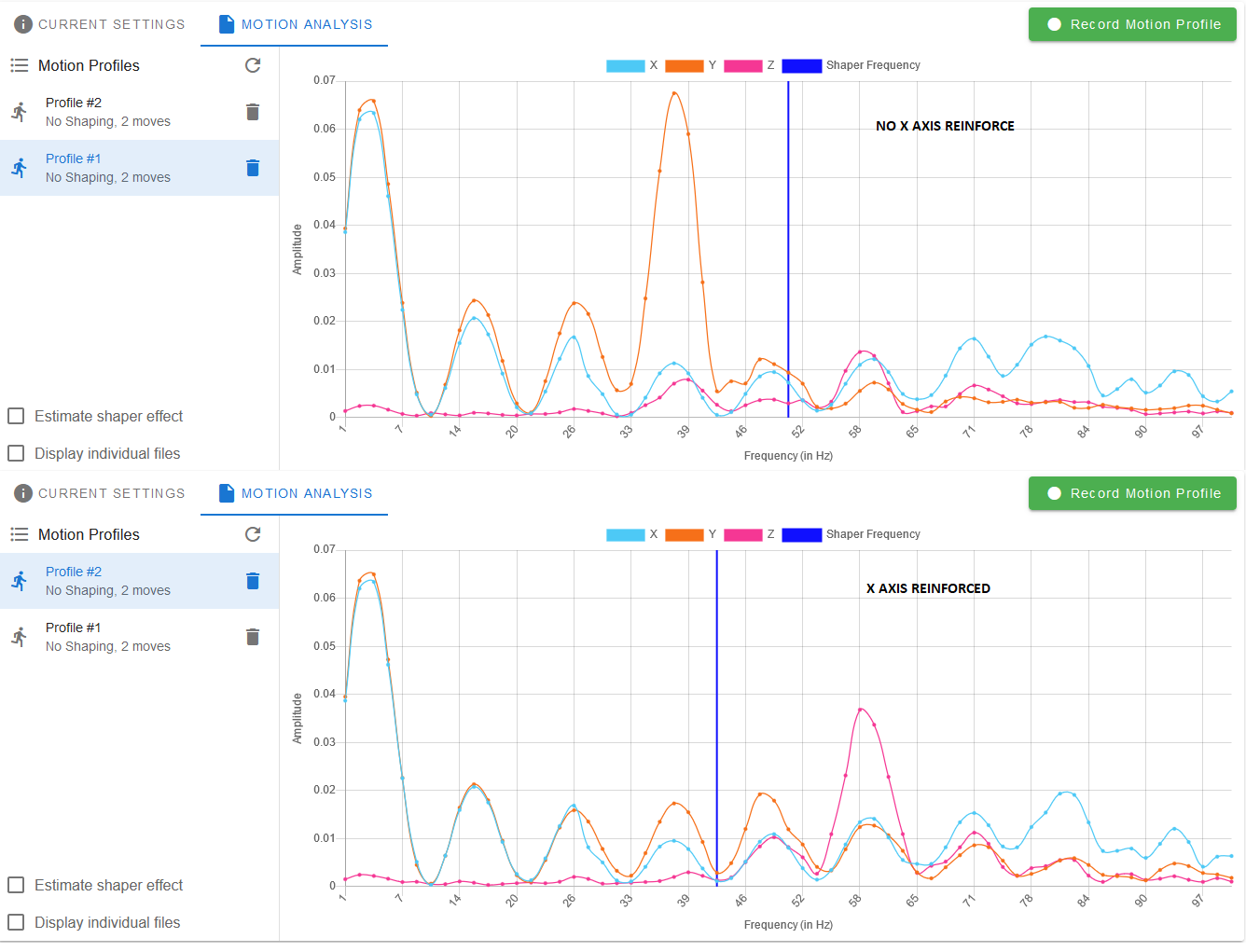

@zapta that's rigth they use to reinforce but with the accelerometer i measured the amplitudes with and without a reinforce and it does not vary a lot. Anyway if that's the case both x printed sides will ave simillar quality and it did not happen.

Anyway again I am waiting for a 10x10mm square cf tube to arrive and add to the rig. -

@zabana, my understanding is that E3D also had insufficient x rail support in their Motion System until they came with this fancy aluminum bar. I don't know though how insufficient support manifests itself in acceleration measurements.

-

@zabana what's the change between the bottom half of each print and the top half?

-

@dc42 there is no change in terms of configuration, the file is the Ripple_JERK_test.STL anyone can download in thingiverse.

I mean this one:Ripple Jerk test Thingiverse

-

side note: A friend of mine has a RailcoreII whose frame seems to have a resonant frequency at around 8.8Hz. He can print well at speeds up to 45mm/sec and above 90mm/sec but in-between the printer turns into a subsonic woofer shaking the house ... you may be running into a similar issue. One way to address this might be adding more deadweight by filling the hollow segments of your extrusion with granite resin pour or similar.

-

@oliof As you said there is a peak at very low frequencies, don´t know if enough high as to be a problem but there it is. Also I tested with and without a reinforcement in the X axis (I added a L shaped aluminum of 10x20mm all the wide axis lenght) and the peak around 40hz is now smaller but the VFA is more notorious in the printing, I will still try to dig some improvements at low speeds.

Here is the graph with the totally helpfull new Input shaping plugin: